Abstract

Today, most NiTi devices are manufactured by a combination of conventional metal fabrication steps, e.g., melting, extrusion, cold working, etc., and are subsequently structured by high accuracy laser cutting. This combination has been proven to be very successful; however, there are several limitations to this fabrication route, e.g., in respect to the fabrication of more complex device designs, device miniaturization or the combination of different materials for the integration of further functionality. These issues have to be addressed in order to develop new devices and applications. The fabrication of micro-patterned films using magnetron sputtering, UV lithography, and wet etching has great potential to overcome limitations of conventional device manufacturing. Due to its fabrication characteristics, this method allows the production of devices with complex designs, high structural accuracy, smooth edge profile, at layer thicknesses up to 75 µm. The aim of this study is to present recent developments in the field of NiTi thin film technology, its advantages and limitations, as well as new possible applications in the medical and in non-medical fields. These developments include among others NiTi scaffold structures covered with NiTi membranes for their potential use as filters, heart valve components or aneurysm treatments, as well as micro-actuators for consumable electronics or automotive applications.

Similar content being viewed by others

Introduction

NiTi is a well-established alloy in the medical industry. It is used in orthodontic applications, for a variety of medical instruments or for temporary or permanent vascular implants [1–4]. Its superelastic properties have numerous advantages, among them constant force delivery, kink resistance, and different deployment methods [5]. The latter allow for the use of smaller catheter diameters to deliver implants and instruments, which is in particular important for minimal invasive treatments. The increasing popularity of vascular disease treatments utilizing stents in the 1990s and the technological ability to fabricate and structure high-quality NiTi tubes was a main trigger for the rise of NiTi in medical applications [6]. Stent markets have been growing since, and NiTi is still one of the main alloys in this field.

The conventional fabrication route for NiTi implants comprises a series of processing steps, including melting, extrusion, hot or cold drawing, laser cutting, and surface finishing [7–9]. This mass fabrication route has been proven to be very successful in providing millions of medical products with high-quality standards. An ongoing trend in medical device development is further miniaturization of the medical device while enhancing its overall functionality allowing for less invasive treatments and shorter healing times. This trend is a challenge for the established fabrication route. Some of these issues can be addressed using an approach where NiTi structures are fabricated by a sequence of microsystem technology processes, i.e., magnetron sputtering, UV lithography, and wet chemical etching. This process is described in detail by Lima de Miranda et al. [10]. This fabrication route has gained increasing interest in recent years, especially since the maximum thickness of thus prepared structures exceeds 75 µm and is therefore in a suitable range for many medical applications. Magnetron sputtering is a vacuum deposition technique. Inside a high vacuum chamber, Ar-ions are accelerated towards a target, in our case a cast-melted NiTi alloy target, target atoms are released due to the ion bombardment and deposit on a cold substrate surface. Oxide and carbide inclusions that are present in cast-melted NiTi alloys with sizes of a few micrometers are not transferred to the deposited film. Thus, a main source of mechanical failure is eliminated, since oxide and carbide inclusions, in particular in combination with voids, act as crack initiation sites and decrease fatigue life [11]. Also, the corrosion resistance of the material increases significantly and exceeds 1000 mV [12]. The biocompatibility of sputtered NiTi films has been subject of several studies, which certify excellent properties [13, 14]. The lateral homogeneity of the deposited films in terms of thickness and chemical composition depends on the sputtering system and on the target homogeneity. Many different sputtering systems exist. Small development systems with static substrate and static magnetron can be used for prototype fabrication, but the area of homogeneous thickness and composition on the substrate may be small. Lager systems with larger targets and magnetrons, moving substrates or moving magnetrons yield better homogeneity. In Fig. 1a, b, the lateral thickness and compositional homogeneity of a binary NiTi film on a 6″ substrate fabricated within a production system are shown. The thickness varies by ±1 % over an area of 150 mm in diameter (measured with an inductive digital comparator Mahr Extramess 2000), chemical composition was measured by EDX (EDX error for each data point approx. 0.5–1.0 at.%). Since this is a wafer-based technology, it is highly scalable and reproducible.

