Abstract

As a critical component of the railway vehicle, underframe equipment has a great influence on the ride comfort of railway vehicles due to their big mass and active vibration. Therefore, study on the relationship between suspension parameters of underframe equipment and the modal frequency of carbody is extremely crucial for controlling the ride quality of railway vehicles. In this paper, a finite element model of the carbody was developed to investigate the effects of the suspension location, the mass of the suspension equipment, and the suspension frequency on the mode of the carbody. Then, the matching relationship between the suspension parameters and the modal frequency of the carbody was studied through the transfer function. In addition, roller rig tests were performed to verify the numerical simulation model of the carbody. The results show that the suspension parameters of the underframe equipment have a great influence on the mode of the carbody, especially for the frequency of the first bending mode. To improve the frequency of carbody high-frequency bending and reduce energy transfer, equipment with a large mass should be suspended toward the middle of the carbody. The weight of the equipment strongly affects the first bending frequency and energy transfer of the carbody. The frequency of heavy suspended equipment should be sufficiently low to increase the transmissibility of high frequencies and improve the vibration characteristics of the carbody. Although the bending frequency of the carbody can be improved effectively by increasing the suspension stiffness of the suspension equipment, in order to reduce carbody vibration effectively, the suspension frequency of the equipment should be slightly lower than the carbody bending frequency.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In modern railway operations, lightweight car bodies are vital to improving average train speeds. However, lowering the carbody weight reduces the stiffness of the structure, and increases accelerations within the vehicle system. This may have a negative impact on ride comfort [1, 2]. To handle these problems, a number of solutions have been proposed. For example, an essentially nonlinear vibration absorber was shown to mitigate the large acceleration transmitted to the passenger compartment of a vehicle and improve ride comfort [3], and a dynamic vibration absorber was installed in the underframe of a high-speed passenger car to suppress vibration [4]. To reduce bending vibration, some authors have suggested the use of piezoelectric elements shunted by an external electric circuit or active damping via a piezo stack of actuators [5, 6]. A constraint layer on the carbody was researched in [7], and a heavy additional mass suspended under the center of the carbody has also been considered [8].

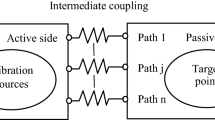

To optimize vibrational comfort in the design stage, the dynamics of the whole vehicle must be taken into account [9, 10]. The natural frequency of rolling stock is not only an important parameter in the dynamic loading of a carbody, but also forms the basis of the vehicle system dynamics. Elastic vibration in the carbody will be excited when the external excitation frequency equals the natural mode of the structure. The relationship between the suspension parameters of the equipment and the inherent carbody modal frequency have attracted widespread attention, as they are essential in ensuring system stability and passengers’ ride comfort. Carbody modeling is now the starting point of such research. By considering the carbody accessory structure, some progress has already been achieved. For instance, the influence of three types of equipment suspended from the carbody and the avoidance of structural resonance by adjusting the stiffness distribution has been reported [11]. Kang and Zeng [12] proposed a rigid coupling of the nonlinear system dynamics model. They discussed the vibration character of suspension equipment and studied the matching relation between the carbody modal frequency and suspension parameters, determining the optimal suspension location from the dynamic response of the underframe equipment. Taking CRH3 electric multiple units (EMU) as an example, Zhao et al. [13] analyzed the influence of underframe equipment on the carbody mode, and suggested that the elastic suspension of equipment could effectively improve the bending and rhombic modes. The modeling of a carbody structure and its suspension units was elaborately described in [14], which presented a reasonable modeling method by changing the mass distribution and boundary conditions. The carbody, wheelset, and frame have been considered as elastomers to analyze the modal frequency of a 270 km/h high-speed EMU [15], and to compare the stiffness matching conditions of the whole vehicle. The modal frequency of passenger cars has been analyzed using a finite element method, with the effect of the mass and stiffness of additional parts also considered [16]. A linear prediction method has been applied to the modal properties of the carbody, and this approach was validated by data from both stationary and running tests [17]. However, most research only considers a modal analysis of the initial frequency. The relation between the modal frequency and vibration has not been studied. High-speed EMUs in China often use both elastic and rigid suspension. Research has shown that elastic suspension effectively reduces the elastic vibration, changing the modal frequency of the carbody. The equipment is equivalent to a dynamic vibration absorber when elastic suspension is used. The two peak values will appear in the curve of the first bending frequency of the carbody. The key problem in this paper is to determine the best combination of carbody mode suspension parameters and vibration. A series of simulations enables us to identify the matching principles between the equipment suspension parameters and the modal frequency of the carbody.

