Abstract

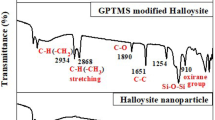

In this study, new clay/silane/epoxy nanocomposites (CSE nanocomposite) were fabricated to enhance the corrosion resistance of epoxy resin. The surface of the clay is modified using 3-aminopropyltriethoxysilane (APTES). The functionalized clay nanoparticle was characterized by Fourier-transform infrared spectroscopy, and thermogravimetric analysis. The fabricated clay nanocomposites coated mild steel was evaluated by electrochemical impedance spectroscopy, scanning electrochemical microscopy and X-ray diffraction (XRD) studies in 3.5% NaCl solution for various days. The experiments indicated that the best epoxy coating performance was obtained by the incorporation of functionalized clay nanoparticles 4 wt% in the epoxy resin. The coated mild steel by CSE nanocomposites showed higher coating resistance (Rc = 238,967 Ω cm2) than that of neat epoxy coating (Rc = 129,532 Ω cm2). Mechanical properties of the coatings were also found to be improved in the presence of modified clay nanoparticle in tensile and hardness measurements. The use of nanoclays enhanced the anticorrosive behavior and physical integrity of the polymer–clay coatings under immersion tests. The surface morphology of the coated sample was analyzed by field-emission scanning electron microscopy and energy-dispersive X-ray spectroscopy. XRD analysis confirms the formation of metal complexes as the corrosion products at 40 days of immersion in 3.5% NaCl solution.

Similar content being viewed by others

References

Pal P, Kundu MK, Malas A, Das CK (2013) Compatibilizing effect of halloysite nanotubes in polar–nonpolar hybrid system. Appl Polym Sci 131:39587

Li Z, Expósito DF, Gonzalez AJ, Wang DY (2017) Natural halloysite nanotube based functionalized nano hybrid assembled via phosphorus-containing slow release method: a highly efficient way to impart flame retardancy to polylactide. Eur Polym J 93:458–470

Kryuchkova M, Danilushkina A, Lvov Y, Fakhrullin R (2016) Evaluation of toxicity of nanoclays and graphene oxide in vivo: a Paramecium caudatum study. Environ Sci Nano 3:442–452

Vahedi V, Pasbakhsh P (2014) Instrumented impact properties and fracture behaviour of epoxy/modified halloysite nanocomposites. Polym Test 39:101–114

Peprnicek T, Duchet J, Kovarova L, Malac J, Gerard JF, Simonik J (2006) Poly (vinyl chloride)/clay nanocomposites: x-ray diffraction, thermal and rheological behavior. Polym Degrad Stab 91:1855–1860

Lee JY, Lee HK (2004) Characterization of organo bentonite used for polymer nanocomposites. Mater Chem Phys 85:410–415

Morawiec J, Pawlak A, Slouf M, Galeski A, Piorkowska E, Krasnikowa N (2005) Preparation and properties of compatibilized LDPE/organo-modified montmorillonite nanocomposites. Eur Polym J 41:1115–1122

Gorrasi G, Tortora M, Vittoria V (2003) Vapor barrier properties of polycaprolactone montmorillonite nanocomposites: effect of clay dispersion. Polymer 44:2271–2279

Someya Y, Shibata M (2005) Morphology, thermal, and visco elastic properties of poly(glycidyl methacrylate-co-methyl methacrylate)-based nanocomposites with various organo modified clays. Polymer 46:4891–4898

Park J, Jana SC (2004) Adverse effects of thermal dissociation of alkyl ammonium ions on nanoclay exfoliation in epoxy–clay systems. Polymer 45:7673–7679

Cao X, James Lee L, Widya MTC (2005) Polyurethane/clay nanocomposites foams: processing, structure and properties. Polymer 46:775–783

Raj XJ (2017) Application of EIS and SECM studies for investigation of anticorrosion properties of epoxy coatings containing zinc oxide nanoparticles on mild steel in 3.5% NaCl solution. J Mater Eng Perform 26(7):3245–3253

