Abstract

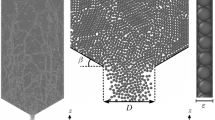

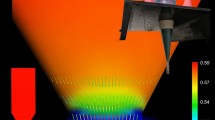

Very recently, we have examined experimentally and numerically the micro-mechanical details of monodisperse particle flows through an orifice placed at the bottom of a silo (Rubio-Largo et al. in Phys Rev Lett 114:238002, 2015). Our findings disentangled the paradoxical ideas associated to the free-fall arch concept, which has historically served to justify the dependence of the flow rate on the outlet size. In this work, we generalize those findings examining large-scale polydisperse particle flows in silos. In the range of studied apertures, both velocity and density profiles at the aperture are self-similar, and the obtained scaling functions confirm that the relevant scale of the problem is the size of the aperture. Moreover, we find that the contact stress monotonically decreases when the particles approach the exit and vanish at the outlet. The behavior of this magnitude is practically independent of the size of the orifice. However, the total and partial kinetic stress profiles suggest that the outlet size controls the propagation of the velocity fluctuations inside the silo. Examining this magnitude, we conclusively argue that indeed there is a well-defined transition region where the particle flow changes its nature. The general trend of the partial kinetic pressure profiles and the location of the transition region results the same for all particle types. We find that the partial kinetic stress is larger for bigger particles. However, the small particles carry a higher fraction of kinetic stress respect to their concentration, which suggest that the small particles have larger velocity fluctuations than the large ones and showing lower strength of correlation with the global flow. Our outcomes explain why the free-fall arch picture has served to describe the polydisperse flow rate in the discharge of silos.

Similar content being viewed by others

References

Rubio-Largo SM, Janda A, Maza D, Zuriguel I, Hidalgo RC (2015) Disentangling the free-fall arch paradox in silo discharge. Phys Rev Lett 114:238002

Sperl M (2006) Experiments on corn pressure in silo cells: translation and comment of janssen’s paper from 1895. Granul Matter 8(2):59–65

Brown RL, Richards JC (1970) Principles of powder mechanics: essays on the packing and flow of powders and bulk solids. Pergamon Press, Oxford

Nedderman RM (1992) Statistics and kinematics of granular materials. Cambridge University Press, Cambridge

Mathews JC, Wei Wu (2016) Model tests of silo discharge in a geotechnical centrifuge. Powder Technol 293:3–14

Beverloo WA, Leniger HA, van de Velde J (1961) The flow of granular solids through orifices. Chem Eng Sci 15(34):260–269

Mankoc C, Janda A, Arévalo R, Pastor JM, Zuriguel I, Garcimartín A, Maza D (2007) The flow rate of granular materials through an orifice. Granul Matter 9(6):407–414

Janda A, Zuriguel I, Maza D (2012) Flow rate of particles through apertures obtained from self-similar density and velocity profiles. Phys Rev Lett 108:248001

Kamrin K, Koval G (2012) Nonlocal constitutive relation for steady granular flow. Phys Rev Lett 108:178301

Henann DL, Kamrin K (2014) Continuum modeling of secondary rheology in dense granular materials. Phys Rev Lett 113:178001

Vivanco F, Rica S, Melo F (2012) Dynamical arching in a two dimensional granular flow. Granul Matter 14(5):563–576

Van Zuilichem DJ, Van Egmond ND, De Swart JG (1974) Density behaviour of flowing granular material. Powder Technol 10:161–169

Pöschel T, Schwager T (2005) Computational granular dynamics. Springer, Berlin

Goldhirsch I (2010) Stress, stress asymmetry and couple stress: from discrete particles to continuous fields. Granul Matter 12:239–252

Weinhart T, Thornton AR, Luding S, Bokhove O (2012) Closure relations for shallow granular flows from particle simulations. Granul Matter 14(4):531–552

Weinhart T, Hartkamp R, Thornton AR, Luding S (2013) Coarse-grained local and objective continuum description of three-dimensional granular flows down an inclined surface. Phys Fluids 25(7):070605

