Abstract

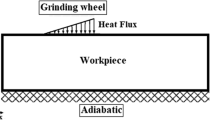

With the increasing requirements of environmental protection, energy conservation, and low consumption, minimum quantity lubrication (MQL) technology has attracted people’s attention. In the grinding process, the cooling performance of MQL has always been the focus. In this study, considering the influence of the grinding wheel speed, grinding fluid flow rate, and gas pressure on the useful flow rate, the MQL grinding cooling performance was studied and analyzed, and the MQL grinding heat transfer coefficient model, grinding energy partition model and grinding temperature calculation model were established. Grinding experiments were carried out with maraging steel 3J33 as the experimental object, of which the results verified the accuracy of the model. The error of temperature calculation model is 9.45%. The influence of different parameters on the surface processing quality of the workpiece was studied through experimental results. The results show that the grinding wheel speed and gas pressure have a more significant influence on the useful flow rate of the grinding fluid. The grinding fluid flow rate but significant impact on the surface quality of the workpiece.

Similar content being viewed by others

Availability of data and materials

Not applicable.

Code availability

Not applicable.

References

Li, K. M., & Chou, S. Y. (2010). Experimental evaluation of minimum quantity lubrication in near micro-milling. Journal of Materials Processing Technology, 210(15), 2163–2170. https://doi.org/10.1016/j.jmatprotec.2010.07.031

Sun, C., Xiu, S., Hong, Y., Kong, X., & Lu, Y. (2021). Prediction on residual stress with mechanical-thermal and transformation coupled in DGH. International Journal of Mechanical Sciences. https://doi.org/10.1016/j.ijmecsci.2020.105629

Zhang, Y., Wang, Q., Li, C., Piao, Y., Hou, N., & Hu, K. (2021). Characterization of surface and subsurface defects induced by abrasive machining of optical crystals using grazing incidence X-ray diffraction and molecular dynamics. Journal of Advanced Research. https://doi.org/10.1016/j.jare.2021.05.006

Guo, W. C., Wu, C. J., Ding, Z. S., & Zhou, Q. Z. (2021). Prediction of surface roughness based on a hybrid feature selection method and long short-term memory network in grinding. International Journal of Advanced Manufacturing Technology, 112(9–10), 2853–2871. https://doi.org/10.1007/s00170-020-06523-z

Zhu, D. H., Feng, X. Z., Xu, X. H., Yang, Z. Y., Li, W. L., Yan, S. J., et al. (2020). Robotic grinding of complex components: A step towards efficient and intelligent machining-challenges, solutions, and applications. Robotics and Computer-Integrated Manufacturing, 65, 101908. https://doi.org/10.1016/j.rcim.2019.101908

Lopes, J. C., Fragoso, K. M., Garcia, M. V., Ribeiro, F. S. F., Francelin, A. P., Sanchez, L. E. D., et al. (2019). Behavior of hardened steel grinding using MQL under cold air and MQL CBN wheel cleaning. International Journal of Advanced Manufacturing Technology, 105(10), 4373–4387. https://doi.org/10.1007/s00170-019-04571-8

Yang, M., Li, C. H., Zhang, Y. B., Jia, D. Z., Zhang, X. P., Hou, Y. L., et al. (2017). Maximum undeformed equivalent chip thickness for ductile-brittle transition of zirconia ceramics under different lubrication conditions. International Journal of Machine Tools and Manufacture, 122, 41–51. https://doi.org/10.1016/j.ijmachtools.2017.06.003

Tawakoli, T., Hadad, M. J., & Sadeghi, M. H. (2010). Influence of oil mist parameters on minimum quantity lubrication—MQL grinding process. International Journal of Machine Tools and Manufacture, 50(6), 521–531. https://doi.org/10.1016/j.ijmachtools.2010.03.005

Jia, D. Z., Li, C. H., Zhang, D. K., Zhang, Y. B., & Zhang, X. W. (2014). Experimental verification of nanoparticle jet minimum quantity lubrication effectiveness in grinding. Journal of Nanoparticle Research, 16(12), 1–15. https://doi.org/10.1007/s11051-014-2758-7

Shao, Y. M., Fergani, O., Ding, Z. S., Li, B. Z., & Liang, S. Y. (2016). Experimental investigation of residual stress in minimum quantity lubrication grinding of AISI 1018 steel. Journal of Manufacturing Science and Engineering-Transactions of the Asme, 138(1), 711–718. https://doi.org/10.1115/1.4029956

Ding, Z., Li, B., Liang, S. Y., Ding, Z. S., Li, B. Z., & Liang, S. Y. (2015). Maraging steel phase transformation in high strain rate grinding. International Journal of Advanced Manufacturing Technology, 80(1–4), 711–718. https://doi.org/10.1007/s00170-015-7014-5

Zhuang, K., Fu, C., Weng, J., & Hu, C. (2021). Cutting edge microgeometries in metal cutting: A review. The International Journal of Advanced Manufacturing Technology. https://doi.org/10.1007/s00170-021-07558-6

