Abstract

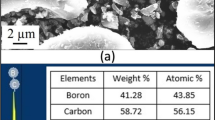

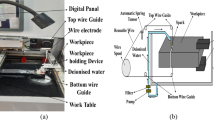

A generous development of electrical discharge machining method has been stimulated in the province of metal matrix composites materials. In this extant work, the optimal condition for various output responses specifically circularity, cylindricity, perpendicularity and radial over cut are exposed by employing grey relational analysis procedure by optimizing the input process parameters alike pulse on time (Ton), peak current (I) and gap voltage (V). The Hybrid Metal Matrix Composite material is evolved by handling the stir casting approach and then machined by exploring the input parameters using L27 orthogonal array. From the consequences of grey relational grade, a response table was discovered to elect the optimal conditions of the individual parameter. The most contributing input parameter is current with 69.08%, which is determined from the ANOVA table. Finally, the optimal conditions which were acquired from the response table are peak current of 12 A, pulse on time of 50 µs and gap voltage of 30 V and also verified through an authentication test which illustrated that optimal process parameters are competently improved by 0.1452 when compared to the predicted parameter. The machined surface is analysed using a scanning electron microscope. The results palpated that the peak current increases the number of microvoids and size of the crater was increased and the poor surface finish was achieved.

Similar content being viewed by others

Abbreviations

- EDM:

-

Electrical discharge machining

- MMCs:

-

Metal matrix composites

- HMMCs:

-

Hybrid metal matrix composites

- AMMCs:

-

Aluminium metal matrix composites

- AHMMCs:

-

Hybrid aluminium metal matrix composites

- SEM:

-

Scanning electron microscope

- CR:

-

Circularity

- CY:

-

Cylindricity

- PP:

-

Perpendicularity

- ROC:

-

Radial overcut

- I:

-

Peak current

- Ton:

-

Pulse on time

- V:

-

Gap voltage

- BN:

-

Boron nitride

- TiCL:

-

Titanium carbide

- h-BN:

-

Hexagonal boron nitride

- Al alloy:

-

Aluminium alloy

- CNC:

-

Computer numerical control

- CMM:

-

Coordinate measuring machining

- GRA:

-

Grey relational analysis

- GRC:

-

Grey relational coefficient

- GRG:

-

Grey relational grade

- ANOVA:

-

Analysis of variance

- S/N ratio:

-

Signal-to-noise ratio

References

Karl UK (2006) Metal matrix composites custom-made materials for automobile and aerospace engineering. https://doi.org/10.1002/3527608117

Chawla KK, Chawla N (2014) Metal matrix composites: automotive applications. Encycl Automot Eng. https://doi.org/10.1002/9781118354179.auto279

Nikhilesh C, Krishan K (2006) Metal matrix composites. Springer, London. https://doi.org/10.1007/978-1-4614-9548-2

Clyne TW, Withers PJ (2014) An introduction to metal matrix composites. https://doi.org/10.1007/s13398-014-0173-7.2

Thirumalai Kumaran S, Uthayakumar M (2014) Investigation on the dry sliding friction and wear behaviour of AA6351-SiC-B4C hybrid metal matrix composites. Proc Inst Mech Eng Part J J Eng Tribol 228(3):332–338. https://doi.org/10.1177/1350650113508103

Alam MT, Ansari AH, Arif S, Alam MN (2017) Mechanical properties and morphology of aluminium metal matrix nanocomposites-stir cast products. Adv Mater Process Technol 698(July):1–16. https://doi.org/10.1080/2374068X.2017.1350543

Ho KH, Newman ST (2003) State of the art electrical discharge machining (EDM). Int J Mach Tools Manuf 43(13):1287–1300. https://doi.org/10.1016/S0890-6955(03)00162-7

Pramanik A (2014) Developments in the non-traditional machining of particle reinforced metal matrix composites. Int J Mach Tools Manuf 86:44–61. https://doi.org/10.1016/j.ijmachtools.2014.07.003

Jameson EC (2001) Electric discharge machining. Society of Manufacturing Engineers, Dearbern

Garg RK, Singh KK, Sachdeva A, Sharma VS, Ojha K, Singh S (2010) Review of research work in sinking EDM and WEDM on metal matrix composite materials. Int J Adv Manuf Technol 50(5–8):611–624. https://doi.org/10.1007/s00170-010-2534-5

Kandpal BC, kumar J, Singh H (2015) Machining of Aluminium metal matrix composites with electrical discharge machining—a review. Mater Today Proc 2(4–5):1665–1671. https://doi.org/10.1016/j.matpr.2015.07.094

Kumar SS, Uthayakumar M, Kumaran ST, Parameswaran P (2014) Electrical discharge machining of Al(6351)–SiC–B4C hybrid composite. Mater Manuf Process 29(11–12):1395–1400. https://doi.org/10.1080/10426914.2014.952024

Ahamed AR, Asokan P, Aravindan S (2009) EDM of hybrid Al–SiCp–B4Cp and Al–SiCp–glassp MMCs. Int J Adv Manuf Technol 44(5–6):520–528. https://doi.org/10.1007/s00170-008-1839-0

