Abstract

We develop multi-mode soft composite bending actuators based on glass fiber textiles interwoven with shape memory alloy (SMA) wires and a soft matrix of polydimethylsiloxane. We describe their detailed design and fabrication. We varied the interweaving patterns of SMA wires, such that the actuators exhibit multi-mode bending behaviors. Actuators with three different bending modes were fabricated, and their performances were evaluated in terms of curvature. We varied the stiffness of glass fiber textiles and the diameters of SMA wires. Bidirectional multi-mode actuations were achieved when SMA wires of different interwoven patterns were combined with glass fiber textiles. We present prototypes of such actuators and demonstrate their actuations. Finally, we prepared gripper prototypes using these actuators; they grasped different objects according to bending mode. Our technique will aid the development of soft robotics, as well as other scientific and engineering applications.

Similar content being viewed by others

References

Kim, S., Laschi, C., & Trimmer, B. (2013). Soft robotics: a bioinspired evolution in robotics. Trends Biotechnol, 31(5), 287–294. https://doi.org/10.1016/j.tibtech.2013.03.002.

Rus, D., & Tolley, M. T. (2015). Design, fabrication and control of soft robots. Nature, 521(7553), 467–475. https://doi.org/10.1038/nature14543.

Mirvakili, S. M., & Hunter, I. W. (2018). Artificial muscles: mechanisms, applications, and Challenges. Advanced materials, 30(6), 1704407. https://doi.org/10.1002/adma.201704407.

Mohd Jani, J., Leary, M., Subic, A., & Gibson, M. A. (2014). A review of shape memory alloy research, applications and opportunities. Materials & Design (1980–2015), 56, 1078–1113. https://doi.org/10.1016/j.matdes.2013.11.084

Han, M. W., Rodrigue, H., Cho, S., Song, S. H., Wang, W., Chu, W. S., & Ahn, S. H. (2016). Woven type smart soft composite for soft morphing car spoiler. Composites Part B: Engineering, 86, 285–298. https://doi.org/10.1016/j.compositesb.2015.10.009.

Jeong, J., Yasir, I. B., Han, J., Park, C. H., Bok, S. K., & Kyung, K. U. (2019). Design of shape memory alloy-based Soft Wearable Robot for assisting wrist motion. Applied Sciences, 9(19), 4025. https://doi.org/10.3390/app9194025.

Lee, S., Lee, S., Na, Y., Ahn, B., Jung, H., Cheng, S. S., Kim, N., Jun, T. S., & Kim, Y. (2019). Shock absorber mechanism based on an SMA spring for Lightweight Exoskeleton Applications. International Journal of Precision Engineering and Manufacturing, 20(9), 1533–1541. https://doi.org/10.1007/s12541-019-00169-y.

Zainal, M., Sahlan, S., & Ali, M. (2015). Micromachined shape-memory-alloy microactuators and their application in Biomedical Devices. Micromachines, 6(7), 879–901. https://doi.org/10.3390/mi6070879.

Akbari, S., Sakhaei, A. H., Panjwani, S., Kowsari, K., & Ge, Q. (2021). Shape memory alloy based 3D printed composite actuators with variable stiffness and large reversible deformation. Sensors and Actuators A: Physical, 321, 112598. https://doi.org/10.1016/j.sna.2021.112598.

Akbari, S., Sakhaei, A. H., Panjwani, S., Kowsari, K., Serjouei, A., & Ge, Q. (2019). Multimaterial 3D printed soft actuators powered by shape memory alloy wires. Sensors and Actuators A: Physical, 290, 177–189. https://doi.org/10.1016/j.sna.2019.03.015.

Du, Y., Liu, B., Xu, M., Dong, E., Zhang, S., & Yang, J. (2015). Dynamic characteristics of planar bending actuator embedded with shape memory alloy. Mechatronics, 25, 18–26. https://doi.org/10.1016/j.mechatronics.2014.11.001.

Kim, H. I., Han, M. W., Song, S. H., & Ahn, S. H. (2016). Soft morphing hand driven by SMA tendon wire. Composites Part B: Engineering, 105, 138–148. https://doi.org/10.1016/j.compositesb.2016.09.004.