NiTi films that are deposited at room temperature are amorphous and require a subsequent heat treatment for crystallization [15]. Hence, the microstructure of sputter-deposited NiTi differs to that of bulk materials which crystallize from the melt and often experience a high degree of cold work to reduce the dimension of the semi-finished product. Microstructural investigations of sputtered films have been carried out for a large variety of binary to quaternary compositions and heat treatments, e.g., [16–22], which demonstrates the large influence of the two parameters on microstructural features (grain size, distribution, type, and size of precipitates), transformation temperatures and consequently their functional properties. Using sputtering techniques, alloy optimization by varying the chemical composition can be achieved in numerous ways, ranging from different target compositions, changing sputtering power or target-substrate distances to complex combinatorial methods where a large area of the composition spread can be investigated simultaneously by high-throughput methods [22–24].

Standard UV lithography allows for structuring photo-sensitive resist with feature sizes in the submicron range [25]. The pattern of the structured resist is then transferred to the NiTi film, e.g., using wet chemical etching. NiTi films with thicknesses of 75 µm have been deposited following the process described in [10]. Since sputtered edges are not perfectly vertical, the minimum feature size increases with increasing film thickness, i.e., ~1 µm for very thin NiTi films, and ~10 µm for film with 75 µm thickness. Thus, aspect ratios of up to 7–8 can be achieved. This is in particular interesting for the fabrication of thin mesh structures where maximum pore or strut size can be in the range of a few tens of micrometers only.

The NiTi layer can be released from the substrate using a sacrificial layer technique. When flat substrates are used, the released, amorphous film is obviously also flat. The cylindrical shape of vascular implants can be achieved by a constraint heat treatment, during which the amorphous film crystallizes within a quartz tube of the desired diameter. For many applications, an open design (beginning and end of circumference are not joint) may be feasible, for others the joint circumference may be required. Pulsatile fatigue investigations on stent structures with laser-welded joints of the circumference showed that the fatigue resistance of the micro-welded joints is sufficiently high, and fractures were rather observed at stent struts than the welding tags [26]. Also, the overall functional behavior of NiTi sheet metal was found to be mainly unaffected by welding, since no significant change in the stress–strain transformation plateau was detected [27]. The necessity of jointing can be avoided when depositing NiTi directly on cylindrical substrates, e.g., using a hollow cathode setup [28] or a rotating substrate approach [29]. The latter is economically less interesting due to the significant decrease in the effective sputtering rate.

Except for laser-welded joints, structured, sputtered NiTi films exhibit no heat-affected zones (HAZ), in contrast to laser-cut tubes. The microstructure is hence less affected which in combination with the lack of oxide and carbide inclusions promises higher fatigue life and improved mechanical properties. Investigations on the fatigue life of sputtered diamond-shaped samples reveal indeed a high fatigue endurance limit. Up to mean strains of 6 %, maximum alternating strains of ±1.5 % did not lead to a fracture of the specimen during 3 × 10E6 cycles, a significantly higher value compared to ±0.5 % maximum alternating strain for NiTi standard material [26].

Limitations of the NiTi sputtering technology are the limited film thickness and lateral dimension (the latter determined by the wafer size used, e.g., 6″, 8″, etc.,), the necessity to utilize the usable area effectively in order to be cost efficient (good if many parts fit into the wafer area), and the lack of cold work as parameter to influence microstructure and thus functional properties.

The unique features of NiTi sputtering, however, have high potential to realize some of the next generation medical implants or tools, where the current technology cannot provide, e.g., the freedom of design or the ability to combine and structure a series of additional materials. The capability of NiTi sputtering is discussed in the following chapter.

Results and Discussion

We have divided this chapter according to what we have named NiTi sputter technology platforms, namely 2D, 2.5-dimensional (2.5D), and multi-layered structures. For each platform, the fabrication process is adjusted in order to realize different features of a NiTi-based sample.

The 2D platform is the base platform; it describes the arbitrary, two-dimensional structuring of a NiTi film with homogeneous thickness up to 75 µm. The characteristics of the produced samples have been mentioned before: feature resolution dependent on film thickness, but below 10 µm for 75 thick films, aspect ratios up to 7–8, thickness and compositional homogeneity of ±1 % and ±0.4 at.%, respectively (depending on the sputtering system and target homogeneity), highly pure material, excellent fatigue properties, possibility of shape setting, and lateral dimension limited to wafer size. Examples are shown in Fig. 2.

Figure 2a shows an 8-µm-thick mesh structure with 8 µm strut width and 75 × 20 µm2 diamond-shaped pore size. Strut width and pore size can be optimized according to application requirements, e.g., when used as embolic filters or as surfaces to engineer tissue growth. Figure 2c, d shows a multitude of parallel, fine lamellae connected to a supporting beam; Fig. 2e, f a connector structure; and Fig. 2g, h generic, shape set stent structures of different diameter.