2 Finite element analysis of carbody

2.1 Finite element model of carbody

Taking a high-speed test train as an example, consider the matching relationship between the carbody mode and the equipment suspension parameters. As the main bearing structure, the carbody consists of the underframe, corrugated floor, side sill, and so on. According to the structural characteristics of the carbody plate and girders, the real structure can be simulated using the ANSYS software. The corrugated sheet and side sills are simulated by Shell63 and beam elements, respectively. Using these elements, the structure of an aluminum alloy carbody can be accurately simulated. For the initial conditions, a mass unit is used to simulate the counterbalance. The equipment suspended from the underframe of the carbody is simulated by mass21 at the actual mass center, and the real connecting positions are rigidly coupled. The sides of each element measure 40–80 mm. The model includes around 122,000 nodes and 197,000 units. The finite element model is shown in Fig. 1.

2.2 Modal analysis

Modal analysis is used to solve the motion equations of the linear system without any damping, and to determine the natural frequency of the system. Because of the complex structure of the carbody, the natural frequency cannot be accurately obtained by analytical methods. However, it can be solved by finite element methods. The motion equation of the carbody is

where \( \varvec{M} \) denotes the mass matrix of the system, \( \varvec{C} \) represents the damping matrix, \( \varvec{K} \) represents the stiffness matrix, \( \varvec{f} \) represents the loading vector, and \( \varvec{x} \) is the deformation shape vector of the carbody structure.

Ignoring the influence of structural damping on the modal frequency, the free vibration solution of the system is

where \( \omega \) and \( \varvec{\varphi }_{0} \) are the squared circular eigenfrequency and initial phase, respectively, and \( \varvec{\delta} \) is a magnitude vector. We substitute Eq. (2) into Eq. (1), and seek non-zero solutions. For such solutions, we require a zero coefficient determinant, that is

The eigenvalues and eigenvectors of Eq. (3) give the intrinsic modes of the system.

3 Validation of modal simulation

3.1 Modal test method for a carbody

We now investigate a modal test for an aluminum alloy carbody. Seats, racks, and suspension equipment are not considered in the test, and the unladen body mass is about 9,000 kg. We also test the preparation conditions, using a traction transformer of 6,000 kg and a traction converter of 3,000 kg. Mass blocks lying on the floor are used to simulate the seats, giving a total carbody mass of about 34,000 kg. Details are shown in Figs. 2 and 3.

We consider seven cross-sections to reflect the vibration form of the carbody, as shown in Fig. 3, and place four acceleration sensors at the top and bottom of each section to measure the vertical and lateral acceleration. Thus, the vibration in the carbody can be obtained by analyzing the acceleration. An excitation force of about 120 N is applied sinusoidally with a scanning frequency range of 1–100 Hz.

3.2 Comparison between simulation and test

The limitations of the test method make it difficult to measure each modal frequency of the carbody. Only low-order modes can be accurately determined by the conventional test method, whereas high-order modes of local vibrations can hardly be measured. However, by comparing the test results with the simulation calculations, we can find all the modes. This comparison validates the rationality and accuracy of the modeling. From Table 1, we can see that the error in the low-order mode is relatively small, whereas higher mode suffer bigger errors. This is because local deformations appear in high-order mode, and the local stiffness of the carbody is not well simulated. However, under the preparation condition, the error in low-order mode is about 10 %, which is acceptable for engineering requirements. Based on the system model, we compare the test results and the simulations in terms of the sweeping frequency. Figure 4 shows that the simulation results can effectively reflect the actual motion.

Thus, the modeling method has been shown to be efficient. This forms the foundation of the following research into the relationship between suspension parameters and carbody modes.

4 Relationship between suspension parameters and carbody modes

High-speed EMUs generally adopt a distributed power system. The equipment is suspended on the crossbeam of the underframe, and weighs from tens of kilograms to several tons. The suspension method and distribution of the equipment will affect the modal frequency of the carbody. To research the relationship between the suspension of equipment and carbody modes, we consider just one device. Some basic laws are then acquired by analyzing the influence of different suspension parameters on the carbody modes.