Li, J., Zu, L., Zhong, G., He, M., Yin, H., & Tan, Y. (2017). Stiffness characteristics of soft finger with embedded SMA fibers. Composite Structures, 160, 758–764. https://doi.org/10.1016/j.compstruct.2016.10.045.

Costanza, G., & Tata, M. E. (2020). Shape memory alloys for Aerospace, recent developments, and New Applications: a short review. Materials (Basel), 13(8), 1856. https://doi.org/10.3390/ma13081856.

Han, M. W., Rodrigue, H., Kim, H. I., Song, S. H., & Ahn, S. H. (2016). Shape memory alloy/glass fiber woven composite for soft morphing winglets of unmanned aerial vehicles. Composite Structures, 140, 202–212. https://doi.org/10.1016/j.compstruct.2015.12.051.

Lee, S. H., & Kim, S. W. (2020). Self-sensing-based deflection control of carbon fibre-reinforced polymer (CFRP)-based shape memory alloy hybrid composite beams. Composite Structures, 251, 112544. https://doi.org/10.1016/j.compstruct.2020.112544.

Shim, J. E., Quan, Y. J., Wang, W., Rodrigue, H., Song, S. H., & Ahn, S. H. (2015). A smart soft actuator using a single shape memory alloy for twisting actuation. Smart Materials and Structures, 24(12), 125033. https://doi.org/10.1088/0964-1726/24/12/125033.

Lohse, F., Kopelmann, K., Grellmann, H., Ashir, M., Gereke, T., Hantzsche, E., Sennewald, C., & Cherif, C. (2022). Experimental and Numerical Analysis of the deformation behavior of Adaptive Fiber-Rubber Composites with Integrated shape memory alloys. Materials (Basel), 15(2), 582. https://doi.org/10.3390/ma15020582.

Smith, C., Villanueva, A., Joshi, K., Tadesse, Y., & Priya, S. (2011). Working principle of bio-inspired shape memory alloy composite actuators. Smart Materials and Structures, 20(1), 012001. https://doi.org/10.1088/0964-1726/20/1/012001.

Ashir, M., & Cherif, C. (2020). Development of shape memory alloy-based adaptive fiber-reinforced plastics by means of open reed weaving technology. Journal of Reinforced Plastics and Composites, 39(15–16), 563–571. https://doi.org/10.1177/0731684420920941.

Ashir, M., Vorhof, M., & Nocke, A. (2019). Influence of thickness ratio and integrated weft yarn column numbers in shape memory alloys on the deformation behavior of adaptive fiber-reinforced plastics. Composite Structures, 215, 493–501. https://doi.org/10.1016/j.compstruct.2019.02.081.

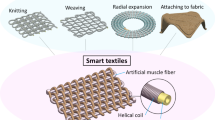

Fu, C., Xia, Z., Hurren, C., Nilghaz, A., & Wang, X. (2022). Textiles in soft robots: current progress and future trends. Biosensors & Bioelectronics, 196, 113690. https://doi.org/10.1016/j.bios.2021.113690.

Ke, J., Gao, J., Wu, Z., Xiang, Z., & Hu, X. (2022). Vari-stiffness characteristics of a 3D SMA hybrid basalt woven composite. Composite Structures, 285, 115192. https://doi.org/10.1016/j.compstruct.2022.115192.

Song, S. H., Lee, J. Y., Rodrigue, H., Choi, I. S., Kang, Y. J., & Ahn, S. H. (2016). 35 hz shape memory alloy actuator with bending-twisting mode. Scientific reports, 6, 21118. https://doi.org/10.1038/srep21118.

Lee, J. H., Chung, Y. S., & Rodrigue, H. (2019). Long shape memory Alloy Tendon-based Soft robotic actuators and implementation as a soft gripper. Scientific reports, 9(1), 11251. https://doi.org/10.1038/s41598-019-47794-1.

Rodrigue, H., Wang, W., Bhandari, B., Han, M. W., & Ahn, S. H. (2015). SMA-based smart soft composite structure capable of multiple modes of actuation. Composites Part B: Engineering, 82, 152–158. https://doi.org/10.1016/j.compositesb.2015.08.020.

