Abstract

Understanding the mechanism of CO2 reduction on iron is crucial for the design of more efficient and cheaper iron electrocatalyst for CO2 conversion. In the present study, we have employed spin-polarized density functional theory calculations within the generalized gradient approximation (DFT-GGA) to elucidate the mechanism of CO2 reduction into carbon monoxide and formic acid on the Fe (100) facet. We also sort to understand the transformations of the other isomers of adsorbed CO2 on iron as earlier mechanistic studies are centred on the transformations of the C2v geometry alone and not the other possible conformations i.e., flip-C2v and Cs modes. Two alternative reduction routes were considered i.e., the direct CO2 dissociation against the hydrogen-assisted CO2 transformation through formate and carboxylate into CO and formic acid. Our results show that CO2 in the C2v mode is the precursor to the formation of both products i.e., CO and formic acid. Both the formation and transformation of CO2 in the Cs and flip-C2v is challenging kinetically and thermodynamically compared to the C2v mode. The formic acid formation is favoured over CO via the reverse water gas shift reaction mechanism on Fe (100). Both formic acid formation and CO formation will proceed via the carboxylate intermediate since formate is a stable intermediate whose transformation into formic acid is challenging both kinetically and thermodynamically.

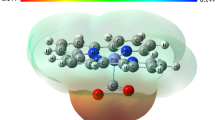

Graphic abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The catalytic CO2 hydrogenation is crucial towards CO2 mitigation. The two CO2 reduction routes currently being explored are the direct hydrogenation into hydrocarbons and the initial CO2 hydrogenation into CO (via the reverse water gas shift (rWGS) reaction) prior to hydrogenation into hydrocarbons [1,2,3,4,5,6]. CO2 conversion to CO via the rWGS reaction (Eq. 1) is attractive as CO is the feedstock for the production of longer chain hydrocarbons (liquid fuels) via the Fischer–Tropsch process [7]. In a 1:1 CO2 and H2 reaction ratio, both CO and the formic acid are plausible products. Formic acid is widely employed in the leather and rubber industries and is a feedstock in the production of numerous chemicals, like sweeteners and fibre [6].

Since the rWGS reaction is a reversible process, catalysts that favour the rWGS reaction are known to be equally active for the water gas shift (WGS) reaction. For example, copper [8], apart from its high reactivity for low-temperature WGS reactions, shows a high selectivity towards CO production over CH4 in mixtures of CO2 and H2 [9]. Although iron has been reported to be an inefficient catalyst for the WGS reaction [10], it is a very stable catalyst at elevated temperatures and hence is employed extensively in the high temperature WGS reaction [11]. Iron has also been reported to stabilize Cu for CO production [8]. The two competing mechanisms reported for the WGS mechanisms are the formate pathway (associative mechanism), and the redox pathway (decomposition mechanism) [12, 13]. DFT calculations on clean and pre-adsorbed Fe (110) [10] and Fe3O4 (111) [14] reported the redox mechanism as the most preferred path. Despite the extensive research on the WGS mechanism on iron-based catalysts, mostly oxides [11], little is known about the rWGS reaction mechanisms on single metal iron crystals towards identifying a more efficient iron surface for the rWGS reaction.

Other metals like Pt and Ru in solid oxide fuel cells, were found to be controlled by formate decomposition [15], and direct dissociation paths [16], respectively. Chen et al. [17] observed formate as a key intermediate on the Cu/Al2O3 catalyst system. A similar mechanism is reported on Cu/SiO2 surface [18] while the redox mechanism is seen on pure Cu(110) [19] and Cu/ZnO [20], systems with the slowest step being the dissociation step [19]. DFT investigations of the rWGS reaction mechanism on nickel (211) indicated the redox path to be favoured both kinetically and thermodynamically [21]. Despite earlier DFT calculations [22,23,24] have reported the spontaneous formation of anionic CO2δ− species on all the low-Miller indices of iron surfaces, to the best of our knowledge, no systematic theoretical study has been conducted to understand the mechanism of the rWGS reaction on iron. In the present study, the catalytic CO2 hydrogenation intermediates and reaction barriers leading to carbon monoxide and formic acid production on iron (100) have been studied.

