Abstract

Piezoelectric vibration energy harvesting (PVEH) has been emerged as an alternative solution for sustainable powering to electronics. It has been well known that a PZT stack operating in 33-mode has higher mechanical to electrical energy conversion efficiency and higher mechanical reliability, compared to a cantilevered PZT bimorph operating in 31-mode. However, there are two challenges to improve the output performance of a PZT stack at a low frequency environment. First, the lower tensile strength of a PZT stack compared to the compressive strength makes it difficult to fully utilize maximum strain at harsh vibration conditions. Second, the relatively high stiffness of a PZT stack prevents being resonant with a base structure vibrating at a low frequency. To solve these challenges, this study thus proposes a double acting compression mechanism (DACM)-based PVEH stack operating in 33-mode. The DACM-based PVEH stack can convert mechanical vibration into elevated two-way compressive loading. The analytic model is used to investigate the electroelastic behaviors of the DACM-based PVEH device at given vibration conditions. The comparative study is performed to verify the effectiveness of the DACM-based PVEH stack over other mechanisms. It can be concluded that the DACM-based PVEH stack enables to generate higher power with the same volume of PZT using elevated two-way compressive loading.

Similar content being viewed by others

Abbreviations

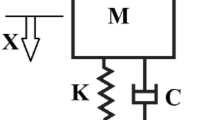

- M :

-

Mass of a weight

- c :

-

Damping coefficient

- k :

-

Stiffness of a spring

- x :

-

Displacement of a damped single degree-of-freedom system

- y :

-

Displacement of base excitation

- X :

-

Maximum displacement

- Y :

-

Maximum displacement of base excitation

- ω :

-

Angular natural frequency

- ζ :

-

Damping ratio

- F T :

-

Maximum compressive load applied to a PZT stack

- r :

-

Frequency ratio

- S :

-

Strain

- T :

-

Stress

- E :

-

Elastic field

- D :

-

Electric displacement

- s E :

-

Elastic compliance at constant electric field

- d :

-

Piezoelectric coupling coefficient

- ε :

-

Dielectric permittivity

- x cs :

-

Displacement of a PZT stack

- h :

-

Thickness of a piezoelectric layer

- A cs :

-

Cross-sectional area

- F :

-

Actuation force to a PZT stack

- Q :

-

Electric charge

- V :

-

Output voltage

- n :

-

The number of piezoelectric layers

- L :

-

Length of a PZT stack

- P :

-

Output electric power

- R :

-

External electrical resistance

- C :

-

Capacitance

References

Kim, J. E., Kim, H., Yoon, H., Kim, Y. Y., & Youn, B. D. (2015). An energy conversion model for cantilevered piezoelectric vibration energy harvesters using only measurable parameters. International Journal of Precision Engineering and Manufacturing-Green Technology, 2(1), 51–57.

Cui, J., Yoon, H., & Youn, B. D. (2018). An omnidirectional biomechanical energy harvesting (OBEH) sidewalk block for a self-generative power grid in a smart city. International Journal of Precision Engineering and Manufacturing-Green Technology, 5(4), 507–517.

Erturk, A., & Inman, D. J. (2008). On mechanical modeling of cantilevered piezoelectric vibration energy harvesters. Journal of Intelligent Material Systems and Structures, 19(11), 1311–1325.

Yoon, H., Youn, B. D., & Kim, H. S. (2016). Kirchhoff plate theory-based electromechanically-coupled analytical model considering inertia and stiffness effects of a surface-bonded piezoelectric patch. Smart Materials and Structures, 25(2), 025017.

Kim, H. S., Kim, J.-H., & Kim, J. (2011). A review of piezoelectric energy harvesting based on vibration. International Journal of Precision Engineering and Manufacturing, 12(6), 1129–1141.

Usharani, R., Uma, G., & Umapathy, M. (2016). Design of high output broadband piezoelectric energy harvester with double tapered cavity beam. International Journal of Precision Engineering and Manufacturing-Green Technology, 3(4), 343–351.

Sodano, H. A., Inman, D. J., & Park, G. (2005). Comparison of piezoelectric energy harvesting devices for recharging batteries. Journal of Intelligent Material Systems and Structures, 16(10), 799.

Yoon, H., & Youn, B. D. (2014). Stochastic quantification of the electric power generated by a piezoelectric energy harvester using a time-frequency analysis under non-stationary random vibrations. Smart Materials and Structures, 23(4), 045035.

Roundy, S., Leland, E. S., Baker, J., Carleton, E., Reilly, E., Lai, E., et al. (2005). Improving power output for vibration-based energy scavengers. Pervasive Computing, 4(1), 28–36.