It has been shown that the elastic suspension of underframe equipment can effectively reduce carbody vibration and improve ride comfort [18–20]. The vibration of the carbody is closely related to the modal frequency; namely, elastic vibration of the carbody will be aroused only when the external excitation frequency matches the frequency of the carbody. Therefore, the relationship between the main mode of the carbody and the two suspension styles (elastic and rigid) is discussed in this section. Table 2 presents simulation results for both rigid and elastic suspension. As we can see, vertical and lateral first-order bending mode appear under the condition of elastic suspension. Using modal analysis, it is easy to determine that the low-frequency mode is mainly coupled with bending movement in the carbody, caused by the natural frequency of the equipment, whereas high-frequency mode is mainly caused by the interaction of the carbody’s natural frequency and the equipment. As a whole, elastic suspension has a significant effect on the first-order bending mode. Compared with the carbody bending mode when the equipment is under rigid suspension, one of the two new frequencies rises while the other decreases. The span between the two new frequencies is directly related to the suspension parameters. Compared with the case of rigid suspension, the other modal frequencies are all lower, and the change is not so obvious. Rigid suspension is equivalent to increasing the body weight, and also changes the mass center of the carbody. The equipment moves together with the carbody, and hence there is only one vertical bending and one lateral bending frequency. From the above analysis, we can see that the key to the modal matching analysis is the influence of suspension parameters on the first bending mode; the other modes can be ignored.

To further research the influence of equipment suspension parameters on the carbody bending mode, the next section studies the effects of changing the equipment mass, suspension position, and suspension stiffness on the carbody mode. The influence of the location of the suspended equipment on carbody vibration is shown in Fig. 5. From these results, we can see that the equipment has the least influence on the carbody mode when the suspension position is about 7.5 m from the carbody center, which is close to the bogie. Between the bogie and the carbody center, a greater longitudinal distance from equipment to carbody center implies the carbody bending frequency will be closer to the bending frequency without suspended equipment. The low-order coupled bending frequency of the carbody obviously increases as the longitudinal distance to the suspended equipment increases, whereas the coupled frequency caused by the carbody decreases. However, there is only one bending frequency in the rigid suspension case. We can also see that, when the equipment is suspended above the bogie, the mode of the carbody is reversed. From the above analysis, we can conclude that elastically suspended equipment should be positioned away from the bogie to improve the first-order bending frequency of the carbody. There is 3.5 m from the bogie to the end of the car, and 7.5 m from bogie to car center, which is sufficient longitudinal distance to improve the bending frequency. Thus, elastically suspended equipment should be suspended near the center of the carbody.

The next section examines the relationship between the modal frequency and transmissibility. The input excitation is a sinusoidal signal. The influence of equipment mass on carbody modes is shown in Fig. 6. In Fig. 6a, the suspension frequency (\( f = (2\pi )^{ - 1} (m^{ - 1} k)^{ - 0.5} \)) is set to 12 Hz, and we can see that the span between high and low frequencies becomes wider as the equipment mass increases. This increase in equipment mass causes the transmissibility of high frequencies to gradually decrease, while that of low frequencies increases. In Fig. 6b, the suspension stiffness is maintained at 33.6 MN/m (when the equipment mass is 6,000 kg, the suspension frequency is 12.45 Hz, which is close to the carbody bending frequency). With an increase in mass, the bending frequency of the carbody gradually decreases. The change in the low-frequency component is more obvious than that of the high frequency. At the same time, the high-frequency transmissibility increases and the low-frequency transmissibility is reduced, which can reduce the sensitive frequency felt by passengers and improve the ride quality. Therefore, the heavier the equipment, the smaller its suspension frequency should be to reduce the suspension stiffness of the equipment and increase the transmissibility of high frequencies. However, we must be careful to avoid bogie resonance. As shown in Fig. 7, the rigid suspension of the equipment is equivalent to increasing the mass of the carbody without changing its stiffness. This serves to decrease the carbody first-order bending frequency and increase the transmissibility. However, these changes are not so obvious.

The relationship between the carbody bending mode and suspension frequency is depicted in Fig. 8. An increase in the suspension frequency causes the bending frequency of the carbody to increase rapidly, and the low-order bending frequency becomes close to that in the absence of suspended equipment. The high-order bending frequency tends to infinity, and is eventually equivalent to the carbody bending frequency under rigid suspension. However, as the suspension frequency changes, the carbody transmissibility also varies. The increase in suspension frequency leads to an increase in low-frequency transmissibility, and a reduced high-frequency transmissibility. When the suspension frequency reaches a certain value (about 10.75 Hz), the transmissibility of high and low frequencies is equal. At this point, the vibration is minimized. To improve the ride quality, the first-order bending frequency should be as high as possible, and the transmissibility should be as low as possible. To meet these two conditions simultaneously, the frequency of suspended equipment should be less than the carbody first-order bending frequency under rigid suspension, so that the carbody transmissibility can be optimized.

