Abstract

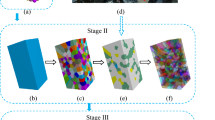

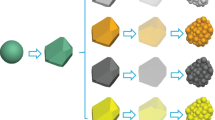

To understand the effect of grain size on the rock dynamic mechanical behaviors, dynamic semi-circular bending (SCB) experiments were carried out by means of a grain-based model based on particle flow code (PFC-GBM) with a split Hopkinson pressure bar (SHPB) system. Simulation results suggest that: (1) When the particle size is less than 0.75 mm, the strain rate presents a double-hump shape waveform; (2) the reflection coefficient rises linearly with increasing grain-to-particle size ratio, while the transmission coefficient remains constant; and (3) increasing grain-to-particle size ratio promotes the migration of particles in grains, resulting in the decrease in crack number and dynamic tensile strength. The results show the feasibility of PFC-GBM in studying the dynamics of crystalline rock, which can provide a reference for dynamic response analysis on the microscopic scale.

Similar content being viewed by others

Data availability

The datasets generated and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Eberhardt E, Stead D, Stimpson B, Read RS (1998) Identifying crack initiation and propagation thresholds in brittle rock. Can Geotech J 35(2):222–233

Cai M, Kaiser PK, Tasaka Y et al (2004) Generalized crack initiation and crack damage stress thresholds of brittle rock masses near underground excavations. Int J Rock Mech Min Sci 41(5):833–847

Dou LT, Yang K, Chi XL (2021) Fracture behavior and acoustic emission characteristics of sandstone samples with inclined precracks. Int J Coal Sci Technol 8(1):77–87

Liu G, Chen Y, Xi D, Wang S, Fernández-Steeger TM (2022) Evolutionary analysis of heterogeneous granite microcracks based on digital image processing in grain-block model. Materials 15(5):1941. https://doi.org/10.3390/ma15051941

Lan HX, Martin CD, Hu B (2010) Effect of heterogeneity of brittle rock on micromechanical extensile behavior during compression loading. J Geophys Res Solid Earth 115(B1):B01202

Cundall PA, Strack ODL (2008) A discrete numerical model for granular assemblies. Géotechnique 30(3):331–336

Wang G, Luo Y, Li XP et al (2022) Study on dynamic mechanical properties and meso-damage mechanism of jointed rock under impact load. Eur J Environ Civ Eng 26(3):1141–1157

Hofmann H, Babadagli T, Zimmermann G (2015) A grain based modeling study of fracture branching during compression tests in granites. Int J Rock Mech Min Sci 77:152–162

Peng J, Wong LNY, Teh CI et al (2018) Modeling micro-cracking behavior of bukit timah granite using grain-based model. Rock Mech Rock Eng 51(1):135–154

Li H, Ma HL, Shi XL et al (2020) A 3D grain-based model for simulating the micromechanical behavior of salt rock. Rock Mech Rock Eng 53(3):2819–2837

Saadat M, Taheri A (2019) A numerical approach to investigate the effects of rock texture on the damage and crack propagation of a pre-cracked granite. Comput Geotech 111:89–111

Zhang XP, Ji PQ, Peng J et al (2020) A grain-based model considering pre-existing cracks for modelling mechanical properties of crystalline rock. Comput Geotech 127(5):103776

Liu XQ, Wang G, Liu TT et al (2020) Study on dynamic mechanical properties of phosphate rock through experimental tests and mesoscale simulation. Arab J Geosci 13(18):969

Gong FQ, Si XF, Li XB et al (2019) Dynamic triaxial compression tests on sandstone at high strain rates and low confining pressures with split Hopkinson pressure bar. Int J Rock Mech Min Sci 113:211–219

Peng J, Wong LNY, Teh CI (2017) Effects of grain size-to-particle size ratio on micro-cracking behavior using a bonded-particle grain-based model. Int J Rock Mech Min Sci 100:207–217

Tian WL, Yang SQ, Huang YH et al (2020) Mechanical behavior of granite with different grain sizes after high-temperature treatment by particle flow simulation. Rock Mech Rock Eng 53(3):1–17

Lv YX, Li HB, Zhu XH et al (2017) Discrete element method simulation of random Voronoi grain-based models. Clust Comput 20(1):335–345

Chong KP, Kuruppu MD (1984) New specimen for fracture toughness determination for rock and other materials. Int J Fract 26(2):R59–R62

Molenaar J, Molenaar A (2000) Fracture toughness of asphalt in the semi-circular bend test. In: Proceedings of the papers submitted for review at 2nd Eurasphalt and Eurobitume congress, September 20–22, Barcelona, Spain, Book 1-Session 1

Geng NN (2013) Numerical simulation of Semi-circular bending test for concrete under quasi-static and dynamic loading conditions. Hefei University of Technology (In Chinese)

Chen X, Li JC, Cai MF et al (2015) Experimental study on wave propagation across a rock joint with rough surface. Rock Mech Rock Eng 48(6):2225–2234

Zhang T, Wei LY, Ju MH et al (2022) Study on the effect of grain size-particle size ratio on the dynamic tensile properties of granite based on PFC3D-GBM. Chin J Rock Mech Eng 41(3):468–478 (In Chinese)

Acknowledgements

The work presented in this paper was financially supported by the National Key R&D Program of China (2018YFC1508501), the National Natural Science Foundation of China (Grants No. 52209130), the National Natural Science Foundation of China (Grants Nos. 41831278 and 51679071).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wangyang, L., Chong, S. & Cong, Z. Numerical study on the effect of grain size on rock dynamic tensile properties using PFC-GBM. Comp. Part. Mech. 11, 481–489 (2024). https://doi.org/10.1007/s40571-023-00634-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40571-023-00634-6