Abstract

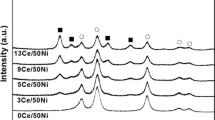

In this study, NiCrAl metal foam was used as the support material. Rh/Al-Ce-Zr-based catalysts were also used as a reforming catalyst, and was coated over a metal foam plate using a rotary vacuum evaporator. The Al-Ce-Zr-based catalytic support material coated over a metal foam plate exhibited a nano-structured morphology. XRD showed that the cerium and zirconium components in the Al-Ce-Zr-based catalytic support material were synthesized in the CeZrO2 crystal structure. CeZrO2 prevents carbon deposition on the catalyst active site due to their high lattice oxygen mobility. The composition of hydrogen by diesel auto-thermal reforming increased with increasing reaction temperature, and 6, 12, and 43% was obtained at 600, 700, and 800°C, respectively. The fuel conversions were 20, 85, and 100%. A long-term activity test of the Rh/Al-Ce-Zr-based catalyst was carried out under the optimal auto-thermal reforming conditions. The composition of hydrogen and carbon monoxide in the dry-product gas was maintained at approximately 45% and 11% during 500 h, respectively. Therefore, the catalytic activity of Rh/Al-Ce-Zr based catalysts for diesel auto-thermal reforming is excellent. The carbon content on the surface of the catalysts after 100, 200, 300, 400, and 500 h reactions was investigated by EDX and no carbon deposition was observed.

Similar content being viewed by others

References

Farrell, J., Cernansky, N., Dryer, F., Law, C., Friend, D., et al., “Development of an Experimental Database and Kinetic Models for Surrogate Diesel Fuels,” SAE Technical Paper, 2007.

Shekhawat, D., Berry, D. A., Gardner, T. H., and Spivey, J. J., “Catalytic Reforming of Liquid Hydrocarbon Fuels for Fuel Cell Applications,” Catalysis, Vol. 19, pp. 184–254, 2006.

Kopasz, J., Applegate, D., Miller, L., Liao, H., and Ahmed, S., “Unraveling the Maze: Understanding of Diesel Reforming through the Use of Simplified Fuel Blends,” International Journal of Hydrogen Energy, Vol. 30, No. 11, pp. 1243–1250, 2005.

Yoon, S., Kang, I., and Bae, J., “Effects of Ethylene on Carbon Formation in Diesel Autothermal Reforming,” International Journal of Hydrogen Energy, Vol. 33, No. 18, pp. 4780–4788, 2008.

Yoon, S., Lee, S., and Bae, J., “Development of a Self-Sustaining KWe-Class Integrated Diesel Fuel Processing System for Solid Oxide Fuel Cells,” International Journal of Hydrogen Energy, Vol. 36, No. 16, pp. 10302–10310, 2011.

Yoon, S. and Bae, J., “A Diesel Fuel Processor for Stable Operation of Solid Oxide Fuel Cells System: I. Introduction to Post-Reforming for the Diesel Fuel Processor,” Catalysis Today, Vol. 156, No. 1, pp. 49–57, 2010.

Lenz, B. and Aicher, T., “Catalytic Autothermal Reforming of Jet Fuel,” Journal of Power Sources, Vol. 149, pp. 44–52, 2005.

Liu, D.-J., Kaun, T. D., Liao, H. -K., and Ahmed, S., “Characterization of Kilowatt-Scale Autothermal Reformer for Production of Hydrogen from Heavy Hydrocarbons,” International Journal of Hydrogen Energy, Vol. 29, No. 10, pp. 1035–1046, 2004.

Xu, X., Li, P., and Shen, Y., “Small-Scale Reforming of Diesel and Jet Fuels to Make Hydrogen and Syngas for Fuel Cells: A Review,” Applied Energy, Vol. 108, pp. 202–217, 2013.

Lindström, B., Karlsson, J., Ekdunge, P., De Verdier, L., Häggendal, B., et al. “Diesel Fuel Reformer for Automotive Fuel Cell Applications,” International Journal of Hydrogen Energy, Vol. 34, No. 8, pp. 3367–3381, 2009.

Wang, P., Zhou, L., Li, G., Lin, H., Shao, Z., et al., “Direct Internal Reforming Molten Carbonate Fuel Cell with Core-Shell Catalyst,” International Journal of Hydrogen Energy, Vol. 37, No. 3, pp. 2588–2595, 2012.

Matsumura, M., Shinoki, T., and Yagi, T., “Cooling Technology for MCFC Stack,” JSME International Journal Series B, Fluids and Thermal Engineering, Vol. 41, No. 3, pp. 691–696, 1998.

Boon, J., Van Dijk, E., De Munck, S., and Van Den Brink, R., “Steam Reforming of Commercial Ultra-Low Sulphur Diesel,” Journal of Power Sources, Vol. 196, No. 14, pp. 5928–5935, 2011.

Achouri, I. E., Abatzoglou, N., Fauteux-Lefebvre, C., and Braidy, N., “Diesel Steam Reforming: Comparison of Two Nickel Aluminate Catalysts Prepared by Wet-Impregnation and Co-Precipitation,” Catalysis Today, Vol. 207, pp. 13–20, 2013.

Kang, I., Bae, J., and Bae, G., “Performance Comparison of Autothermal Reforming for Liquid Hydrocarbons, Gasoline and Diesel for Fuel Cell Applications,” Journal of Power Sources, Vol. 163, No. 1, pp. 538–546, 2006.

Son, J.-W. and Song, H.-S., “Influence of Current Collector and Cathode Area Discrepancy on Performance Evaluation of Solid Oxide Fuel Cell with Thin-Film-Processed Cathode,” Int. J. Precis. Eng. Manuf.-Green Tech., Vol. 1, No. 4, pp. 313–316, 2014.

Choi, H., Cho, G. Y., and Cha, S.-W., “Fabrication and Characterization of Anode Supported YSZ/GDC Bilayer Electrolyte SOFC Using Dry Press Process,” Int. J. Precis. Eng. Manuf.-Green Tech., Vol. 1, No. 2, pp. 95–99, 2014.

Ji, S., Ha, J., Park, T., Kim, Y., Koo, B., et al., “Substrate-Dependent Growth of Nanothin Film Solid Oxide Fuel Cells Toward Cost-Effective Nano Structuring,” Int. J. Precis. Eng. Manuf.-Green Tech., Vol. 3, No. 1, pp. 35–39, 2016.

Author information

Authors and Affiliations

Corresponding author

Additional information

This paper was presented at ISGMA 2016

Rights and permissions

About this article

Cite this article

Choi, W.Y., Lee, J.W., Kim, M.J. et al. Durability tests of Rh/Al-Ce-Zr catalysts coated on NiCrAl metal foam for ATR of dodecane at high temperature. Int. J. of Precis. Eng. and Manuf.-Green Tech. 4, 183–189 (2017). https://doi.org/10.1007/s40684-017-0023-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40684-017-0023-0