Abstract

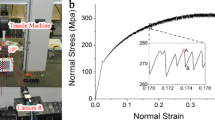

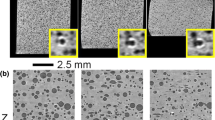

This paper proposes a methodology to determine wall thickness distributions in thermoformed products derived from in-situ surface strain measurements obtained with stereo digital image correlation (DIC), under the assumption of material incompressibility. Wall thickness equations are derived for the Green-Lagrange, Hencky, Biot, logarithmic Euler-Almansi and Euler-Almansi strain definitions and validated with an analytic example. The equations are then used to calculate the wall thickness from digital image correlations with both a commercial software (VIC-3D, version 2012) and an academic software (MatchID3D). Obviously, the choice of the strain definition in the correlation software should not influence the resulting wall thickness values. The comparison reveals that the wall thickness values prove to be identical, regardless of the strain definition that was used, and manual measurements show the validity of the DIC based results. It was also found that, when using VIC-3D version 2009, an earlier release in the software series of Correlated Solutions, all but the Green-Lagrange strain definition bring forth unrealistic minimum principal strain values, resulting in different values for the wall thickness.

Similar content being viewed by others

References

Throne JL (1996) Technology of thermoforming: Hanser

Van Mieghem B, Lava P, Debruyne D, Van Bael A, Ivens J (2013) Digital image correlation for on-line wall thickness measurements in thick gauge thermoforming. Key Eng Mater 554–557:1583–1591

Peters WH, Ranson WF (1982) Digital imaging techniques in experimental stress-analysis. Opt Eng 21(3):427–431

Peters WH, Ranson WF, Sutton MA, Chu TC, Anderson J (1983) Application of digital correlation methods to rigid body mechanics. Opt Eng 22(6):738–742

Chu TC, Ranson WF, Sutton MA, Peters WH (1985) Applications of digital-image-correlation techniques to experimental mechanics. Exp Mech 25(3):232–244

Sutton MA, Cheng MQ, Peters WH, Chao YJ, McNeill SR (1986) Application of an optimized digital correlation method to planar deformation analysis. Image Vis Comput 4(3):143–150

Sutton MA, Orteu J, Schreier H (2009) Image correlation for shape, motion and deformation measurements: Springer

Pan B, Qian KM, Xie HM, Asundi A (2009) Two-dimensional digital image correlation for in-plane displacement and strain measurement: a review. Meas Sci Technol 20(6)

Zhang ZY (2000) A flexible new technique for camera calibration. IEEE Trans Pattern Anal Mach Intell 22(11):1330–1334

Patterson EA, Hack E, Brailly P et al (2007) Calibration and evaluation of optical systems for full-field strain measurement. Opt Lasers Eng 45(5):550–564

Pan B, Lu ZX, Xie HM (2010) Mean intensity gradient: An effective global parameter for quality assessment of the speckle patterns used in digital image correlation. Opt Lasers Eng 48(4):469–477

Lecompte D, Smits A, Bossuyt S et al (2006) Quality assessment of speckle patterns for digital image correlation. Opt Lasers Eng 44(11):1132–1145

Hua T, Xie HM, Wang SM, Hu ZX, Chen PW, Zhang QM (2011) Evaluation of the quality of a speckle pattern in the digital image correlation method by mean subset fluctuation. Opt Laser Technol 43(1):9–13

Yaofeng S, Pang JHL (2007) Study of optimal subset size in digital image correlation of speckle pattern images. Opt Lasers Eng 45(9):967–974

Pan B, Xie H, Wang Z, Qian K, Wang Z (2008) Study on subset size selection in digital image correlation for speckle patterns. Opt Express 16(10):7037–7048

Lava P, Cooreman S, Coppieters S, De Strycker M, Debruyne D (2009) Assessment of measuring errors in DIC using deformation fields generated by plastic FEA. Opt Lasers Eng 47(7–8):747–753

Lava P, Cooreman S, Debruyne D (2010) Study of systematic errors in strain fields obtained via DIC using heterogeneous deformation generated by plastic FEA. Opt Lasers Eng 48(4):457–468

Lava P, Coppieters S, Wang Y, Van Houtte P, Debruyne D (2011) Error estimation in measuring strain fields with DIC on planar sheet metal specimens with a non-perpendicular camera alignment. Opt Lasers Eng 49(1):57–65

Wang YQ, Sutton MA, Bruck HA, Schreier HW (2009) Quantitative error assessment in pattern matching: effects of intensity pattern noise, interpolation, strain and image contrast on motion measurements. Strain 45(2):160–178

Lava P, Cooreman S, Coppieters S, Debruyne D (2010) Sources of systematic errors in the determination of heterogeneous strain fields obtained via DIC. Proceedings of SEM Annual Conference; 271–281

Biot MA (1964) Mechanics of incremental deformations. Wiley, London

Malvern LE (1969) Introduction to the mechanics of a continuous medium. Prentice-Hall, Englewood Cliffs

Kaye A, Stepto RFT, Work WJ, Aleman JV, Malkin AY (1998) Definition of terms relating to the non-ultimate mechanical properties of polymers. Pure Appl Chem 70(3):701–754

Van Mieghem B, Hamblok M, Van Bael A et al (2015) On the potential of stereo digital image correlation in thermoforming. Thermoforming Q 34(2):20–28

Van Mieghem B, Van Bael A, Ivens J (2013) Impact assessment of extrusion anisotropy on quality of thermoformed products. Proceedings of Composites Week @ Leuven and TEXCOMP-11 Conference. Leuven, Belgium; 1–8

Greenleaf AR (1950) Photographic optics. The Macmillan Company, New York

Acknowledgments

The authors would like to thank Pascal Lava from the MeM2P group of KU Leuven Technology Campus Ghent for his technical support with MatchID3D.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Van Mieghem, B., Ivens, J. & Van Bael, A. Consistency of Strain Fields and Thickness Distributions in Thermoforming Experiments Through Stereo DIC. Exp Tech 40, 1409–1420 (2016). https://doi.org/10.1007/s40799-016-0143-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40799-016-0143-4