Abstract

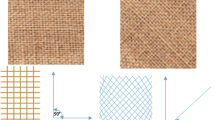

Green composites can reduce the use of synthetic fibers in many applications. The motivation behind the fabrication of green composites is their excellent biodegradability and recyclability. However, fundamental issues related to green composites are their inferior mechanical properties and the reinforcement’s hydrophilic nature. This paper presents the hand layup technique to produce green composites containing different ratios of synthetic fiber (E-glass) and natural fiber (Jute). The mechanical properties were characterized as per ASTM standards. The impact strength was also investigated for different impact energies. In addition to this, the numerical simulations using ABAQUS were performed. The experimental results for tensile and flexural results were compared and validated with finite element analysis (FEA) results. An error of nearly 4% was observed between the numerical and experimental results. The microscopic analysis of fractured tensile specimens indicated that more pull out of jute fabric in high jute weight percentage composites was the leading cause of its lower tensile strength.

Similar content being viewed by others

References

Siregar, J. P., et al. (2019). The effect of maleic anhydride polyethylene on mechanical properties of pineapple leaf fibre reinforced polylactic acid composites. International Journal of Precision Engineering and Manufacturing-Green Technology, 6(1), 101–112. https://doi.org/10.1007/s40684-019-00018-3

Ali, H. T., et al. (2021). Fiber reinforced polymer composites in bridge industry. Structures, 30, 774–785. https://doi.org/10.1016/j.istruc.2020.12.092

Khalid, M. Y., et al. (2021). Developments in chemical treatments, manufacturing techniques and potential applications of natural-fibers-based biodegradable composites. Coatings, 11(3), 293. https://doi.org/10.3390/coatings11030293

Malinowski, R., et al. (2020). Studies on manufacturing, mechanical properties and structure of poly(butylene adipate-co-terephthalate)-based green composites modified by coconut fibers. International Journal of Precision Engineering and Manufacturing - Green Technology, 7(6), 1095–1105. https://doi.org/10.1007/S40684-019-00171-9

Shah, A. U. R., Prabhakar, M. N., & Song, J.-I. (2017). Current advances in the fire retardancy of natural fiber and bio-based composites–A review. International Journal of Precision Engineering and Manufacturing-Green Technology, 4(2), 247–262. https://doi.org/10.1007/s40684-017-0030-1

Khalid, M. Y., Al Rashid, A., Arif, Z. U., Ahmed, W., Arshad, H., & Zaidi, A. A. (2021). Natural fiber reinforced composites: Sustainable materials for emerging applications. Results in Engineering, 11, 100263. https://doi.org/10.1016/J.RINENG.2021.100263

Kim, J.-H., et al. (2015). Review of nanocellulose for sustainable future materials. International Journal of Precision Engineering and Manufacturing-Green Technology, 2(2), 197–213. https://doi.org/10.1007/s40684-015-0024-9

Jaafar, J., Siregar, J. P., Mohd Salleh, S., Mohd Hamdan, M. H., Cionita, T., & Rihayat, T. (2019). Important considerations in manufacturing of natural fiber composites: A review. International Journal of Precision Engineering and Manufacturing - Green Technology, 6(3), 647–664. https://doi.org/10.1007/s40684-019-00097-2

Dwivedi, S. P., & Srivastava, A. K. (2019). Utilization of chrome containing leather waste in development of aluminium based green composite material. International Journal of Precision Engineering and Manufacturing-Green Technology, 7, 781–790. https://doi.org/10.1007/s40684-019-00179-1

Chaitanya, S., & Singh, I. (2018). Ecofriendly treatment of aloe vera fibers for PLA based green composites. International Journal of Precision Engineering and Manufacturing-Green Technology, 5(1), 143–150. https://doi.org/10.1007/s40684-018-0015-8

Khalid, M. Y., Al Rashid, A., Arif, Z. U., Sheikh, M. F., Arshad, H., & Nasir, M. A. (2021). Tensile strength evaluation of glass/jute fibers reinforced composites: An experimental and numerical approach. Results in Engineering, 10, 100232. https://doi.org/10.1016/j.rineng.2021.100232

Mastura, M. T., Sapuan, S. M., Mansor, M. R., & Nuraini, A. A. (2018). Materials selection of thermoplastic matrices for ‘green’ natural fibre composites for automotive anti-roll bar with particular emphasis on the environment. International Journal of Precision Engineering and Manufacturing-Green Technology, 5(1), 111–119. https://doi.org/10.1007/s40684-018-0012-y

