Abstract

Single-fluid nozzles and dual-fluid nozzles are the two typical jet crushing methods used in spray dust reduction. To distinguish the atomization mechanism of single-fluid and dual-fluid nozzles and improve dust control efficiency at the coal mining faces, the atomization characteristics and dust reduction performance of the two nozzles were quantitatively compared. Results of experiments show that, as water supply pressure increased, the atomization angle of the swirl pressure nozzle reaches a maximum of 62° at 6 MPa and then decreases, but its droplet size shows an opposite trend with a minimum of 41.7 μm. The water supply pressure helps to improve the droplet size and the atomization angle of the internal mixing air–liquid nozzle, while the air supply pressure has a suppressive effect for them. When the water supply pressure is 0.2 MPa and the air supply pressure reaches 0.4 MPa, the nozzle obtains the smallest droplet size which is 10% smaller than the swirl pressure nozzle. Combined with the dust reduction experimental results, when the water consumption at the working surface is not limited, using the swirl pressure nozzle will achieve a better dust reduction effect. However, the internal mixing air–liquid nozzle can achieve better and more economical dust reduction performance in working environments where water consumption is limited.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The large amount of dust generated by the deepening of mechanized coal mining has become one of the main reasons for polluting the underground environment, endangering workers’ occupational health and safety production. At present, the dust concentration of China's coal workers has far exceeded the concentration limit set by the National Occupational Exposure Limits for Hazardous Agents in the Workplace, which is regulated by national security supervision. On the one hand, a high concentration of dust may cause serious dust explosion. On the other hand, workers’ health and safety will be seriously threatened when they work under high dust concentrations for a long time (Yuan 2020; Wang et al. 2017; Zhou et al. 2020). Exposure to dust over time can lead to pneumoconiosis, an incurable lung disease. According to the data released by the National Health Commission of China, 15407 new cases of various occupational diseases were reported in China in 2021. Among them, 11809 cases of occupational pneumoconiosis were reported, accounting for 76.66% (Xie et al. 2022; Cheng et al. 2020). Therefore, dust caused by mechanized digging and mining, especially respiratory dust, is a significant concern (Wang, 2022). At present, many effective technical means of dust prevention and control technology have been applied to production workplaces, including ventilation, dust collector purification, spray dust reduction, and airtight isolation (Wang et al. 2019a, b, c; Liu et al. 2019a). Spray dust reduction is part of coal mine working faces’ most widely used dust control technology measures because of its simple and adaptable devices (Wang et al. 2019b, d, e, f, g).

The spray dust reduction mainly sprays the liquid particles into the roadway through the nozzles, so the atomization nozzle is the fundamental component of spray dust reduction. According to the atomization form, the atomization nozzle can be mainly divided into single-fluid nozzles and dual-fluid nozzles (Engelbert et al. 1995; Jiang et al. 2017). Single-fluid nozzles are widely used in mine, among which swirl pressure nozzles are the most important type of single-fluid nozzles. Wang and Lefebvre (2010) experimentally obtained an equation for the thickness of the liquid film at the outlet of the cyclonic nozzle and this equation can be used to predict the Sauter Mean Diameter (SMD). Based on the assumption of definite liquid film rupture thickness, Couto et al. (2011) established a theoretical equation for the SMD of the swirl pressure nozzle. The calculation results of the established theoretical equation are in general agreement with the existing empirical equations, semi-empirical equations, and experimental data. Based on the VOF method, Zhao et al. (2017) applied Fluent software to simulate the internal flow of the swirl pressure nozzle. Through numerical simulation, they obtained the variation law of flow field characteristics parameters such as pressure field, density field, and velocity field in each section inside the swirl pressure nozzle. The study realized the successful prediction of liquid film thickness and atomization angle at the nozzle exit.

