Abstract

The variations of strain and permeability of coal were systematically studied through the physical simulation of N2 and water injection. The effects of fluid adsorption capacity and initial permeability on strain, permeability and the dominant effect of pore pressure were discussed. The adsorption strain and strain rate of coal during water injection are significantly higher than those during N2 injection. An edge of free adsorption exists in the early phase of N2 and water injection, which is related to fluid saturation. Within this boundary, the strain rate and pore pressure are independent. Moreover, the injection time of initial stage accounts for about 20% of the total injection time, but the strain accounts for 70% of the total strain. For water injection, this boundary is about half of water saturation of coal. Besides, the influence of pore pressure on permeability is complex, which is controlled by adsorption capacity and initial permeability of coal. When the initial permeability is large enough, the effect of adsorption strain on permeability is relatively weak, and the promoting effect of pore pressure on fluid migration is dominant. Therefore, the permeability increases with increasing pore pressure. When the initial permeability is relatively low, the pore pressure may have a dominant role in promoting fluid migration for the fluid with weak adsorption capacity. However, for the fluid with strong adsorption capacity, the adsorption strain caused by pore pressure may play a leading role, and the permeability reduces first and then ascends with increasing pore pressure.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

As a kind of unconventional natural gas with rich resources (Wu et al. 2020), the development and utilization of coalbed methane (CBM) are very important to the world energy supply (Yi et al. 2021; Zou et al. 2019). CBM and water often coexist in coal. The occurrence forms of CBM and water in coal are diverse. CBM is often adsorbed in coal, accompanied with a small amount of free gas and dissolved gas (Tao et al. 2019). Water not only adsorbs on the surface of coal, but also fills in the pores and fractures. CBM is produced by dewatering the formation (Moore 2012; Shi et al. 2018; Wu et al. 2020). Meanwhile, water has a certain blocking effect on the diffusion and migration of CBM (Si et al. 2021). The development of CBM is the process of adsorption and desorption of gas and water. The adsorption and desorption of CBM and water can affect many properties of coal, such as porosity, permeability, mechanical properties and molecular structure of coal (Chen and Cheng 2015; Miao et al. 2018; Ranathunga et al. 2016; Tan et al. 2018; Tang et al. 2018; Xu et al. 2014; Yi et al. 2021).

The variation of permeability plays a key role during CBM production. It is mainly influenced by coal deformation, effective stress and pore pressure (Tao et al. 2018; Zhang et al. 2019). Pore pressure has multiple effects on CBM production (Liu et al. 2020). The results of previous studies are also different. Some scholars believed that the effective stress reduced with increasing pore pressure, and the permeability ascended under the condition of constant confining pressure (Tan et al. 2018). Besides, some studies considered that the increase of pore pressure promoted the adsorption deformation of coal, leading to the decrease or first decrease and then increase of permeability (Li et al. 2020; Mazumder and Wolf 2008; Wang et al. 2011). Therefore, the leading role of pore pressure may be different in different stages. The effective stress also influences permeability through coal deformation. Moreover, a lot of researches have been done on the adsorption deformation caused by gas (Liu et al. 2020, 2021; Wang et al. 2021; Zhu et al. 2018). Most studies suggested that Langmuir law could be used to describe the relationship between adsorption deformation and pressure (Meng and Li 2018; Zang et al. 2015). The adsorption deformation increases linearly with increasing adsorption quantity (Liu et al. 2010). Besides, the adsorption deformation in vertical bedding direction and parallel bedding direction are consistent (Meng and Li 2018).

