Abstract

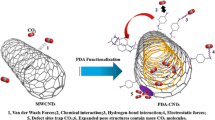

As a preliminary investigation towards obtaining carbon nanotube composite adsorbent for CO2 capture, in this study CO2 adsorption performance of three commercial carbon nanotubes (CNTs) one single-walled carbon nanotubes (SWCNTs), and two (2) different multi-walled carbon nanotubes (referred to as A-MWCNTs and B-MWCNTs) were evaluated and compared. The purpose of this study was to compare the different types of CNTs and select the best to serve as the solid anchor in the development of a hydrophobic composite adsorbent material for CO2 capture. The N2 physi-sorption of the CNTs was conducted to determine their surface area, pore volume and pore size. In addition, morphology and purity of the CNTs were checked with Transmission Electron Microscopy and Raman Spectroscopy, respectively. The CO2 adsorption capacity of the CNTs was evaluated using Thermo-gravimetric analysis (TGA) at 1.1 bar, at operating temperature ranged from 25 to 55 °C and at different CO2 feed flow rates, in order to evaluate the effects of these variables on the CO2 adsorption capacity. The results of CO2 adsorption with the TGA show that CO2 adsorption capacity for both SWCNTs and MWCNTs was the highest at 25 °C. Changing the CO2 flowrates had no significant effect on the adsorption capacity of MWCNTs, but decreasing the CO2 flow rate resulted in the enhancement of the CO2 adsorption capacity of SWCNTs. Overall, it was found that the SWCNTs displayed the highest CO2 adsorption capacity (29.97 gCO2/kg adsorbent) when compared to the MWCNTs (12.09 gCO2/kg adsorbent), indicating a 150% increase in adsorption capacity over MWCNTs.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The most common technology to generate electricity is the combustion of fossil fuels in power plants. The generation of electricity via power plants emits a lot of carbon dioxide (CO2), which is one of the greenhouse gases (GHG) causing global warming that contributes to global climate change. CO2 capture and storage (CCS) is a proposed technique for mitigating global climate change and is widely considered as highly relevant for the sustainable use of fossil fuels (IEA 2015). Absorption, using amine-based solvents such as monoethanolamine (MEA), is currently the mature technology applied in the capture of CO2 from power plants. However, emission of amines into the air (as vapour during CO2 capture using the technology) poses health and environmental risks. Furthermore, the efficiency penalty caused by CO2 capture and the huge costs associated with the regeneration of the spent solvents poses a threat to the economic viability of the absorption process. Adsorption technology seems promising due to its moderate energy consumption (which stems from the ability to operate at moderate temperatures and pressures) as well as the health and environmental benign nature of the adsorbents employed in the process. Recently, extensive research has been conducted on designing adsorbents in which the amine functionality is impregnated onto solid materials, thereby resulting in the enhancement of the CO2 adsorption capacity of these materials due to the presence of amine functional groups in them (Pires et al. 2011). Carbon nanotubes (CNTs) could be used as one of such materials unto which amine could be impregnated. Application of CNTs has attracted a great attention in the medical scientific world owing to their unique structure providing a large surface area. Possession of larger surface area is one of the desired characteristics of a good adsorbent for CO2 capture. Carbon nanotubes are desirable as solid supports in the preparation of composite adsorbents for CO2 capture because they possess very high surface area with good geometric structure that could be used to improve geometric structure of other adsorbents. In addition, they are hydrophobic and will not be affected by the presence of water vapour (Ganesh 2013), giving them a unique advantage over other solid sorbents such as zeolites. Therefore, the hydrophobicity of CNTs could be explored in developing composite adsorbents, with good resistance to water, for CO2 capture from flue gas. Carbon nanotubes are simple hollow cylinders of carbon commonly formed in bundles, and have the appearance of rolled tubes of graphite (Ganesh 2013). They are characteristically a nanometre wide and several microns in length. The bulk material of the CNTs is extremely porous and allows for good adsorption of CO2 (Boot-Handford et al. 2014). In addition, the structure of the nanotube allows for the possibility of the occurrence of adsorption both on the inside and outside of the nanotube, thus allowing for enhanced adsorption of CO2 in the material (Friedrich et al. 2010). However extensive research reports on the application of CNTs for CO2 capture are still limited in literature.