Based on studies of the swirl pressure nozzle, scholars have put forward the idea of using compressed air to enhance the atomization effect of the nozzle (Jones et al. 2010). The air–liquid dual-fluid nozzle has gradually been one of the main ways to treat industrial particles and waste pollution. Lorenzetto (1977) found that the increase in liquid surface tension and viscosity will reduce the quality of atomization. So he proposed that when the liquid’s viscosity is low, the higher the air–liquid relative velocity at the nozzle outlet, the smaller the droplets produced. In addition, the air velocity is also an important parameter that determines the effect of atomization. In Liu's experimental research, air pressure has the greatest influence on atomization performance, followed by the air–liquid ratio. While the water pressure has the least influence from the point of view of the droplet size distribution of the spray axis (Liu et al. 2013). Bai's point of view is the same as Liu's, he thinks the air–liquid ratio can effectively reduce the droplet size of the spray, and the air pressure is the main factor that causes the particle size reduction (Bai et al. 2015). Wang et al. (2018) tested internal mixing air–liquid nozzles with different outlet diameters through a self-designed spray dust reduction experimental platform. The experimental data indicated that nozzles with outlet diameters of 2–3 mm are suitable for extraction sites. Li et al. (2012) and others pointed out that the flow pattern of the internal mixing nozzle is mainly determined by the air–liquid mass ratio. At the same time, their experiments show that the average diameter of the droplet decreases as the air–liquid ratio increases, and the optimal atomization pressure is 0.2–0.3 MPa.

In summary, there have been many studies on swirl pressure nozzles and internal mixing air–liquid nozzles. However, most of the studies on nozzles rely on a single type and lack a transversal comparative analysis of swirl pressure nozzles and internal mixing air–liquid nozzles. In addition, most of the research on dust reduction performance of nozzles is focused on the total dust, while there is less research on the reduction efficiency of fine dust such as respiratory dust. Therefore, this study selected the swirl pressure nozzle and the internal mixing air–liquid nozzle as the object of study, and systematically compared the atomization performance and respirable dust reduction performance of the two through self-designed experimental systems. It can provide a reference basis for the design and selection of nozzles for coal mining working face.

2 Experimental systems and scheme

2.1 Nozzle selection

Based on previous site investigations, the nozzles selected for this study are swirl pressure nozzle and internal mixing air–liquid nozzle. The nozzles are made of stainless steel. The outlet diameter of the nozzles is 1.2 mm. The nozzles selected in the experiment are shown in Fig. 1. Specifically, the swirl pressure nozzles, can only generate one high-speed rotating liquid flow. The rotary core is the main part to achieve the spinning, increasing speed and breaking of the jet. The energy of the liquid breakage mainly comes from the pressure energy of the liquid. The internal mixing air–liquid nozzles, can generate high-speed air flow and high-speed liquid flow respectively and mix them inside the nozzle. Compressed air and high-speed jets are mixed and broken in the mixing chamber after entering the nozzle. The energy of the liquid breakage comes from the pressure energy of the compressed air. Internal mixing air–liquid nozzles can achieve a finer atomization effect at a lower pressure. Due to the different internal structure of the two nozzles, the atomisation mechanism differs between the two. Internal mixing air–liquid nozzle crushes the internal water flow with high-pressure air, which is significantly different from the atomisation mechanism of swirl pressure nozzle that uses cyclonic flow to enhance droplet crushing.

2.2 Experimental systems

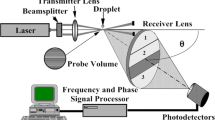

In the experiment, the Phase Doppler Particle Analysis System (PDPA) and spray atomization device were used to measure atomization characteristic parameters of nozzles, the system is shown in Fig. 2. The spray atomization device consists of a pressure pump, air compressor, water pipe, air pipe, pressure gauge, pressure limiting valve, water flow meter, rotameter, and the nozzle.

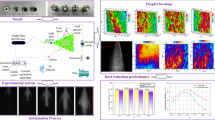

The dust reduction experiment system via spraying was designed to simulate the dust production, spraying, and ventilation conditions of industrial workplaces, as shown in Fig. 3. The system consists of 2 sections of 3.0 m × 1.2 m × 1.2 m rectangular tunnels which made of tempered glass and rigid skeleton spliced together. The dust reduction experimental system, consisting of a dust dispersion system, diffusion fan, blower, simulated tunnel, spray device, dust concentration test device and wind speed test device, etc., can simulate the spray dust reduction environment at the underground working face. A single nozzle was used in the experiment. It is located at the middle position of the section and is sprayed in the middle part of the spray section through the water pipe which is perpendicular to the roadway. The axial distance from the dust collector is 15 m.

2.3 Atomization properties measurement

The nozzle atomization characteristics parameters mainly include flow rate, atomization angle, droplet velocity, and droplet particle size. In the experiment, an electronic water flow meter and digital pressure gauge were used to assess the water flow rate and water supply pressure, respectively. To measure the atomization angle, a high-performance digital camera was used to photograph the spray field of the nozzle, and then the calculation of the atomization angle was performed using Image-Pro Plus 6.0 software. PDPA was used to measure the droplet velocity and particle size. It is capable of measuring the particle size and velocity of the flow field measurement points in real-time. The system composition and measurement principle of PDPA are shown in Fig. 4.

