Abstract

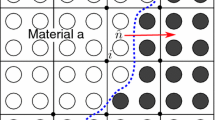

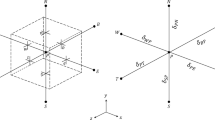

Heat conduction through an object with material interfaces or cracks is influenced by heat flow across those discontinuities. This paper presents a numerical particle method for modeling such heat flow coupled to computational mechanics all within the material point method (MPM). In brief, MPM models contacts and cracks by extrapolating multiple velocity fields to a grid. To model interfacial heat flow, MPM should similarly extrapolate multiple temperature fields. Interface nodes that “see” more than one temperature field modify their heat flow to reflect interfacial physics. For example, interfaces in contact may transfer heat by perfect conduction, while separated interfaces may block heat flow or cause reduced heat flow by convection. After some validation examples, two real-world examples consider cooling an ingot within a crucible where cooling causes the ingot to lose contact with the crucible walls and thermal imaging of cracks within an opaque solid.

Similar content being viewed by others

References

Almond DP, Peng W (2001) Thermal imaging of composites. J Microsc 201(2):163–170

Bardenhagen SG, Guilkey JE, Roessig KM, Brackbill JU, Witzel WM, Foster JC (2001) An improved contact algorithm for the material point method and application to stress propagation in granular material. Comput Model Eng Sci 2:509–522

Bardenhagen SG, Kober EM (2004) The generalized interpolation material point method. Comput Model Eng Sci 5:477–496

Brackbill J, Kothe D, Ruppel H (1988) FLIP: a low-dissipation, particle-in-cell method for fluid flow. Comput Phys Commun 48(1):25–38

Carlson DE (1984) Linear thermoelasticity. In: Truesdell C (ed) Mechanics of solids, vol II. Springer, New York, pp 297–345

Guenther RB, Lee JW (1996) Partial differential equations of mathematical physics and integral equations. Dover Books, New York

Lemiale V, Hurmane A, Nairn JA (2010) Material point method simulation of equal channel angular pressing involving large plastic strain and contact through sharp corners. Comput Model Eng Sci 70(1):41–66

Maurer GE (1989) Primary and secondary melt processing–superalloys. In: Tien JK, Caulfield T (eds) Superalloys, supercomposites and superceramics. Academic Press, New York, pp 49–97

Nairn JA (2003) Material point method calculations with explicit cracks. Comput Model Eng Sci 4:649–664

Nairn JA (2007) Numerical implementation of imperfect interfaces. Comput Mater Sci 40:525–536

Nairn JA (2013) Modeling of imperfect interfaces in the material point method using multimaterial methods. Comput Model Eng Sci 92(3):271–299

Nairn JA (2017) Material point method (NairnMPM) and finite element analysis (NairnFEA) open-source software. http://osupdocs.forestry.oregonstate.edu

Nairn JA, Aimene Y (2017) Modeling interacting and propagating cracks in the material point method: Application to simulation of hydraulic fractures interacting with natural fractures. In preparation

Nairn JA, Bardenhagen SG, Smith GS (2018) Generalized contact and improved frictional heating in the material point method. Comput Part Mech 5(3):285–296

Nairn JA, Guilkey JE (2015) Axisymmetric form of the generalized interpolation material point method. Int J Numer Methods Eng 101:127–147

Sulsky D, Chen Z, Schreyer HL (1994) A particle method for history-dependent materials. Comput Methods Appl Mech Eng 118:179–186

Funding

This work was made possible by the endowment for the Richardson Chair in Wood Science and Forest Products. The author also thanks Rigel Woodside, Paul King, and Kevin Gartner for helpful discussions.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The corresponding author states that he has no conflicts of interest.

Rights and permissions

About this article

Cite this article

Nairn, J.A. Modeling heat flow across material interfaces and cracks using the material point method. Comp. Part. Mech. 6, 133–144 (2019). https://doi.org/10.1007/s40571-018-0201-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40571-018-0201-z