Abstract

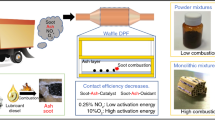

The soot combustion efficiency of a Pt-based catalyzed soot filter (CSF) was compared to a Cu-SCR catalyst-coated soot filter (SCRF® catalyst) under active regeneration conditions. The CSF was found to have a significantly higher soot combustion efficiency compared to the SCRF® catalyst under typical active regeneration conditions (550–600 °C). Despite the thermodynamic equilibrium limitation of the NO oxidation reaction at high temperatures and the relatively small quantity of NOx in diesel exhaust compared to O2, there is sufficient NO2 production capacity in a CSF where the impact of NO2 to the overall soot combustion efficiency under active regeneration conditions is significant. The differences between a standard porosity filter typically used for a CSF vs a high-porosity filter used for an SCRF® catalyst can only account for a minor portion of the difference in the soot combustion efficiency observed between the CSF and SCRF® catalyst. The fast consumption of the NO2 produced in situ in the CSF by soot may be driving the thermodynamic equilibrium of the NO oxidation reaction to continuously produce more NO2 for further soot combustion during active regeneration, resulting in a significant increase in the soot combustion efficiency in a CSF compared to an SCRF® catalyst or an uncoated filter.

Similar content being viewed by others

References

Stanmore, B.R., Brilhac, J.F., Gilot, P.: The oxidation of soot: a review of experiments, mechanisms and models. Carbon 39, 2247–2268 (2001)

McClure, B.T., Bagley, S.T., Gratz, L.D.: The influence of an oxidation catalytic converter and fuel composition on the chemical and biological characteristics of diesel exhaust emissions. In: SAE Technical paper, 920854 (1992)

Christensen, R., Hansen. M.B., Schramm, J., Binderup M.L., Jorgensen, V.: Mutagenic activity of the soluble organic fraction of exhaust gas particulate from a direct injection diesel engine. In: SAE Technical paper, 961977 (1996)

Johnson, T.V.: Review of diesel emissions and control. SAGE Journals. Int. J. Engine. Res 10, 275–285 (2009)

Konstandopoulos, A.G., Papaioannou, E.: Update on the science and technology of diesel particulate filters. Hosokava Powder Technology Foundation, KONA Powder and Particle Journal 26, 36–65, (2008)

Allansson, R., Blakeman, P.G., Cooper, B.J., Hess, H., Silcock, P.J., Walker, A.P.: Optimising the low temperature performance and regeneration efficiency of the continuously regenerating diesel particulate filter (CR-DPF) system. In: SAE Technical Paper, 2002-01-0428 (2002)

Setiabudi, A., Makkee, M., Moulijn, J.: The role of NO2 and O2 in the accelerated combustion of soot in diesel exhaust gases. Appl. Catal. B Environ. 50, 185–194 (2004)

Watling, T., Ravenscroft, M., Avery, G.: Development, validation and application of a model for an SCR catalyst coated diesel particulate filter. Catal. Today 188(1), 32–41 (2012)

Jeguirim, M., Tschamber, V., Brilhac, J.F.: Kinetics of catalyzed and non-catalyzed soot oxidation with nitrogen dioxide under regeneration particle trap conditions. J. Chem. Technol. Biotechnol. 84(5), 770–776 (2009)

Cooper, B., Thoss, J.: Role of NO in diesel particulate emission control. In: SAE Technical Paper, 890404, (1989)

York, A., Ahmadinejad, M., Watling, T., Walker, A. Cox, J.P., Gast, J., Blakeman, P.G., Allansson, R.: Modeling of the catalyzed continuously regenerating diesel particulate filter (CCR-DPF) system: model development and passive regeneration studies. In: SAE Technical Paper, 2007-01-0043 (2007)

Wade, W., White, J., and Florek, J.: Diesel particulate trap regeneration techniques. In: SAE Technical Paper, 810118 (1981)

Naseri, M., Chatterjee, S., Castagnola, M., Chen, H., Fedeyko, J., Hess, H., Li, J.: Development of SCR on diesel particulate filter system for heavy duty applications. SAE Int. J. Engines 4(1), 1798–1809 (2011)

Naseri, M., Conway, R., Hess, H., Aydin, C., Chatterjee, S.: Development of emission control systems to enable high NOx conversion on heavy duty diesel engines. In: SAE Technical Paper, 2014-01-1525 (2014)

Naseri, M., Aydin, C., Mulla, S., Conway, R., Chatterjee, S.: Development of emission control systems to enable high NOx conversion on heavy duty diesel engines. SAE Int. J. Engines 8(3), 1144–1151 (2015)

Conway, R., Chatterjee, S., Naseri, M., and Aydin, C.: Demonstration of SCR on a diesel particulate filter system on a heavy duty application. In: SAE Technical Paper, 2015-01-1033 (2015)

Tang, W., Youngren, D., SantaMaria, M., Kumar, S.: On-engine investigation of SCR on filters (SCRoF) for HDD passive applications. SAE Int. J. Engines 6(2), 862–872 (2013)

Rappe, K.: Integrated selective catalytics reduction-diesel particulate filter aftertreatnent: insights into pressure drop, NOx conversion, and passive soot oxidation behavior. Ind. Eng. Chem. Res. 53, 17547–17557 (2014)

Lee, J., Paratore, M., Brown, D.: Evaluation of Cu-based SCR/DPF technology for diesel exhaust emission control. SAE Technical Paper, 2008-01-0072 (2008)

Tan, J., Solbrig, C., Schmieg, S.: The development of advanced 2-way SCR/DPF systems to meet future heavy-duty diesel emissions. SAE Technical Paper. 2011-01-1140 (2011)

Ballinger, T., Cox, J., Konduru, M., De, D., Manning, W., Anderson, P. SAE Technical Paper, 2009-01-0910 (2009)

Tronconi, E., Nova, I., Marchitti, F., Koltsakis, G., Karamitros, D., Maletic, B., Markert, N., Chatterjee, D., Hehle, M.: Interaction of NOx reduction and soot oxidation in a DPF with Cu-zeolite SCR coating. Emission Control Scie Tech 1(2), 134–151 (2015)

Hands, T., Twigg, M., Gallinger, M.: A new instrument for diesel particulate filter functional tests in development and quality control applications. In: SAE Technical Paper, 2010-01-0809 (2010)

Perry, R.H., Green, D.W.: Perry’s Chemical Engineers’ Handbook, 7th edn. McGraw-Hill, New York (1997)

Haralampous, O.A., Koltsakis, G.C.: Back-diffusion modeling of NO2 in catalyzed diesel particulate filters. Ind. Eng. Chem. Res. 43, 875–883 (2004)

Acknowledgements

We would like to thank Johnson Matthey Plc. and Johnson Matthey Inc. for permission to publish this paper. We would also like to thank Megan Kardine and Claire Storms for preparing some of the catalysts used in this study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cumaranatunge, L., Chiffey, A., Stetina, J. et al. A Study of the Soot Combustion Efficiency of an SCRF® Catalyst vs a CSF During Active Regeneration. Emiss. Control Sci. Technol. 3, 93–104 (2017). https://doi.org/10.1007/s40825-016-0059-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40825-016-0059-6