To fully investigate the atomization characteristics of the swirl pressure nozzle at different pressure, the experimental water pressure (pwater) was set to 1–7 MPa with a gradient of 1 MPa. While the air–liquid two-phase spraying requires less pwater than single-phase flow spraying, the air supply pressure also directly affects the atomization characteristics of the two-fluid nozzle. Therefore, the range of air supply pressure (pair) variation was set to 0.2–0.4 MPa, and a total of three water supply pressures (0.10, 0.15, 0.20 MPa) were studied. At the same time, the nozzle axial distance of 25, 30, 35, 40, 45, 50, 55, and 60 cm was selected as the measurement points.

2.4 Dust reduction performance measurement

During the measurement of dust reduction performance of the nozzles, the aerosol generator was used to generate dust. Compressed air provided by an air compressor was used as the conveying power to feed the dust from the entrance to the roadway. Two dust testers were placed in the pre-spray measurement section and post-spray measurement section of the model roadway to sample the dust in the two areas under different operating conditions. Two dust measurement points were sampled at the same time with a sampling flow rate of 20 L/min for 30 s. The dust concentration was averaged after four consecutive sampling sessions under each working condition to calculate the respirable dust reduction efficiency.

3 Results and discussion on atomization characteristics

3.1 Atomization angle

Atomization angle refers to the liquid being ejected from the nozzle to form an opening angle, which is called atomization angle for short (Wang et al. 2019d, g; Liu et al. 2019a, b). It is an important atomization characteristic of nozzles. Increasing the atomization angle of the nozzle increases the cross section area covered by the spray field, which can reduce the number of nozzles required for the on-site application (Yang et al. 2019). The atomization angle of the selected nozzles was measured under various operating conditions. The experimental results are shown in Figs. 5 and 6.

As can be seen in Fig. 5, the atomization angle of the swirl pressure nozzle tends to increase first and then decrease with increasing pwater. The atomization angle at 1.89 L/min is the smallest, and reaches a maximum of 62° at 6 MPa then drops to 60° at 7 MPa with the increase of water supply pressure. This is due to the increase of the nozzle flow rate which increases with increasing pwater. Increasing the cyclonic strength in the nozzle is conducive to increasing the radial velocity of the nozzle exit jet. So the atomization angle increases with the increase in pwater. However, when pwater exceeds 6.0 MPa, the negative pressure in the center of the swirling flow becomes so strong that the flog flow shrinks towards the center, causing the atomization angle to become smaller.

Figure 6 shows the atomization angle of the internal mixing air–liquid nozzle under different operating conditions. It is found that when pwater is determined, the atomization angle of the nozzle decreases with the increase of pair. In contrast, when pair is determined, the atomization angle is positively related to pwater. This is because the spray field pattern of the nozzle mainly depends on the air phase. The increase in pwater strengthens the mixing chamber water pressure, and will affect the air flow in the mixing chamber, resulting in reduced airflow. Since the air–liquid mixing chamber is a shrinking structure, the water pressure enhances the movement of the mixed airflow along the edge of the flare, which eventually leads to an increase in the turbulence intensity at the nozzle outlet and adds atomization angle. While pair increases, the velocity of the air flow increases significantly, causing the air flow to be ejected before the expansion, finally resulting in a decreased atomization angle. In addition, by comparing the atomization angle data in Figs. 5 and 6, the atomization angle of the internal mixing air–liquid nozzle is much smaller than that of the swirl pressure nozzle.

From the above analysis, it is found that the swirl pressure nozzle has a larger atomization angle. Therefore, corresponding to the project site to develop a spray dust reduction program, according to the nozzle performance should be a reasonable selection of nozzles. For industrial sites where dust is widely distributed and requires extensive dust suppression, we can choose a swirl pressure nozzle with a larger atomization angle, and increase the water supply pressure appropriately to save the number of nozzles installed.

3.2 Flow rate

Table 1 shows the measured water flow rates Qwater of the swirl pressure nozzle (Test No. 1) as a function of pwater and of the internal air–liquid mixing nozzle (Tests No. 2–4) as a function of pwater and pair.

