Abstract

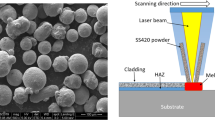

This paper describes an experimental corrosion study performed on austenitic stainless steel deposited mild steel substrate in 0.5 M sodium chloride medium. The study was performed with an aim to improve the corrosion resistance of mild steel substrate through surface deposition of a thin film of asutenitic stainless steel. The thin SS film was deposited by pulse laser deposition technique while using 316 L grade stainless steel foil as a target. Thin film deposition of 316 L stainless steel on mild steel brought about relative improvement in its resistance against corrosion. However, with respect to 316 L stainless steel foil, the specimen exhibited poor corrosion resitance in terms of corrosion rate (corrosion current density), lack of passivity and pitting potential. The reason for the inferior corrosion behaviour of deposited specimen is attributed to defective ferritic microstructure of the thin film and lack of nickel constituent which was associated with lower resistance and higher capacitance with respect to 316 L stainless steel foil. Similarly, with respect to mild steel, deposited mild steel showed better corrosion resistance due to passive role of chromium enriched film.

Similar content being viewed by others

References

Eddy, N.O., Ebenso, E.E.: Int. J. Electrochem. Sci. 5, 731 (2010)

Burstein, G.T., Souto, R.M., Liu, C., Vines, S.P.: New process for passive metal surfaces. Corros. Mater. 29, S1–S4 (2004)

Yaya, K., Khelfaoui, Y., Malki, B., Kerkar, M.: Numerical simulations study of the localized corrosion resistance of AISI 316L stainless steel and pure titanium in a simulated body fluid environment. Corros. Sci. 53, 3309–3314 (2011)

BinSabt, M., Abdel Nazeer, A., Madkour, M., Al-Sagheer, F.: Hydrothermally modified PVA/ZnS-NCQD nanocoating for stainless steel corrosion protection in saline water. RSC Adv. 6, 6888–6895 (2016)

Shreir, L.L., Jarman, R.A., Burstein, G.T.: Corrosion, 3rd edn. Butterworth-Heinemann, Oxford (1994)

Caselis, J.L.V., Rosas, E.R., Meneses, V.M.C.: Hybrid PMMAsilica anticorrosive coatings for stainless steel 316L. Corros. Eng. Sci. Technol. 47, 131–137 (2012)

Schultze, J.W., Lohrengel, M.M.: Electrochim. Acta. 45, 2499 (2000)

Kruger, J.: Int. Mater. Rev. 33, 113 (1988)

Marcus, P.: Electrochim. Acta. 43, 109 (1998)

Okamoto, G., Shibata, T.: Nature. 206, 1350 (1965)

Olsson, C.-O.A., Landolt, D.: Electrochim. Acta. 48, 1093 (2003)

Eason, R.: Pulsed Laser Deposition of Thin Films: Application Led Growth of Functional Materials, 1st edn. Wiley Interscience New York, New York (2007)

Ninghsen, S., Mudali, U.K., Raj, B.: Corros. Rev. 27, 493–532 (2009)

Sedriks, A.J.: Corrosion of Stainless Steels. Wiley, New York (1979)

McCullough, H.M., Fontana, M.G., Bech, F.H.: Trans. Am. Soc. Met. 43, 404–425 (1951)

Ehsani, A., Mahjani, M.G., Moshrefi, R., Mostaanzadeh, H.: JShabani RSC Adv. 4, 38 (2014)

Ningshen, S., KamachiMudali, U., Amarendra, A., Gopalan, P., Dayal, R.K., Khatak, H.S.: Corros. Sci. 48, 1106 (2006)

Macdonald J.R. ed: Impedance Spectroscopy: emphasizing solid materials and systems. John Wiley & Sons, chapters 1–4 (1987)

Drogowska, M., Ménard, H., Lasia, A., Brossard, L.: J. Appl. Electrochem. 26, 1169 (1996)

Ilevbare, G.O., Scully, J.R.: Corrosion. 39, 466 (1983)

Hsu, C.H., Mansfeld, F.: Corrosion. 57, 747 (2001)

Macdonald J.R. ed: Impedance spectroscopy: Emphasizing solid materials and systems. John Wiley and Sons, chapters 1–4 (1987)

Ningshen, S., Kamachi Mudali, U., Amarendra, G., Gopalan, P., Dayal, R.K., Khatak, H.S.: Corros. Sci. 48, 1106–1121 (2006)

Ningshen S., KamachiMudali U., Khatak H.S., Raj B.: Paper No 04–26.14th Asian- Pacific Corrosion Control Conference (14APCCC), October 21–24, 2006, Shanghai, China

In: Proceedings of the international conference on advances in electron microscopy and related techniques and thirty first annual meeting of EMSI, 78–79 (2010)

Inoue, S., Saeki, T., Uchida, H., Koterazawa, K., Iwasa, M.: Vacuum. 66, 257–261 (2002)

Cusenza, S., Borchers, C., Carpene, E., Schaaf, P.: J. Phys. Condens. Matter. 19, 106211 (2007)

Amin, M.A., Saracoglu, M., El-Bagoury, N., Sharshar, T., Ibrahim, M.M., Wysocka, J., Krakowiak, S., Ryl, J.: Int. J. Electrochem. Sci. 11, 10029–10052 (2016)

Acknowledgements

Authors are thankful to Mr. Ram Nihal Ram for specimen preparation.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

All data generated or analysed during this study are included in this article.

Conflict of Interest

There is no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gupta, R.K., Mishra, S., Verma, S. et al. Effect of Pulsed Laser Deposition of Thin Surface Film of 316 L Stainless Steel on Corrosion Behaviour of Mild Steel. Lasers Manuf. Mater. Process. 8, 312–324 (2021). https://doi.org/10.1007/s40516-021-00149-z

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40516-021-00149-z