Abstract

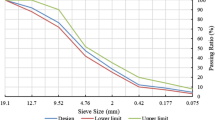

Cellulose fibers are generally used as a stabilizer in bituminous mixes like stone matrix asphalt (SMA) mixes, to stop draindown of the binder from a mix, and are also helpful in reinforcing the cracked roadway. This present study investigates the potential use of naturally occurring fibers known as sisal fiber as a stabilizer in stone matrix asphalt as well as dense-graded bituminous mix namely bituminous concrete (BC). Marshall test is simple, economical, and commonly available to evaluate the optimum bitumen content (OBC) and optimum fiber content (OFC) of mixes and to predict various Marshall criteria: Marshall stability, flow value, air voids, voids in mineral aggregate, and voids filled with bitumen. In this study, VG 30 bitumen has been used as a binder and fly ash, a waste material which has been used as filler. Further, the paving mixes were investigated based on various laboratory tests such as draindown test, moisture susceptibility test, and dynamic modulus test where mixes are prepared at their respective OBC and OFC. The test results indicated that addition of 0.3% of sisal fiber to a mix with fly ash as filler remarkably improves the engineering properties of both mixes considered.

Similar content being viewed by others

References

AASHTO T 283: Standard Method of Test for Resistance of Compacted Asphalt Mixtures to Moisture-Induced Damage. American Association of State Highway and Transportation Officials, Washington, D.C (2014)

AASHTO TP 62: Determining Dynamic Modulus of Hot-Mix Asphalt Concrete Mixtures. American Association of State High-way and Transportation Officials, Washington, DC (2007)

Apeagyei, A.K., Diefenderfer, B.K., Diefenderfer, S.D.: Development of dynamic modulus master curves for hot mix asphalt with abbreviated testing temperature. Int J Pavement Eng. 13(2), 98–102 (2012)

Asi Ibrahim, M.: Laboratory comparison study for the use of stone matrix asphalt in hot weather climates. Constr. Build. Mater. 20, 982–989 (2006)

ASTM D 1559: Test Method for Resistance of Plastic Flow of Bituminous Mixtures Using Marshall Apparatus. American Society for Testing and Materials, Philadelphia, USA (1989)

ASTM D 6931: Indirect Tensile (IDT) Strength for Bituminous Mixtures. American Society for Testing and Materials, Philadelphia, USA (2012)

Bose, S., Kamaraj, C., Nanda, P.K.: Stone mastic asphalt a long life pavement surface. In: Technical Paper of International Seminar on Innovations in Construction and Maintenance of Flexible Pavements, Agra, India, vol. 1, pp. 169–117 (2006)

Brown, E.R. (1992). Experience with Stone Matrix Asphalt in United States. NCAT Publication, Auburn University, Alabama

Brown, E. R., Haddock, J. E., Mallick, R.B. & Lynn, T.A. (1997). Development of a Mixture Design Procedure for Stone Matrix Asphalt (SMA). NCAT Report 97–93. National Center for Asphalt Technology, Auburn, Alabama, USA

Cao, W., Liu, S., Feng, Z.: Comparison of performance of stone matrix asphalt mixtures using basalt and limestone aggregate. Constr. Build. Mater. 41, 474–479 (2013)

Cho, Y.H., Park, D.W., Hwang, S.D.: A predictive equation for dynamic modulus of asphalt mixture used in Korea. Constr. Build. Mater. 24, 513–519 (2010)

IS 1203: Methods for Testing Tar and Bituminous Materials: Determination of Penetration. Bureau of Indian Standards, New Delhi, India (1978)

IS 1205: Methods for Testing Tar and Bituminous Materials: Determination of Softening Point. Bureau of Indian Standards, New Delhi, India (1978)

IS 2386 (Part I). (1963). Methods of test for aggregates for concrete. Bureau of Indian Standards, New Delhi, India

IS 2386 (Part III). (1963). Methods of test for aggregates for concrete. Bureau of Indian Standards, New Delhi, India

IS 2386 (Part IV).(1963). Methods of test for aggregates for concrete. Bureau of Indian Standards, New Delhi, India

IS 73: Paving Bitumen-Specification (Second Revision). Bureau of Indian Standards, New Delhi, India (2006)

Kandhal, P.S.: Waste Material in Hot Mix Asphalt an Over View. NCAT Report, pp. 92–96. National Center for Asphalt Technology, Auburn, Alabama, USA (1992)

Kar, D.: A Laboratory Study of Bituminous Mixes Using a Natural Fibre. Unpublished M.Tech Thesis, NIT Rourkela, Odisha, India (2012)

Kar, D., Panda, M., Giri, J.P.: Influence of fly ash as a filler in bituminous mixes. ARPN Journal of Engineering and Applied Science. 9(6), 895–900 (2014)

Karasahin, M., Terzi, S.: Evaluation of marble waste dust in the mixture of asphaltic concrete. Constr. Build. Mater. 21, 616–620 (2007)

Kumar, P., Chandra, S., Bose, S.: Laboratory investigation on SMA mixes with different additives. Int J Pavement Eng. 8(1), 11–18 (2007)

Ministry of Road Transport and Highways (MoRTH): Specifications for Road and Bridge Works, Section 500, Fifth Revision. Indian Roads Congress, New Delhi, India (2013)

MS 2: Mixture Design Methods for Asphalt Concrete and Other Hot Mixture Types (Sixth Edition). Asphalt Institute (1993)

National Cooperative Highway Research Program (NCHRP). (2015). Fibre additives in asphalt mixtures a synthesis of highway practice, NCHRP Synthesis 475, Transportation Research Board, Washington, D.C. USA

Panda, M., Suchismita, A., Giri, J.P.: Utilization of ripe coconut fibre in stone matrix asphalt mixes. International Journal of Transportation Science and Technology. 2(4), 289–302 (2013)

Pandey, S.N., Majumdar, A.K.: Jute and applied fibres as non-woven Geo-Jute and their application in civil engineering. International reinforced soil conference. In: University of Strathclyde. Glasgow, UK (1990)

Wu, S., Xue, Y., Ye, Q., Chen, Y.: Utilization of steel slag as aggregates for stone mastic asphalt (SMA) mixtures. Build. Environ. 42(7), 2580–2585 (2007)

Xue, Y., Hou, H., Zhu, S., Zha, J.: Utilization of municipal solid waste incineration ash in stone mastic asphalt mixture - pavement performance and environmental impact. Constr. Build. Mater. 23(2), 989–996 (2009)

Zhao, Y., Tang, J., Liu, H.: Construction of triaxial dynamic modulus master curves for asphalt mixture. Constr. Build. Mater. 37, 21–26 (2012)

Zulkati, A., Diew, W.Y., Delai, D.S.: Effects of fillers on properties of asphalt-concrete mixture. J. Transp. Eng. 138(7), 902–910 (2011)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kar, D., Giri, J.P. & Panda, M. Performance Evaluation of Bituminous Paving Mixes Containing Sisal Fiber as an Additive. Transp. Infrastruct. Geotech. 6, 189–206 (2019). https://doi.org/10.1007/s40515-019-00079-6

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40515-019-00079-6