2.5D structures offer a limited freedom of design perpendicular to the film plane. This can be achieved in two ways. Either the film thickness is homogeneous, but lens-shaped cavities are patterned into the structured films, see Fig. 3.

A different approach is shown in Fig. 4 where a second NiTi layer was deposited and patterned on top of a structured NiTi base layer. In this case, a 40-µm-thick ring was structured on top of a 5-µm-thick layer. Within the prior given limitations, the dimension of each layer can be varied freely. Hence, reservoirs can be created, e.g., for drug eluting systems or for micropump systems. Volume and shape of the reservoirs can be varied in wide range to adjust for the specific requirements of the application. Using the second approach novel components with unique properties can be created.

Figure 5a–c shows a supporting structure (50 µm thick) with a fine mesh (5 µm thick, 75 × 20 µm2 diamond-shaped pore size) between the supporting beams. Despite its stiffness, these kinds of superelastic structures can be crimped into a catheter of 3 mm without breaking. Figure 5e, f shows a micro-patterned strut surface, and Fig. 5g, h stent-like structures with flaps attached.

The application potential of the 2.5D platform in the medical field is manifold: micro-patterned surfaces for drug eluting systems, tissue engineering or friction control, robust filters with scaffolds, artificial heart valves, or flow diverters for aneurysm treatments can be realized.

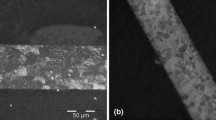

The third platform involves the deposition and structuring of other materials on a NiTi structure. An example is the deposition of a radiopaque material, preferentially a heavy metal such as Ta, Au, or Pt–Ir [4] on a NiTi structure. In Fig. 6a, a SEM image of a 50-µm-thick stent-like structure with 35 µm strut with coated with 10 µm Ta is shown, the corresponding radiopacity results are shown in Fig. 6b: areas 1–6 contain samples covered with Ta, areas 7–9 uncovered samples of identical NiTi thickness. Areas 2, 3, 5, 6, 7, and 8 contain stent structures, and areas 1, 4, and 9 diamond-shaped control specimen.

The NiTi structure can be completely or partly coated. In the former case, the thickness of the radiopaque material has to be sufficiently high to increase radiopacity but small enough not to hinder the stress-induced martensitic transformation of the underlying NiTi. Also, delamination of the radiopaque layer must be avoided during mechanical loading. In the second case, the radiopaque layer can be patterned so that heavily loaded areas are uncoated and thus free to transform, whereas less loaded areas are coated (Fig. 6c).

A novel field is the combination of flexible NiTi substrates with structured isolating and conducting layers. Circuit paths can be deposited on NiTi with a top and bottom isolating layer. The top isolation might be absent in certain areas so that electrodes for stimulation, sensing, or mapping can be realized.

So far we have considered mostly superelastic materials for medical applications. On the other hand, Ti-rich films exhibiting the shape memory effect can be used as miniaturized actuator components (Fig. 7). Due to the high work output of NiTi small, flat, lightweight actuators can be realized for applications within the automotive or consumable electronics industry. Since the 2D design of the actuators is free to choose, optimized force-stroke relationships and additional design elements to facilitate system integration of the actuator component (instead of wire crimping) can be realized.

The lack of oxide and carbide inclusions in sputtered films promises good fatigue life also for actuator applications.

Often Joule heating is used as a simple heating mechanism to increase the sample temperature above the austenite finish temperature. Using the combination with isolating and conducting layers, local heating elements can be created on the NiTi surface and the NiTi actuator structure can be activated in selected areas only, if required.

Summary and Conclusion

The present paper investigates the capability of magnetron sputtering, UV lithography, and wet chemical etching to fabricate different NiTi-based components.

The characteristic features of sputtered micro-patterned NiTi films (feature resolution, maximum thickness, thickness and compositional homogeneity, certain microstructural aspects, fatigue performance) have been discussed briefly. The main focus of this paper, however, is not on the functional properties or the microstructure of sputtered films, but the freedom of design that can be realized with the combination of the above-named microsystem technology processes. In particular, 2.5D structures offer in our view novel design opportunities in the medical field for drug eluting systems, filters, valves, tissue engineering, or flow diverters. Prototypes of 2D and 2.5D structures can be fabricated with only few adjustments (different lithography masks) required. The integration of additional functionality using radiopaque, electrically conducting or insulating, or magnetic layers is a promising approach to design and fabricate next generation medical devices.