For the swirl pressure nozzle, the trend of Qwater with the change of pwater is shown in Fig. 7. From the figure, its growth trend gradually slowed down, such as in 1 MPa, 4 MPa, 7 MPa conditions, the flow rate of 1.92, 4.1, 5.4 L/min respectively. By fitting the experimental data, it was found that there is a power function relationship between water flow rate and water supply pressure, The experimental data can be fitted with a power function with a coefficient of determination of 0.9965. For the internal mixing air–liquid atomization nozzle, it is unlike the swirl pressure nozzle. The air–liquid mixing pressure in the air–liquid mixing chamber is a major factor affecting the air and water flow. Figure 8 shows the trend of Qwater under different pwater and pair. As can be seen from Fig. 8, with the increase in pair, the water flow is decreasing. For example, at 0.2 MPa pwater, when pair is raised from 0.2 to 0.4 MPa, the water flow decreases from 0.781 to 0.387 L/min, which is reduced by about one-half. Due to structural constraints, the flow rate through the mixing chamber is fixed per unit time. An increase in air pressure therefore leads to an increase in the air flow in the mixing chamber, at this time the water flow in the mixing chamber being suppressed by the higher velocity air flow, although the water pressure is then given. Fits through the experimental data at various pair show highly linear relationships between pwater and Qwater with coefficients of determination greater than 0.986.

By comparing the experimental data of Qwater between the two nozzles, it can be found that the water required by the swirl pressure nozzle is much higher than that of the internal mixing air–liquid nozzle. So in practical application, internal mixing air–liquid nozzle can reduce water consumption.

3.3 Droplet size

Droplet size is an important parameter to evaluate the atomization performance of nozzles. We chose D32 (Sauter Mean Diameter) to represent droplet size in this paper because it is one of the most commonly used and informative parameters for characterizing droplet sizes. This is beacuse D32 takes into account both the volume and number of droplets, thus incorporating size and quantity information comprehensively and accurately. It avoids the drawbacks of other single parameters like D10 (tend to be too small) or D30 (can be overly influenced by large droplets). So it can reduce the errors of using one single parameter. In addition, D32 is simpler and more practical to calculate and measure compared to obtaining full droplet size distributions and then calculating other diameters. As a single parameter that provides relatively comprehensive and accurate information, D32 has advantages in application and calculation convenience. These properties motivate our choice to use it for characterizing droplet sizes in this work.

Figures 9 and 10 show the variation curve of droplet size under different conditions of the two nozzles. From the figures can be seen that when pwater and pair is fixed, droplet size increases with the increase of axial distance (S). Spraying is a process of converting pressure potential energy into kinetic energy of liquid droplets. Collision or condensation of droplets depends mainly on their impact angle and impact velocity. When operating conditions is certain, as the axial distance (S) increases, the kinetic energy of the droplets gradually decreases, resulting in an increased probability of condensation between the droplets. So the droplet size at the far end of the spray field is larger. Meanwhile, the droplet size of the swirl pressure nozzle is decreasing first and then increases with the increase of water pressure. This is because that when the droplets are in the spray near-field, droplets have greater kinetic energy and concentration, so the probability of collision breakage is greater, which will result in a decrease in droplet size with the increase in water supply pressure. However, when the water pressure exceeds 3 MPa, the high initial kinetic energy of the droplets makes the water flow inside the nozzle not completely broken before being sprayed. It is a reason for resulting in a gradual increase in droplet size.

From the droplet particle size data in Fig. 10, the slope of the curve decreases with increasing pair at pwater of 0.2 MPa, indicating that the droplet size growth rate slows down. When pair is given, with the increase in pwater the slope of the curve gradually increases, indicating that increasing pwater will promote the condensation between the droplets. This is due to the internal mixing air–liquid nozzle which has the ability to use the strong shear properties of the high-speed air flow to enhance the droplet surface fluctuations in a limited space and promote the breaking of the liquid. After the liquid leaves the nozzle, it is wrapped by high-speed air, which drives the droplets to break up further and produce tiny droplets. Unlike the swirl pressure nozzle using pwater on the jet to break, high-velocity air is the main factor affecting the droplet breakup of the internal mixing air–liquid nozzle (Han et al. 2020a, b).

Comparing with Figs. 9 and 10, we can find that the droplet size of the internal mixing air–liquid nozzle is always smaller than the droplet size of the swirl pressure nozzle when pair is maintained at 0.4 MPa. This also shows that internal mixing air–liquid nozzle can get smaller droplet size at lower water pressure. Therefore, using the dual-fluid approach to break jet can achieve smaller droplet size while reducing water consumption.