The use of two main types of CNTs, namely: single-walled nanotubes (SWCNTs) and multi-walled nanotubes (MWCNTs), have been reported in connection with adsorption (O’Connell 2006). The SWCNTs are made of one single layer of graphene cylinder, whilst the MWCNTs are made of many layers of graphene cylinders nested one inside the other (Ganesh 2013). This difference in structure provides each type of the CNTs different properties that could be explored and exploited towards developing high CO2 adsorption capacity composite materials for CO2 capture.

It has been shown that grafting or impregnating a surfactant onto the surface of CNTs enhances the CO2 adsorption capacity of the composite material. Lee and Park reported that impregnating polyethyleneimine onto MWCNTs increased the CO2 adsorption capacity of the CNTs by 200% (Lee and Park 2015). In the same vein, Ngoy et al. reported that grafting a polyaspartamine surfactant onto MWCNTs could increase the CO2 adsorption capacity of the material by about 500% (Ngoy et al. 2014). In addition, Su et al. demonstrated that MWCNT/3-aminopropyltriethoxysilane (APTS) composite adsorbent displayed good CO2 adsorption performance than the amine-functionalized activated carbon, and the composite material also displayed a lower theoretical energy of regeneration and superior cyclic stability when compared to those of the amine-functionalized activated carbon (Su et al. 2011). However, reports on the CO2 adsorption behaviour of CNTs during CO2 capture, especially with regard to the use of SWCNTs, are limited in literature.

Against this background, this article presents results of comparative study of CO2 adsorption performance of SWCNTs and MWCNTs, in the context of post-combustion CO2 capture, for the purpose of understanding the CO2 adsorption performance of CNTs when used as solid supports in the development of composite adsorbents for CO2 capture. Results documented in this article could pave the way for the optimization of CO2 adsorption capacity of CNTs for CO2 capture.

2 Experimental

2.1 Materials and method

Three different types of CNTs were used in this study. The three CNTs denoted as SWCNT, A-MWCNT and B-MWCNT were commercial CNTs purchased from Sigma Aldrich (Pty) and Cheap Tubes (Pty) SA situated in South Africa. The characteristics of the CNTs (according to the suppliers) are presented in Table 1.

2.2 Characterization and CO2 adsorption test

Morphology and purity of the CNTs were checked with Transmission Electron Microscopy (TEM) and Raman Spectroscopy, respectively. Nitrogen (N2) physi-sorption was also carried out on the CNTs to determine their surface area (BET), pore volume and pore size. The CO2 adsorption performance of the CNTs was evaluated using a Thermogravimetric Analyser (TGA) (TA STD Q6000). The CO2 adsorption of the CNTs was evaluated at 1.1 bar and a temperature range of 25–55 °C. The sample (10 mg for MWNCTs and 6 mg for SWCNTs) was swept with N2 (flowrate = 60 mL/min) at atmospheric pressure and at 110 °C for 30 min to desorb water and other gases present on the surface. After cooling, the CNTs were exposed to pure CO2 (flowrate = 60 mL/min) under a pressure of 1.1 bar for 120 min. Keeping the CO2 flow rate and pressure constant, the temperature was varied from 25 to 55 °C at a step increase of 10 °C to understand the effect of temperature on the adsorption capacity of the CNTs and obtain optimum adsorption temperature. Furthermore, the adsorption pressure and the optimum adsorption temperature were kept constant, and the CO2 flow rate was varied from 15 to 45 mL/min at a step increase of 15 mL/min to understand the effect of feed flow rate on the adsorption capacity of the materials. Each experiment began with a fresh sample and was run in triplicate for accuracy. Further experiments were conducted at the optimum adsorption temperature and optimum CO2 flowrate following the results obtained from the investigation of the effect of temperature and CO2 flow rate on the CO2 adsorption keeping adsorption pressure at 1.1, after which the CNTs were then regenerated by desorbing the adsorbed CO2. In the desorption cycles, the CNTs were swept with N2 (flowrate = 60 mL/min) at atmospheric pressure at temperature: 90, 100 and 110 °C. Three adsorption–desorption cycles were performed per desorption temperature to allow for the determination of the optimum desorption temperature. It should be noted that 100% CO2 was used in this study instead of mimicking the actual CO2 concentration in the flue gas (about 15%). Since this is a comparative study of CO2 adsorption capacity of CNTs before using them in the synthesis of composite adsorbents, using 100% CO2 will provide holistic information about the CO2 adsorption capacity of the materials without influence from any impurities. For this reason, the use of 100% CO2 in this study as against the 15% CO2 in the flue gas was considered. It could be speculated that presence of impurities, if 15% CO2 is used on the CNTs, will dramatically reduce the CO2 adsorption capacity of the materials due to competitive adsorption in the presence of impurities. As it is envisaged that the presence of impurities will affect the CO2 capacity of the materials when used as solid supports during the development of composite adsorbents, effect of impurities on CO2 adsorption capacity of composite adsorbents obtained from these CNTs will be reported in the future.

