Abstract

Coal and gas outburst is a complex dynamic disaster during coal underground mining. Revealing the disaster mechanism is of great significance for accurate prediction and prevention of coal and gas outburst. The geo-dynamic system of coal and gas outburst is proposed. The framework of geo-dynamic system is composed of gassy coal mass, geological dynamic environment and mining disturbance. Equations of stress–damage–seepage interaction for gassy coal mass is constructed to resolve the outburst elimination process by gas extraction with boreholes through layer in floor roadway. The results show the occurrence of outburst is divided into the evolution process of gestation, formation, development and termination of geo-dynamic system. The scale range of outburst occurrence is determined, which provides a spatial basis for the prevention and control of outburst. The formation criterion and instability criterion of coal and gas outburst are established. The formation criterion F1 is defined as the scale of the geo-dynamic system, and the instability criterion F2 is defined as the scale of the outburst geo-body. According to the geo-dynamic system, the elimination mechanism of coal and gas outburst—‘unloading + depressurization’ is established, and the gas extraction by boreholes through layer in floor roadway for outburst elimination is given. For the research case, when the gas extraction is 120 days, the gas pressure of the coal seam is reduced to below 0.4 MPa, and the outburst danger is eliminated effectively.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Coal and gas outburst is a mine gas dynamic phenomenon, which threatens the safety production of coal mines (Wang and Cheng 2023; Ma et al. 2020). Since the world 's first coal and gas outburst occurred in the Issac mine of the French Ruhr coal field in 1834, coal and gas outbursts have occurred in 18 countries, including China, Australia, France, Britain, Poland, Canada and other countries, with more than 30,000 gas outbursts (Zhang et al. 2023; Fu et al. 2020; Xue et al. 2022). China is the country with the most serious disaster of coal and gas outburst in the world. Coal and gas outbursts have occurred in many provinces and regions of the country (Zhang et al. 2020; Tong et al. 2019; Han et al. 2022; Ji et al. 2023). As of 2022, out of 4397 coal mines in China, 713 are coal and gas outburst mines. From 2017 to 2022, 31 large gas accidents with 188 deaths occurred in coal mines in China. For instance, a coal and gas outburst accident occurred in Limin Coal Mine, Guizhou Province, causing 7 deaths on March 2, 2022. And a coal and gas outburst accident occurred in the advancing face of Hebi No.6 Mine in Henan Province, causing 8 deaths on June 4, 2021. With the increase of mining intensity and depth, the number of outburst mines continues to increase, and the outburst threat is more serious (Wang et al. 2020; Niu et al. 2022).

The mechanism and prevention countermeasures of coal and gas outburst were widely researched. Zhou et al. (2022) studied the failure mode of coal mass in the process of internal and external stress, and analyzed the mechanical state, failure mode and tendency of the coal mass in the process of outburst. Shu et al. (2022) proposed the disaster-causing theory of key structure for coal and gas outburst, and established the mechanical criterion and energy criterion of coal and gas outburst initiation. Luo et al. (2018) clarified the composition of geo-dynamic system of coal and gas outburst, analyzed the evolution process of geo-dynamic system, and constructed the instability criterion of geo-dynamic system. Zhang et al. (2022) analyzed the stress field of the coal mass in working face under the coupling effect of seepage and solid, and obtained the mechanical model of the combined action of geo-stress, gas pressure and mechanical properties of the coal mass during the instability and failure of the coal mass. Chen et al. (2020) established a multi-physical field coupling relations based on strain softening constitutive model and Mohr–Coulomb criterion related to gas pressure and second principal stress. Zheng et al.(Zheng et al. 2021) analyzed the mechanism of strong and weak coupling structure to prevent coal and gas outbursts from the perspective of energy, and studied the stress response and deformation evolution in surrounding rock of strong–weak structure roadway. Ding et al. ( 2018) investigated the effects of gas pressure, water content and gas decompression rate on coal and gas outburst through experiments. Peng et al. (2012) studied the influence mechanism of gas seepage on coal and gas outburst through a self-developed triaxial servo-controlled seepage equipment for thermo-fluidsolid coupling of the gassy coal mass and a self-developed device for coal and gas outburst simulation test. To improve the prediction accuracy of outburst risk, Lin et al. (2023) constructed a prediction model of coal and gas outburst based on multi-algorithm and multivariate analysis. Wang et al. (2021) developed an outburst risk prediction system and a risk grade index evaluation system using the extension theory. Numerous scholars have numerically simulated coal and gas outburst. Zhu et al. (2018) used RFPA2D-Flow numerical calculation software to simulate the occurrence and development process of coal and gas outburst under different geo-stress and different gas pressure conditions. Gao et al. (2019a) used RFPA-GAS numerical simulation software to analyze the dynamic failure mechanism of coal and gas outburst under different support strength, support and no support conditions. Four dynamic processes of coal and gas outburst are discussed, and the dynamic failure mechanism of coal and gas outburst was revealed. Tang et al. (2022) carried out simulations of coal and gas outburst in deep roadways under different buried depths, and obtained the variation law between critical gas pressure, effective stress and impact parameters (peak impact force, peak arrival time, and outburst duration), revealing the two-phase flow impact failure mechanism of coal and gas outburst. Xu et al. (2022) studied the formation mechanism and propagation characteristics of coal and gas outburst impact airflow. The formation and migration model of impact airflow was established and applied to the numerical simulation.