Xiao, G., Song, K., He, Y., Wang, W., Zhang, Y., & Dai, W. (2021). Prediction and experimental research of abrasive belt grinding residual stress for titanium alloy based on analytical method. The International Journal of Advanced Manufacturing Technology, 115, 1111–1125. https://doi.org/10.1007/s00170-021-07272-3

Li, C., Li, X. L., Huang, S. Q., Li, L. Q., & Zhang, F. H. (2021). Ultra-precision grinding of Gd3Ga5O12 crystals with graphene oxide grinding fluid: Material deformation mechanism and performance evaluation. Journal of Manufacturing Processes, 61, 417–427. https://doi.org/10.1016/j.jmapro.2020.11.037

Sun, C., Duan, J. C., Lan, D. X., Liu, Z. X., & Xiu, S. C. (2018). Prediction about ground hardening layers distribution on grinding chatter by contact stiffness. Archives of Civil and Mechanical Engineering, 18(4), 1626–1642. https://doi.org/10.1016/j.acme.2018.06.010

Xi, X. X., Zhu, Y. J., Chen, T., Wu, Z. X., Angge, I. L., & Ding, W. F. (2021). Surface burn behavior in creep-feed deep grinding of gamma titanium aluminide intermetallic: characterization, mechanism, and effects. International Journal of Advanced Manufacturing Technology, 113(3–4), 985–996. https://doi.org/10.1007/s00170-021-06677-4

Ji, X., Li, B. Z., Zhang, X. P., & Liang, S. Y. (2014). The effects of minimum quantity lubrication (MQL) on machining force, temperature, and residual stress. International Journal of Precision Engineering and Manufacturing, 15(11), 2443–2451. https://doi.org/10.1007/s12541-014-0612-6

Balan, A. S. S., Vijayaraghavan, L., & Krishnamurthy, R. (2013). Minimum quantity lubricated grinding of Inconel 751 alloy. Materials and Manufacturing Processes, 28(4), 430–435. https://doi.org/10.1080/10426914.2013.763965

Liao, Y. S., Liao, C. H., & Lin, H. M. (2017). Study of oil-water ratio and flow rate of MQL fluid in high speed milling of Inconel 718. International Journal of Precision Engineering and Manufacturing, 18(2), 257–262. https://doi.org/10.1007/s12541-017-0033-4

Huang, X. M., Ren, Y. H., Li, T., Zhou, Z. X., & Zhang, G. F. (2018). Influence of minimum quantity lubrication parameters on grind-hardening process. Materials and Manufacturing Processes, 33(1), 69–76. https://doi.org/10.1080/10426914.2016.1269916

Balan, A. S. S., Kullarwar, T., Vijayaraghavan, L., & Krishnamurthy, R. (2017). Computational fluid dynamics analysis of MQL spray parameters and its influence on superalloy grinding. Machining Science and Technology, 21(4), 603–616. https://doi.org/10.1080/10910344.2017.1365889

Silva, L. R., Correa, E. C. S., Brandao, J. R., & De Avila, R. F. (2020). Environmentally friendly manufacturing: Behavior analysis of minimum quantity of lubricant—MQL in grinding process. Journal of Cleaner Production. https://doi.org/10.1016/j.jclepro.2013.01.033

Sun, Y., Su, Z., Gong, Y., Ba, D., Yin, G., Zhang, H., & Zhou, L. (2021). Analytical and experimental study on micro-grinding surface-generated mechanism of DD5 single-crystal superalloy using micro-diamond pencil grinding tool. Archives of Civil and Mechanical Engineering, 21(1), 1–22. https://doi.org/10.1007/s43452-020-00163-6

Liu, H., Song, W. Q., Niu, Y. H., & Zio, E. (2021). Generalized cauchy method for remaining useful life prediction of wind turbine gearboxes. Mechanical Systems and Signal Processing, 153(15), 107471. https://doi.org/10.1016/j.ymssp.2020.107471

Yang, M., Li, C. H., Zhang, Y. B., Wang, Y. G., Li, B. K., Jia, D. Z., et al. (2017). Research on microscale skull grinding temperature field under different cooling conditions. Applied Thermal Engineering, 126, 525–537. https://doi.org/10.1016/j.applthermaleng.2017.07.183

Jamshidi, H., & Budak, E. (2018). Grinding temperature modeling based on a time dependent heat source. 8th Cirp Conference on High Performance Cutting (Hpc 2018), 77, 299–302. https://doi.org/10.1016/j.procir.2018.09.020

Ding, Z. S., Jiang, X. H., Guo, M. X., & Liang, S. Y. (2018). Investigation of the grinding temperature and energy partition during cylindrical grinding. International Journal of Advanced Manufacturing Technology, 97(5–8), 1767–1778. https://doi.org/10.1007/s00170-018-1900-6

