Abstract

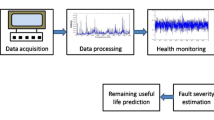

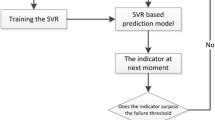

Slewing bearing is the key component of wind turbine and is used to transmit radial and axial load as well as the resulting overturning moments. The poor working condition will easily result in fatigue failure. An effective method for predicting the residual useful life of slewing bearing is proposed. Firstly, the features of temperature, torque and vibration signal of service sample and reference sample are extracted separately. Second, principal component analysis (PCA) based multiple sensitive features is used to establish performance decline indicator. Further analysis on these three PCA indicators is made by Support Vector Data Description (SVDD). Then the similarity is calculated between service sample and reference sample by normalized cross correlation (NCC) and residual useful life of service sample is predicted according to the life of reference sample. Finally, the method is verified by two experiments based on different working conditions. The prediction absolute error is only 0.9% when interval length is 50.

Similar content being viewed by others

References

Mosallam A, Medjaher K, Zerhouni N (2016) Data-driven prognostic method based on Bayesian approaches for direct remaining useful life prediction. J Intell Manuf 27(5):1037–1048

Vachtsevanos G, Lewis F, Roemer M, Hess A, Wu B (2007) Intelligent fault diagnosis and prognosis for engineering systems. John Wiley & Sons Inc., New Jersey

Wahbi M, Sloukia F, Aroussi ME (2013) Bearings prognostic using mixture of Gaussians Hidden Markov model and support vector machine. 2013 ACS International Conference on Computer Systems and Applications (AICCSA), https://doi.org/10.1109/AICCSA.2013.6616438

Lu C, Chen J, Hong R (2016) Degradation trend estimation of slewing bearing based on LSSVM model. Mech Syst Signal Process 76-77:353–366

Wang D, Peter WT, Guo W, Miao Q (2011) Support vector data description for fusion of multiple health indicators for enhancing gearbox fault diagnosis and prognosis. Meas Sci Technol 22(2):025102

Aye SA, Heyns PS (2017) An integrated Gaussian process regression for prediction of remaining useful life of slow speed bearings based on acoustic emission. Mech Syst Signal Process 84:485–498

Wang B, Hu X, Li H (2017) Rolling bearing performance degradation condition recognition based on mathematical morphological fractal dimension and fuzzy C-means. Measurement 109:1–8

Caesarendra W, Kosasih B, Tieu K (2016) Acoustic emission-based condition monitoring methods: review and application for low speed slew bearing. Mech Syst Signal Process 72-73:134–159

Kusiak A, Verma A (2012) Analyzing bearing faults in wind turbines: a data-mining approach. Renew Energy 48:110–116

Kosasih B, Caesarendra W, Tieu K (2014) Degradation trend estimation and prognosis of large low speed slewing bearing lifetime. Appl Mech Mater 493:343–348

Guo L, Li N, Jia F (2017) A recurrent neural network based health indicator for remaining useful life prediction of bearings. Neurocomputing 240:98–109

Kang M, Kim J, Kim JM (2015) Reliable fault diagnosis for incipient low-speed bearings using feature analysis based on a binary bat algorithm. Inf Sci 294:423–438

Hecke BV, Yoon J, He D (2016) Low speed bearing fault diagnosis using acoustic emission sensors. Appl Acoust 105:35–44

Benkedjouh T, Medjaher K, Zerhouni N, Rechak S (2013) Remaining useful life estimation based on nonlinear feature reduction and support vector regression. Eng Appl Artif Intell 26(7):1751–1760

Chen X, Shen Z, He Z (2013) Remaining life predictions of rolling bearing based on relative features and multivariable support vector machine. Proc IME C J Mech Eng Sci 227(12):2849–2860

Javed K, Gouriveau R, Zerhouni N (2015) Enabling health monitoring approach based on vibration data for accurate prognostics. IEEE Trans Ind Electron 62(1):647–656

Caesarendra W, Kosasih PB, Tieu AK (2013) Condition monitoring of naturally damaged slow speed slewing bearing based on ensemble empirical mode decomposition. J Mech Sci Technol 27(8):2253–2262

Zvokelj M, Zupan S, Prebil I (2010) Multivariate and multiscale monitoring of large-size low-speed bearings using ensemble empirical mode decomposition method combined with principal component analysis. Mech Syst Signal Process 24(4):1049–1067

Zvokelj M, Zupan S, Prebil I (2011) Non-linear multivariate and multiscale monitoring and signal denoising strategy using kernel principal component analysis combined with ensemble empirical mode decomposition method. Mech Syst Signal Process 25(7):2631–2653

Shieh G (2010) Estimation of the simple correlation coefficient. Behav Res Methods 42(4):906–917

Abdi H, Williams LJ (2010) Principal component analysis. Wiley Interdiscip Rev: Comput Stat 2(4):433–459

Huang J, Yan X (2015) Dynamic process fault detection and diagnosis based on dynamic principal component analysis, dynamic independent component analysis and Bayesian inference. Chemom Intell Lab Syst 148:115–127

Tax DMJ, Duin RPW (1999) Support vector domain description. Pattern Recogn Lett 20(11):1191–1199

Tsai DM, Lin CT, Chen JF (2003) The evaluation of normalized cross correlations for defect detection. Pattern Recogn Lett 24(15):2525–2535

Nakhmani A, Tannenbaum A (2013) A new distance measure based on generalized image normalized cross-correlation for robust video tracking and image recognition. Pattern Recogn Lett 34(3):315–321

Zhang Q, Tse WT, Wan X (2015) Remaining useful life estimation for mechanical systems based on similarity of phase space trajectory. Expert Syst Appl 42(5):2353–2360

Acknowledgments

The authors gratefully acknowledge the support provided by the National Natural Science Foundation of the China (51105191, 51375222), the project of Jiangsu provincial Six Talent Peaks (GDZB-033), the Shanghai Sailing Program (16YF1408500) and China Postdoctoral Science Foundation (Project No.2015 M580632).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, B., Wang, H., Tang, Y. et al. Residual Useful Life Prediction for Slewing Bearing Based on Similarity under Different Working Conditions. Exp Tech 42, 279–289 (2018). https://doi.org/10.1007/s40799-018-0235-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40799-018-0235-4