3 Results and discussion

3.1 Characterization of the CNTs

3.1.1 BET surface area, pore volume and pore size of the CNTs

Nitrogen physisorption experiments, to obtain the Brunauer–Emmett–Teller (BET) surface area and pore volume of the CNTs, were conducted with a Micromeritics Tristar-Surface area and Porosity analyzer. Sample with an approximate mass of 0.2 g was degassed under the flow of N2 gas at 150 °C for 4 h prior to analysis using a Micromeritics flow Prep 060, sample degas system. 0.2 g of sample is sufficient to obtain accurate results with this type of analyser. The N2 adsorbed was recorded and used to determine the surface geometry of the CNTs.

Large surface area is a desired characteristic of any adsorbents because larger surface area implies larger amount of surface for CO2 adsorption. According to literature, surface area of MWCNTs is typically between 200 and 400 m2/g, whilst that of the SWCNTs is between 400 and 900 m2/g (Monthioux et al. 2010). The surface area obtained for SWCNTs was 664.63 m2/g (see Table 2), thus falling within the range specified in literature. In addition, the surface area obtained for the A-MWCNTs and B-MWCNTs were 225.9 and 452.7 m2/g respectively (see Table 2). These results are also consistent with literature. The SWCNTs displayed largest surface area (664.6 m2/g) than the MWCNTs, indicating that the SWCNTs could display the highest CO2 adsorption capacity.

According to literature, the typical pore volumes for MWCNTs range from 0.025 to >1.67 cm3/g depending on the pore size and surface area of the nanotube (Su et al. 2011). As depicted in Table 2, the A-MWCNTs have the largest pore volume (2.91 cm3/g) and the B-MWCNTs displayed the smallest pore volume (0.74 cm3/g). These results are in agreement with literature (Su et al. 2011). Furthermore, the pore volume of the SWCNTs was 1.94 cm3/g, larger than that of the A-MWCNTs, but smaller than that of the B-MWCNTs. Notwithstanding, the values obtained in this study are consistent with literature.

The average pore size of the A-MWCNTs is the biggest of all the three CNTs (50.72 nm) (see Table 2), followed by that of the SWCNTs (11.73 nm) (Table 2). B-MWCNTs had the smallest pore size of 6.57 nm (Table 2). The values are consistent with literature (Wu et al. 2007). The CNTs used in this study were all mesoporous materials because they all have average pore sizes between 2 and 50 nm (Chen et al. 2006). Pore size is an important characteristic of an adsorbent because different gases possess different molecular sizes based on the intramolecular forces and the bond strength within the gas molecule. In the case of separation application (and not adsorption capacity) the pore size of the adsorbent should be similar to that of the adsorbate to enhance selectivity. For example, the kinetic diameter of CO2 is 0.34 nm (Kurniawan et al. 2006) and the pore size of the A-MWCNTs is 15 times larger; indicating that A-MWCNTs will display poor selectivity towards CO2 from a mixture of gases that contains CO2. The pore size of the SWCNTs is 4 times larger than the size of a CO2 molecule, and the pore size of the B-MWCNTs is twice as large as the size of a CO2 molecule, indicating that the B-MWCNTs should display highest selectivity towards CO2.

3.1.2 Morphological property of the CNTs

The TEM images of the CNTs are depicted in Fig. 1a–c. Figure 1a shows that the raw SWCNTs are extremely thin, owing to the very small diameter of SWCNTs, usually in the range 0.6–5 nm (Monthioux et al. 2010). In addition, the figure shows that the SWCNTs are grouped closely together and are entangled with each other forming bundles, due to the strong van der Waals interaction between the CNTs that causes the agglomeration of the tubes (Sethi and Barron 2009). In contrast, the MWCNTs are thicker than the SWCNTs and do not form as many bundles as the SWCNTs (see Fig. 1b, c). The small dark spots vividly seen on the MWCNTs could be attributed to the presence of small metallic particle residues from the catalyst used during the synthesis of the CNTs (Dresselhaus et al. 2001). The manufacturer specified that the sample was only 95% pure, therefore it is reasonable to expect some impurities. From the micrographs some of the layers of the multi-layered MWCNT can be clearly seen, where one graphene layer is nested in another, hence forming a MWCNT. Thus, the difference in structure between the SWCNTs and the MWCNTs, is evident by the visible layers of graphene in the MWCNTs, but not present in the SWCNTs.

