Abstract

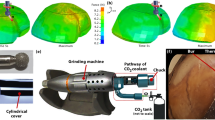

Bone grinding has cemented its applications in the various sorts of the neurosurgeries. Generally, a rotating burr is used to remove a part of the bone to expose the tumors present underneath the bone. The abrasion caused by the grinding wheel causes a rise in temperature owing to the generation of the heat during grinding and would have severe consequences with the initiation of thermogenesis. To bridge this gap, an in-house experimental setup was developed to perform multi-pass rotary ultrasonic neurosurgical bone grinding. Three functional characteristics, namely rotational speed, feed rate, and amplitude, have been investigated using Taguchi L18 orthogonal array design. The regression equations have been obtained and validated with confirmation experiments using a random set of machining parameters. Further, machining parameters are optimized using genetic algorithm and confirmatory trials are performed using optimized conditions. The results of statistical analysis (ANOVA) revealed that the feed rate is the most significant parameter influencing the change in temperature during osteotomy. Nevertheless, the standard deviation was most affected by rotational speed. Furthermore, a comparative analysis has been carried out for conventional and rotary ultrasonic neurosurgical grinding. A hybrid approach using cumulative equivalent minutes (CEM43°C) and Arrhenius model has been used to predict the thermal damage caused to the human body’s tissues during bone grinding. The results obtained have been experimentally validated, and outcomes revealed that ultrasonically actuated grinding burr may prevent osteonecrosis and neural damage duly supported with infrared thermograms and graphical plots.

Similar content being viewed by others

Abbreviations

- Ω :

-

Tissue damage function

- A :

-

Pre-exponential factor (s−1)

- E a :

-

Arrhenius activation energy (J/mol)

- τ :

-

Time (s)

- R :

-

Universal gas constant (J/mol k)

- K :

-

Rate constant

- T :

-

Actual exposure temperature (°C)

- T break :

-

Breaking point temperature

- CEM43°C:

-

Cumulative number of equivalent minutes at 43 °C

- F :

-

Feed rate (mm/min)

- A :

-

Amplitude (µm)

- D :

-

Depth of cut (mm)

- ∆T :

-

Change in temperature (°C)

- σ :

-

Standard deviation

- CG:

-

Conventional grinding

- RUNG:

-

Rotary ultrasonic neurosurgical grinding

References

Robinson L (2015) Traumatic injury to peripheral nerves. In: Nerves and nerve injuries. Elsevier, pp 611–628

Banu MA, Mehta A, Ottenhausen M et al (2016) Endoscope-assisted endonasal versus supraorbital keyhole resection of olfactory groove meningiomas: comparison and combination of 2 minimally invasive approaches. J Neurosurg 124:605–620. https://doi.org/10.3171/2015.1.JNS141884

Zhang L, Tai BL, Wang G et al (2013) Thermal model to investigate the temperature in bone grinding for skull base neurosurgery. Med Eng Phys 35:1391–1398. https://doi.org/10.1016/j.medengphy.2013.03.023

Aslan A, Vatansever HS, Aslan GG et al (2005) Effect of thermal energy produced by drilling on the facial nerve: histopathologic evaluation in guinea pigs. J Laryngol Otol. https://doi.org/10.1258/0022215054516250

Kumar R, Hynes NRJ (2019) Influence of rotational speed on mechanical features of thermally drilled holes in dual-phase steel. Proc Inst Mech Eng Part B J Eng Manuf 233:1614–1625. https://doi.org/10.1177/0954405418805601

Kumar R, Hynes NRJ (2018) Finite-element simulation and validation of material flow in thermal drilling process. J Braz Soc Mech Sci Eng 40:162. https://doi.org/10.1007/s40430-018-1091-y

Hynes NRJ, Kumar R (2017) Process optimization for maximizing bushing length in thermal drilling using integrated ANN–SA approach. J Braz Soc Mech Sci Eng 39:5097–5108. https://doi.org/10.1007/s40430-017-0820-y

Rajesh N, Hynes J, Kumar R, Sujana JAJ (2017) Optimum bushing length in thermal drilling of galvanized steel using artificial neural network coupled with genetic algorithm. Mater Technol 51:813–822. https://doi.org/10.17222/mit.2016.290

Kumar R (2017) Simulation and experimental validation of Al7075–T651 flow drilling process. J Chin Soc Mech Eng 38:413–420. https://doi.org/10.29979/JCSME