Figure 11 shows the volume distribution of droplets at each measurement point of the swirl pressure nozzle under 5 MPa water pressure. The orange line in the figure represents the cumulative percentage of droplet size, and the blue bar represents the droplet volume frequency. From the histogram in Fig. 11, it can be observed that as S increases, the peak droplet volume frequency keeps shifting to the right, i.e., toward the direction of increasing droplet particle size. This means that the maximum droplet size of the swirl pressure nozzle increases with the increase in S. This is due to the fact that the kinetic energy of the droplets is gradually reduced by gravity, which increases the probability of condensation between droplets. This leads to an increase in the maximum droplet size of the nozzle. From the cumulative curves, it can also be found that the characteristic particle sizes of droplets (D90, D50, and D10) all show the same variation pattern as Fig. 9, i.e., they increase with the increase of axial distance.

The droplet size distribution of the internal mixing air–liquid nozzle at pwater = 0.2 MPa and pair = 0.4 MPa at each measurement point is shown in the Fig. 12. It can be seen from the figure that in the near-field spray (< 40 cm), the droplet size volume distribution is “spike-like”, and the highest peak value accounted for less than 50 μm particle size interval. While in the far-field spray (> 40 cm), the particle size distribution tends to be dispersed. The peak droplet volume distribution gradually shifted to the right with the increase in the axial distance, and the droplet size in Fig. 10 shows the same pattern of change. This is due to the internal mixing air–liquid nozzle has a smaller initial droplet size, so even though the droplet velocity in the spray near-field is larger at this point, more non-centric collisions occur, resulting in a larger droplet size. This causes droplets of small size to become progressively larger as S increases and the droplet velocity decreases. The droplet peak gradually shifts to the right and causes the volume distribution to become progressively more dispersed.

3.4 Droplet velocity

Figures 13 and 14 are the variation curve of axial droplet velocity with different operating conditions for the two nozzles. It can be seen from the figures that when the water pressure is fixed, the droplet speed decreases as S increases. Moreover, the higher the water pressure, the greater effect on the velocity of the near-field spray. The liquid completed atomization near the outlet to form droplets, then the droplets moved along the nozzle axis at a high initial velocity. Due to the effect of air resistance, the droplet velocity continuously decayed along the nozzle axis. Combined with the atomization angle experimental results, we can find that when the water supply pressure increases, the swirl pressure nozzle has a more dispersed fog flow. Therefore, the spray field downstream droplet velocity decay is more dramatic, resulting in further reduction in droplet velocity. From Fig. 13 we can see that, when pwater exceeds 4 MPa, the effect of water supply pressure on droplet velocity enhancement has been very weak in the spray near field (S ≤ 40 cm). This may be because the nozzle structure limits the flow coefficient, resulting in little increase in liquid per unit time through the nozzle outlet despite the high water supply pressure. Another reason may be the near-field droplet concentration of the high-pressure nozzle, which increases the likelihood of droplet collisions.

From Fig. 14 we can find that when pair is low (< 0.4 MPa), the droplet velocity is logarithmically related to the spray distance and the droplet velocity change rate decreases gradually. But when pair reaches 0.4 MPa, the two are linearly related. Combined with the droplet particle size of the internal mixing air–liquid nozzle, the droplet velocity under 0.4 MPa pair is low, but the number of droplets is high. This results in a large number of collisions between droplets consuming energy, thus the droplet velocity decreases exponentially. While in 0.4 MPa pair conditions, Qwater of this nozzle becomes smaller, resulting in smaller droplet particle size, higher velocity, and inter-droplet collision is greatly reduced. Therefore, the velocity is linearly decreased.

By comparing Figs. 13 and 14, the droplet velocity of the internal mixing air–liquid nozzle at each measurement point is always less than the droplet velocity of the swirl pressure nozzle at high pwater (> 3 MPa). However, the difference in maximum droplet velocity between the two nozzles is not much within 10%. The droplet velocity of the internal mixing air–liquid nozzle is influenced by both pair and pwater. On the one hand, the water supply and air supply pressure of this nozzle is much smaller than that of the swirl pressure nozzle. On the other hand, the high-speed airflow and water flow which mix in the nozzle cavity break the jet while while weakening the kinetic energy of both. Therefore, at the outlet of the internal mixing air nozzle the droplet velocity is small. Droplet size and droplet velocity are important indicators of nozzle atomization performance. Smaller droplet size and higher droplet velocity facilitate respirable dust deposition (Wang et al. 2020; Charinpanitkul and Tanthapanichakoon 2011). After comparing the droplet size and droplet velocity between the swirl pressure nozzle and internal mixing air–liquid nozzle under different operating conditions, we found that the internal mixing air–liquid nozzle can obtain the same droplet velocity as the swirl pressure nozzle by using less water, and its droplet size is smaller. Therefore, it has better atomization performance, especially when the water supply pressure is low.