There is often a closed environment with broken coal mass, high geo-stress, high gas content and pressure near the geological structure, which is usually the location that coal and gas outburst occurs (Zhao et al. 2022). Therefore, many scholars believe that the outburst is controlled by geological structure, and different forms of coal and gas outburst can occur under different tectonic backgrounds. Cheng et al. ( 2020), Tu et al. (2019, 2022) found that coal and gas outburst is prone to occur in the areas with tectonic coal development, and the distribution of tectonic coal has a controlling effect on coal and gas outburst. Cheng et al. (2021) revealed the internal relationship between tectonic coal and outburst, systematically reviewed and compared the pore structure, methane adsorption, desorption, diffusion, seepage and mechanical properties of tectonic coal and primary coal, and quantitatively analyzed the outburst energy. Xian et al. (2009) explored conditions for the stimulation and occurrence of coal and gas outburst by the deductive method, revealing that the main energy of outburst is gas expansion energy and geological structure is the key factor that leads to outburst. Cao et al. (2022) believed that the fault zone is the main geological unit of coal and gas outburst, and studied the variation law of the geo-stress field on the hanging wall of the normal fault before and after mining. Cao et al. (2001) believed that coal and gas outburst mostly occurs in the lower plate area of the inverse fault and verified their research results through field experiments with the four outburst coalmines in Pingdingshan, Henan province, China. Tu et al. (2021) analyzed the geological characteristics of typical outburst cases and the influence of tectonic movement on outburst, and divided the outburst stages considering geological factors. Pan et al. (2020) developed a multi-physical field experimental device for coal and gas outburst. On this basis, the failure characteristics of tectonic coal under different gas pressure and stress conditions are quantitatively studied, and the evolution of gas pressure and breakage degree of coal sample during coal and gas outburst are quantitatively discussed. Gao et al. (2019b) analyzed the propagation law of blasting stress wave and its influence on the damage and failure of tectonic coal and rock and gas occurrence state, and carried out the simulation experiment by using the self-developed gas–solid coupling blasting test device. Considering the interaction between geological structure, gas pressure, coal mechanical properties and overburden stress, Zhao et al. (2020) established a multi-field coupling model of coal seam, and numerically simulated the mining process of horizontal coal seam and fault coal seam, thus revealing the mechanism of coal and gas outburst.

Through coalmine field monitoring, laboratory experiments and numerical simulation, many scholars have analyzed the mechanism and influencing factors of coal and gas outburst, which has laid a foundation for the study of coal and gas outburst, but most of them are based on the mechanism of coal and gas outburst and geological structure. There are few literatures have systematically and comprehensively studied coal and gas outbursts from the aspects of coal and gas outburst mechanism, instability criterion, multi-field coupling model and outburst elimination mechanism. Therefore, the mechanism of geo-dynamic system of coal and gas outburst will be studied to expound a basic framework of geo-dynamic system. A stress–damage–seepage coupling model for gassy coal mass will be established to simulate the ‘unloading + depressurization’ outburst elimination process by means of gas extraction using boreholes through layer in floor roadway. This study may provide a reference for the prevention of coal and gas outburst disaster under similar conditions.

2 Geo-dynamic system of coal and gas outburst

2.1 Basic principle of outburst geo-dynamic system

By summarizing the field cases of coal and gas outburst, the disaster mechanism of geo-dynamic system of coal and gas outburst is put forward. The occurrence of coal and gas outburst is the instability phenomenon of geo-dynamic system of porous gassy coal mass containing a large amount of gas. The outburst geo-dynamic system exists in gassy coal mass within a certain spatial range. After being transformed by the geological dynamic environment such as faults, folds, magmatic intrusion and tectonic movement, the outburst prone gassy coal mass is formed. Then, under the action of stress loading or unloading caused by engineering activities, e.g. coal mining or roadway excavation, the physical fields of stress, seepage and damage are coupled. The local stress concentration and elastic potential increase to expand the damage zone suddenly, and the energy is released to gather local cracks and followed to fragment coal mass. The damaged coal will quickly release a large amount of gas stored in it in adsorbed or free state, and gather in the damage zone to form a gas aggregate. A large amount of coal mass and gas quickly throw out of the mining space, and result in outburst disaster eventually.

Coal and gas outburst occurs in a certain range of coal-rock geological dynamic system, which includes three mandatory components: the gassy coal mass, the geological dynamic environment and the mining disturbance. Among them, the gassy coal mass is the material basis, which provides material sources such as coal and gas for outburst. The geological dynamic environment is the internal driving force. In the geological history process of coal seam deposition and accumulation, the coal seam is reformed, such as sealing gas, forming tectonic coal mass, generating tectonic stress, et al. The mining disturbance is an external driving force, which provides complex mining loading and unloading in the outburst gestation stage, and provides spatial conditions for rapid release of coal rock mass and gas in the outburst evolution stage (Fan et al. 2017). The relationship among influencing factors within geo-dynamic system of coal and gas outburst, as shown in Fig. 1.

Relationship among influencing factors within geo-dynamic system of coal and gas outburst (Fan et al. 2017)

The two core contents of the outburst geo-dynamic system are the stage leading role of factors and the range of gas outburst scale. The mechanism of geo-dynamic system expounds the role of gas and stress (geo-stress, mining stress) in the process of gas outburst, and puts forward that the factors that play a leading role in different stages are different. In the outburst gestation stage, the stress plays a leading role. The geo-stress and mining stress cause the coal mass to be broken to form a large number of cracks, and the gas is released and sealed to form the so-called gas aggregate. In the outburst evolution stage, the gas with high pressure gradient between the mining space and the gas aggregate drives the coal mass to move forward quickly, and further breaks down coal fragments, resulting in gas desorbing and aggravating for promoting gas outburst. The mechanism of geo-dynamic system reveals the spatial range of coal and gas outburst, and points out this spatial range is the object for implementing outburst prevention measures. This fills the gap where to take outburst preventive measures, and provides scientific basis for gas outburst prevention technologies.

The mechanism of outburst geo-dynamic system believes that ‘gas aggregate’ exist objectively. This is not contrary to the hypothesis of gas leading role. They all emphasize that the high pressure gas stored in the coal seam is the main cause of gas outburst. Differently, the mechanism of outburst geo-dynamic system also expounds the source of 'gas aggregate' and the stage leading role of gas. In other words, high pressure and high energy gas will be produced mainly after the destruction of coal rock mass, and drive the further evolution of gas outburst disaster.