Furthermore, water and gas are different fluids. Water can also cause adsorption deformation of coal, which is similar to the adsorption deformation of gas (Fan et al. 2018; Liu et al. 2018; Pan et al. 2010; Thararoop et al. 2015). The adsorption deformation laws of gas are also applicable to the adsorption deformation of water. According to the study on the adsorption deformation of water vapor on coal surface under static conditions, it was considered that the adsorption expansion model of water on coal surface could be established based on the adsorption expansion model of gas (Pan 2012). Some studies showed that the deformation caused by water adsorption could be restored to its original state after drying completely (Fry et al. 2009). Meanwhile, because of the adsorption and desorption of gas and water on coal surface, the deformation of coal has a great influence on permeability (Zang et al. 2015; Zhang et al. 2018). This may be affected by adsorption stress (Zhou et al. 2021). The water in coal can significantly retard the adsorption and desorption rate of gas, and then affect the coal permeability (Li et al. 2018; Liu and Wu 2017). The research on the adsorption deformation of coal on water can provide fundamental basis for revealing the influence of water on the production of CBM. However, compared with the study on adsorption deformation of gas, the research on the adsorption deformation of water is relatively less.

To sum up, gas and water coexist in coal, and CBM production is affected by coal deformation. The influence of gas and water on coal permeability needs systematic analysis. It can provide theoretical basis for CBM simulation and optimization of drainage system. In our previous research, the changes of strain and permeability of coal during gas injection have systematically analyzed (Liu et al. 2020). However, there is also a lack of systematic comparison of gas and water adsorption strain, especially the variation of gas and water adsorption strain at the early phase. Besides, the adsorption strain of gas and water and its impact on permeability have been discussed by predecessors, but there are still different opinions on the role of pore pressure. Given this, the strain and its influence on permeability during gas and water injection were systematically studied on the basis of our previous research, especially in the early phase, and the similarities and differences of coal deformation and permeability were systematically analyzed. Besides, the effects of pore pressure during injection were discussed.

2 Samples and experimental equipment

2.1 Coal samples

The coal samples were collected from Hongfa coal mine situated in Yuwang of Eastern Yunnan, China. The coal pillars (50 mm in diameter and 100 mm in length) used in this text (HF1 and HF2) drilled from the same coal sample. They were obtained along the bedding plane. The properties of the coal were tested according to GB/T 212–2008, GB/T 8899 − 2013 and GB/T 6948 − 2008 (Table 1). Mad, Ad and Vdaf represent moisture of air-drying base, ash of dying base and volatile of dry and ash free base respectively. Ro,max represents vitrinite reflectance. Clay minerals were not detected in these coal samples.

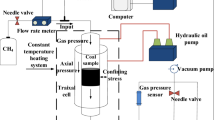

2.2 Experimental methods

The experimental apparatus was shown in Fig. 1. A water injection device was added based on Liu et al. (2020). Valve 1 and 7 were used to control the pipeline of gas and water injection. Radial extensometer was used to record radial deformation.

Pore pressure and adsorption can cause coal deformation when fluid is injected into coal. In order to remove the strain directly caused by pore pressure, the non-adsorbable He was first injected into the coal. After that, the adsorbed N2 and water were injected into the coal. The experimental processes were as follows:

-

(1)

Samples drying and loading were in accordance with our previous research (Liu et al. 2020). The axial pressure and confining pressure were 5 MPa.

-

(2)

He and N2 injection. The coal pillar of HF1 was used. The processes were consistent with our previous research (Liu et al. 2020). The injection pressure was set from 1 MPa to 4 MPa with 0.5 MPa intervals. The adsorption of each pressure was not completely saturated. Even at the end of the experiment, the adsorption of the sample did not reach saturation. For cylindrical samples, if it is completely saturated, it will take a very long time. Meanwhile, considering that creep may occur under long-term compression. Combined with the purpose of this paper, without affecting the experimental results, the injection pressure was increased to the next point when the strain changed slowly for a period of time. Due to the non-adsorption of He, the strain was stable soon, and the duration of each injection pressure was about 2 h. The duration of each injection pressure was about 12 h during N2 injection.