Sharmin, I., Moon, M., Talukder, S., Alam, M., & Ahmed, M. F. (2021). Impact of nozzle design on grinding temperature of hardened steel under MQL condition. Materials Today-Proceedings, 38, 3232–3237. https://doi.org/10.1016/j.matpr.2020.09.717

Li, B. K., Li, C. H., Zhang, Y. B., Wang, Y. G., Jia, D. Z., & Min, Y. (2016). Grinding temperature and energy ratio coefficient in MQL grinding of high-temperature nickel-base alloy by using different vegetable oils as base oil. Chinese Journal of Aeronautics, 29(4), 1084–1095. https://doi.org/10.1016/j.cja.2015.10.012

Wang, Y. G., Li, C. H., Zhang, Y. B., Yang, M., Li, B. K., Jia, D. Z., et al. (2016). Experimental evaluation of the lubrication properties of the wheel/workpiece interface in minimum quantity lubrication (MQL) grinding using different types of vegetable oils. Journal of Cleaner Production, 127, 487–499. https://doi.org/10.1016/j.jclepro.2016.03.121

Zhang, Y. B., Li, C. H., Jia, D. Z., Zhang, D. K., & Zhang, X. W. (2015). Experimental evaluation of MoS2 nanoparticles in jet MQL grinding with different types of vegetable oil as base oil. Journal of Cleaner Production, 87, 930–940. https://doi.org/10.1016/j.jclepro.2014.10.027

Hadad, M., & Sadeghi, B. (2012). Thermal analysis of minimum quantity lubrication-MQL grinding process. International Journal of Machine Tools & Manufacture, 63, 1–15. https://doi.org/10.1016/j.jclepro.2014.10.027

Kim, H. J., Kim, N. K., & Kwak, J. S. (2006). Heat flux distribution model by sequential algorithm of inverse heat transfer for determining workpiece temperature in creep feed grinding. International Journal of Machine Tools and Manufacture, 46(15), 2086–2093. https://doi.org/10.1016/j.ijmachtools.2005.12.007

Guo, C., & Malkin, S. (1992). First international conference on transport phenomena in processing. Heat transfer in grinding. (pp. 377). Technomic Publishing Company Inc

Sai, S. S., Manojkumar, K., & Ghosh, A. (2015). Assessment of spray quality from an external mix nozzle and its impact on SQL grinding performance. International Journal of Machine Tools and Manufacture, 89, 132–141. https://doi.org/10.1016/j.ijmachtools.2014.10.004

Hadad, M. J., Tawakoli, T., Sadeghi, M. H., & Sadeghi, B. (2012). Temperature and energy partition in minimum quantity lubrication-MQL grinding process. International Journal of Machine Tools and Manufacture, 54–55, 10–17. https://doi.org/10.1016/j.ijmachtools.2011.11.010

Ding, Z. S., Sun, G. X., Guo, M. X., Jiang, X. H., Li, B. Z., & Liang, S. Y. (2020). Effect of phase transition on micro-grinding-induced residual stress. Journal of Materials Processing Technology, 281, 116647. https://doi.org/10.1016/j.jmatprotec.2020.116647

Zhao, M., Mao, J., Ji, X., Feng, Y. X., & Liang, S. Y. (2021). Effect of crystallographic orientation on residual stress induced in micro-grinding. International Journal of Advanced Manufacturing Technology, 112(5–6), 1271–1284. https://doi.org/10.1007/s00170-020-06329-z

Jiang, X. H., Kong, X. J., Zhang, Z. Y., Wu, Z. P., Ding, Z. S., & Guo, M. X. (2020). Modeling the effects of Undeformed Chip Volume (UCV) on residual stresses during the milling of curved thin-walled parts. International Journal of Mechanical Sciences. https://doi.org/10.1016/j.ijmecsci.2019.105162

Wu, C. J., Pang, J. Z., Li, B. Z., & Liang, S. Y. (2019). High-speed grinding of HIP-SiC ceramics on transformation of microscopic features. International Journal of Advanced Manufacturing Technology, 102(5–8), 1913–1921. https://doi.org/10.1007/s00170-018-03226-4

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant number 51705323).

Funding

The National Natural Science Foundation of China (Grant number 51705323).

Author information

Authors and Affiliations

Contributions

ZD: conceptualization; investigation; resources; methodology; writing—reviewing and editing; project administration; funding acquisition. JS: investigation; data curation; formal analysis; methodology; validation; writing—original draft; writing—reviewing and editing. WG: investigation; data curation; formal analysis; writing—reviewing and editing. XJ and CW: validation; resources. SYL: supervision.

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ding, Z., Sun, J., Guo, W. et al. Thermal Analysis of 3J33 Grinding Under Minimum Quantity Lubrication Condition. Int. J. of Precis. Eng. and Manuf.-Green Tech. 9, 1247–1265 (2022). https://doi.org/10.1007/s40684-021-00391-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40684-021-00391-y