Wu, R., Han, M. W., Lee, G. Y., & Ahn, S. H. (2013). Woven type smart soft composite beam with in-plane shape retention. Smart Materials and Structures, 22(12), 125007. https://doi.org/10.1088/0964-1726/22/12/125007.

Rodrigue, H., Wang, W., Kim, D. R., & Ahn, S. H. (2017). Curved shape memory alloy-based soft actuators and application to soft gripper. Composite Structures, 176, 398–406. https://doi.org/10.1016/j.compstruct.2017.05.056.

She, Y., Li, C., Cleary, J., & Su, H. J. (2015). Design and fabrication of a Soft Robotic Hand with embedded actuators and sensors. Journal of Mechanisms and Robotics, 7(2), 021007. https://doi.org/10.1115/1.4029497.

Shintake, J., Cacucciolo, V., Floreano, D., & Shea, H. (2018). Soft robotic grippers. Advanced materials, 30(29), 1707035. https://doi.org/10.1002/adma.201707035.

Wang, W., & Ahn, S. H. (2017). Shape memory alloy-based soft gripper with variable stiffness for compliant and effective grasping. Soft robotics, 4(4), 379–389. https://doi.org/10.1089/soro.2016.0081.

Wang, W., Rodrigue, H., Kim, H. I., Han, M. W., & Ahn, S. H. (2016). Soft composite hinge actuator and application to compliant robotic gripper. Composites Part B: Engineering, 98, 397–405. https://doi.org/10.1016/j.compositesb.2016.05.030.

Wang, W., Tang, Y., & Li, C. (2021). Controlling bending deformation of a shape memory alloy-based soft planar gripper to grip deformable objects. International Journal of Mechanical Sciences, 193, 106181. https://doi.org/10.1016/j.ijmecsci.2020.106181.

Han, M. W., Kim, M. S., & Ahn, S. H. (2020). Shape memory textile composites with multi–mode actuations for soft morphing skins. Composites Part B: Engineering, 198, 108170. https://doi.org/10.1016/j.compositesb.2020.108170.

Sharma, A. K., Bhandari, R., Aherwar, A., & Rimašauskienė, R. (2020). Matrix materials used in composites: A comprehensive study. Materials Today: Proceedings, 21, 1559–1562. https://doi.org/10.1016/j.matpr.2019.11.086

Nespoli, A., Besseghini, S., Pittaccio, S., Villa, E., & Viscuso, S. (2010). The high potential of shape memory alloys in developing miniature mechanical devices: a review on shape memory alloy mini-actuators. Sensors and Actuators A: Physical, 158(1), 149–160. https://doi.org/10.1016/j.sna.2009.12.020.

Bekker, A., & Brinson, L. C. (1997). Temperature-induced phase transformation in a shape memory alloy: phase diagram based kinetics approach. Journal of the Mechanics and Physics of Solids, 45(6), 949–988. https://doi.org/10.1016/S0022-5096(96)00111-1.

Lalegani Dezaki, M., Bodaghi, M., Serjouei, A., Afazov, S., & Zolfagharian, A. (2022). Adaptive reversible composite-based shape memory alloy soft actuators. Sensors and Actuators A: Physical, 345, 113779. https://doi.org/10.1016/j.sna.2022.113779.

Mersch, J., Bruns, M., Nocke, A., Cherif, C., & Gerlach, G. (2021). High-Displacement, Fiber‐Reinforced shape memory Alloy Soft Actuator with Integrated Sensors and its Equivalent Network Model. Advanced Intelligent Systems, 3(7), 2000221. https://doi.org/10.1002/aisy.202000221.

Leary, M., Huang, S., Ataalla, T., Baxter, A., & Subic, A. (2013). Design of shape memory alloy actuators for direct power by an automotive battery. Materials & Design, 43, 460–466. https://doi.org/10.1016/j.matdes.2012.07.002.