-

(3)

Water injection. The coal pillar of HF2 was used. Step (1) was repeated. The injection pressure was increased from 1 MPa to 3 MPa with 0.5 MPa intervals. The injection time before the experiment was designed to be 12 h. However, it was found that the early strain was very fast during water injection, so the early injection time was prolonged, and the later injection time was appropriately shortened according to the change of strain. When the radial strain changed slowly for a period of time, the injection pressure was increased to the next point. The outlet co mmunicated with atmosphere during water injection. The radial strain and flux were recorded.

3 Results and discussion

3.1 Strain characteristics of coal during N2 and water injection

According to the above experimental steps, based on the strain characteristics of coal during He, N2 and water injection, the adsorption strain characteristics of samples during N2 and water injection could be obtained after the strain directly caused by pore pressure was eliminated (Wang et al. 2011). The following radial strain of N2 and water refers to the adsorption strain. According to previous studies (Meng and Li 2018), the volume strain and strain in parallel bedding direction and vertical bedding direction have similar variation characteristics, and the strain in vertical bedding direction is higher than that in parallel bedding direction in the process of gas adsorption. The samples used in this paper were all drilled parallel to the bedding direction, and the radial strain represents the strain in the vertical bedding direction. Although the axial strain was not monitored, the radial strain used in this paper is also representative, and does not affect the analysis results.

As shown in Fig. 2, the radial strain and injection time conforms to the Langmuir formula. The radial strain induced by water is obviously higher than that induced by N2 in the low-pressure stage. With continuous injection, the gap gradually decreases. The radial strain decreases with the injection of water. The strain under 1 MPa is much higher than that under subsequent injection pressure. Compared with the radial strain of 5 h under each injection pressure, the radial strain decreases from 0.026% of 1 MPa to 0.005% of 3 MPa, and the radial strain reduces about 5 times. At the end of N2 injection experiment, the coal has not reached gas saturation. However, the radial strain is basically stable under 3 MPa. So overall, compared with the adsorption of N2 on coal surface, the rate of water adsorption on coal surface is very fast, which is also related to the strong hydrophilic ability of coal.

In addition, in order to show that the variation characteristics of strain during water injection are not caused by accidental factors. Meanwhile, in order to verify whether the variation characteristics of radial strain, axial strain and volumetric strain are consistent during water injection. The radial strain and axial strain were measured again by strain gauge under the same confining pressure and axial pressure (Fig. 3). The difference is that the injection pressure increases from 0.5 MPa to 3.0 MPa at intervals of 0.5 MPa. Because the strain test methods (Fig. 2 was measured by extensometer, and Fig. 3 was measured by strain gauge) are different, they cannot be compared quantitatively. The qualitative comparison was only carried out in this paper.

It can be seen from Fig. 3 that the radial strain, axial strain and volumetric strain have similar variation characteristics during water injection, and the variation characteristics of strain are consistent with the water injection in Fig. 2. Namely, the strain changes rapidly at the initial stage of injection. The injection time of 0.5 MPa is only about 20% of the total injection time, but the strain accounts for more than 70% of the total strain, and then gradually slows down until stable (Fig. 3). It also shows that the adsorption rate of water on coal surface is very fast in the early stage of injection, which is much higher than that in the later stage.

As reflected in Fig. 4, the variation of water adsorption strain with injection pressure accords with Langmuir law. The strain of coal adsorbed with N2 is still in the linear phase. Meanwhile, the radial strain of water injection is significantly larger than that of N2 injection, and the radial strain of N2 injection is significantly larger than that of He injection. These show that the strain caused by the fluid with different adsorption capacity is quite different. The strain of the fluid with strong adsorption capacity is much higher than that of the fluid with weak adsorption capacity. Besides, when the confining pressure is constant, increasing injection pressure is equivalent to increasing pore pressure, that is, the radial strain of coal increases with increasing pore pressure. It shows that pore pressure can promote the adsorption strain of gas and water.

