Abstract

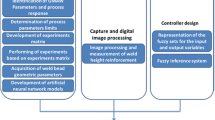

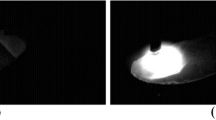

The need to improve productivity and quality has led to the development and improvement of techniques and systems for monitoring and controlling welding processes. This work presents a methodology to perform the modeling, optimization and control of the weld bead width, enabling the adjustment of process parameters in real time. An integrated system was developed for image acquisition, modeling and control of the welding process, allowing a real-time response, through artificial neural networks. Parameters such as welding speed, wire feed velocity and arc voltage are predicted in the function of a desired weld bead width. To get the closed-loop control system, it was designed with a “fuzzy” controller, in which the difference between the width to be achieved and the actual width of the bead is taken as reference. This weld bead is measured through an acquisition system and images processed using a low-price webcam. The control action is carried out preferably at welding speed, a parameter that has the greatest influence on the weld bead width and has no influence on the metal transfer behavior. Weld beads with pre-defined width, good appearance and quality were obtained.

Similar content being viewed by others

References

Modenesi P, Marques P, Santos D (2012) Introdução à Metalurgia da Soldagem. Universidade Federal de Minas Gerais, Departamento de Engenharia Metalúrgica e de Materiais, Belo Horizonte

Esme U, Bayramoglu M, Kazancoglu Y, Ozgun S (2011) Optimization of weld bead geometry in TIG welding process using grey relation analysis and Taguchi method. Mater Technol 43:143–149

Byrd TA, Hauser RD (1991) Expert systems in production and operations management: research directions in assessing overall impact. Int J Prod Res 29:2471–2482

Krishnakumar K (2003) Intelligent systems for aerospace engineering—an overview. NASA Technical Report. doi: 20030105746

Bezdek JC (1994) “What is computational intelligence?” Computational Intelligence, Imitating Life, IEEE Computer Society Press, pp 1–12

Rudas IJ, Fodor J (2008) Intelligent Systems. J. of Computers, Communications & Control, ISSN 1841-9836, 3:132-138

Kumar S (2009) Artificial neural network seminar report-09’. AL-Ameen Engineering College, Department of Electronics and Communication Engineering, Tamilnadu

Rojas R (1996) Neural networks: a systematic introduction. Springer-Verlag, Berlin

Torres EMM, Cruz JAG, Lopera JEP, Alfaro S (2013) Parameter optimization in GMAW process with solid and metal-cored wires. In: 22nd International Congress of Mechanical Engineering (COBEM 2013). Nov 3–7, Ribeirão Preto, SP, Brazil

Lee J, Um K (2000) A comparison in a back-bead prediction of gas metal arc welding using multiple regression analysis and artificial neural network. J Opt Lasers Eng 34:149–158

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Glauco A. de P. Caurin.

Rights and permissions

About this article

Cite this article

Cruz, J.G., Torres, E.M. & Absi Alfaro, S.C. A methodology for modeling and control of weld bead width in the GMAW process. J Braz. Soc. Mech. Sci. Eng. 37, 1529–1541 (2015). https://doi.org/10.1007/s40430-014-0299-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40430-014-0299-8