Khalid, M. Y., Al Rashid, A., Arif, Z. U., Ahmed, W., & Arshad, H. (2021). Recent advances in nanocellulose-based different biomaterials: types, properties, and emerging applications. Journal of Materials Research and Technology, 14, 2601–2623. https://doi.org/10.1016/J.JMRT.2021.07.128

Paglicawan, M. A., Kim, B. S., Basilia, B. A., Emolaga, C. S., Marasigan, D. D., & Maglalang, P. E. C. (2014). Plasma-treated abaca fabric/unsaturated polyester composite fabricated by vacuum-assisted resin transfer molding. International Journal of Precision Engineering and Manufacturing-Green Technology, 1(3), 241–246. https://doi.org/10.1007/s40684-014-0030-3

Khalid, M. Y., Al Rashid, A., & Sheikh, M. F. (2021). Effect of anodizing process on inter laminar shear strength of GLARE composite through T-peel test: Experimental and numerical approach. Experimental Techniques, 45, 227–235. https://doi.org/10.1007/s40799-020-00433-1

Khalid, M. Y., et al. (2021). Interlaminar shear strength (ILSS) characterization of fiber metal laminates (FMLs) manufactured through VARTM process. Forces in Mechanics, 4, 100038. https://doi.org/10.1016/J.FINMEC.2021.100038

Jothibasu, S., Mohanamurugan, S., Vijay, R., Lenin Singaravelu, D., Vinod, A., & Sanjay, M. R. (2018). Investigation on the mechanical behavior of areca sheath fibers/jute fibers/glass fabrics reinforced hybrid composite for light weight applications. Journal of Industrial Textiles. https://doi.org/10.1177/1528083718804207

Khalid, M. Y., Al Rashid, A., Arif, Z. U., Akram, N., Arshad, H., & García Márquez, F. P. (2021). Characterization of failure strain in fiber reinforced composites: Under on-axis and off-axis loading. Crystals, 11(2), 216. https://doi.org/10.3390/cryst11020216

Chandekar, H., Chaudhari, V., & Waigaonkar, S. (2020). A review of jute fiber reinforced polymer composites. Materials Today: Proceedings, 26, 2079–2082. https://doi.org/10.1016/j.matpr.2020.02.449

Saleem, M. H., et al. (2020). Jute: A potential candidate for phytoremediation of metals—A review. Plants, 9(2), 1–14. https://doi.org/10.3390/plants9020258

Maity, S., Singha, K., Gon, D. P., Paul, P., & Singha, M. (2012). A review on jute nonwovens: Manufacturing, properties and applications. International Journal of Textile Science, 1(5), 36–43. https://doi.org/10.5923/j.textile.20120105.02

Rafiquzzaman, M., Islam, M., Rahman, H., Talukdar, S., & Hasan, N. (2016). Mechanical property evaluation of glass–jute fiber reinforced polymer composites. Polymers for Advanced Technologies, 27(10), 1308–1316. https://doi.org/10.1002/pat.3798

Al Rashid, A., Imran, R., & Khalid, M. Y. (2020). Determination of opening stresses for railway steel under low cycle fatigue using digital image correlation. Theoretical and Applied Fracture Mechanics, 108, 102601. https://doi.org/10.1016/j.tafmec.2020.102601

Rashid, A.A., Imran, R., Arif, Z. U., and Khalid, M. Y. (2021). Finite element simulation technique for evaluation of opening stresses under high plasticity. Journal of Manufacturing Science and Engineering, 143(12), 121005. https://doi.org/10.1115/1.4051328

Lee, M. S., Seo, H. Y., & Kang, C. G. (2016). Comparative study on mechanical properties of CR340/CFRP composites through three point bending test by using theoretical and experimental methods. International Journal of Precision Engineering and Manufacturing-Green Technology, 3(4), 359–365. https://doi.org/10.1007/s40684-016-0045-z

Ali, A., et al. (2019). Experimental and numerical characterization of mechanical properties of carbon/jute fabric reinforced epoxy hybrid composites. Journal of Mechanical Science and Technology, 33(9), 4217–4226. https://doi.org/10.1007/s12206-019-0817-9

Rafiquzzaman, M., Zannat, M., Roy, R., & Sultana, M. N. (2017). Jute-glass fiber based composite for engineering application. European Journal of Advances Engineering and Technology, 4(7), 510–515.