As presented in Fig. 5, the change of radial strain rate during N2 injection and water injection is completely different in the early phase. The radial strain rate remains unchanged during N2 injection. However, it decreases during water injection. The radial strain rate reduces by about 3 times when the injection pressure from 1.0 MPa to 1.5 MPa. From 1.5 MPa to 2.5 MPa, it is relatively stable. From 2.5 MPa to 3.0 MPa, it decreases by half. Meanwhile, according to the water content of pumped before water passing through the sample, the variation of water saturation at different times could be obtained. The cumulative radial strain varies linearly with water saturation (Fig. 6). Previous studies also showed that the strain is positively correlated with the adsorption volume (Fry et al. 2009). Therefore, at the beginning of water injection, the water adsorption rate of coal is very fast, and then it can be stable for a period. The radial strain rate suddenly decreases from 2.5 MPa to 3.0 MPa, which indicates that the sample is close to water saturation. In addition, the radial strain rate of water injection is larger than that of N2 injection under 1 MPa, which indicates that the water adsorption rate of coal is larger than that of N2, that is, the hydrophilic ability of coal is stronger than that of N2. When the coal was close to water saturation, it was not saturated by N2 until the end of the experiment, which also reflects that coal has strong hydrophilic ability.

According to the above analysis, the strain characteristics of water injection is quite different from that of N2 injection. According to our previous research, there is an edge of free adsorption in the early phase of gas injection (Liu et al. 2020). Does this phenomenon exist during water injection? For the water adsorption features in the early phase, the variation of water saturation under two conditions of water injection (under different injection pressures) and non-pressurized vacuum was compared (Fig. 7).

As exhibited in Fig. 7, the water saturation of the coal increases with time, and the variation rate gradually slows down. When the water saturation is below 50%, the increase rate of water saturation is very fast, which only took about 16 h. Moreover, the change trend of water saturation with time is basically consistent under two conditions. The variation of water saturation with the pressure is not obvious. Meanwhile, comparing the strain characteristics during water injection in Figs. 2 and 3, it can be seen that although the initial injection pressure (1 MPa in Fig. 2 and 2.5 MPa in Fig. 3) is different, the variations of strain at the initial injection pressure are consistent. This also shows that the relationship between the water saturation and the injection pressure is not obvious at the initial stage of water injection. It demonstrates that the edge of free adsorption exists in the early phase of water saturation. For this coal sample, this boundary is about half of water saturation. However, in the following phase, the increase rate of water saturation with time under injection pressure is significantly higher than that under non-pressurized vacuum condition. Water saturation from 50% to 100%, it took about 200 h for vacuum saturation without pressure. The results show that it is difficult to complete the saturation only by the adsorption capacity of coal in the later phase, and the injection pressure can obviously promote the saturation rate of the coal in the later phase.

Combined with our previous research (Liu et al. 2020), it is shown that the edge of free adsorption exists for the adsorption of gas and water. It is related to the saturation of gas or water in coal. Within this boundary, the relationship between the adsorption rate of coal for gas or water and pore pressure is not obvious. On the contrary, when the saturation of gas or water drops to this range, it is difficult to desorb by simply reducing the pressure.

3.2 Characteristics of permeability variation during gas injection and water injection

Permeability was measured according to flux and Darcy’s law. As shown in Fig. 8, the permeability was obtained at the end of each injection pressure. The variation trend of permeability with injection pressure for gas and water is completely different. The permeability varies linearly with injection pressure during He and N2 injection. However, the permeability reduces first and then ascends with increasing injection pressure during water injection. Before 2.5 MPa, the permeability reduces with increasing injection pressure. After that, the permeability ascends gradually. The main reason is that the injection pressure increases the pore pressure, and the pore pressure promotes the deformation of coal. Meanwhile, the adsorption stress was generated (Zhou et al. 2021), squeezing the pores and fractures in the coal, resulting in the reduction of permeability. After that, the deformation of coal is not obvious when the sample is nearly water saturation at 3 MPa. The positive effect of pore pressure on water transport in pores and fractures has a dominant role. Therefore, the permeability reduces first and then increases during water injection. The pore pressure has a dominant role in the enhancement of gas migration during He and N2 injection. The positive effect of pore pressure on permeability is better than the negative effect of adsorption stress on permeability. Therefore, the permeability always increases. It is generally considered that He is an inert gas and does not adsorb, while N2 and water injection into coal can lead to adsorption deformation, and then affect permeability. Comparing the permeability variations of He, N2 and water injection (Fig. 8), it can be concluded that the N2 permeability varies more slowly with injection pressure than that of He. The permeability of water even reduces with increasing injection pressure. These aspects reveal that the adsorption strain of coal inhibits the increase of permeability.