4 Results and discussion of dust reduction performance

4.1 Dust mass concentration and respirable dust reduction efficiency

Respirable dust is one of the most important substances endangering human health and is also the focus and difficulty in dust hazard prevention and control. For this reason, dust reduction experiments were conducted using dust below 10 μm to study the dust removal efficiency of two nozzles on respirable dust.

Tables 2 and 3 show the dust concentration (cmt) of the measured section before and after spraying of the two nozzles under different conditions. From the table, it can be seen that the dust mass concentration in the measurement section before spraying is close.

Figure 15 shows the change in dust reduction efficiency (μr) of the two nozzles under different operating conditions. As we can see from Fig. 15a, for the swirl pressure nozzle, the respirable dust reduction efficiency gradually increases as pwater increases. According to the experimental results on the atomization characteristics of the nozzles, the swirl pressure nozzle with high water pressure has a large flow rate, atomization angle, and a low droplet particle size. Therefore, it can effectively increase the density of the droplets after the jet was broken and the collision probability between the droplets and the dust. Finally, it can help improve dust reduction efficiency. Although the droplet size is larger when the water supply pressure reaches 6 MPa, the nozzle has a higher water flow and droplet speed. The dust is washed by high-speed water, resulting in a slight increase in dust reduction efficiency.

From Table 3 and Fig. 15b, we can see that when the pwater is 0.1 MPa, the respirable dust reduction efficiency of the internal mixing air–liquid nozzle decreases gradually with the increase of pair, from 40.31% at 0.2 to 31.95% at 0.4 MPa. The spray droplet particle size at this time is very small, and the droplet speed is very high, but the water flow rate under 0.2 MPa pair is only 0.284 L/min, resulting in the number of droplets being very small. When pwater exceeds 0.15 MPa, the dust reduction efficiency increases first and then decreases with the increase of pair. This is due to the increase in pair significantly reducing Qwater and atomization angle at low pwater. Although the spray droplet particle size is very small at this time, the number of droplets and spray field coverage is small, resulting in droplets being difficult to trap dust, thus reducing the efficiency of dust reduction (Yu et al. 2018). Therefore, a certain spray flow rate is a prerequisite to guarantee the efficiency of dust reduction.

4.2 Comparative analysis of application conditions of nozzles

According to the results of dust reduction experiments, when pwater reaches 4 MPa, the growth of respirable dust reduction efficiency of the swirl pressure nozzle is small. At this time, the atomization angle growth of the swirl pressure nozzle is not large, but the droplet particle size is smaller, and the droplet velocity is greater. Therefore, after considering the economy, energy saving, atomization performance, and dust reduction efficiency, for dust production sites that can realize high-pressure water supply and need a large range of close spraying, we can choose 4 MPa water supply pressure to obtain better dust reduction efficiency. Although there are still defects of large water consumption and serious water pollution.

According to the results of the internal mixing air atomization nozzle dust reduction experiments, it can be found the nozzle dust reduction efficiency difference is not significant in the water pressure 0.15 MPa, air pressure 0.30 MPa, and water pressure 0.20 MPa, air pressure 0.30 MPa. However, when water pressure is 0.150 MPa, the nozzle has a smaller water flow rate and droplet particle size. Although the atomization angle of the internal mixing air–liquid nozzle is always below 20°, it has a further spray distance and requires less water. Therefore, in the dust production sites which inability to install other equipment and needs long-distance dust reduction, we can choose the internal mixing air atomization nozzle to obtain a better dust reduction effect. It can also help to avoid excessive water caused by water pollution, water waste, and other problems.