Computational details

All calculations were carried out within the framework of spin-polarized density functional theory (DFT) as implemented in the Quantum ESPRESSO package [25]. The generalized gradient approximation (GGA), with the Perdew, Burke, Ernzerhof (PBE) exchange–correlation functional [26] were used to calculate the total free energies. The surface was described by a slab model, where periodic boundary conditions were applied to the central super-cell so that it is reproduced periodically throughout space. XcrysDen [27] software was employed for the visualization of structures and electron densities. The Fermi-surface effects were treated by the smearing technique of Fermi–Dirac, using a smearing parameter of 0.03 Ry. The energy threshold defining self-consistency of the electron density was set to 10–6 eV. Using convergence tests, the kinetic energy cut off of the plane wave basis set was set to 40 Ry and 320 Ry for the charge density cut off. Also, by convergence tests, the Monkhorst–pack K-points grid of (11 × 11 × 11) and (3 × 3 × 1) was sufficient to describe the bulk and the p (3 × 3) super-cell, respectively. The Climbing Image Nudged Elastic Band (CI-NEB) method was used to determine the energy barriers and the transition state structures on the surface. Vibrational frequencies of the transition state structures were characterized by a single imaginary frequency.

Results and discussion

The low-Miller index (100) surface was cleaved from the optimized bulk using the METADISE code [28], which does not only consider periodicity in the plane direction but also provides the different atomic layer stacking resulting in a zero dipole moment perpendicular to the surface plane, as is required for reliable and realistic surface calculations. The slab was constructed with 6 atomic layers in thickness and a vacuum of 12 Å was introduced to the system along the z-axis to avoid interactions between periodic slabs. All gaseous adsorbates were optimized in a cubic box of size 20 Å. In all calculations, adsorbates and the topmost 3 layers of the substrate were allowed to relax while the bottom 3 layers were fixed at the bulk position. Neighbouring adsorbates in laterally repeating units of the slabs were more than 5 Å apart, to prevent interaction between repeated units. A p(3 × 3) slab (Fig. 1) was employed to mimic the Fe (100) surface.

CO2 adsorption

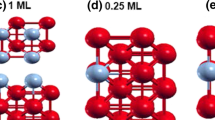

The preferred CO2 adsorption site on the clean Fe (100) surface has been reported to be the hollow site [24]. At the hollow site, we considered CO2 binding through the carbon and the two oxygen atoms in the 3 possible configurations (see Fig. 2) i.e. C2v mode, flip-C2v mode (observed on the Fe (111) facet) [29] and the Cs mode. In the C2v mode, CO2 binds through the carbon and two oxygen atoms in a v shape (see Fig. 2a). In the flip-C2v mode, CO2 binds through the carbon and two oxygen atoms with a flipped v shape to the surface (see Fig. 2b). In the Cs adsorption mode, CO2 binds through a single oxygen and carbon atom as shown in Fig. 2c. Upon geometry optimization, the flip-C2v mode was seen to be unstable with an adsorption energy of 0.91 eV and not favourable formed on the Fe (100) surface. This is due to the difference in surface topology between Fe (100) and Fe (111), since the flip-C2v mode has been reported on Fe (111). The surface packing of the (100) surface is more packed than the stepped (111) surface, and the open nature of the (111) surface therefore stabilizes CO2 even in the flip-C2v mode. CO2 binds most strongly in the C2v mode with an adsorption energy of -1.34 eV. Apart from the 'v' shape structure, we have also obtained the Cs mode with a less stable adsorption energy of − 1.26 eV. In both of these configurations, we observe elongation in the C−O bonds from 1.19 Å in the gaseous state and change in the α(OCO) angles, suggesting an activated CO2 species. In the C2v mode, the two C−O bonds were calculated to be 1.35 Å, whereas, for the Cs mode, these were calculated at 1.30 Å and 1.36 Å. In the unstable flip-v mode, CO2 is bound and still activated to 1.35 Å as seen in the C2v mode (see Table 1). This is consistent with the work of Nassir in 1993, who only observed the Cs and C2v activated CO2 modes on the hollow site of Fe (100) at 110 K [30]. This is due to the high instability of the CO2 in the flip-C2v mode on Fe (100), making this adsorbed species transient and not favourably formed and observed.

Upon the adsorption of CO2, we considered CO2 hydrogenation by gaseous hydrogen through different hydrogenated conformations to identified the stable compounds formed as indicated in Fig. 3. CO2 can either be hydrogenated though the carbon of CO2 i.e., 1a, 2a and 3a, or through the oxygen atom i.e., 1b, 2b and 3b, or through both carbon and oxygen i.e., 1c, 2c and 3c.