Experimental

The underlying process to fabricate NiTi films presented in this paper is a combination of three microsystem technology processes: UV lithography, physical vapor deposition, and wet etching as described in [10]. In order to obtain more complex geometries such as 2.5D structures or structures that are combined with other materials, some of the above process steps are repeated or slightly altered. The NiTi films are deposited using magnetron sputtering devices at base pressures below 1 × 10−7 mbar, Ar gas flow, and deposition rates between 3.8 and 5.6 nm/s, depending on sputtering system.

The processing sequence (Fig. 8) starts with the deposition of a Cu sacrificial layer and a NiTi seed layer. Substrates are then coated with positive photoresist (AZ1518) with 2.3 μm thickness using spin coating followed by UV exposure on a Karl Suss mask aligner in soft contact mode for 2 s, a soft bake on a 105 °C hotplate for 2 min and rehydration for another 2 min. The resist is then developed using AZ716 MIF solution for 1 min, forming the desired geometry. Hard bake is performed at 120 °C for 20 min. The third step consists of wet etching the NiTi seed layer using a HF solution with an etching rate of 10 nm/s. In the fourth step, the sacrificial layer is wet etched which results in mushroom-like structures due to undercutting during isotropic etching of the sacrificial layer. As selective etchant, a standard BASF Selectipur Chromium Etch (etching rate 13.5 nm/s) is used. After etching, the photoresist is removed using acetone. To achieve the required Nitinol film thickness, a thick NiTi layer is now deposited on top of the seed layer. The mushroom-like structures allow for the growth of the structured NiTi film while avoiding any coalescence with adjacent areas in between the mushroom-like structures. As a final step, the sacrificial layer is removed, again using BASF Selectipur Chromium Etch, which results in a freestanding micro-patterned NiTi structure.

Subsequently, the amorphous samples were crystallized in a high vacuum chamber in order to avoid oxidation during the annealing process. Heat treatment was carried out ex situ by means of a rapid thermal annealing system. The halogen-lamp driven heating chamber enables typical heating rates of 50 K/s in a vacuum environment of about 10−6–10−7 mbar. The annealing temperature was held constant for 10 min at the maximum temperature of 650 °C, which turned out to be sufficient for crystallization of amorphous NiTi. In a second step, films were annealed for further 10 min at 450 °C, which is a common procedure for Ni-rich Nitinol samples to induce the formation of Ni4Ti3 precipitates in order to adjust phase transformation temperatures.

References

Thompson SA (2000) An overview of nickel–titanium alloys used in dentistry. Int Endod J 33:297

Stöckel D (2000) Nitinol medical devices and implants. Minim Invasive Ther 9(2):81–88

Pelton A, Schroeder V, Mitchell MR, Gong X-Y, Barney M, Robertson SW (2008) Fatigue and durability of Nitinol stents. J Mech Behav Biomed Mater I 1(2):153–164

Stöckel D, Pelton A, Duerig T (2009) Self-expanding Nitinol stents for the treatment of vascular disease. In: Yoneyama T, Miyazaki S (eds) Shape memory alloys for biomedical applications. CRC Woodhead Publishing, Boca Raton, pp 237–256

Duerig T, Pelton A, Stöckel D (1999) An overview of Nitinol medical applications. Mater Sci Eng A 273:149–160

Pelton A, Duerig T, Berg B, Hodgson D, Mertmann M, Mitchell M, Proft J, Wu M, Yang J (2005) Nitinol medical devices. Adv Mater Proc 163(10):63

Hodgson D, Russell S (2000) Nitinol melting, manufacture and fabrication. Minim Invasive Ther Allied Technol 9(2):61

Favier D, Orgéas L, Ferrier D, Poncin P, Liu Y (2001) Influence of manufacturing methods on the homogeneity and properties of nitinol tubular stents. J Phys IV 11(PR8):541

Poncet P, Adler PH, Carpenter S, Wu MH (2003) Manufacture of Nitinol tubing. In: ASM Materials & Processes for Medical Devices Conference, Anaheim

Lima de Miranda R, Zamponi C, Quandt E (2013) Micropatterned freestanding superelastic TiNi films. Adv Eng Mater 15(1–2):66

Rahim M, Frenzel J, Frotscher M, Pfetzing-Micklich J, Steegmüller R, Wohlschlögel M, Mughrabi H, Eggeler G (2013) Impurity levels and fatigue lives of pseudoelastic NiTi shape memory alloys. Acta Mater 61:3667