5 Conclusions

In this study, the swirl pressure nozzle and the internal mixing air–liquid nozzle were selected as representatives of single-fluid nozzles and dual-fluid nozzles. The atomization characteristics of the selected nozzles were compared through experiments using PDPA System, and flow measurement instruments. On this basis, experiments on the respirable dust reduction performance of nozzles were carried out using a self-designed spray dust reduction experimental platform. The following conclusions were drawn:

-

(1)

The water flow rate of the two nozzles increases with water supply pressure increasing. Meanwhile, the atomization angle of the swirl pressure nozzle reaches a maximum of 62° at 6 MPa and then decreases. For the internal mixing air–liquid nozzle, the atomization angle and the water supply pressure are positively correlated, while the air pressure will inhibit the atomization angle. The maximum atomization angle of this nozzle is only one-third of that of the swirl pressure nozzle.

-

(2)

The droplet size of the swirl pressure nozzle tends to decrease with a minimum of 41.7 μm and then increase as the water pressure increases, but the droplet velocity is proportional to the water supply pressure. The droplet speed of the internal mixing air–liquid nozzle is affected by both water supply pressure and air supply pressure. When both of the nozzles under a smaller water pressure, the droplet size of the internal mixing air–liquid nozzle is 10% smaller than the droplet size of the swirl pressure nozzle and the speed of the two is similar.

-

(3)

The dust reduction experimental results show that the dust reduction efficiency of the swirl pressure nozzle increases with an increase in water supply pressure. The dust reduction efficiency of the internal mixing air–liquid nozzle decreases with the increase of air supply pressure when water supply pressure is low. However, when water supply pressure reaches 0.15 MPa, the dust reduction efficiency shows a trend of increasing first and decreasing then with the increase of air supply pressure.

-

(4)

The swirl pressure nozzle at a water supply pressure of over 4 MPa achieves a better dust reduction effect. It is appropriate for industrial dust-producing environments that can realize high-pressure water supply. For industrial dust production sites which inability to install other equipment and also need long-distance dust reduction, it is better to use the internal mixing air atomization nozzle to obtain a better dust reduction effect.

References

Bai PB, Xing YM, Wang Z (2015) Experimental and simulation study of atomization characteristics of internal mixing nozzle. Fluid Mech 43(02):1–6

Charinpanitkul T, Tanthapanichakoon W (2011) Deterministic model of open-space dust removal system using water spray nozzle: effects of polydispersity of water droplet and dust particle. Sep Purif Technol 77:382–388

Cheng WM, Zhou G, Chen LJ et al (2020) Research progress and prospect of dust control theory and technology in China’s coal mines in the past 20 years. Coal Sci Technol 48(2):1–20

Couto HS, Carvalho JA, Bastos-Netto D (2011) Theoretical formulation for Sauter mean diameter of pressure-swirl atomizers. J Propul Power 13(5):691–696

Engelbert C, Hardalupas Y, Whitelaw JH (1995) Breakup phenomena in coaxial air-blast atomizers. Proc R Soc a: Math Phys Eng Sci 451(1941):189–229

Han H, Wang PF, Li YJ et al (2020a) Effect of water supply pressure on atomization characteristics and dust-reduction efficiency of internal mixing air atomizing nozzle. Adv Powder Technol 31(1):252–268

Han H, Wang PF, Li YJ et al (2020b) Experimental study on atomization characteristics and dust-reduction performance of four common types of pressure nozzles in underground coal mines. Int J Coal Sci Technol 7:581–596

Jiang H, Du C, Dong J (2017) Investigation of rock cutting dust formation and suppression using water jets during mining. Powder Technol 307:99–108

Jones WP, Lettieri C (2010) Large eddy simulation of spray atomization with stochastic modeling of breakup. Phys Fluids 22(11):15106

Lefebvre AH, Wang XF (2010) Mean drop sizes from pressure-swirl nozzles. J Propul Power 3(1):11–18

Li Z, Wu Y, Cai C et al (2012) Mixing and atomization characteristics in an internal-mixing twin-fluid atomizer. Fuel 97:306–314

Liu LY, Yang J, Kong QS et al (2013) Experimental study of droplet atomization performance of air atomization nozzle. Chem Ind Eng 30(03):60–65

Liu Q, Nie W, Hua Y et al (2019a) A study on the dust control effect of the dust extraction system in TBM construction tunnels based on CFD computer simulation technology. Adv Powder Technol 30:2059–2075

Liu ZQ, Nie W, Peng HT et al (2019b) The effects of the spraying pressure and nozzle orifice diameter on the atomizing rules and dust suppression performances of an external spraying system in a fully-mechanized excavation face. Powder Technol 350:62–80

Lorenzetto GE, Lefebvre AH (1977) Measurements of drop size on a plain-jet airblast atomizer. AIAA J 15(7):1006–1010