Figure 9 shows the inhibition of coal strain on the increase of permeability. The variation of permeability is obviously different for He, N2 and water injection. He permeability varies exponentially with radial strain. N2 permeability varies linearly with radial strain. Because of the leading role of pore pressure on gas migration, the permeability is still increasing. Water permeability decreases first and then increases with radial strain. Therefore, compared with N2 adsorption strain, the influence of adsorption strain during water injection on permeability is more significant.

Besides, according to the experimental date (the basic parameters of the samples are similar to those in this paper) of Wang et al. (2011), the permeability of He increases with the pore pressure under the confining pressure of 6 MPa, while the permeability of CH4 and CO2 first reduces and then ascends with increasing pore pressure for the sample A (Fig. 10). By further analyzing the experimental date in Fig. 10, the variation of permeability with pore pressure is not completely consistent under the same confining pressure for the sample A and sample B. Combined with the experimental results of this paper, this is related to the dominant role of pore pressure. The pore pressure promotes the increase of permeability for non-adsorbable He and N2 with relatively weak adsorption capacity. For CH4, CO2 and water with relatively strong adsorption capacity, the adsorption strain caused by pore pressure may play a leading role in the first. At this time, adsorption stress plays a leading role in the compression of pores and fractures, which leads to the reduction of permeability. With increasing pore pressure, pore pressure has a dominant role in the enhancement of gas migration, and the permeability begins to increase gradually. However, why is the same gas (CH4, and CO2) injected into two different samples (sample A and sample B) with different trends? After comparison, the initial permeability of the two samples is different, so it is speculated that the dominant role of pore pressure is also affected by the initial permeability of coal. For relatively high permeability samples, pore pressure plays a leading role in promoting fluid migration, and the influence of coal adsorption strain on permeability is relatively weak. For relatively low permeability samples, the influence of adsorption strain on permeability is relatively strong. Therefore, in the initial stage, the promoting effect of pore pressure on fluid migration may not be able to offset the compression of pores and fractures caused by the adsorption stress, which makes the permeability gradually decrease. After the adsorption tends to saturation, the promoting effect of pore pressure on fluid migration begins to play a vital role, which makes the permeability gradually increase. This explanation can be verified by Fig. 11 (Harpalani and Schraufnagel 1990). As displayed in Fig. 11, with increasing pore pressure, the adsorption volume increases and the permeability reduces rapidly in the early phase, which shows that the stress produced by adsorption strain plays a significant role at this stage. After that, the permeability increases gradually when the adsorption volume is close to saturation, which shows that pore pressure plays a key role in promoting gas migration. These phenomena are consistent with the results of water injection in this paper.

Permeability versus pore pressure during gas injection with different initial permeability (Wang et al. 2011)

Adsorption volume of CH4 and permeability versus pore pressure (Harpalani and Schraufnagel 1990)

In a word, during the injection of fluid, the variation of permeability is intimately related to the effect of pore pressure. Pore pressure provides power for fluid migration. Meanwhile, the increase of pore pressure also promotes fluid adsorption, leading to coal deformation, thus preventing the improvement of permeability. This process is a game between the two interactions, which is connected to the fluid adsorption capacity and the initial permeability of coal.