As seen in Fig. 4, after optimisation, hydrogen adsorption to CO2 through the carbon centre to form formate, Figs. 1a and 2a, is more favoured (− 2.11 eV) over through the oxygen centre to form carboxylate (− 0.85 eV and − 1.08 eV), Figs. 1b and 3b ii. However, the interatomic distances show that hydrogen binds more strongly to oxygen (O–H = 0.99 Å) than to carbon (C–H = 1.10 Å) centre showing that the oxygen is a more electronegative centre for hydrogenation. Hydrogenation of CO2 also leads to CO2 decomposition and hydroxyl formation on the surface of iron as seen in Figs. 2b and 3b. In all hydrogenation cases, the adsorption energies are seen to be exothermic. Formic acid formation energy was calculated to be − 1.41 eV (in Figs. 1c and 2c) while the (CO + H2O) formation energy is − 2.63 eV. All adsorption energies and interatomic distances of the hydrogenated CO2 species are tabulated in Table 1. These adsorption conformations are further explored via the hydrogen assisted and non-hydrogen-assisted transformation into molecular formic acid formation and decomposed CO formation on the Fe (100) surface.

CO2 reduction mechanism

To elucidate the mechanism of CO2 reduction into CO and HCOOH, two proposed reaction schemes were explored. Scheme 1 shows the pathways leading to CO formation. Hydrogenation of CO2 in the C2v adsorption mode could lead to carboxylate formation whose hydroxyl could be picked by hydrogen via TSa2 to form product. CO2 in the Cs geometry could lead to CO2 decomposition into CO and hydroxyl, hence the barrier for CO2 dissociation was considered through the hydrogen-assisted CO2 dissociation via TSc2 and hydrogen unassisted CO2 decomposition into CO via TSc3. Scheme 2 shows the pathways leading to formic acid production, CO2 can be reduced through the carboxylate or formate intermediates into formic acid. Transition state structures along these pathways were then sort for and the reaction profiles for these transformations shown in Figs. 5 and 6.

CO2 reduction into CO

As shown in the reaction profile diagram in Fig. 5, the transition states leading to CO formation were determined. The barrier to direct CO2 dissociation was sort from the least stable CO2 activated molecule, in the Cs mode (c) which is a most likely reactive species to dissociation. The barrier to CO2 activation is seen to be 2 eV and the rate determining step is seen to be the barrier for the decomposition step of 6.40 eV, which makes this pathway very unlikely for CO formation. Hydrogenation of the Cs molecule to carboxylate is more favoured kinetically through a barrier of 1.54 eV. Upon the formation of carboxylate, OH hydrogenation to water requires an energy of 1.40 eV. Hence, the rate limiting step is seen to be 1.54 eV which will enable carboxylate formation. The dissociative hydrogenation of CO2 in the Cs mode is most feasible transformation of CO2 in the Cs mode, requiring an energy of 0.17 eV. Surface hydroxyl is then hydrogenated via a barrier of 1.49 eV, this makes the CO2 activation step the most challenging step for the Cs pathways. A barrier of 0.17 eV through TSA1 is required to activate CO2 in the C2v preferred mode. CO2 in the C2v mode requires a lower barrier of 0.30 eV to form carboxylate which transforms through a barrier of 1.40 eV to form CO. Considering the varies pathways for CO2 transformation through the reverse water gas shift mechanism to CO and water, CO2 is adsorbed and activated in the C2v mode, a thermodynamically favoured step (∆E = − 1.34 eV) with a barrier of 0.17 eV. Activated CO2 is hydrogenated through an unfavoured thermodynamic step through a barrier of 0.30 eV. Carboxylate OH is then hydrogenated into an unstable product (∆E = − 0.68 eV), through the rate limiting step of 1.40 eV. Product formation however from the decomposed CO and hydroxyl intermediate (2b) is both thermodynamically and kinetically more challenging than the associative path.

