Abstract

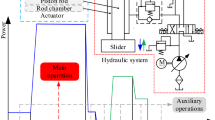

In machine tools, hydraulic units are one of the main consumers of energy. Hydraulically driven functionalities of machine tools include tool clamping, tool change, work piece clamping or palette change operating. For these functions, two pressure circuits (60 bar and 200 bar) are necessary. This paper introduces a novel, energy-efficient hydraulic unit that combines a variable displacement pump with a variable speed controlled drive and hydraulic booster. The result is a lower overall energy consumption and decreased operating temperatures of the hydraulic unit. Hydraulic fluids contain up to 85% mineral oil. This paper also introduces a mineral oil-free, water-based hydraulic fluid, which will be replacing a conventional mineral oil-based hydraulic fluid (ISO-VG 46) within the novel energy-efficient hydraulic unit. The effects on the unit’s performance (operating temperature, pressure, flow rate, power consumption, efficiency) will be evaluated.

Similar content being viewed by others

Abbreviations

- p:

-

Pressure

- Q:

-

Flow rate

- p:

-

Power

- η :

-

Efficiency

References

Roland, B., “Studie: Effizienzsteigerung in Stromintensiven Industrien, Ausblick und Handlungsstrategien bis 2050,” München: Roland Berger Strategy Consultants GmbH, 2011.

European Commission, “Climate Strategies & Targets,” http:// ec.europa.eu/clima/policies/strategies/index_en.htm (Accessed 8 December 2016)

Triebs, J. B., “Analyse, Optimierung und Simulation des Energieumsatzes Dezentraler Fluidkreisläufe von Werkzeugmaschinen,” RWTH Aachen, 2015.

Campatelli, G., Scippa, A., Lorenzini, L., and Sato, R., “Optimal Workpiece Orientation to Reduce the Energy Consumption of a Milling Process,” Int. J. Precis. Eng. Manuf.-Green Tech., Vol. 2, No. 1, pp. 5–13, 2015.

Bundesamt für Wirtschaft und Ausfuhrkontrolle, “Entwicklung der Inlandsablieferungen von Schmierstoffen 1995-2015,” http:// www.bafa.de/SharedDocs/Downloads/DE/Energie/Mineraloel/moel_entwicklung_inlandsablieferung_schmierstoffe_1995_2015.html (Accessed 9 December 2016)

Schmidt, C., Li, W., Thiede, S., Kara, S., and Herrmann, C., “A Methodology for Customized Prediction of Energy Consumption in Manufacturing Industries,” Int. J. Precis. Eng. Manuf.-Green Tech., Vol. 2, No. 2, pp. 163–172, 2015.

Brecher, C., Bäumler, S., and Triebs, J., “Design of Energy Efficient Hydraulic Units for Machine Tools,” Proc. of the Global Conference on Sustainable Manufacturing in St. Petersburg, pp. 190–195, 2011. Fig. 7 Behavior of the hydraulic unit during base load condition

Mori, M. and Fujishima, M., “Energy Efficiency Improvement of Machine Tools,” Proc. of the International Chemnitz Manufacturing Colloquium, Auerbach, pp. 581–593, 2012.

Dornfeld, D. A., “Moving towards Green and Sustainable Manufacturing,” Int. J. Precis. Eng. Manuf.-Green Tech., Vol. 1, No. 1, pp. 63–66, 2014.

Abele, E., Kuhrke, B., and Rothenbücher, S., “Entwicklungstrends zur Erhöhung und Bewertung der Energieeffizienz spanender Werkzeugmaschinen,” Energieeffiziente Produkt- und Prozessinnovationen in der Produktionstechnik, pp. 99–105, 2010.

Brecher, C., Triebs, J., and Jasper, D., “Energy Efficient Solutions for Hydraulic Units of Machine Tools,” in: Re-Engineering Manufacturing for Sustainability, Nee, A. Y. C, Song, B., and Ong, S.-K., (Eds.), Springer, pp. 191–196, 2013.

Brecher, C., Bäumler, S., and Triebs, J., “Energieeffizienz von Werkzeugmaschinen: Messtechnik und Optimierungsmöglichkeiten der Hydraulik,” Ressourceneffiziente Produktion, pp. 109–119, 2012.

Will, D., Gebhardt, N., and Ströhl, H., “Hydraulik. Grundlagen, Komponenten, Schaltungen,” Springer, Berlin, 5th Ed., 2011.

Bock, W., “Hydraulik-Fluide als Konstruktionselement,” Vereinigte Fachverlage, 2007.

ISO No. DIN ISO 3448, “Flüssige Industrie-Schmierstoffe- ISOViskositätsklassifikation,” 2010

Malberg, A., “Besser Schmieren Ohne Öl,” Fraunhofer- Forschung Kompakt- Sonderausgabe, 2012.

Bechem Lubrication Technology, “Berufluid- Tomorrow’s Technologies,” 2012.

Vieweg, K.-U., “Kühlen, Schmieren, Ressourcen Schonen, “Medizin & Technik”,” Vol. 4, pp. 46–47, 2012.

Winter, M., Herfellner, T., Malberg, A., Dwuletzki, H., Zein, A., et al., “Mineral Oil Free Machine Tool: The Usage of Ecologically Benign Lubricants as Coolant and Hydraulic Fluid,” Proc. of the Industrial and Automotive Lubrication- 18th International Colloquium Tribology, pp. 143–149, 2012.

Ralph, A., “Neues Konzept für Kühlen und Schmieren Verzichtet auf Öl,” VDI-Nachrichten, 2012.

Ralf, B., “Mineralölfreier Schmierstoff auf Polymerbasis- Kostensenkung und Ressourcenschonung,” Institut für Verfahrenstechnik und Verpackung IVV, pp. 36–38, 2010.

Wire Extra, “Schmierstoffe für Nachhaltigkeit,” 2013.

Dwuletzki, H., “Kühlschmierstoffe der Neuen Generation,” Wissenschaft & Forschung, Vol. 2, pp. 54–61, 2010.

Schleifen+Polieren,” “Berufluid- Das Innovative Kühlschmierkonzept der Zukunft,” www.oekoplus-service.de/?download=32344 (Accessed 9 December 2016)

Standard No. DIN 51562 “Messung der Kinematischen Viskosität mit Dem Ubbelohde-Viskosimete,” 1999.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Brecher, C., Jasper, D. & Fey, M. Analysis of new, energy-efficient hydraulic unit for machine tools. Int. J. of Precis. Eng. and Manuf.-Green Tech. 4, 5–11 (2017). https://doi.org/10.1007/s40684-017-0001-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40684-017-0001-6