Soriano J, Garay A, Aristimuño P et al (2013) Effects of rotational speed, feed rate and tool type on temperatures and cutting forces when drilling bovine cortical bone. Mach Sci Technol 17:611–636. https://doi.org/10.1080/10910344.2013.837353

Alam K, Silberschmidt VV (2014) Analysis of temperature in conventional and ultrasonically-assisted drilling of cortical bone with infrared thermography. Technol Heal Care 22:243–252. https://doi.org/10.3233/THC-140813

Boa K, Barrak I, Varga E et al (2016) Intraosseous generation of heat during guided surgical drilling: an ex vivo study of the effect of the temperature of the irrigating fluid. Br J Oral Maxillofac Surg 54:904–908. https://doi.org/10.1016/j.bjoms.2016.06.004

Van Rhoon GC, Samaras T, Yarmolenko PS et al (2013) CEM43°C thermal dose thresholds: a potential guide for magnetic resonance radiofrequency exposure levels? Eur Radiol 23:2215–2227. https://doi.org/10.1007/s00330-013-2825-y

Alam K, Hassan E, Bahadur I (2015) Experimental measurements of temperatures in ultrasonically assisted drilling of cortical bone. Biotechnol Biotechnol Equip 29:753–757. https://doi.org/10.1080/13102818.2015.1034176

Gupta V, Pandey PM, Gupta RK, Mridha AR (2017) Rotary ultrasonic drilling on bone: a novel technique to put an end to thermal injury to bone. Proc Inst Mech Eng Part H J Eng Med 231:189–196. https://doi.org/10.1177/0954411916688500

Shakouri E, Sadeghi MH, Karafi MR et al (2015) An in vitro study of thermal necrosis in ultrasonic-assisted drilling of bone. Proc Inst Mech Eng Part H J Eng Med 229:137–149. https://doi.org/10.1177/0954411915573064

Kumar V, Singh H (2019) Investigation of hole quality in rotary ultrasonic drilling of borosilicate glass using RSM. J Braz Soc Mech Sci Eng 41:36. https://doi.org/10.1007/s40430-018-1524-7

Alam K, Mitrofanov AV, Silberschmidt VV (2011) Experimental investigations of forces and torque in conventional and ultrasonically-assisted drilling of cortical bone. Med Eng Phys 33:234–239. https://doi.org/10.1016/j.medengphy.2010.10.003

Wang Y, Cao M, Zhao X et al (2014) Experimental investigations and finite element simulation of cutting heat in vibrational and conventional drilling of cortical bone. Med Eng Phys 36:1408–1415. https://doi.org/10.1016/j.medengphy.2014.04.007

Wang W, Shi Y, Yang N, Yuan X (2014) Experimental analysis of drilling process in cortical bone. Med Eng Phys 36:261–266. https://doi.org/10.1016/j.medengphy.2013.08.006

Lughmani WA, Bouazza-Marouf K, Ashcroft I (2015) Drilling in cortical bone: a finite element model and experimental investigations. J Mech Behav Biomed Mater 42:32–42. https://doi.org/10.1016/j.jmbbm.2014.10.017

Singh G, Jain V, Gupta D, Ghai A (2016) Optimization of process parameters for drilled hole quality characteristics during cortical bone drilling using Taguchi method. J Mech Behav Biomed Mater 62:355–365. https://doi.org/10.1016/j.jmbbm.2016.05.015

Gupta V, Pandey PM (2016) Experimental investigation and statistical modeling of temperature rise in rotary ultrasonic bone drilling. Med Eng Phys 38:1330–1338. https://doi.org/10.1016/j.medengphy.2016.08.012

Gupta V, Pandey PM, Silberschmidt VV (2017) Rotary ultrasonic bone drilling: improved pullout strength and reduced damage. Med Eng Phys 41:1–8. https://doi.org/10.1016/j.medengphy.2016.11.004

Sharma A, Babbar A, Jain V, Gupta D (2018) Enhancement of surface roughness for brittle material during rotary ultrasonic machining. MATEC Web Conf 249:01006. https://doi.org/10.1051/matecconf/201824901006

Singh D, Babbar A, Jain V et al (2019) Synthesis, characterization, and bioactivity investigation of biomimetic biodegradable PLA scaffold fabricated by fused filament fabrication process. J Braz Soc Mech Sci Eng 41:121. https://doi.org/10.1007/s40430-019-1625-y

Babbar A, Singh P, Farwaha HS (2017) Regression model and optimization of magnetic abrasive finishing of flat brass plate. Indian J Sci Technol 10:1–7. https://doi.org/10.17485/ijst/2017/v10i31/113860