Based on the above analysis, the variation of parameters has both similarities and differences during N2 injection and water injection. The relationship of strain with time and pressure is similar, and an edge of free adsorption exists in the early phase. The strain rate during water injection is larger than that of N2. The opposite trend was observed for permeability. The permeability decreases in the early phase and increases when the water content is close to saturation. This is mainly due to the adsorption strain caused by pore pressure in the early phase of water injection. However, the pore pressure has an advantage in promoting gas production during N2 injection, which leads to a gradual increase in permeability. Therefore, the influences of pore pressure on coal permeability are different for different fluids and coal with different initial permeability.

Figure 12 shows the effect of fluid adsorption capacity and initial permeability on coal permeability. For non-adsorbable fluids, there is no adsorption strain in coal. The pore pressure plays an important role in promoting the fluid migration for the coal with high permeability or low permeability. The permeability increases with the increase of pore pressure. For the fluid with relatively weak adsorption, the pore pressure may play a leading role in promoting fluid migration (Fig. 12c and e). Although it can cause adsorption strain, the decrease of permeability caused by adsorption strain is weaker than the increase of permeability caused by pore pressure. Hence the permeability increases with the increase of pore pressure. For strongly adsorbed fluid, if the coal permeability is high enough, pore pressure still plays a crucial role in promoting fluid migration (Fig. 12d), and the permeability increases with increasing pore pressure. If the permeability is relatively low (Fig. 12e), the adsorption strain caused by pore pressure has a dominant role in the early phase. The increase of permeability with increasing pore pressure cannot offset the decrease of permeability with the increase of adsorption strain. In the later stage, the adsorption is close to saturation, and the adsorption strain does not change with the increase of pore pressure. At this time, the permeability reduction caused by adsorption strain is weak, and the promotion effect of pore pressure on fluid migration begins to play a key role, and the permeability begins to increase. Therefore, the permeability may reduce first and then ascend with increasing pore pressure.

4 Conclusions

-

(1)

The strain characteristics of N2 injection and water injection are different. Although the strain variations with time is in accord with Langmuir law, the adsorption strain of water is obviously higher than that of N2, especially in the early phase of N2 injection and water injection. At the beginning of water injection, there is an edge of free adsorption. Within this phase, the adsorption rate of coal is very high, and water saturation and adsorption strain increase rapidly. This boundary is about half of water saturation. The variation of water adsorption rate with pore pressure is weak within this scope, and then the water adsorption rate is controlled by pore pressure.

-

(2)

The pore pressure has multiple effects, which can not only promote the fluid migration, but also promote the fluid adsorption. Pore pressure affects the variation of coal permeability. For non-adsorption fluid, pore pressure mainly promotes fluid migration, and the increase of pore pressure can improve coal permeability. For adsorptive fluid, pore pressure can not only promote fluid migration, but also promote fluid adsorption. The promotion of fluid migration can improve coal permeability, while the promotion of fluid adsorption can inhibit the increase of coal permeability. Moreover, the impact of pore pressure on coal permeability is related to fluid type and initial permeability of coal. When the initial permeability is high enough, the pore pressure may mainly promote the fluid migration. When the initial permeability is relatively low, the effect of pore pressure on fluid migration is also related to the adsorption capacity of the fluid. When the adsorption capacity of the fluid is weak, the promotion of pore pressure on fluid migration may be dominant. When the adsorption capacity of the fluid is strong, the pore pressure may have a dominant role on the adsorption strain. Finally, the variation of permeability is the result of multiple effects. Therefore, the initial permeability of coal reservoir and fluid type should be considered in the implementation of stimulation technology.

Data availability

Not applicable.