The mechanism of outburst geo-dynamic system is that the combined action of geo-stress and mining stress destroys the coal mass, and then a large amount of gas gushes out to form gas outburst disaster. In terms of roadway advancing face, the stress around the roadway is redistributed due to the excavation engineering activities. In the coal mass on the advancing face, the stress in the axial direction is reduced from the original geo-stress to freedom constraint, while the stress in the vertical direction is increased from the original geo-stress to the maximum bearing pressure, and then decreases rapidly as the coal mass is failed. The coal mass located from the maximum bearing pressure to the coal wall occurs plastic failure and the gas is desorbed dramatically. This is consistent with the stress dominant hypothesis, which emphasizes the important role of mechanical failure in gas outburst. Differently, the mechanism of gas outburst geo-dynamic system expounds the leading role of stress in the initial stage of gas outburst. It is considered that the prerequisite for gas outburst is that the coal rock mass in front of the working face suddenly appears a certain range of damage zone, which is precisely the result of stress loading or unloading. This is different from the existing stress dominant hypothesis, that is, the gas outburst risk of coal seam cannot be evaluated simply from the level of geo-stress field. The size of damage zone in coal mass, the fragmentation degree of coal rock mass should be comprehensively considered from the mining stress, coal rock mechanical parameters and gas parameters to evaluate the gas outburst risk.

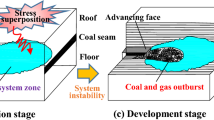

The mechanism of outburst geo-dynamic system believes that the occurrence process of outburst is divided into stages of gestation (preparation) and evolution (initiation, development and termination). The gas outburst is controlled by stress change, coal rock fracture, gas accumulation and energy release. This is consistent to the comprehensive action hypothesis—the coal and gas outburst is the result of the combined action of geo-stress, coal-rock mass, and gas parameters. The deformation potential of coal mass reflects the relationship between stress and mechanical properties of coal mass, while the internal energy of gas reflects the relationship between gas pressure and gas volume. Therefore, the mechanism of geo-dynamic system satisfies the comprehensive action hypothesis, and the energy accumulation and dissipation always works through the whole process of gestation and evolution.

Therefore, the mechanism of gas outburst geo-dynamic system not only conforms to the dominant idea of gas leading hypothesis, stress leading hypothesis, and comprehensive action hypothesis, but also emphasizes the importance of mining disturbance and the stage leading of gas and stress. It breaks through the qualitative description of the previous hypothesis, delineates the scale range of outburst, and provides a theoretical basis for the quantitative study of the gestation and evolution of coal and gas outburst.

2.2 Formation and instability criterion for gas outburst

2.2.1 Formation criterion

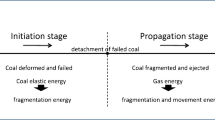

The instability process of the outburst geo-dynamic system must meet certain mechanical and energy conditions. The geo-dynamic system should be first formed, and then the system is unstable until the end. Therefore, the coal and gas outburst needs to both satisfy the formation criterion and the instability criterion for the geo-dynamic system.

When the advancing face excavates to the position near the tectonic zone, the mining stress and the tectonic stress around the tectonic zone are superimposed to generate an instantaneous load acting on the coal rock mass. The maximum tensile stress criterion and the Mohr–Coulomb criterion are used to determine whether tensile or shear damage occurs after the coal is stressed. The formation criterion can be expressed as (Chen et al. 2018):

where, σ1 is the maximum principal stress, Pa; σ3 is the minimum principal stress, Pa; σt and σc are tensile and compressive strength of the coal respectively, Pa; θ is the internal friction angle of the coal, °; F1 is the threshold functions for tensile or shear damage.

2.2.2 Instability criterion

The instantaneous outburst requires to meet the energy conditions in the formation and development of geo-dynamic system. From the perspective of energy conservation, the outburst energy mainly comes from the elastic potential energy of the coal mass, the elastic potential energy of roof and floor, and the gas internal energy of the desorbed gas. These energies are dissipated into the crushing work on the coal mass and the kinetic work on crushed coal, et. al. in the process of gas outburst. During the formation of the dynamic system, the mechanical failure plays a leading role. Ignoring the frictional heating, vibration, sound and other energy loss, the development process of outburst dynamic system should satisfy (Hu et al. 2008a):

where, Eg is the internal energy of the outburst gas, J; Ep is the gravitational potential energy of the outburst coal rock mass, J; Ee is the elastic potential energy of the outburst coal mass, J; Ef is the crushing work required for the coal rock mass in the dynamic system, J; Ek is the kinetic work required for the outburst coal, J.

Based on the previous research results, the instability criterion for the geo-dynamic system can be obtained as (Li et al. 2012; Wang et al. 2015):

where, p1 is the gas pressure in the coal mass of the geo-dynamic system, Pa; p2 is the gas pressure in the roadway, Pa; φ is the porosity of coal; η is the proportion of adsorbed gas participating in the outburst in total adsorbed gas, which is related to the initial velocity of diffusion; n is the process index, and the adiabatic process can be taken as 1.25; ρs is the density of the coal mass, kg/m3; VL is Langmuir volume constant, m3/kg; PL is Langmuir pressure constant, Pa; sg is gas saturation in the fractures; T0 is the standard temperature, K, and p0 is standard atmospheric pressure, Pa; g is the acceleration due to gravity, m/s2; h is the relative height between the pre-outburst and post-outburst positions of the coal rock, m; Yp1 is the percentage of the mass of coal broken into particle sizes ≤ 0.2 mm in the total coal mass; f is the firmness coefficient of the coal in the geo-dynamic system; v is the speed of the thrown coal rock mass, m/s. According to the former outburst measured data (Hu and Wen 2013), the transport speed of throwing crushed coal is 17.6–55.5 m/s with an average of 39 m/s.