Weinhart T, Labra C, Luding S, Ooi JY (2016) Influence of coarse-graining parameters on the analysis of DEM simulations of silo flow. Powder Technol 293:138–148. doi:10.1016/j.powtec.2015.11.052

Valdes JR, Santamarina JC (2007) Particle transport in a nonuniform flow field: retardation and clogging. Appl Phys Lett 90(24):244101

Katsuragi H, Abate AR, Durian DJ (2010) Jamming and growth of dynamical heterogeneities versus depth for granular heap flow. Soft Matter 6:3023–3029

Zuriguel I, Janda A, Garcimartín A, Lozano C, Arévalo R, Maza D (2011) Silo clogging reduction by the presence of an obstacle. Phys Rev Lett 107:278001

Kanzaki T, Acevedo M, Zuriguel I, Pagonabarraga I, Maza D, Hidalgo RC (2011) Stress distribution of faceted particles in a silo after its partial discharge. Eur Phys J E 34:133

Lozano C, Lumay G, Zuriguel I, Hidalgo RC, Garcimartín A (2012) Breaking arches with vibrations: the role of defects. Phys Rev Lett 109:068001

Thomas CC, Durian DJ (2013) Geometry dependence of the clogging transition in tilted hoppers. Phys Rev E 87:052201

Hidalgo RC, Lozano C, Zuriguel I, Garcimartín A (2013) Force analysis of clogging arches in a silo. Granul Matter 15(6):841–848

Aguirre MA, Grande JG, Calvo A, Pugnaloni LA, Géminard J-C (2010) Pressure independence of granular flow through an aperture. Phys Rev Lett 104:238002

Zuriguel I, Parisi DR, Hidalgo RC, Lozano C, Janda A, Gago PA, Peralta JP, Ferrer LM, Pugnaloni LA, Clément E, Maza IPD, Garcimartín A (2014) Clogging transition of many-particle systems flowing through bottlenecks. Sci Rep 4:7324

Kamath S, Kunte A, Doshi P, Orpe AV (2014) Flow of granular matter in a silo with multiple exit orifices: jamming to mixing. Phys Rev E 90:062206

Benyamine M, Djermane M, Dalloz-Dubrujeaud B, Aussillous P (2014) Discharge flow of a bidisperse granular media from a silo. Phys Rev E 90:032201

Thomas CC, Durian DJ (2015) Fraction of clogging configurations sampled by granular hopper flow. Phys Rev Lett 114:178001

Gutiérrez G, Colonnello C, Boltenhagen P, Darias JR, Peralta-Fabi R, Brau F, Clément E (2015) Silo collapse under granular discharge. Phys Rev Lett 114:018001

Gray JMNT, Thornton AR (2005) A theory for particle size segregation in shallow granular free-surface flows. Proc R Soc Lond A 461(2057):1447–1473

Hill KM, Zhang J (2008) Kinematics of densely flowing granular mixtures. Phys Rev E 77:061303

Fan Y, Hill KM (2011) Theory for shear-induced segregation of dense granular mixtures. New J Phys 13(9):095009

Prescott JK, Carson JW (2000) Analyzing and overcoming industrial blending and segregation problems. Springer, Dordrecht, pp 89–101

Samadani A, Pradhan A, Kudrolli A (1999) Size segregation of granular matter in silo discharges. Phys Rev E 60:7203–7209

Rubio-Largo SM, Lind PG, Maza D, Hidalgo RC (2015) Granular gas of ellipsoids: analytical collision detection implemented on gpus. Comput Part Mech 2(2):127–138

Hidalgo RC, Kanzaki T, Alonso-Marroquin F, Luding S (2013) On the use of graphics processing units (gpus) for molecular dynamics simulation of spherical particles. AIP Conf Proc 1542:169–172

Tunuguntla DR, Thornton AR, Weinhart T (2016) From discrete elements to continuum fields: extension to bidisperse systems. Comput Part Mech 3(3):349–365

Madrid M, Asencio K, Maza D (2016) Soft matter. Submitted

Artoni R, Richard P (2015) Average balance equations, scale dependence, and energy cascade for granular materials. Phys Rev E 91:032202