Furst, S. J., & Seelecke, S. (2012). Modeling and experimental characterization of the stress, strain, and resistance of shape memory alloy actuator wires with controlled power input. Journal of Intelligent Material Systems and Structures, 23(11), 1233–1247. https://doi.org/10.1177/1045389x12445036.

Dana, A., Vollach, S., & Shilo, D. (2021). Use the force: review of high-rate actuation of shape memory alloys. Actuators, 10(7), 140. https://doi.org/10.3390/act10070140.

Jeong, S., & Yoo, H. H. (2017). Flexibility modeling of a beam undergoing large deflection using the assumed mode method. International Journal of Mechanical Sciences, 133, 611–618. https://doi.org/10.1016/j.ijmecsci.2017.08.059.

Shin, J. H., Park, J. G., Kim, D. I., Yoon, H. S. (2021). A universal soft gripper with the optimized fin ray finger. International Journal of Precision Engineering and Manufacturing-Green Technology, 8(3), 889–899. https://doi.org/10.1007/s40684-021-00348-1

Gwon, M., Park, G., Hong, D., Park, Y-J., Han, S., Kang, D., Koh, J. (2022). Soft directional adhesion gripper fabricated by 3D printing process for gripping flexible printed circuit boards. International Journal of Precision Engineering and Manufacturing-Green Technology, 9(4), 1151–1163. https://doi.org/10.1007/s40684-021-00368-x

Huang, X., Ford, M., Patterson, Z. J., Zarepoor, M., Pan, C., Majidi, C. (2020). Shape memory materials for electrically-powered soft machines. Journal of Materials Chemistry B, 8(21), 4539–4551. https://doi.org/10.1039/D0TB00392A

Park, S., Koh, D., Shim, J., Kim, J.-J., Lee, S.-K. (2021). Gantry type lapping manipulator toward unmanned lapping process for a large work surface. International Journal of Precision Engineering and Manufacturing-Green Technology, 8(6), 1723–1737. https://doi.org/10.1007/s40684-020-00274-8

Rus, D., Tolley, M. T. (2015). Design fabrication and control of soft robots. Nature, 521(7553), 467–475. https://doi.org/10.1038/nature14543

Pham, A.-D., Ahn, H.-J. (2021). Rigid precision reducers for machining industrial robots. International Journal of Precision Engineering and Manufacturing, 22(8), 1469–1486. https://doi.org/10.1007/s12541-021-00552-8

Lee, C., Kim, S., Chu, B. (2021). A survey: flight mechanism and mechanical structure of the UAV. International Journal of Precision Engineering and Manufacturing, 22(4), 719–743. https://doi.org/10.1007/s12541-021-00489-y

Acknowledgements

This work was supported by the grant funded by Ministry of Trade, Industry and Energy (MOTIE, Korea) and the Korea Evaluation Institute of Industrial Technology (KEIT) (Grant No. 20006388, and No. 20017462); and the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIT) (No. NRF-2020R1A2C4001731).

Author information

Authors and Affiliations

Contributions

G-YL conceptualized this work. G-YL and OT designed the materials and specimens. G-YL and G-SL designed the experiments and set the experimental setups. OT and G-YL fabricated the specimens. G-YL, OT, G-SL conducted the experiments. G-YL and OT analyzed the data and wrote the paper, and all authors provided feedback. G-YL supervised the project.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic Supplementary Material

Below is the link to the electronic supplementary material.

Supplementary file1 (MP4 3179 KB)

Supplementary file1 (MP4 2787 KB)

Supplementary file1 (MP4 1142 KB)

Supplementary file1 (MP4 5465 KB)

Supplementary file1 (MP4 6132 KB)

Supplementary file1 (MP4 7651 KB)

Supplementary file1 (MP4 5701 KB)

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tuyboyov, O.V., Lee, GS. & Lee, GY. Multi-mode Soft Composite Bending Actuators Based on Glass fiber Textiles Interwoven with Shape Memory Alloy Wires: Development and use in the Preparation of Soft Grippers. Int. J. of Precis. Eng. and Manuf.-Green Tech. 10, 1263–1280 (2023). https://doi.org/10.1007/s40684-022-00491-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40684-022-00491-3