Wohlschlögel M, Steegmüller R, Schüssler A (2014) Nitinol: tubing versus sputtered foil—microcleanliness and corrosion behavior. In: SMST Conference 2014, Pacific Grove

Kealey CP, Whelan SA, Chun YJ, Soojung CH, Tulloch AW, Mohanchandra KP, DiCarlo D, Levi DS, Carman GP, Rigberg DA (2010) In vitro hemocompatibility of thin film nitinol in stenotic flow conditions. Biomaterials 31(34):8864

Habijan T, Lima De Miranda R, Zamponi C, Quandt E, Greulich C, Schildhauer TA, Köller M (2012) The biocompatibility and mechanical properties of cylindrical NiTi thin films produced by magnetron sputtering. Mater Sci Eng C 32:2532

Ishida A, Sato M, Takei A, Miyazaki S (1995) Effect of heat treatment on shape memory behavior of Ti-rich Ti–Ni thin films. Mater Trans JIM 36(11):1349–1355

Miyazaki S, Ishida A (1999) Martensitic transformation and shape memory behavior in sputter-deposited TiNi-base thin films. Mater Sci Eng A 273–275:106–133

Ishida A, Sato M, Kimura T, Miyazaki S (2000) Stress-strain curves of sputter-deposited Ti–Ni thin films. Philos Mag A 80(4):967–980

Otsuka K, Ren X (2005) Physical metallurgy of Ti–Ni-based shape memory alloys. Prog Mater Sci 50:511

Ishida A, Sato M (2006) Microstructure and shape memory behaviour of annealed Ti51.5Ni(48.5−x)Cux(x=6.5−20.9) thin films. Philos Mag Lett 86:13–20

Ishida A, Sato M, Gao ZY (2013) Properties and applications of Ti–Ni–Cu shape-memory-alloy thin films. J Alloys Comp 577(S1):S184

Zarnetta R, Takahashi R, Young ML, Savan A, Furuya Y, Thienhaus S, Maaß B, Rahim M, Frenzel J, Brunken H, Chu YS, Srivastava V, James RD, Takeuchi I, Eggeler G, Ludwig A (2010) Identification of quaternary shape memory alloys with near-zero thermal hysteresis. Adv Funct Mater 20(12):1917

Zarnetta R, Buenconsejo PJ, Savan A, Thienhaus S, Ludwig A (2012) High-throughput study of martensitic transformations in the complete Ti–Ni–Cu system. Intermetallics 26:98

Cui J, Chu Y, Famodu O, Furuya Y, Hattrick-Simpers J, James D, Ludwig A, Thienhaus S, Wuttig M, Zhang Z, Takeuchi I (2006) Combinatorial search of thermoelastic shape-memory alloys with extremely small hysteresis width. Nat Mater 5:287

Zarnetta R, Savan A, Thienhaus S, Ludwig A (2007) Combinatorial study of phase transformation characteristics of a Ti–Ni–Pd shape memory thin film composition spread in view of microactuator applications. Appl Surf Sci 254(3):743–748

Madou MJ (2002) Fundamentals of microfabrication, 2nd edn. CRC Press LLC, Boca Raton

Siekmeyer G, Schüßler A, Lima de Miranda R, Quandt E (2014) Comparison of the fatigue performance of commercially produced Nitinol samples versus sputter-deposited Nitinol. JMEPEG 23:2437

Maletta C, Falvo A, Furgiuele F, Barbieri G, Brandizzi M (2009) Fracture behaviour of Nickel–Titanium laser welded joints. J Mater Eng Perform 18:569

Marton D, Boyle CT, Wiseman RW, Banas CE (2010) High strength vacuum deposited Nitinol alloy films and method of making same. US Patent 8083908 B2

Lima de Miranda R, Zamponi C, Quandt E (2009) Fabrication of TiNi thin film stents. Smart Mater Struct 18:104010

Acknowledgments

We thank Dr. C. Zamponi for EDX measurements and Dr. Jens Trentmann at the department of Radiology and Neuroradiology at the UKSH Kiel for radiopacity investigations.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bechtold, C., Lima de Miranda, R. & Quandt, E. Capability of Sputtered Micro-patterned NiTi Thick Films. Shap. Mem. Superelasticity 1, 286–293 (2015). https://doi.org/10.1007/s40830-015-0029-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40830-015-0029-9