The instability criterion of the geo-dynamic system involves the regional tectonic stress, mining induced stress, strength of the coal rock mass and gas properties. These parameters reflect the interactions among the coal rock mass, geo-stress, and coal seam gas. The occurrence of coal and gas outburst requires that both the formation criterion and the instability criterion are satisfied. The outburst geo-body is defined as the coal rock mass satisfying the instability criterion F2, indicating that the energy accumulation and release in the geo-dynamic system dominates in the initiation and development of outburst. The energy change comprehensively reflects the mechanical strength characteristics, the geo-stress state and the gas adsorption / desorption in the coal rock mass.

2.3 Gas outburst elimination mechanism based on outburst geo-dynamic system

The fracture in the crushed coal mass will expand, penetrate and even dramatically fragment coal under gas pressure and external stress loading after the initiation of gas outburst. This process will consume the major energy accumulated in the geo-dynamic system to increase the surface energy of pulverized coal. The rising of the coal-rock strength will increase the crushing work required by the gassy coal rock mass, hereby increase the energy threshold required for outburst. While, the rising of gas pressure and geo-stress will increase the energy accumulated in the gassy coal rock mass, and thus increase the energy to be dissipated by outburst. The formation of the damage zone in coal mass is a prerequisite for the energy dissipation in outburst. The energy density dissipated in the outburst dynamic system greater than the required dissipation energy density is the key to determine whether the outburst can continue.

In Fig. 2, the effective stress, dominated by the geo-stress, acts on the coal rock mass in front of the working face. When the formation criterion F1 is satisfied, damage occurs to form the outburst geo-dynamic system. Under the action of geo-stress and gas pressure, the low strength coal rock mass in the geo-dynamic system satisfies the instability criterion F2, and the geo-dynamic system is further unstable and outburst occurs. In the instability process, the coal rock mass satisfying the energy instability criterion F2 can always satisfy the mechanical criterion F1 (Hu et al. 2008b). Therefore, we propose to eliminate the risk of outburst by controlling the major factors of the formation criterion F1 and the instability criterion F2 of the geo-dynamic system.

The high geo-stress in the coal seam formed by the combination of mining stress and tectonic stress are the controlling factors of the formation criterion F1 for the geo-dynamic system. It dominates the mechanical damage and failure process of the gassy coal rock mass and reduces the strength of the coal rock mass. At the same time, the fractures and pores in the coal-rock mass in the high geo-stress state are often compressed, compacted and closed, which has a sealing effect on the coal seam gas. In engineering practice, regional measures of mining protective layer and local measures of hydraulic flushing or large diameter boreholes are usually adopted to alleviate high geo-stress, namely the ‘unloading’ countermeasure. By this, the formation conditions of the geo-dynamic system will not be satisfied, so as to prevent coal and gas outburst. In view of the energy instability criterion F2 of the geo-dynamic system, the regional measures of gas pre-extraction and the local measures of gas extraction ahead the working face are usually adopted to reduce the gas pressure and content in the coal seam, namely the ‘depressurization’ countermeasure. By this, the energy instability criterion F2 can not be satisfied and thus achieve the purpose of outburst prevention.

Therefore, the outburst elimination mechanism based on the geo-dynamic system includes two aspects. The first is unloading. By the measures of reducing the geo-stress, the stress conditions of the coal seam are improved, which prevent an effective spatial scale of outburst geo-dynamic system. At the same time, the improved stress condition can also increase the permeability in the coal seam and promote gas extraction. The second is depressurization. By reducing the gas pressure and content in the coal seam to avoid the energy in the coal rock mass from satisfying the energy instability criterion F2, thus the geo-dynamic system can maintain stability and eliminate the risk of gas outburst.

3 Equations of stress–damage–seepage interactions for outburst simulation

Coal and gas outburst involves the instability in coal deformation-failure and gas rapid desorption-diffusion-seepage. In this section, we develop the equations for the stress–damage–seepage interaction in outburst coal seams and a method for numerical simulation. The coal is characterized as a pore-fracture dual porosity structure with the coal composed of coal matrix (containing micro-pores) and fractures.

The total strain of the coal includes strain caused by solid stress, by fluid pressure in the pores and fractures, and by gas adsorption/desorption. The governing equation of the stress field can be expressed as a modified Navier equation (Hu et al. 2008b):

where, G is the shear modulus of coal, Pa; K is the bulk modulus of coal, Pa; αm and αf are Biot’s effective stress coefficients corresponding to pores and fractures respectively; εs is the gas adsorption induced coal skeletal strain; pm is the pressure in matrix pores, Pa; pf is the fluid pressure in the fractures, Pa; F is the volume force, Pa; ui is the displacement in i direction.

Stress concentrations develop ahead of the advancing face, and this damages the coal seam. The elastic modulus of the coal decreases with the damage and may be expressed as (Fan et al. 2017):

where, E and E0 are the elastic modulus of coal post- and pre-damage, respectively, Pa; D is the damage variable.

The maximum tensile stress criterion (f1) and the Mohr–Coulomb criterion (f2) are used to determine whether tensile and shear damage occurs in coal seams. The damage variable in coal is expressed as (Xu et al. 2006):

where, εt is the maximum tensile strain in the coal; εc is the minimum compressive strain in the coal; εt0 represents the ultimate tensile strain in the coal; εc0 represents the ultimate compressive strain in the coal.

The governing equation for gas migration in the coal matrix is (Fan et al. 2019a):

where, φm is the porosity in coal matrix; Mg is the molar mass of gas, kg/mol; R is the molar constant of gas, J/mol K; T is the temperature in the coal seam, K; VL is Langmuir volume constant, m3/kg; PL is the Langmuir pressure constant, Pa; ρgs is gas density in standard state, kg/m3; αD1 is the coefficient of damage on desorption rate; τ is the gas desorption time, s.