Using the scale of the given magnification for each micrograph and statistical parameters, the diameters of the A-MWCNTs and B-MWCNT were calculated as (9 ± 0.5) and (8 ± 0.3) nm, respectively, and these values are consistent with the information provided by the manufacturer. The diameter of the SWCNTs was calculated to be (2 ± 0.6) nm, which correlates with literature (Jagtoyen et al. 2000), and is fairly consistent with the information provided by the manufacturer.

3.1.3 Purity and surface chemistry of the CNTs

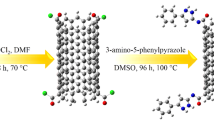

Raman spectroscopy is a popular tool used in the characterization of CNTs due to the good spatial resolution and sensitivity as well as the minimal sample preparation required for the testing of the sample using the spectrometer. Raman spectra were acquired with the 514.5 nm line of an argon ion laser and a Horiba Jobin–Yvon LabRAM HR Raman spectrometer equipped with an Olympus BX41 microscope attachment. The incident beam was focused onto the sample with a 100X objective and the power at the sample was kept low (~0.6 mW) to prevent localised heating by the laser. The backscattered light was dispersed via a 600 lines/mm grating onto a liquid nitrogen cooled CCD detector and the data was collected with LabSpec v5 software. The Raman spectra of the CNTs are shown in Fig. 2a, b.

Radial Breathing Mode (RBM) bands are found between 75 and 300 cm−1, and are specific to the Raman spectra of carbon nanotubes (Fig. 2a). RBM correspond to a single graphene cylinder located at a certain wavenumber and is experienced because of the radial expansion–contraction of the CNTs subjected to the axial pressure, similar to if the tube was ‘breathing’ (Sethi and Barron 2009). For SWCNT, there is only one graphene cylinder, but with MWCNT consisting of multiple graphene cylinders, each located at different wavenumbers, the Raman intensity peaks that are produced are drowned out by competing graphene cylinders (Dresselhaus et al. 2005). Thus, the RBM is the most obvious means used to distinguish between SWCNT and MWCNT. The RBM is unique to SWCNTs and is hardly visible for MWCNTs (compare Fig. 2a, b).

The D-band, can be viewed around 1300–1400 cm−1 for both SWCNTs and MWCNTs (Fig. 2a, b). D-band originates from impurities (such as catalyst residues), but can also be caused by structural defects of a material (Costa et al. 2008). The D-band in Fig. 2a is very small, indicating that the SWCNTs sample contained few impurities or structural defects, while the much higher peak in MWCNT indicates the presence of impurities. This is attributed to the more complex nature of the multi-layered MWCNTs in comparison to the single graphene layer SWCNTs as well as catalyst residues. The observation and speculation were confirmed with the TEM images as well. The structural quality of the CNTs can be quantified by the use of the ratio between the G- and D-bands. A large D-peak in comparison to a G-peak is indicative of the poor structural quality of the sample, as it signifies the presence of amorphous carbon (Sethi and Barron 2009). From Fig. 2, it can be seen that this is not true for the SWCNT implying that the sample is of excellent quality. For the MWCNTs, the D-peak is slightly higher than the G-peak (as seen in Fig. 2b), implying that the sample is of moderate quality. Yet the difference between the peaks is not much, indicating that the samples are not of poor quality either. The presence of these impurities confirmed the findings from the TEM images and supported the necessity to heat up the samples to 110 °C for 30 min under N2 to remove the impurities before CO2 adsorption experiments (Fig. 3).