Hourmand M, Farahany S, Sarhan AAD, Noordin MY (2015) Investigating the electrical discharge machining (EDM) parameter effects on Al-Mg2Si metal matrix composite (MMC) for high material removal rate (MRR) and less EWR–RSM approach. Int J Adv Manuf Technol 77(5–8):831–838. https://doi.org/10.1007/s00170-014-6491-2

Mathai VJ, Dave HK, Desai KP (2017) Experimental investigations on EDM of Ti6Al4 V with planetary tool actuation. J Braz Soc Mech Sci Eng 39(9):3467–3490. https://doi.org/10.1007/s40430-016-0657-9

Mahanta S, Chandrasekaran M, Samanta S, Arunachalam RM (2018) EDM investigation of Al 7075 alloy reinforced with B4C and fly ash nanoparticles and parametric optimization for sustainable production. J Braz Soc Mech Sci Eng. https://doi.org/10.1007/s40430-018-1191-8

Kumar P, Parkash R (2016) Experimental investigation and optimization of EDM process parameters for machining of aluminum boron carbide (Al–B4C) composite. Mach Sci Technol 20(2):330–348. https://doi.org/10.1080/10910344.2016.1168931

Dhar S, Purohit R, Saini N, Sharma A, Kumar GH (2007) Mathematical modeling of electric discharge machining of cast Al–4Cu–6Si alloy–10wt.% SiCP composites. J Mater Process Technol 194(1-3):24–29. https://doi.org/10.1016/j.jmatprotec.2007.03.121

Sidhu SS, Batish A, Kumar S (2013) Fabrication and electrical discharge machining of metal-matrix composites: a review. J Reinf Plast Compos 32(17):1310–1320. https://doi.org/10.1177/0731684413489366

Selvarajan L, Manohar M, Udhaya kumar A, Dhinakaran P (2017) Modelling and experimental investigation of process parameters in EDM of Si3N4-TiN composites using GRA-RSM. J Mech Sci Technol 31(1):111–122. https://doi.org/10.1007/s12206-016-1009-5

Souza CC, Arencibia RV, Costa HL, Filho AP (2005) A contribution to the measurement of circularity and cylindricity deviations. In: ABCM symposium series in Mechatronics vol 5, pp 791–800

Selvarajan L, Narayanan CS, Jeyapaul R (2016) Optimization of EDM parameters on machining Si3N4-TiN composite for improving circularity, cylindricity, and perpendicularity. Mater Manuf Process 31(4):405–412. https://doi.org/10.1080/10426914.2015.1058947

Dhanabalan S, Sivakumar K, Narayanan CS (2014) Analysis of form tolerances in electrical discharge machining process for inconel 718 and 625. Mater Manuf Process 29(3):253–259. https://doi.org/10.1080/10426914.2013.852213

Selvarajan L, Sathiya Narayanan C, Jeyapaul R (2015) Optimization of process parameters to improve form and orientation tolerances in EDM of MoSi2-SiC composites. Mater Manuf Process 30(8):954–960. https://doi.org/10.1080/10426914.2014.962041

Selvarajan L, Sathiya Narayanan C, Jeyapaul R, Manohar M (2016) Optimization of EDM process parameters in machining Si3N4-TiN conductive ceramic composites to improve form and orientation tolerances. Meas J Int Meas Confed 92:114–129. https://doi.org/10.1016/j.measurement.2016.05.018

Malik A, Manna A (2018) Multi-response optimization of laser-assisted jet electrochemical machining parameters based on thegray relational analysis. J Braz Soc Mech Sci Eng 40(3):148. https://doi.org/10.1007/s40430-018-1069-9

Nair A, Kumanan S (2018) Optimization of size and form characteristics using multi-objective grey analysis in abrasive water jet drilling of Inconel 617. J Braz Soc Mech Sci Eng 40(3):121. https://doi.org/10.1007/s40430-018-1042-7

Suresh Kumar S, Uthayakumar M, Thirumalai Kumaran S et al (2015) Parametric optimization of wire electrical discharge machining on aluminium based composites through grey relational analysis. J Manuf Process 20:33–39. https://doi.org/10.1016/j.jmapro.2015.09.011

Pandey AK, Gautam GD (2018) Grey relational analysis-based genetic algorithm optimization of electrical discharge drilling of the Nimonic-90 superalloy. J Braz SocMech Sci Eng 40(3):117. https://doi.org/10.1007/s40430-018-1045-4

Anand G, Alagumurthi N, Elansezhian R, Palanikumar K, Venkateshwaran N (2018) Investigation of drilling parameters on hybrid polymer composites using grey relational analysis, regression, fuzzy logic, and ANN models. J Braz Soc Mech Sci Eng 40:214. https://doi.org/10.1007/s40430-018-1137-1

Suresh Kumar S, Uthayakumar M, Thirumalai Kumaran S, Parameswaran P (2014) Electrical discharge machining of Al(6351)–SiC–B4C hybrid composite. Mater Manuf Process 29:1395–1400. https://doi.org/10.1080/10426914.2014.952024

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Márcio Bacci da Silva.

Rights and permissions

About this article

Cite this article

Senthilkumar, T.S., Muralikannan, R. Enhancing the geometric tolerance of aluminium hybrid metal matrix composite using EDM process. J Braz. Soc. Mech. Sci. Eng. 41, 41 (2019). https://doi.org/10.1007/s40430-018-1553-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-018-1553-2