Combined with the generalized Darcy's law for two-phase gas–water seepage, the mass conservation equation of the gas phase and water phase in the fracture system can be expressed as (Wu et al. 2010; Pan and Connell 2012):

where, φf is the fracture porosity; k is the absolute fracture permeability, m2; krg is the relative permeability of gas; μg is dynamic viscosity of CH4, Pa·s; bk is the slippage factor, Pa; ρw is the water density, kg/m3; krw is the relative permeability to water; μw is the dynamic viscosity of water, Pa·s.

The evolution of coal permeability is related to the change in fracture opening and fracture volume in coal. In the elastic stage, the change in fracture volume results from the effective stress induced strain and the gas adsorption induced strain. According to previous studies, the porosity in the coal matrix can be expressed as (Fan et al. 2019b):

where, εe = εv + pmg/Ks − εs; εv is the volumetric strain of the coal; the subscript '0' represents the initial value.

The fracture state in the coal can be defined as:

The relationship between permeability and fracture porosity satisfies the cubic law. The damage-induced permeability of the coal increases rapidly, which may reach 300–500 times that of the initial state (Guo 2017). Therefore, the permeability of coal ahead of the advancing face is divided into elastically-influenced permeability and damage-influenced permeability. The damage jump coefficient on coal permeability increases exponentially with the damage variable (Xue et al. 2015). We integrate the permeability in both elastic and damage stages, the general elastic-damage permeability model can be obtained:

where αD is the damage coefficient.

Combining Eqs. (4)–(8), the equations in stress–damage–seepage interactions for outburst coal seams are obtained. Due to the time–space nonlinearity of the partial differential equations (PDEs), it is difficult to solve these by analytical methods (Yang et al. 2023). Therefore, we apply the Comsol with Matlab software to obtain the numerical solution in outburst risk prediction and outburst elimination.

4 Application of outburst elimination based on geo-dynamic system

4.1 Background of field application

The studied coal mine is located in the eastern part of the Pingdingshan mining area. The overall structure is a monoclinic structure that strikes NWW and dips NNE. The main structures include the NW-trending reverse fault and Guozhuang anticline fault fold belt. A total of 28 times of coal and gas outburst occurred in the coal mine. The maximum outburst gas volume is 25,704 m3, and the maximum outburst coal volume is 293 t. The amount of coal and gas outburst is decreasing with the continuous improvement of gas extraction technology. Between 2006 and 2016, there was no coal and gas outburst. With the depletion of shallow coal resources in the mine, coal mining has gradually shifted to the deep part. The coal seam shows complex existing conditions, e.g. high geo-stress, high gas and low permeability, which make it difficulty to deplete coal seam gas, and greatly increases the risk of coal and gas outburst. On November 25, 2017, a dynamic phenomenon occurred at 427 m in the intake airway of 31020 panel. The outburst location was 910 m deep, with a total outburst gas of 2458 m3 and outburst coal of 83 t.

The 31020 panel is located in the upper part of the three-level west wing of the mine. The south is adjacent to the mined 17220 panel, and the north is adjacent to the unmined 31040 panel. The tendency of 31020 panel is 203 m in width. In 31020 panel, the length of return airway is 911 m, while that of intake airway is 761 m. The coal seam is relatively stable and the structure is simple. The thickness of coal seam is about 3.2– 4.5 m, with an average of 3.3 m. The original gas content is 14.97 m3/t, the gas pressure is 1 MPa, and the ground temperature is 29.4–32.2 °C, and the lithology of roof and floor of coal seam at 31020 intake airway as shown in Table 1.

The 31020 intake airway is excavated along the roof of Ji15 coal seam. The distance between 31020 intake airway and overlying Ji14 coal seam is 11–14 m, and the distance between 31020 intake airway and underlying Ji16-17 coal seam is 1.5–12.0 m. The lower position gas control roadway for 31020 intake airway excavation is constructed at 20 m outside, and the distance between the two roadways is 18 m. The cross section of the roadway is 4.6 m × 3.4 m, which is supported by anchor-net-cable, and the row spacing is 700 mm. The working face is constructed by blasting excavation, with speed of 12 m/day.

4.2 Simulation of outburst risk based on geo-dynamic system

According to the position of 30120 intake airway, a three-dimensional geometry model of roadway excavation is established, with size of 52 m × 70 m × 40 m, as shown in Fig. 3. According to the derived equations of stress–damage–seepage interactions in the outburst geo-dynamic system, the numerical solutions of the outburst risk prediction and outburst elimination are realized by the finite element software—Comsol with Matlab.

According to the results of geo-stress test in Coal Mine, the vertical stress of 22 MPa (σv) is applied to the top boundary of the model, the horizontal stress (σH) of 25 MPa is applied in the x direction, and the horizontal stress (σh) of 20 MPa is applied in the y direction. The bottom boundary is set as a fixed boundary, and the other two horizontal directions are sliding boundaries that limit horizontal displacement, as shown in Fig. 4. The model is surrounded by impermeable boundary. Affected by the fault structure, the stress concentration factor of the coal seam in the simulated area is between 1.25 and 1.5. Therefore, the maximum horizontal geo-stress and vertical geo-stress are set as a linear increase function along the axis of the roadway, in which the vertical stress is σv − 1.25σv, and the horizontal stress is σH − 1.5σH.

The physical and mechanical parameters of coal and rock mass are obtained from the field and laboratory tests, as shown in Table 2. Some of the parameters for outburst risk simulation during advancing are obtained from the field and laboratory tests, and other parameters are from the literature (Fan et al. 2019a; Li et al. 2016; Zheng et al. 2017), as shown in Table 3. The mechanical properties of coal rock mass are heterogeneous in spatial, and the initial values for mesoscopic elements are randomly generated by Monte-Carlo. The geometry is meshed into 19,491 domain elements and 5972 boundary elements.