3.2 CO2 adsorption capacity of the CNTs

Effects of adsorption temperature and CO2 flow rate on the CO2 adsorption capacity of the CNTs are depicted in Figs. 4 and 5, respectively. The three CNTs show the same trend for the influence of temperature on the CO2 adsorption capacity. The CO2 adsorption decreased with increase in temperature with the highest adsorption capacity obtained at 25 °C. This observation is consistent with literature because adsorption of gases decreases with increase in temperature. At constant pressure, the kinetic energy of gases increases with temperature, resulting therefore in lesser surface coverage of CO2 gas. Furthermore, increasing the temperature during adsorption reduces the surface coverage of CO2 gas and the reduction in the CO2 adsorbed at higher temperatures indicates that the adsorption is exothermic. Figure 5 shows a dramatic decrease in the adsorption capacity of the SWCNT at increasing CO2 flow rate. At increasing flow rate, a decrease in the contact between the adsorbate and the adsorbent is expected. The decrease in the contact between the adsorbate and the adsorbent should result in a decrease in the amount of adsorbate adsorbed by the adsorbent. This expected trend is obviously displayed the CO2 adsorption onto SWCNTs (see Fig. 5). The behaviour of the SWCNTs at increasing CO2 flow rate is consistent with literature (Alhamid et al. 2015). When the temperature, pressure and adsorption time are kept the same, an increase in CO2 flow rate will prolong the time for the adsorption process to complete (i.e. adsorbate takes a longer time to saturate the adsorbent) (Alhamid et al. 2015). However, in contrary to the behaviour of the SWCNTs, CO2 adsorption capacity of the MWCNTs increased slightly when the CO2 flow rate was increased from 45 to 60 mL/min. The increase in the CO2 adsorption capacity of the MWCNTs when the flow rate was increased from 45 to 60 mL/min might be attributed to some experimental errors during the conduct of the experiments.

Based on the results depicted in Fig. 3, the optimum operating parameters (adsorption temperature, CO2 adsorption flowrate and desorption temperature) for each CNT were selected and used in the comparative study for the CO2 adsorption capacity of the CNTs. Cyclic adsorption desorption experiments were then conducted, as explained in the experimental section of this article.

Table 3 shows the results obtained from the cyclic adsorption–desorption experiments. The CO2 adsorbed per adsorption cycle as well as the average CO2 adsorbed were calculated and reported in terms of mg CO2 adsorbed/g of adsorbent. The SWCNTs showed an average CO2 adsorption capacity in the range of 28.8–30.2 mg/g adsorbent (Table 3). The A-MWCNTs showed an average CO2 adsorption capacity in the range of 5.4–6.6 mg/g (Table 3). The B-MWCNTs showed an average CO2 adsorption capacity in the range of 11.4–12.1 mg/g (Table 3). Ngoy et al. reported an adsorption capacity of 12.1 mg/g for pure MWCNTs at a temperature and a pressure of 25 °C and 1.1 bar (see Table 4). But as the carbon nanotubes used in this study were similar to those used by Ngoy et al. (obtained from the same also supplier) it is expected that they will display similar CO2 adsorption capacities (Ngoy et al. 2014). Su et al. reported a CO2 adsorption capacity of 21.5 mg/g for MWCNTs using a mixed gas stream at atmospheric pressure and a temperature of 50 °C (Table 4), which is higher than the temperature of this study (Su et al. 2011). Lee and Park (2015) reported a CO2 adsorption capacity of 21.02 mg/g for MWCNTs with at a temperature and pressure of 25 °C and 1 bar respectively (Table 4). The A-MWCNTs achieved a much lower CO2 adsorption capacity, and are thus not comparable with CNTs from literature and are unlikely to be suitable adsorbents for CO2 capture. The B-MWCNTs achieved a similar adsorption capacity to the MWCNTs produced by the same supplier but not to other MWCNTs found in literature. The CO2 adsorption capacity of the B-MWCNTs is only comparable with that of the MWCNTs from the same supplier and not with the other MWCNTs from literature. The matchless of the CO2 adsorption results obtained for the MWCNTs used in this study with those of the MWCNTs reported in literature implies that different MWCNTs show substantially different CO2 adsorption properties attributable to the complex structure of the CNTs and partly to the methods employed in the production of the CNTs. Results of this study compared with literature are shown in Table 4. In this study, the SWCNTs displayed average CO2 adsorption capacity of 30.0 mg/g adsorbent (see Table 3). In a theoretical study reported by Cinke et al. (2003), SWCNTs was shown to have displayed a CO2 adsorption capacity of 91.1 mg/g at 1.1 bar and 35 °C. The CO2 adsorption capacity reported by these authors is about three times higher than the CO2 adsorption capacity displayed by the SWCNTs in this study. However, it should be noted that the surface area of the SWCNTs used by Cinke et al. was three times larger than that of the SWCNTs used in this study, explaining therefore the higher CO2 adsorption capacity reported by the authors (Cinke et al. 2003). Furthermore, the difference in the CO2 adsorption capacity of the CNTs used in this study compared to the reports from literature could be attributed to the presence of impurities that blocked the pores of the CNTs. In this study, purification of the CNTs was not carried out before the CO2 adsorption tests. Purification helps to remove the occluded materials from the pore volume of the CNTs, thereby making the pores accessible to CO2 molecules. It is therefore recommended that purification of the CNTs using wet chemical method that uses strong acids (such as HNO3, H2SO4, HNO3/H2O2, and H2SO4/HNO3) (Buang et al. 2012; Rehman et al. 2013) or a non-destructive purification with mild chemicals (Uchechukwu et al. 2013) should be used. Notwithstanding, the CO2 adsorption capacity of the SWCNTs is comparable to the MWCNTs from literature. The SWCNTs displayed the highest CO2 adsorbed per cycle as well as the highest average CO2 adsorbed, and could be adjudged the best adsorbent in this study when compared with the A-MWCNTs that displayed the lowest CO2 adsorbed per cycle as well as the lowest average CO2 adsorbed. The observation aligns with the expected behaviour of these materials when their morphological properties are taken into consideration.