Anton, S. R., & Sodano, H. A. (2007). A review of power harvesting using piezoelectric materials (2003–2006). Smart Materials and Structures, 16(3), 1.

Yoon, H., Kim, M., Park, C.-S., & Youn, B. D. (2018). Time-varying output performances of piezoelectric vibration energy harvesting under nonstationary random vibrations. Smart Materials and Structures, 27(1), 015004.

Goldschmidtboeing, F., & Woias, P. (2008). Characterization of different beam shapes for piezoelectric energy harvesting. Journal of Micromechanics and Microengineering, 18(10), 104013.

Lee, S., Youn, B. D., & Jung, B. C. (2009). Robust segment-type energy harvester and its application to a wireless sensor. Smart Materials and Structures, 18(9), 095021.

Jung, B. C., Yoon, H., Oh, H., Lee, G., Yoo, M., et al. (2016). Hierarchical model calibration for designing piezoelectric energy harvester in the presence of variability in material properties and geometry. Structural and Multidisciplinary Optimization, 53(1), 161–173.

Roundy, S., Wright, P. K., & Rabaey, J. (2003). A study of low level vibrations as a power source for wireless sensor nodes. Computer Communications, 26(11), 1131–1144.

Sodano, H. A., Park, G., & Inman, D. J. (2004). Estimation of electric charge output for piezoelectric energy harvesting. Strain, 40(2), 49–58.

Chen, S. N., Wang, G. J., & Chien, M. C. (2006). Analytical modeling of piezoelectric vibration-induced micro power generator. Mechatronics, 16(7), 379–387.

Xu, T., Siochi, E. J., Kang, J. H., Zuo, Lei, Zhou, W., Tang, X., & Jiang, X. (2011) A Piezoelectric PZT ceramic Multilayer Stack for Energy Harvesting under Dynamic Forces. In: Proceedings of the ASME 2011 International Design Engineering Technical Conference and Computers and Information in Engineering Conference.

Xu, T., Siochi, E. J., Kang, J. H., Zuo, L., Zhou, W., Tang, X., et al. (2013). Energy harvesting using a pzt ceramic multilayer stack. Smart Materials and Structures, 22(6), 065015.

Feenstra, J., Gransttrom, J., & Sodano, H. (2008). Energy harvesting through a backpack employing a mechanically amplified piezoelectric stack. Mechanical Systems and Signal Processing, 22(3), 721–734.

Song, H., Kim, H., Kang, C., Kim, H., Yoon, S., & Jeong, D. (2009). Multilayer piezoelectric energy scavenger for large current generation. Journal of Electroceramics, 23(2), 301–304.

Yuan, J., Shan, X., Xie, T., & Chen, W. (2010). Modeling and improvement of a cymbal transducer in energy harvesting. Journal of Intelligent Material Systems and Structures, 21(8), 765–771.

Lee, A., Wang, Y., & Inman, D. J. (2014). Energy harvesting of piezoelectric stack actuator from a shock event. Journal of Vibration and Acoustics, 136(1), 011016.

Zhao, S. (2013). Energy harvesting from random vibrations of piezoelectric cantilevers and stacks. PhD thesis, Georgia Institute of Technology.

Morgan Advanced Materials website. http://www.morgantechnicalceramics.com. Accessed 1 Feb 2019.

PIECO.COM website. https://piezo.com. Accessed 1 Feb 2019.

Flynn, A. M., & Sanders, S. R. (2002). Fundamental limits on energy transfer and circuit considerations for piezoelectric transformers. IEEE Transactions on Power Electronics, 17(1), 8–14.

Inman, D. J. (2013). Engineering vibration (4th ed.). Pearson Education, Inc., Upper Saddle River, NJ.

Lee, S., & Youn, B. D. (2011). A design and experimental verification methodology for an energy harvester skin structure. Smart Materials and Structures, 20(5), 057001.

Keawboonchuay, C., & Engel, T. G. (2003). Electrical power generation characteristics of piezoelectric generator under quasi-static and dynamic stress conditions. IEEE Transactions on Ultrasonics, Ferroelectrics, and Frequency Control, 50(10), 1377–1382.

Acknowledgements

This research was partially supported by the Main Project of Korea Institute of Machinery and Materials (Project Code: NK213E). This research was also supported by the National Research Council of Science & Technology (NST) grant by the Korea Government (MSIT) (No. CAP-17-04-KRISS).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jung, B.C., Yoon, H. Double Acting Compression Mechanism (DACM) for Piezoelectric Vibration Energy Harvesting in 33-Mode Operation. Int. J. of Precis. Eng. and Manuf.-Green Tech. 6, 681–690 (2019). https://doi.org/10.1007/s40684-019-00039-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40684-019-00039-y