Wang HT, Wang C, Wang DM (2017) The influence of forced ventilation airflow on water spray for dust suppression on heading face in underground coal mine. Powder Technol 320:498–510

Wang PF, Tan XH, Liu RH et al (2018) Effect of outlet diameter on atomization characteristics and dust reduction performance of internal mixing air atomization nozzle. J Coal 43(10):2823–2831

Wang HT, Wu JL, Du YH et al (2019a) Investigation on the atomization characteristics of a solid-cone spray for dust reduction at low and medium pressures. Adv Powder Technol 30(5):903–910

Wang HT, Wei XB, Du YH et al (2019b) Effect of water-soluble polymers on the performance of dust-suppression foams: wettability, surface viscosity and stability. Colloids Surfaces A-Physicochem Eng Asp 568:92–98

Wang PF, Li YJ, Liu RH et al (2019c) Effect of forced-to-exhaust ratio of air volume on dust control of wall-attached swirling ventilation for mechanized excavation face. Tunnell Undergr Space Technol 90:194–207

Wang HT, Du YH, Wei XB et al (2019d) An experimental comparison of the spray performance of typical water-based dust reduction media. Powder Technol 345:580–588

Wang HT, Wei XB, Du YH et al (2019e) Experimental investigation on the dilatational interfacial rheology of dust-suppressing foam and its effect on foam performance. Process Saf Environ Prot 123:351–357

Wang PF, Tan XH, Zhang LY et al (2019f) Influence of particle diameter on the wettability of coal dust and the dust suppression efficiency via spraying. Process Saf Environ Prot 132:189–199

Wang PF, Tian C, Liu RH et al (2019g) Mathematical model for multivariate nonlinear prediction of SMD of X-type swirl pressure nozzles. Process Saf Environ Prot 125:228–237

Wang PF, Han H, Liu RH et al (2020) Effect of outlet diameter on atomization characteristics and dust reduction performance of X-swirl pressure nozzle. Process Saf Environ Prot 137:340–351

Wang ZM, Zhou W, MithalJiskani I et al (2022) Dust pollution in cold region surface mines and its prevention and control. Environ Pollut 292:118293

Xie XX, Liu YY, Chen WT (2022) Research status of occupational pneumoconiosis and dust prevention and control technology. J Wuhan Univ Technol (inf Manag Eng) 44(01):39–44

Yang SB, Nie W, Lv SS et al (2019) Effects of spraying pressure and installation angle of nozzles on atomization characteristics of external spraying system at a fully-mechanized mining face. Powder Technol 343:754–764

Yu HM, Cheng WM, Peng HT et al (2018) An investigation of the nozzle’s atomization dust suppression rules in a fully-mechanized excavation face based on the airflow-droplet-dust three-phase coupling model. Adv Powder Technol 29:941–956

Yuan L (2020) Scientific conception of coal mine dust control and occupational safety. J China Coal Soc 45(1):1–7

Zhao JG, He W (2017) Simulation and experimental research on highly efficient atomization nozzle with a core. Mach Des Manuf 55:137–140

Zhou WD, Wang HT, Wang DM et al (2020) The effect of geometries and cutting parameters of conical pick on the characteristics of dust generation: experimental investigation and theoretical exploration. Fuel Process Technol 198:106243

Acknowledgements

This work was funded by the National Natural Science Foundation of China (52274237), the Fundamental Research Funds for the Central Universities (2021ZDPYYQ007), the Postgraduate Research & Practice Innovation Program of Jiangsu Province (KYCX22_2656), and the Graduate Innovation Program of China University of Mining and Technology (2022WLKXJ026). We also would like to thank Mrs. Li Bei, a teacher of academic English course in China University of Mining and Technology and Academic Language Service Center. She has provided many suggestions for the aspects of academic language norms, academic thinking norms and language logic.

Author information

Authors and Affiliations

Contributions

HH: Methodology, validation, formal analysis, writing-original draft, visualization. HW: Conceptualization, resources, writing-review and editing, supervision, project administration, funding acquisition. QZ: Methodology, resources, writing-original draft. YD: Validation, investigation, data curation. HW: Validation, data curation. HW: Validation, data curation.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Han, H., Wang, H., Zhang, Q. et al. Investigations of the effects of two typical jet crushing methods on the atomization and dust reduction performance of nozzles. Int J Coal Sci Technol 10, 50 (2023). https://doi.org/10.1007/s40789-023-00606-4

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40789-023-00606-4