5 Vehicle dynamic system modeling and vibration response analysis

5.1 Dynamic rigid–flexible coupled theory and modeling

Elastic vibration of the carbody cannot be properly reflected in the traditional rigid body model, and our track test shows that the equipment clearly influences the carbody modal frequency. To properly reflect the coupling between suspension equipment and carbody elastic vibration, we require a rigid–flexible coupled dynamic model. In this section, we discuss the rigid–flexible theory. Consider an undeformed carbody in which the location of each point \( q \) relative to a local fixed reference system \( O \) is represented by the vector \( \varvec{r}_{\text{A}} \) (see Fig. 9).

The point \( q \) moves to a new location \( p \) under elastic deformation, so that the position vector relative to the global coordinate system is

where \( \varvec{A} \) is the transformation matrix, and \( \varvec{r}_{\text{A}} \) is the location vector of the fixed reference system relative to the global system. The global location vector of an arbitrary point on the flexible carbody is \( \varvec{r}_{\text{p}} \), \( \varvec{u}_{0} \) is the position of point \( q \) in the undeformed state, and \( \varvec{u}_{\text{f}} \left( t \right) \) denotes the deformed vector. The displacement vector field due to the structure flexibility is expressed as

where \( \varvec{n}_{j} \) represents the deformation shape \( j \) and \( \eta_{\varvec{j}} (t) \) is the shape amplitude.

Differentiating the deformation equation with respect to time yields

The kinetic energy of the deformable body can be defined as

where \( \varvec{m} \) is the mass of the flexible body and η the vector of shape amplitude. In the multi-body dynamics software Simpack, we can use virtual work theory to describe a generalized elastic force. The dynamic equations of the system are

where \( \varvec{M}_{\text{e}} \), \( \varvec{D}_{\text{e}} \), \( \varvec{K}_{\text{e}} \), \( \varvec{C}_{\text{e}} \) denote the general mass matrix, general damping matrix, general stiffness matrix, and constraint matrix, respectively; \( \varvec{f}_{\text{e}} \) denotes a general force consisting of force elements, gravity, external force, and general inertia force.

In engineering practice, the finite element method is often used to model flexible carbodies because of its versatility. First, we extract the carbody substructure SUB file and the vibration modal RST file through finite element analysis. Then, a SID file is generated by the pre-processing module of Simpack. By considering the wheelset and bogie to be a rigid structure, we fix the suspended equipment to a beam of the carbody underframe by four hangers. The suspension equipment has a mass of 6,000 kg, and the carbody with its accessory structures has a mass of 28,000 kg. The model of this vehicle system is shown in Fig. 10, which contains 34 rigid degrees of freedom and 20-order eigenmodes.

5.2 Analysis of vibration response

The vehicle running quality is seriously affected by the suspension parameters of the equipment. It is difficult to study the influence of these parameters experimentally, but we can simulate the vibration characteristics of the carbody under different combinations of suspension parameters. We can then analyze the matching relationship between the equipment and the modal frequency. The following is based on the rigid–flexible coupled dynamics model. The measured irregularity excitation is used to determine the input response, allowing the matching principles between the equipment suspension parameters and carbody mode to be identified. Figures 11, 12 and 13 show the vertical ride quality of the central carbody for various locations, mass, and frequencies of the suspended equipment. From Figs. 11 and 12 we can see that the ride quality index is significantly improved by the use of elastic suspension. The following conclusions can be drawn from an analysis of the equipment location. First, a suspension position close to the center of the carbody is favorable in terms of ride quality. Second, heavier equipment improves ride quality. From these two observations, we can conclude that heavy equipment should be suspended as close as possible to the center of the carbody to improve ride comfort. Figure 13 shows the influence of suspension stiffness on the ride quality index under elastic suspension. According to Fig. 8, we can see that vibration is not adequately reduced when the frequency of suspended equipment is too high or too low. As the suspended frequency increases, the high-frequency part of the carbody coupled bending vibration will decrease. However, when the suspension frequency is higher than the carbody bending frequency under rigid suspension, the low-frequency bending vibration plays a more important role. As a result, the vibration is aggravated, and ride quality will worsen. A suspension frequency that is too low will lead to serious equipment vibration and a worsening of the carbody stability. However, when the frequency is too high, the connection becomes similar to that of rigid suspension, and the carbody vibration will be more serious. Therefore, the suspension frequency of the equipment should be close to, and preferably smaller than, the carbody bending frequency in the rigid case.