The spatial distribution of the damage zone in the coal rock mass around the roadway is shown in Fig. 5. As the advancing face excavates forward, the damage zone around the roadway increases. In general, the expansion of the damage zone in the coal seam is greater than that in the roof and floor. The damage range is 3–4 m in the coal wall, while this would be 1–2 m in the roof and floor rock. When the intake airway is excavated at 20 m and 40 m, the damage zone near the working face is small. When the intake airway is excavated at 60 m, a large damage zone appears in front of the advancing face, because the bearing pressure generated by the roadway excavation and the tectonic stress generated by the fault structure in the coal rock mass. As the roadway is excavated forward, the higher the tectonic stress, the greater the damage in the coal rock mass on the working face. Therefore, we believe that the generation of this damage zone provides conditions for the occurrence of outburst, which is the area where the scale range of the outburst dynamic system is located.

The gas pressure in coal seam is higher than that in coal wall of roadway—atmospheric pressure. The gas migrates into the roadway under the pressure gradient. In Fig. 6, the gas pressure in the coal wall on both sides of the roadway decreases. The greater the damage degree, the faster the gas pressure decreases. When the intake airway is excavated at 20 m and 40 m, the gas pressure in the coal wall is reduced in a small range. When the intake airway is excavated at 60 m, the permeability increases sharply after a large area of damage zone is generated in front of the excavation face, the gas pressure in the coal seam in this area is rapidly reduced, and the gas is quickly released into the roadway.

We define the scale range of the geo-dynamic system as the coal and rock mass satisfying the formation criterion F1, and the scale range of the outburst geo-body as the coal and rock mass satisfying both criterions F1 and F2. The spatial distribution of the geo-dynamic system and the outburst geo-body in the surrounding rock of the intake airway is shown in Fig. 7. The range of outburst geo-body with adequate energy of crushing and throwing the outburst coal rock is narrow, appearing at 0–3 m in front of the advancing face. Few part of the coal rock mass in the damage zone is completely broken and thrown out, as the high geo-stress caused rapid gas release in front of the roadway. The outburst geo-body is calculated, and the volume of coal rock is 48.5 m3, including 45.9 m3 of coal and 2.6 m3 of rock, which is consist with the 83 t of outburst coal rock in the field with an error of 10.8%.

The formation of outburst geo-dynamic system is affected by coal rock strength, geo-stress and gas pressure. The rapid gas release dominates the energy instability process. Reducing the gas pressure in the coal seam and slowing down the rate of gas release in the coal rock mass are the key to preventing the outburst (Wang et al. 2022).

4.3 Simulation of gas extraction and outburst elimination based on geo-dynamic system

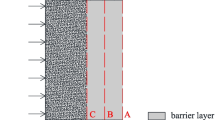

The gas extraction of cross-layer boreholes through floor roadway is adopted to prevent outburst in 31020 intake airway. A group of cross-layer boreholes is constructed every 6 m, there are 10 groups, and each group has 9 boreholes, including 3 hydraulic flushing boreholes and 6 ordinary boreholes. The diameter of ordinary boreholes is 89 mm, and the extraction pressure is 20 kPa. In addition, a set of hydraulic flushing holes are arranged every 6 m, there are 10 groups, and 6 flushing holes are arranged in each group. The layout scheme of gas extraction boreholes is shown in Fig. 8. A numerical calculation model is established to study the gas extraction law. The external stress boundary of the model is the same as that of the outburst risk simulation. The external seepage boundary of the model is the gas non-permeability boundary, and the extraction pressure of the borehole wall is set as 20 kPa.

With the increase of extraction time, the gas pressure of coal seam gradually decreases, and the range of gas pressure reduction gradually expands until it extends to the whole coal seam. The distribution of gas pressure after different extraction time is shown in Fig. 9. After 10 days of extraction, the gas pressure around boreholes in the coal seam is reduced slighted; while after 120 days of extraction, the gas pressure decreased significantly, and the gas pressure in most areas of the coal seam decreased from the initial gas pressure of 1 MPa to smaller than 0.4 MPa. The gas depletion effect of hydraulic flushing is obviously better than that of ordinary boreholes. Because hydraulic flushing flushes coal mass out from the ordinary borehole, which expands the contact area between the borehole wall and the coal seam. After the coal mass is flushed out, the coal mass around the hydraulic flushing is unloaded, which improves the permeability of the coal seam and accelerates the speed of gas migration to the hydraulic flushing, thus promoting the efficiency of gas extraction.

The distribution of gas pressure in coal seam after different time is taken as the initial gas pressure in coal seam during roadway excavation, which is introduced into the simulation of outburst. The risk of coal and gas outburst after different time is evaluated again. The scale range of outburst geo-body in roadway advancing face after different time of gas extraction is calculated, and the three-dimensional spatial evolution of outburst geo-body is obtained, as shown in Fig. 10. As the time prolongs, the gas pressure in the coal seam decreases, and the scale of the outburst geo-body gradually shrinks. After 10, 30, 60 and 120 days of gas extraction, the volume of the outburst geo-body in front of the roadway is 25, 13, 4 and 0 m3, respectively, indicating that the outburst risk is gradually reduced. After 120 days of gas extraction, the gas pressure in the coal seam is reduced to smaller than 0.4 MPa, and the outburst danger is eliminated. This implies the occurrence of outburst is effectively eliminated.

5 Conclusions

-

(1)

The mechanism of geo-dynamic system of coal and gas outburst is put forward, and the basic framework and function relationship of geo-dynamic system composed of the gassy coal mass, the geological dynamic environment and the mining disturbance are expounded. The occurrence of outburst is divided into the evolution process of gestation, formation, development and termination of geo-dynamic system.

-

(2)

The scale range of outburst occurrence is determined, which provides a spatial basis for the prevention and control of outburst. The formation criterion and instability criterion of coal and gas outburst are established. The formation criterion F1 is defined as the scale of geo-dynamic system, and the instability criterion F2 is defined as the scale of the outburst geo-body. The governing equations of the stress–damage–seepage coupling model of the outburst dynamic system is composed of the deformation and damage equation of the gassy coal mass, the gas desorption and diffusion equation of the coal matrix pores, the gas and water seepage equation of the coal fractures. The permeability model of the coal rock mass in elastic deformation stage and damage stage is constructed.