References

Chen X, Cheng Y (2015) Influence of the injected water on gas outburst disasters in coal mine. Nat Hazards 76(2):1093–1109

Fan K, Li Y, Elsworth D, Dong M, Yin C, Li Y et al (2018) Three stages of methane adsorption capacity affected by moisture content. Fuel 231:352–360

Fry R, Day S, Sakurovs R (2009) Moisture-induced swelling of coal. Int J Coal Prep Util 29(6):298–316

Harpalani S, Schraufnagel RA (1990) Shrinkage of coal matrix with release of gas and its impact on permeability of coal. Fuel 69(5):551–556

Li J, Chen Z, Wu K, Zhang T, Zhang R, Xu J et al (2018) Effect of water saturation on gas slippage in circular and angular pores. Aiche J 64(9):3529–3541

Li J, Li B, Pan Z, Wang Z, Yang K, Ren C, Xu J (2020) Coal permeability evolution under different water-bearing conditions. Nat Resour Res 29(4):2451–2465

Liu A, Liu S, Liu P, Harpalani S (2021) The role of sorption-induced coal matrix shrinkage on permeability and stress evolutions under replicated in situ condition for CBM reservoirs. Fuel 294:120530

Liu J, Fokker PA, Peach CJ, Spiers CJ (2018) Applied stress reduces swelling of coal induced by adsorption of water. Geomech Energy Envir 16:45–63

Liu X, Wu C (2017) Simulation of dynamic changes of methane state based on NMR during coalbed methane output. Fuel 194:188–194

Liu X, Wu C, Wei G, Zhang X, Jia T, Li H et al (2020) Adsorption deformation characteristics of coal and coupling with permeability during gas injection. J Petrol Sci Eng 195:107875

Liu Y, Cao S, Li Y, Wang J, Guo P, Xu J et al (2010) Experimental study of swelling deformation effect of coal induced by gas adsorption. Chin J Rock Mech Eng 29(12):2484–2491

Mazumder S, Wolf KH (2008) Differential swelling and permeability change of coal in response to CO2 injection for ECBM. Int J Coal Geol 74(2):123–138

Meng Y, Li Z (2018) Experimental comparisons of gas adsorption, sorption induced strain, diffusivity and permeability for low and high rank coals. Fuel 234:914–923

Miao Y, Li X, Zhou Y, Wu K, Chang Y, Xiao Z et al (2018) A dynamic predictive permeability model in coal reservoirs: Effects of shrinkage behavior caused by water desorption. J Petrol Sci Eng 168:533–541

Moore TA (2012) Coalbed methane: A review. Int J Coal Geol 101:36–81

Pan Z (2012) Modeling of coal swelling induced by water vapor adsorption. Front Chem Sci Eng 6(1):94–103

Pan Z, Connell LD, Camilleri M, Connelly L (2010) Effects of matrix moisture on gas diffusion and flow in coal. Fuel 89(11):3207–3217

Ranathunga AS, Perera MSA, Ranjith PG (2016) Influence of CO2 adsorption on the strength and elastic modulus of low rank Australian coal under confining pressure. Int J Coal Geol 167:148–156

Shi J, Wang S, Zhang H, Sun Z, Hou C, Chang Y et al (2018) A novel method for formation evaluation of undersaturated coalbed methane reservoirs using dewatering data. Fuel 229:44–52

Si L, Zhang H, Wei J, Li B, Han H (2021) Modeling and experiment for effective diffusion coefficient of gas in water-saturated coal. Fuel 284:118887

Tan Y, Pan Z, Liu J, Zhou F, Connell LD, Sun W et al (2018) Experimental study of impact of anisotropy and heterogeneity on gas flow in coal. Part II: Permeability Fuel 230:397–409

Tang Z, Yang S, Zhai C, Xu Q (2018) Coal pores and fracture development during CBM drainage: Their promoting effects on the propensity for coal and gas outbursts. J Nat Gas Sci Eng 51:9–17

Tao S, Chen S, Pan Z (2019) Current status, challenges, and policy suggestions for coalbed methane industry development in China: A review. Energy Sci Eng 7(4):1059–1074