4 Conclusions

The TEM and the Raman analyses conducted on the CNTs used in this study confirmed that the carbon nanotubes were SWCNTs and MWCNTs. Nitrogen (N2) physisorption showed good geometric structure of SWCNTs, indicating that SWCNTs could be good solid anchor for composite adsorbents. The B-MWCNTs did not display good geometric structure when compared to that of the SWCNTs, but still possess a geometric structure that can be beneficial as a solid anchor in the development of composite adsorbents for CO2 capture. The A-MWCNTs have an undesirable geometric structure as solid supports for composite materials. TEM and Raman Spectra results showed that the SWCNTs contained a few defects. In addition, the results show that A-MWCNTs might not be suitable solid supports for developing composite adsorbents for CO2 capture due to its poor porosity as inferred from the results of the N2 physisorption experiment. TGA results confirmed predictions made from the physico-chemical characterisation. The SWCNTs displayed the highest CO2 adsorption capacity of 30 gCO2/kg adsorbent when compared to that of the MWCNTs of 11.8 gCO2/kg adsorbent. There is a ~150% increase in CO2 adsorption capacity of the SWCNTs than that of the MWCNTs. Based on the results obtained from the physico-chemical characterisation and the evaluation of the CO2 adsorption performance of the CNTs, the SWCNTs displayed the best CO2 adsorption capacity, hence the best support recommended for the development of CNTs composite adsorbent for CO2 capture.

In addition, it is expected that grafting the MWCNTs with some absorbents that possess high adsorption capacity for CO2, such as amines and ionic liquids, could enhance CO2 adsorption capacity of the MWCNTs. Thus, CNT-based composite adsorbents could be developed and used for CO2 capture as an alternative to amines-based absorbents, which pose health and environmental risks when emitted into the atmosphere. While this study only investigated CO2 adsorption performance of CNTs using pure CO2 stream, future work will consider the investigation under diluted CO2 stream (15% CO2) towards understanding the performance and adsorption behaviour in the real flue gas stream. It is expected that the CO2 adsorption capacity of the CNTs investigated in this study will reduce when a gas mixture containing only 15% CO2 is used as the feed. The expected decrease in the CO2 adsorption capacity could be attributed to the competitive adsorption between the CO2 and the impurities such as N2, SO2 or H2O that might be present in the gas mixture.

References

Al Hamid M, Nasruddin N, Senoadi S, Perdana M, Ratiko R (2015) Effect of methane gas flow rate on the adsorption capacity and temperature distribution of activated carbon. Int J Technol 6(4):584–593

Boot-Handford ME, Abanades JC, Anthony EJ, Blunt MJ, Brandani S, Mac Dowell N, Fernández JR, Ferrari M-C, Gross R, Hallett JP, Haszeldine RS, Heptonstall P, Lyngfelt A, Makuch Z, Mangano E, Porter RTJ, Pourkashanian M, Rochelle GT, Shah N, Yao JG, Fennell PS (2014) Carbon capture and storage update. Energy Environ Sci 7(1):130–189

Buang N, Fadil A, Majid ZA, Shahir S (2012) Characteristic of mild acid functionalized multiwalled carbon nanotubes towards high dispersion with low structural defects. Dig J Nanomater Biostruct 7(1):33–39