-

(3)

According to the geo-dynamic system of coal and gas outburst, the ‘unloading + depressurization’ outburst elimination mechanism is established. The technical scheme of gas outburst elimination by cross-layer boreholes and hydraulic flushing boreholes through floor roadway is given, and the process of gas outburst elimination is simulated numerically. After 10 days of extraction, the gas pressure around boreholes in the coal seam is reduced slighted; while after 120 days of extraction, the gas pressure decreased significantly, and the gas pressure in most areas of the coal seam decreased to smaller than 0.4 MPa. After 10, 30, 60 and 120 days of gas extraction, the volume of the outburst geo-body in front of the roadway is 25, 13, 4 and 0 m3, respectively, indicating that the outburst risk is gradually reduced.

-

(4)

When coal and gas outburst occurs, the broken coal-rock mass carrying gas into the roadway or stope space is a highly discrete dynamic problem. At present, the coupling model is difficult to simulate the migration and disaster process of discrete coal-rock mass in the roadway by using the finite element method. In the future, the simulation method combining finite element and discrete element will be further considered to reproduce the whole process of the gestation and evolution of the outburst geo-dynamic system and the disaster caused by the inrush of the outburst mass into the mining space, so as to have a deeper understanding of the outburst mechanism.

References

Cao Y, He D, Glick D (2001) Coal and gas outbursts in footwalls of reverse faults. Int J Coal Geol 48(1–2):47–63

Cao Y, Zhang H, Zhang Z et al (2022) Characteristics of coal and gas outburst and controlling mechanism of stress field in the hanging wall of normal faults. Coal Geol Explor 50(4):61–69

Chen S, Wei C, Yang T et al (2018) Three-dimensional numerical investigation of coupled flow-stress-damage failure process in heterogeneous poroelastic rocks. Energies 11(8):1923

Chen D, He W, Xie S et al (2020) Increased permeability and coal and gas outburst prevention using hydraulic flushing technology with cross-seam borehole. J Nat Gas Sci Eng 73:103067

Cheng Y, Lei Y (2021) Causality between tectonic coal and coal and gas outbursts. J China Coal Soc 46(01):180–198

Cheng Y, Pan Z (2020) Reservoir properties of Chinese tectonic coal: a review. Fuel 260:116350

Ding Y, Yue ZQ (2018) An experimental investigation of the roles of water content and gas decompression rate for outburst in coal briquettes. Fuel 234:1221–1228

Fan CJ, Li S, Luo MK et al (2017) Coal and gas outburst dynamic system. Int J Min Sci Technol 27(01):49–55

Fan C, Li S, Luo M et al (2019a) Numerical simulation of hydraulic fracturing in coal seam for enhancing underground gas drainage. Energy Explor Exploit 37(1):166–193

Fan C, Elsworth D, Li S et al (2019b) Thermo-hydro-mechanical-chemical couplings controlling CH4 production and CO2 sequestration in enhanced coalbed methane recovery. Energy 173:1054–1077

Fu G, Xie X, Jia Q et al (2020) Accidents analysis and prevention of coal and gas outburst: understanding human errors in accidents. Process Saf Environ Prot 134:1–23

Gao M, Zhang S, Li J et al (2019a) The dynamic failure mechanism of coal and gas outbursts and response mechanism of support structure. Therm Sci 23(Suppl. 3):867–875

Gao K, Qiao G, Liu Z et al (2019b) On classification conception of coal and gas outburst mechanism and its application. J Min Saf Eng 36(05):1043–1051

Guo H (2017) Equivalent characteristics of coal with dual pore structure and its influence mechanism on its mechanical and osmotic properties. China University of Mining and Technology, Xuzhou

Hai L, Zhou J, Jin H et al (2023) Cooperative prediction method of coal and gas outburst risk grade based on feature selection and machine learning algorithm. J Min Saf Eng 40(02):361–370

Han Y, Lyu S, Zhang F et al (2022) Research progress and prospect of coal and gas outburst simulation experiments. J Henan Polytech Univ (nat Sci) 4(1):1–8

Hu Q, Wen G (2013) Mechanism of mechanical action of coal and gas outburst. Science Press, Beijing, pp 67–84

Hu Q, Zhou S, Zhou X (2008a) Mechanical mechanism of coal and gas outburst process. J China Coal Soc 33(12):1368–1372

Hu Q, Zhou S, Zhou X (2008) Mechanical mechanism of coal and gas outburst process. J China Coal Soc 33

Ji P, Shi S, Shi X (2023) Research on early warning of coal and gas outburst based on HPO-BiLSTM. J Appl Math 1(1):46

Li C, Xie B, Cao J et al (2012) The energy evaluation model of coal and gas outburst intensity. J China Coal Soc 37(09):1547–1552

Li S, Fan C, Han J et al (2016) A fully coupled thermal-hydraulic-mechanical model with two-phase flow for coalbed methane extraction. J Nat Gas Sci Eng 33:324–336

Luo M, Fan C, Li S et al (2018) Failure criteria of the geo-dynamic system of coal and gas outburst. J China Univ Min Technol 47(01):137–144

Ma Y, Nie B, He X et al (2020) Mechanism investigation on coal and gas outburst: an overview. Int J Miner Metall Mater 27:872–887

Niu Y, Wang E, Li Z et al (2022) Identification of coal and gas outburst-hazardous zones by electric potential inversion during mining process in deep coal seam. Rock Mech Rock Eng 55(6):3439–3450

Pan Z, Connell L (2012) Modelling permeability for coal reservoirs: a review of analytical models and testing data. Int J Coal Geol 92:1–44