Tao S, Chen S, Tang D, Zhao X, Xu H, Li S (2018) Material composition, pore structure and adsorption capacity of low-rank coals around the first coalification jump: A case of eastern Junggar Basin, China. Fuel 211:804–815

Thararoop P, Karpyn ZT, Ertekin T (2015) Development of a material balance equation for coalbed methane reservoirs accounting for the presence of water in the coal matrix and coal shrinkage and swelling. J Unconv Oil Gas Resour 9:153–162

Wang S, Elsworth D, Liu J (2011) Permeability evolution in fractured coal: The roles of fracture geometry and water-content. Int J Coal Geol 87(1):13–25

Wang Z, Fu X, Hao M, Li G, Pan J, Niu Q et al (2021) Experimental insights into the adsorption-desorption of CH4/N2 and induced strain for medium-rank coals. J Petrol Sci Eng 204:108705

Wu Chuan Y, Chengxiang W Guojun, Han Lei, Liu Haojie (2020) A dynamic evaluation technique for assessing gas output from coal seams during co mmingling production within a coalbed methane well: a case study from the Qinshui Basin. Int J Coal Sci Technol 7(1):122–132. https://doi.org/10.1007/s40789-019-00294-z

Xu H, Tang DZ, Tang SH, Zhao JL, Meng YJ, Tao S (2014) A dynamic prediction model for gas–water effective permeability based on coalbed methane production data. Int J Coal Geol 121:44–52

Yi M, Wang L, Hao C, Liu Q, Wang Z (2021) Method for designing the optimal sealing depth in methane drainage boreholes to realize efficient drainage. Int J Coal Sci Technol 8(6):1400–1410. https://doi.org/10.1007/s40789-021-00448-y

Zang J, Wang K, Zhao Y (2015) Evaluation of gas sorption-induced internal swelling in coal. Fuel 143:165–172

Zhang X, Wu C, Wang Z (2019) Experimental study of the effective stress coefficient for coal permeability with different water saturations. J Petrol Sci Eng 182:106282

Zhang Y, Lebedev M, Al-Yaseri A, Yu H, Xu X (2018) Nanoscale rock mechanical property changes in heterogeneous coal after water adsorption. Fuel 218:23–32

Zhou X, Liu S, Zhang Y (2021) Permeability evolution of fractured sorptive geomaterials: A theoretical study on coalbed methane reservoir. Rock Mech Rock Eng 54(7):3507–3525

Zhu W, Liu L, Liu J, Wei C, Peng Y (2018) I MPact of gas adsorption-induced coal damage on the evolution of coal permeability. Int J Rock Mech Min 101:89–97

Zou C, Yang Z, Huang S, Ma F, Sun Q, Li F et al (2019) Resource types, formation, distribution and prospects of coal-measure gas. Petrol Explor Dev 46(3):451–462

Funding

This work was supported by the National Natural Science Foundation of China (41872170, 42072189), China Postdoctoral Science Foundation (2021M690916), Key Science and Technology Program of Henan Province (222102320154), State Key Laboratory Cultivation Base for Gas Geology and Gas Control (Henan Polytechnic University) (WS2020B10), Key Scientific Research Projects of Colleges and Universities in Henan Province (21A440006), Doctor foundation of Henan Polytechnic University (B2020-6, B2021-5).

Author information

Authors and Affiliations

Contributions

Xiaolei Liu, Conceptualization, Methodology and Writing – original draft. Jianping Wei, Supervision, Project administration. Guoying Wei, Project administration, review and editing. Caifang Wu, Funding acquisition, Supervision and review. Cao Liu, Review and editing. Xiaoming Ni, Review and editing.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Liu, X., Wei, J., Wei, G. et al. Combined control of fluid adsorption capacity and initial permeability on coal permeability. Int J Coal Sci Technol 9, 85 (2022). https://doi.org/10.1007/s40789-022-00545-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40789-022-00545-6