Owens JD, Houston M, Luebke D, Green S, Stone JE, Phillips JC (2008) Gpu computing. Proc IEEE 96(5):879–899

Fincham D (1992) Leapfrog rotational algorithms. Mol Simul 8(3–5):165–178

Verlet L (1968) Computer “experiments” on classical fluids. ii. equilibrium correlation functions. Phys Rev 165(1):201–214

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Funding

This study was funded by the MINECO (Spain) (FIS2014-57325). S. M. Rubio-Largo thanks Asociación de Amigos de la Universidad de Navarra for a scholarship. Special thanks to R. H. Bellows for proofreading the manuscript.

Conflict of interest

The authors declare that they have no conflict of interest.

Appendix: Discrete element modeling implementation (DEM)

Appendix: Discrete element modeling implementation (DEM)

The DEM implementation is a polydisperse generalization of a monodisperse hybrid CPU / GPU algorithm that allows us to efficiently evaluate the dynamics of several hundred thousand particles [37, 41]. For each particle \(i=1 \ldots N\), the DEM simulation includes three translational degrees of freedom and the rotational movement is described by a quaternion formalism. We have used a linear spring approach; thus, the normal interaction force \({\mathbf {F}}_{ij}^{n}\) between the particles i with radius \(r_i\) and j with radius \(r_j\) depends linearly on the particles’ overlap distance \(\delta = r_i + r_j - \Vert \Delta R_{ij}\Vert \), where \(\Vert \Delta R_{ij}\Vert \) is the relative distance between the particles. Moreover, the local dissipation is introduced by a non-linear viscous damping term, which depends on the normal relative velocity \({\mathbf {v}}_{rel}^{n}\). Hence, the total normal force reads as

where

and

represent the damping coefficient, \(m_{eff} = m_im_j/(m_i+m_j)\), \(R_{eff} = r_ir_j/(r_i+r_j)\), and Y is the particles Young’s modulus. The tangential component \(F_{ij}^{t}\) also includes an elastic term and a viscous term,

where \(\gamma _t\) is a damping coefficient and \( {\mathbf {v}}_{rel}^{t} \) is the tangential relative velocity of the overlapping pair. The variable \(|{\mathbf {\xi }}|\) represents the elongation of an imaginary spring with elastic constant \(k_t\). As long as there is an overlap between the interacting particles, \({\mathbf {\xi }}\) increases as \(d{\mathbf {\xi }}/dt = {\mathbf {v}}_{rel}^t\) [13]. The elastic tangential elongation \({\mathbf {\xi }}\) is kept orthogonal to the normal vector [15] and it is truncated as necessary to satisfy the Coulomb constraint \(|{\mathbf {F}}_{ij}^{t}|<\mu | {\mathbf {F}}_{ij}^{n}|\), where \(\mu \) is the friction coefficient. The equations of motion are integrated using Fincham’s leap-frog algorithm (rotational) [42] and a Verlet Velocity algorithm (translational) [43].

In all the simulations reported here, the used contact parameters correspond to particles with a Young’s modulus \(Y = 120~GPa\), normal restitution coefficient \(e_n=0.88\), density \(\rho _p=7520\) kg/m\(^3\), and friction \(\mu =0.5\). We set \(\frac{k_t}{k_n} = \frac{2}{7}\) and \(\frac{\gamma _t}{\gamma _n}=0.1\), and gravitational acceleration \(g=10~m/s^2\). In all cases, the molecular dynamics time step was set as \(\Delta t = \frac{t_c}{50} = 6.3 \times 10^{-7}~s\), where \(t_c\) is approximately equal to time of contact between two small particles \(t_c = \pi \sqrt{\frac{m_{eff}}{2k_n}}\).

Rights and permissions

About this article

Cite this article

Rubio-Largo, S.M., Maza, D. & Hidalgo, R.C. Large-scale numerical simulations of polydisperse particle flow in a silo. Comp. Part. Mech. 4, 419–427 (2017). https://doi.org/10.1007/s40571-016-0133-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40571-016-0133-4