Pan X, Cheng H, Chen J et al (2020) An experimental study of the mechanism of coal and gas outbursts in the tectonic regions. Eng Geol 279:105883

Peng S, Xu J, Yang H, Liu D (2012) Experimental study on the influence mechanism of gas seepage on coal and gas outburst disaster. Saf Sci 50(4):816–821

Shu L, Wang K, Liu Z et al (2022) A novel physical model of coal and gas outbursts mechanism: insights into the process and initiation criterion of outbursts. Fuel 323:124305

Tang J, Zhang X, Pan Y et al (2022) Experimental study on outburst and impact evolution characteristics of coal and gas in deep roadways. Chin J Rock Mech Eng 41(06):1081–1092

Tong R, Yang Y, Ma X et al (2019) Risk assessment of Miners’ unsafe behaviors: a case study of gas explosion accidents in coal mine, china. Int J Environ Res Public Health 16(10):1765

Tu Q, Cheng Y, Ren T et al (2019) Role of tectonic coal in coal and gas outburst behavior during coal mining. Rock Mech Rock Eng 52:4619–4635

Tu Q, Cheng Y, Xue S et al (2021) Analysis of the coal and gas outburst mechanism from the perspective of tectonic movement. Geofluids 2021:1–18

Tu Q, Xue S, Cheng Y et al (2022) Experimental study on the guiding effect of tectonic coal for coal and gas outburst. Fuel 309:122087

Wang C, Cheng Y (2023) Role of coal deformation energy in coal and gas outburst: a review. Fuel 332:126019

Wang G, Wu M, Cheng W et al (2015) Analysis of energy conditions for coal and gas outburst and factors influencing outburst intensity. Rock Soil Mech 36(10):2974–2982

Wang L, Lu Z, Chen D et al (2020) Safe strategy for coal and gas outburst prevention in deep-and-thick coal seams using a soft rock protective layer mining. Saf Sci 129:104800

Wang W, Wang H, Zhang B et al (2021) Coal and gas outburst prediction model based on extension theory and its application. Process Saf Environ Prot 154:329–337

Wang E, Zhang G, Zhang C et al (2022) Research progress and prospect on theory and technology for coal and gas outburst control and protection in China. J China Coal Soc 47(01):297–322

Wu Y, Liu J, Elsworth D et al (2010) Development of anisotropic permeability during coalbed methane production. J Nat Gas Sci Eng 2(4):197–210

Xian X, Gu M, Li X et al (2009) Excitation and occurrence conditions for coal and gas outburst. Rock Soil Mech 30(03):577–581

Xu T, Tang C, Yang T et al (2006) Numerical investigation of coal and gas outbursts in underground collieries. Int J Rock Mech Min Sci 43(06):905–919

Xu J, Cheng L, Peng S et al (2022) Formation and propagation law of coal and gas outburst impact airflow. J China Coal Soc 47(01):333–347

Xue Y, Gao F, Liu X (2015) Effect of damage evolution of coal on permeability variation and analysis of gas outburst hazard with coal mining. Nat Hazards 79(2):999–1013

Xue X, Shi S, Gui F et al (2022) Accident case data-accident cause model hybrid-driven coal and gas outburst accident analysis: evidence from 84 accidents in China during 2008–2018. Process Saf Environ Prot 164:67–90

Yang L, Fan C, Wen H et al (2023) An improved gas–liquid–solid coupling model with plastic failure for hydraulic flushing in gassy coal seam and application in borehole arrangement. Phys Fluids 35:036603

Zhang S, He S (2022) Analysis of the influence of gas pressure on coal stress and instability failure characteristics. J Min Saf Eng 39(04):847–856

Zhang J, Xu K, Reniers G et al (2020) Statistical analysis the characteristics of extraordinarily severe coal mine accidents (ESCMAs) in China from 1950 to 2018. Process Saf Environ Prot 133:332–340

Zhang C, Wang P, Wang E et al (2023) Coal and gas outburst mechanism: research progress and prospect in China over the past 70 years. Coal Geol Explor 51(02):59–94

Zhao Y, Lin B, Liu T et al (2020) Mechanism of multifield coupling-induced outburst in mining-disturbed coal seam. Fuel 272:117716

Zhao B, Wen G, Nian J, Ma Q, Fan C, Lv X, Deng C (2022) Numerical simulation study on the multi-physical field response to underground coal and gas outburst under high geo-stress conditions. Minerals 12(2):151

Zheng C, Kizil M, Chen Z et al (2017) Effects of coal damage on permeability and gas drainage performance. Int J Min Sci Technol 27(5):783–786

Zheng Y, Zhai C, Xin H et al (2021) Theories and methods of coal and gas outburst prevention by strong-weak coupling energy control in coal roadway driving face. J Min Saf Eng 38(06):1269–1280

Zhou B, Xu J, Peng S et al (2022) Evolution of mechanical state and failure tendency of loaded outburst coal. J China Coal Soc 47(03):1260–1274

Zhu L, Yang T, Xu T et al (2018) Explore the mechanism of ground stress and gas pressure in coal-gas outburst. J Min Saf Eng 35(05):1038–1044

Acknowledgements

This research was financially supported by the National Natural Science Foundation of China (52004117, 52174117 and 51674132), the Postdoctoral Science Foundation of China (2021T140290 and 2020M680975), the Discipline Innovation Team of Liaoning Technical University (LNTU20TD-03 and LNTU20TD-30).

Author information

Authors and Affiliations

Contributions

LX: Conceptualization, Methodology, Writing—original draft; CF: Methodology, Supervision; ML: Formal analysis; SL: Writing—review & editing; JH: Visualization; XF: Writing— review & editing; BX: Revision.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Xu, L., Fan, C., Luo, M. et al. Elimination mechanism of coal and gas outburst based on geo-dynamic system with stress–damage–seepage interactions. Int J Coal Sci Technol 10, 74 (2023). https://doi.org/10.1007/s40789-023-00651-z

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40789-023-00651-z