Raj XJ, Nishimura T (2014) Corrosion protection performance of epoxy coated high tensile strength steel measured by scanning electrochemical microscope and electrochemical impedance spectroscopy techniques. ISIJ Int 54(3):693–699

Yeh JM, Chen CL, Chen YC (2002) Enhancement of corrosion protection effect of poly(o-ethoxyaniline) via the formation of poly(o-ethoxyaniline)-clay nanocomposite materials. Polymer 43:2729–2746

Hang TTX, Truc TA, Nam TH, Oanh VK, Jorcin JB, Pebere N (2007) Corrosion protection of carbon steel by an epoxy resin containing organically modified clay. Surf Coat Technol 201:7408–7415

Sugama T (2006) Polyphenylene sulfied/montomorillonite clay nanocomposite coatings: their efficacy in protecting steel against corrosion. Mater Lett 60:2700–2706

Yeh JM, Huang HY, Chen CL, Su WF, Yu YH (2006) Siloxane-modified epoxy resin-clay nanocomposite coatings with advanced anticorrosive properties prepared by a solution dispersion approach. Surf Coat Technol 200:2753–2763

Hedenqvist MS, Backman A, Gallstedt M, Boyd RH, Gedde UW (2006) Morphology and diffusion properties of whey/montmorillonite nanocomposites. Compos Sci Technol 66:2350–2359

Hackman I, Hollaway L (2006) Epoxy-layered silicate nanocomposites in civil engineering. Compos A 37:1161–1170

Azeez AA, Rhee KY, Park SJ, Hui D (2013) Epoxy clay nanocomposites—processing, properties and applications: a review. Compos B Eng 45:308–320

Boomadevi Janaki G, Xavier JR (2020) Evaluation of mechanical properties and corrosion protection performance of surface modified nano-alumina encapsulated epoxy coated mild steel. J Bio Tribo Corros 6:20. https://doi.org/10.1007/s40735-019-0316-7

Tomic MD, Dunjic B, Likic V, Bajat J, Rogan J, Djonlagic J (2014) The use of nanoclay in preparation of epoxy anticorrosive coatings. Prog Org Coat 77:518–527

Xavier JR (2018) Investigation on the effect of nano-ceria on the epoxy coatings for corrosion protection of mild steel in natural seawater. Anti-Corros Methods Mater 65:38–45

Xavier JR, Nallaiyan R (2016) Application of EIS and SECM studies for investigation of anticorrosion properties of epoxy coatings containing ZrO2 nanoparticles on mild steel in 3.5% NaCl solution. J Fail Anal Prev 16:1082–1091

Joseph Raj X, Nishimura T (2016) Evaluation of the corrosion protection performance of epoxy-coated high manganese steel by SECM and EIS techniques. J Fail Anal Prev 16:417–426

ASTM G106 (2004) Standard practice for verification of algorithm and equipment for electrochemical impedance measurements. ASTM International, West Conshohocken, PA, USA

Xavier JR, Nishimura T (2017) Evaluation of the corrosion protection performance of epoxy coatings containing Mg nanoparticle on carbon steel in 0.1 M NaCl solution by SECM and EIS techniques. J Coat Technol Res 14:395–406. https://doi.org/10.1007/s11998-016-9856-7

Yuan P, Southon PD, Hook JM (2008) Functionalization of halloysite clay nanotubes by grafting with aminopropyltriethoxysilane. J Phys Chem C 112:15742–15751

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Beryl, J.R., Xavier, J.R. Electrochemical and Mechanical Studies of Epoxy Coatings Containing Eco-Friendly Nanocomposite Consisting of Silane Functionalized Clay–Epoxy on Mild Steel. J Bio Tribo Corros 6, 126 (2020). https://doi.org/10.1007/s40735-020-00424-0

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40735-020-00424-0