Abstract

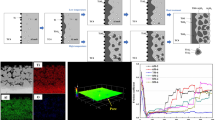

A layer of TiC coating has been deposited on commercially pure aluminium by tungsten inert gas (TIG) cladding process. Microscopic image of the TIG-cladded aluminium substrate shows crack and defects free uniform deposition of TiC layer on the substrate. The XRD analysis confirms the presence of TiC on the coated surface without formation of any other intermetallic phases. Micro-hardness measured at the coating cross-section revealed a substantial improvement in the hardness value than that of as-received aluminium substrate. The investigation also revealed that increasing the processing current enhances the coating thickness significantly by compromising the average micro-hardness value marginally, which is attributed to dilution of TiC layer with the substrate material. The sliding wear test of the TiC-coated aluminium specimen performed against hardened steel disc (HRC 58) through a pin-on-disc arrangement shows a significant augmentation in the wear resistance property of the coating surface than that of as-received aluminium substrate.

Similar content being viewed by others

References

Feng Y, Luo Z, Li Y, Ling Z (2016) A novel method for resistance plug welding of 7075 aluminum alloy. Mater Manuf Process 31:2077–2083. https://doi.org/10.1080/10426914.2015.1103853

Fu Y, Batchelor AW (1998) Laser alloying of aluminum alloy AA 6061 with Ni and Cr. Part II. The effect of laser alloying on the fretting wear resistance. Surf Coat Technol 102:119–126

Vaziri SA, Shahverdi HR, Torkamany MJ, Shabestari SG (2009) Effect of laser parameters on properties of surface-alloyed Al substrate with Ni. Opt Lasers Eng 47:971–975. https://doi.org/10.1016/j.optlaseng.2009.04.007

Rathee S, Maheshwari S, Siddiquee AN (2018) Issues and strategies in composite fabrication via friction stir processing: A review. Mater Manuf Process 33:239-261. https://doi.org/10.1080/10426914.2017.1303162

Berger LM (2015) Application of hardmetals as thermal spray coatings. Int J Refract Met Hard Mater 49:350–364. https://doi.org/10.1016/j.ijrmhm.2014.09.029

Sahu JK, Sahoo CK, Masanta M (2015) In-situ TiB2–TiC–Al2O3 composite coating on aluminum by laser surface modification. Mater Manuf Process 30:736–742. https://doi.org/10.1080/10426914.2014.984225

Bartkowski D, Bartkowska A (2017) Wear resistance in the soil of Stellite-6/WC coatings produced using laser cladding method. Int J Refract Met Hard Mater 64:20–26. https://doi.org/10.1016/j.ijrmhm.2016.12.013

Patel P, Mridha S, Baker TN (2014) Influence of shielding gases on preheat produced in surface coatings incorporating SiC particulates into microalloy steel using TIG technique. Mater Sci Technol 30:1506–1514. https://doi.org/10.1179/1743284713Y.0000000481

Du B, Wang X, Zou Z (2011) Microstructure and tribological behavior of laser in situ synthesized TiC-reinforced Fe-based composite coatings. Tribol Lett 43:295–301. https://doi.org/10.1007/s11249-011-9808-4

Katipelli LR, Agarwal A, Dahotre NB (2000) Laser surface engineered TiC coating on 6061 Al alloy: microstructure and wear. Appl Surf Sci 153:65–78. https://doi.org/10.1016/S0169-4332(99)00368-2

Viswanathan A, Sastikumar D, Kamachimudali U, Kumar H, Nath AK (2007) TiC reinforced composite layer formation on Al–Si alloy by laser processing. Surf Eng 23:123–128. https://doi.org/10.1179/174329407X169458

Mabhali LAB, Pityana SL, Sacks N (2010) Laser surface alloying of aluminum (AA1200) with Ni and SiC powders. Mater Manuf Process 25:1397–1403. https://doi.org/10.1080/10426914.2010.498073

D’Amato C, Buhagiar J, Betts JC (2014) Tribological characteristics of an A356 aluminium alloy laser surface alloyed with nickel and Ni–Ti–C. Appl Surf Sci 313:720–729. https://doi.org/10.1016/j.apsusc.2014.06.061

Uenishi K, Kobayashi KF (1999) Formation of surface layer based on Al 3 Ti on aluminum by laser cladding and its compatibility with ceramics. Intermetallics 7:553–559

Mridha S, Baker TN (2015) Overlapping tracks processed by TIG melting TiC preplaced powder on low alloy steel surfaces. Mater Sci Technol 31:337–343. https://doi.org/10.1179/1743284714Y.0000000530

Sahoo CK, Masanta M (2017) Microstructure and mechanical properties of TiC–Ni coating on AISI304 steel produced by TIG cladding process. J Mater Process Technol 240:126–137. https://doi.org/10.1016/j.jmatprotec.2016.09.018

Saroj S, Sahoo CK, Tijo D, Kumar K, Masanta M (2017) Sliding abrasive wear characteristic of TIG cladded TiC reinforced Inconel825 composite coating. Int J Refract Met Hard Mater 69:119–130. https://doi.org/10.1016/j.ijrmhm.2017.08.005

Mridha S, Idriss ANM, Maleque MA, Yaacob II, Baker TN (2015) Melting of multipass surface tracks in steel incorporating titanium carbide powders. Mater Sci Technol 31:1362–1369. https://doi.org/10.1179/1743284714Y.0000000712

Chong PH, Man HC, Yue TM (2002) Laser fabrication of Mo-TiC MMC on AA6061 aluminum alloy surface. Surf Coat Technol 154:268–275

Sahoo CK, Soni L, Masanta M (2016) Evaluation of microstructure and mechanical properties of TiC/TiC-steel composite coating produced by gas tungsten arc (GTA) coating process. Surf Coat Technol 307:17–27. https://doi.org/10.1016/j.surfcoat.2016.08.056

Mridha S, Idriss ANM, Baker TN (2012) Incorporation of TiC particulates on AISI 4340 low alloy steel surfaces via tungsten inert gas arc melting. Adv Mater Res 445:655–660. https://doi.org/10.4028/www.scientific.net/AMR.445.655

Peng D-X, Kang Y, Li Z-X, Chang S-Y (2013) Wear behavior of ceramic powder cladded on carbon steel surface by gas tungsten arc welding. Ind Lubr Tribol 65:129–134. https://doi.org/10.1108/00368791311303492

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Márcio Bacci da Silva.

Rights and permissions

About this article

Cite this article

Sahoo, C.K., Masanta, M. Microstructure and wear characteristic of hard and wear resistance TiC coating deposited on aluminium by tungsten inert gas (TIG) cladding process. J Braz. Soc. Mech. Sci. Eng. 40, 247 (2018). https://doi.org/10.1007/s40430-018-1178-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-018-1178-5