Chen Y, Liu C, Li F, Cheng H (2006) Pore structures of multi-walled carbon nanotubes activated by air, CO2 and KOH. J Porous Mater 13(2):141–146

Cinke M, Li J, Bauschlicjer C, Ricca A, Meyyappan M (2003) CO2 adsorption in single-walled carbon nanotubes. Chem Phys Lett 376(5–6):761–766

Costa S, Borowiak-Palen E, Kruszyñska M, Bachmatiuk A, Kalenczuk R (2008) Characterization of carbon nanotubes by the raman spectroscopy. Mater Sci Pol 26(2):433–441

Dresselhaus MS, Dresselhaus G, Avouris P (2001) Carbon nanotubes: synthesis, structure, properties and applications, topics in applied physics. Springer, New York. ISBN 978-3-540-39947-6

Dresselhaus M, Dresselhaus G, Saito R, Jorio A (2005) Raman spectroscopy of carbon nanotubes. Phys Rep 409(2):47–99

Friedrich D, Ferrari M-C, Patel L, Brandani S (2010) Efficient numerical schemes for the simulation of adsorption processes to cyclic steady state’. In: AIChE annual meeting, Salt Lake City, UT, USA

Ganesh E (2013) Single walled and multi walled carbon nanotube structure, synthesis and applications. Int J Innov Technol Explor Eng (IJITEE) 2(4):2278–3075

International Energy agency (IEA) (2015) CO2 emissions from Fuel combustions highlights, vol 1. IEA Publications, p 139

Jagtoyen M, Pardue J, Rantell T, Grulke E, Derbyshire F (2000) Porosity of carbon nanotubes. Adsorpt Sci Technol 17:289–293

Kurniawan Y, Bhatia S, Rudolph V (2006) Simulation of binary mixture dsorption of methane and CO2 at supercritical conditions in carbons. AIChE J 52(3):957–967

Lee M, Park S (2015) Silica-coated multi-walled carbon nanotubes impregnated with polyethyleneimine for carbon dioxide capture under flue gas condition. J Solid State Chem 226:17–23

Monthioux M, Serp P, Flahaut E, Razafinimanana M, Laurent C, Peigney A, Broto J (2010) Introduction to carbon nanotubes. Springer handbook of nanotechnology. Springer, New York, pp 47–118

Ngoy J, Wagner N, Riboldi L, Bolland O (2014) A CO2 capture technology using multi-walled carbon nanotubes. Energy Proced 63:2230–2248

O’Connell JM (2006) Carbon nanotubes properties and application. CRC Press, London. ISBN 9780849327483

Pires J, Martins F, Alvium-Ferraz M, Simoes M (2011) Recent developments on carbon capture and storage: an overview. Chem Eng Res Des 89(9):1446–1460

Rehman A, Abbas SM, Ammad HM, Badshah A, Ali Z, Anjum DH (2013) A facile and novel approach towards carboxylic acid functionalization of multiwalled carbon nanotubes and efficient water dispersion. Mater Lett 108:253–256

Sethi R, Barron A (2009) Characterization of single-walled carbon nanotubes by raman spectroscopy. OpenStax-CNX avaliable at http://cnx.org/contents/28-ksnhZ@2/Characterization-of-Single-Wal

Su F, Lu C, Chen H (2011) Adsorption, desorption, and thermodynamic studies of CO2 with high-amine-loaded multiwalled carbon nanotubes. Langmuir 27(13):8090–8098

Uchechukwu C, Wejinya SN, Chalamalasetty S, Dong Z, Meyyappan M, Iyuke SE (2013) Dimensional analysis of acid etching effects on vertically grown carbon nanofibers using atomic force microscopy. Nanomater Nanotechnol 3(9):1–8

Wu G, Xu B (2007) Carbon nanotube supported platinum electrodes for methanol oxidation: a comparison between multi- and single-walled carbon nanotubes. J Power Sour 174(1):148–158

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Osler, K., Dheda, D., Ngoy, J. et al. Synthesis and evaluation of carbon nanotubes composite adsorbent for CO2 capture: a comparative study of CO2 adsorption capacity of single-walled and multi-walled carbon nanotubes. Int J Coal Sci Technol 4, 41–49 (2017). https://doi.org/10.1007/s40789-017-0157-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40789-017-0157-2