6 Conclusions

Using finite element simulations and analyzing test data, we verified that our modeling approach was correct and provided a valid foundation for further calculations. We then analyzed the relationship between carbody modal frequencies and equipment suspended from the car. The resulting modal matching principles can be summarized as follows:

-

To improve the frequency of carbody high-frequency bending and reduce energy transfer, equipment with a large mass should be suspended toward the middle of the carbody.

-

The weight of the equipment strongly affects the first bending frequency and energy transfer of the carbody. The frequency of heavy suspended equipment should be sufficiently low to increase the transmissibility of high frequencies and improve the vibration characteristics of the carbody.

-

The bending frequency of the carbody can be effectively improved by increasing the suspension stiffness. However, this will also increase low-frequency energy transfer. When the suspension frequency is lower than the first-order bending frequency of the carbody under rigid suspension, high-frequency energy transfer plays a leading role. Thus, the suspension frequency of the equipment should be slightly lower than the carbody bending frequency.

References

Zeng J, Luo R (2007) Vibration analysis of railway passenger car systems by considering flexible carbody effect. J China Railw Soc 29(6):19–25

Wu PB, Xue SH, Yang CH (2005) Dynamic response of high-speed passenger car based on flexible carbody model. J Traffic Transp Eng 5(2):5–8

Wang D, Lee YS et al (2009) Mitigating the effect of impact loading on a vehicle using an essentially nonlinear absorber. J Veh Syst Dyn 4(10):1183–1204

Zhou JS, Zhang W et al (2009) Vibration reduction analysis of the dynamic vibration absorber on the flexible carbody of railway vehicles. J China Railw Sci 30(3):86–90

Takigami T, Tomioka T (2008) Bending vibration suppression of railway vehicle carbody with piezoelectric elements. J Mech Syst Transp Logist 1(1):111–121

Kozek M, Benatzky C, Schirrer A (2008) Vibration damping of a flexible carbody structure using piezo-stack actuators. J Int Fed Autom Control Seoul Korea 7:6–11

Huang CH, Zeng J (2010) Flexural vibration suppression of carbody for high2speed passenger car based on constrained damping layers. J Traffic Transp Eng 10(1):36–41

Holst C (1998) Active damping of carbody vibraton. M Master thesis, Department of Mechanics, Royal Institute of Technology (KTH)

Braghin F, Cheli F, Melzi S, Negrini S et al (2013) Experimental modal analysis and numerical modelling of agricultural vehicles. J Conf Proc Soc Exp Mech Ser 5(11):213–220

Lethonen TJ, Juhala M (2005) Predicting the ride behavior of a suspended agricultural tractor. J Int J Heavy Veh Syst 1:131–142

Xiang YC, Xiang WL (2012) Modal analysis of hanging equipment carbody of CRH5 EMU. J Mach Build Autom 41(4):43–46

Kang HG, Zeng J et al (2011) Coupled vibration analysis between carbody and underframe of high-speed intergrated test train. J Beijing Jiaotong Univ 6(35):62–66

Zhao YY, Liu SY, Zhang W (2012) The influence of hanging way and the flexible suspension mass on the body modal frequency. J Jiamusi Univ (Natural Science Edition) 30(3):326–333

Zhao HW, Tian AQ, Wang WJ et al (2011) Simulation and consistence test analysis of carbody structure vibration modal. J Dalian Jiaotong Univ (Natural Science Edition) 32(6):26–29

Lu ZJ, Tian HQ, Zhou D (2005) Modal analysis of 270 km/h high-speed motor car. J China Railw Sci 26(6):18–23

Hao LB, Hu QN, Li G (2004) Disscussion of finite element analysis on modal condition of passenger cars in the preparation conditions. J Roll Stock 42(11):4–7

Tomioka T, Takigami T, Ichiro K (2009) Modal analysis of railway vehicle carbodies using a linear prediction model. J Syst Des Dyn 32(6):918–931

Luo GB, Zeng J (2013) Study on carbody flexible vibrations with considering underframe suspended equipment. J Mod Manuf Eng 5:1–6 (in Chinese)

Wu HC, Wu PB (2012) Effect of equipment suspension stiffness on riding quality E. J Noise Vib Control 32(8):73–77

Sun WJ, Gong D et al (2012) Influences of suspended equipment under carbody on high speed train ride quality. J Procedia Eng 16:812–817

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (No. U1334206) and the National Basic Research Program of China (No. 2011CB711106).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

This article is published under license to BioMed Central Ltd.Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Luo, G., Zeng, J. & Wang, Q. Identifying the relationship between suspension parameters of underframe equipment and carbody modal frequency. J. Mod. Transport. 22, 206–213 (2014). https://doi.org/10.1007/s40534-014-0060-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40534-014-0060-0