Acharya, S. K., Bera, T., Prakash, V., & Pradhan, S. (2020). Materials Today: Proceedings Effect of stacking sequence on the tribological behaviour of jute-glass hybrid epoxy composite. Materials Today: Proceedings, 28, 936–939. https://doi.org/10.1016/j.matpr.2019.12.328

Bandaru, A. K., Patel, S., Sachan, Y., Ahmad, S., Alagirusamy, R., & Bhatnagar, N. (2016). Mechanical behavior of Kevlar/basalt reinforced polypropylene composites. Composites Part A: Applied Science and Manufacturing, 90, 642–652. https://doi.org/10.1016/j.compositesa.2016.08.031

Damanpack, A. R., Bodaghi, M., & Liao, W. H. (2020). Contact/impact modeling and analysis of 4D printed shape memory polymer beams. Smart Materials and Structures, 29(8), 85016. https://doi.org/10.1088/1361-665x/ab883a

Asadi, H., Bodaghi, M., Shakeri, M., & Aghdam, M. M. (2015). Nonlinear dynamics of SMA-fiber-reinforced composite beams subjected to a primary/secondary-resonance excitation. Acta Mechanica, 226(2), 437–455. https://doi.org/10.1007/s00707-014-1191-4

Isavand, S., Bodaghi, M., Shakeri, M., & Aghazadeh, M. (2015). Dynamic response of functionally gradient austenitic-ferritic steel composite panels under thermo-mechanical loadings. Steel and Composite Structures, 18(1), 1–28.

Sudheer, M., Pradyoth, K. R., & Somayaji, S. (2015). Analytical and numerical validation of epoxy/glass structural composites for elastic models. American Journal of Materials Science, 5(3C), 162–168. https://doi.org/10.5923/c.materials.201502.32

Nirbhay, M., Dixit, A., Misra, R. K., & Mali, H. S. (2014). Tensile test simulation of CFRP test specimen using finite elements. Procedia Materials Science, 5, 267–273. https://doi.org/10.1016/j.mspro.2014.07.266

Abhishek, A. P., Gowda, B. S. K., Prasad, G. L. E., & Velmurugan, R. (2017). Probabilistic study of tensile and flexure properties of untreated jute fiber reinforced polyester composite. Materials Today: Proceedings, 4(10), 11050–11055. https://doi.org/10.1016/j.matpr.2017.08.066

Braga, R. A., & Magalhaes, P. A. A. (2015). Analysis of the mechanical and thermal properties of jute and glass fiber as reinforcement epoxy hybrid composites. Materials Science and Engineering C, 56, 269–273. https://doi.org/10.1016/j.msec.2015.06.031

Rana, R. S., Kumre, A., Rana, S., & Purohit, R. (2017). Characterization of properties of epoxy sisal/glass fiber reinforced hybrid composite. Materials Today: Proceedings, 4(4), 5445–5451. https://doi.org/10.1016/j.matpr.2017.05.056

Santulli, C., et al. (2013). Mechanical behaviour of jute cloth/wool felts hybrid laminates. Materials and Design, 50, 309–321. https://doi.org/10.1016/j.matdes.2013.02.079

Khalid, M. Y., Al Rashid, A., Abbas, Z., Akram, N., Arif, Z. U., & Márquez, F. P. G. (2021). Evaluation of tensile properties of glass/sisal and glass/jute fibers reinforced hybrid composites at different stacking sequences TT—stacking sequences에 따른 Glass/Sisal과 Glass/Jute Fiber로 강화된 복합체의 연신 특성 평가. Polymer (Korea), 45(3), 390–397. https://doi.org/10.7317/pk.2021.45.3.390

Khalid, M. Y., Arif, Z. U., Sheikh, M. F. et al. (2021). Mechanical characterization of glass and jute fiber-based hybrid composites fabricated through compression molding technique. International Journal of Material Forming, 14, 1085–1095. https://doi.org/10.1007/s12289-021-01624-w

Selver, E., Dalfi, H., & Yousaf, Z. (2020). Investigation of the impact and post-impact behaviour of glass and glass/natural fibre hybrid composites made with various stacking sequences: Experimental and theoretical analysis. Journal of Industrial Textiles. https://doi.org/10.1177/1528083719900670

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Khalid, M.Y., Arif, Z.U. & Al Rashid, A. Investigation of Tensile and Flexural Behavior of Green Composites along with their Impact Response at Different Energies. Int. J. of Precis. Eng. and Manuf.-Green Tech. 9, 1399–1410 (2022). https://doi.org/10.1007/s40684-021-00385-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40684-021-00385-w