Babbar A, Jain V, Gupta D (2019) Neurosurgical bone grinding. In: Prakash C et al (eds) Biomanufacturing. Springer, Cham, pp 137–155. https://doi.org/10.1007/978-3-030-13951-3_7

Babbar A, Sharma A, Jain V, Jain AK (2019) Rotary ultrasonic milling of C/SiC composites fabricated using chemical vapor infiltration and needling technique. Mater Res Express. https://doi.org/10.1088/2053-1591/ab1bf7

Feldmann A, Wili P, Maquer G, Zysset P (2018) The thermal conductivity of cortical and cancellous bone. Eur Cells Mater 35:25–33. https://doi.org/10.22203/eCM.v035a03

Jr HF (1947) Studies of thermal injury; the predictability and the significance of thermally induced rate processes leading to irreversible epidermal injury. Arch Pathol 43:489–502

Martin NA, Falder S (2017) A review of the evidence for threshold of burn injury. Burns 43:1624–1639

Borrelli M, Thompson L, Cain C, Dewey W (1990) Time-temperature analysis of cell killing of BHK cells heated at temperatures in the range of 43.5°C to 57.0°C. Int J Radiat Oncol 19:389–399. https://doi.org/10.1016/0360-3016(90)90548-X

Sapareto SA, Dewey WC (1984) Thermal dose determination in cancer therapy. Int J Radiat Oncol Biol Phys. https://doi.org/10.1016/0360-3016(84)90379-1

Alam K, Khan M, Muhammad R et al (2015) In-vitro experimental analysis and numerical study of temperature in bone drilling. Technol Heal Care 23:775–783. https://doi.org/10.3233/THC-151035

Lee JE, Ozdoganlar OB, Rabin Y (2012) An experimental investigation on thermal exposure during bone drilling. Med Eng Phys 34:1510–1520. https://doi.org/10.1016/j.medengphy.2012.03.002

Augustin G, Davila S, Mihoci K et al (2008) Thermal osteonecrosis and bone drilling parameters revisited. Arch Orthop Trauma Surg 128:71–77. https://doi.org/10.1007/s00402-007-0427-3

Sezek S, Aksakal B, Karaca F (2012) Influence of drill parameters on bone temperature and necrosis: a FEM modelling and in vitro experiments. Comput Mater Sci 60:13–18. https://doi.org/10.1016/j.commatsci.2012.03.012

Pujana J, Rivero A, Celaya A, López de Lacalle LN (2009) Analysis of ultrasonic-assisted drilling of Ti6Al4V. Int J Mach Tools Manuf 49:500–508. https://doi.org/10.1016/j.ijmachtools.2008.12.014

Olson S, Clinton JM, Working Z et al (2011) Thermal effects of glenoid reaming during shoulder arthroplasty in vivo. J Bone Jt Surg Ser A 93:11–19. https://doi.org/10.2106/JBJS.I.01227

Eriksson AR, Albrektsson T, Albrektsson B, Albrekt T (1984) Heat caused by drilling cortical bone : temperature measured in vivo in patients and animals. Acta Orthop Scand 55(6):629–631. https://doi.org/10.3109/17453678408992410

Eriksson AR, Albrektsson T (1983) Temperature threshold levels for heat-induced bone tissue injury: a vital-microscopic study in the rabbit. J Prosthet Dent. https://doi.org/10.1016/0022-3913(83)90174-9

Takata A (1974) Development of criterion for skin burns. Aerosp Med 45:634–637

Chang I (2010) Considerations for thermal injury analysis for RF ablation devices. Open Biomed Eng J 4:3–12. https://doi.org/10.2174/1874120701004020003

Acknowledgements

The authors would like to express special thanks of gratitude to Dr. Deepak Agrawal, All India Institute of Medical Science (AIIMS), New Delhi, for their timely guidance and allowing them access to facilities by providing details of neurosurgical bone grinding operation and special visits to Out-Patient Department (OPD) to carefully examine the whole bone grinding operation prior to tumor removal.

Funding

The author(s) of this article has not received funding in any form from any financial body/institution.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There are no potential conflicts of interest among all authors.

Additional information

Technical Editor: Lincoln Cardoso Brandao.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Babbar, A., Jain, V. & Gupta, D. Thermogenesis mitigation using ultrasonic actuation during bone grinding: a hybrid approach using CEM43°C and Arrhenius model. J Braz. Soc. Mech. Sci. Eng. 41, 401 (2019). https://doi.org/10.1007/s40430-019-1913-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-019-1913-6