CO2 reduction into formic acid

Formate formation can proceed via the hydrogenation of the flip-C2v mode or the hydrogenation and concerted flip of CO2 from the C2v mode into formate. Via the flip-C2v CO2 activated molecule, adsorption is seen to be both thermodynamically and kinetically challenging, requiring an energy barrier of 6.40 eV and reaction energy of 0.9 eV to occur. Due to the instability and high activation barrier the flip-C2v is not a likely species to be formed on the Fe (100) surface. This activated CO2 species if formed will transform in a barrierless step to formate. Preferred activated CO2 mode can be hydrogenated into carboxylate or formate. As seen in Fig. 6, the transformation to carboxylate is an endothermic step whiles conversion to formate is exothermic step. Transformation to formate is also kinetically more favoured, through a barrier of 0.09 eV and is sequentially hydrogenated through the oxygen via a barrier of 0.96 eV to form formic acid. The rate limiting step through the formate intermediate is seen to be formic acid formation step via a barrier of 0.96 eV. Carboxylate although not favoured thermodynamically, requires an energy of 0.3 eV to be formed and is subsequently hydrogenated into formic acid via a barrier of 0.16 eV, where carbon is protonated to form formic acid. The rate limiting barriers show that CO2 transformation to formic acid will proceed via the carboxylate intermediate. Activated C2v CO2 is formed through a barrier of 0.17 eV in an exothermic step (∆E = − 1.34 eV). CO2 is then protonated into carboxylate (∆E = − 1.08 eV) through a barrier of 0.3 eV and further protonated to formic acid (∆E = − 1.41 eV). Both CO and formic acid reactions will proceed favourably via the carboxylate intermediate and not the formate or decomposed CO2 pathway. Comparing the rate limiting steps, the rWGS reaction (1.40 eV) is less favoured on Fe (100) compared to formic acid formation (0.3 eV). Carboxylate transformation into formic acid is favoured kinetically and thermodynamically over its transformation into CO.

Comparing our results with other DFT simulations on transition metals, we observe in this work that the hydrogen-assisted dissociation of CO2 via carboxylate is favoured over the direct dissociation of CO2 into CO. This is contrary to what is observed on the Ni (211) surface where the direct dissociation is seen to be preferred kinetically over hydrogen-assisted CO2 transformation [21]. Our result is however consistent with the work of Vesseli and co., on Ni (110), where carboxylate led to CO formation and formate is too stable to be transformed [31, 32]. Our previous studies on Fe (111), also shows that CO is preferentially formed from carboxylate and flipped-C2v CO2 is stable and converted via a barrier of 0 eV into formate [29]. These results show that surface topology and composition affect the formation of surface species and the impact on the preferred reaction mechanisms for formic acid formation.

Summary and conclusions

A detailed spin-polarized DFT-GGA calculation has been utilized to elucidate the mechanisms of CO2 conversion into CO via the rWGS reaction and the conversion to formic acid as an alternative reaction on Fe (100) surface. Rate-limiting barriers of 0.3 eV and 1.40 eV were computed for the production of formic acid and CO, respectively, indicating that the formic acid production reaction will proceed faster than the formation of CO. CO2 associative transformation of CO2 via carboxylate on Fe (100) is favoured over its dissociative transformation via carbonyl into CO. Our results reveal that although CO2 binds on the Fe (100) surface in C2v and Cs mode at the hollow site, CO2 adsorption in the flipped-C2v mode is seen to be thermodynamically and kinetically challenging. CO2 in the C2v mode is seen to be the most preferred CO2 adsorption mode and the precursor leading to the formation of desired products i.e., CO and formic acid. Formic acid is selectively produced via the carboxylate pathway over the formate pathway. The high stability of the formate intermediate (ΔE = − 2.11 eV) and the energetics to transform it into formic acid (Ea = 0.96 eV) shows that formate formation could be a dead-end along that pathway. Fe surfaces with lower surface work functions may be promising for the rWGS as they favour easier charge transfer and stronger CO2 binding in the ‘v’ mode which is the precursor to carboxylate and product formation.

References

Jiang, Z., Xiao, T., Kuznetsov, V.L., Edwards, P.P.: Turning carbon dioxide into fuel. Philos. Trans. A. Math. Phys. Eng. Sci. 368, 3343–3364 (2010). https://doi.org/10.1098/rsta.2010.0119

Whipple, D.T., Kenis, P.J.A.: Prospects of CO 2 utilization via direct heterogeneous electrochemical reduction. J. Phys. Chem. Lett. 1, 3451–3458 (2010). https://doi.org/10.1021/jz1012627

Centi, G., Perathoner, S.: Opportunities and prospects in the chemical recycling of carbon dioxide to fuels. Catal. Today. 148, 191–205 (2009). https://doi.org/10.1016/j.cattod.2009.07.075

Razali, N.A.M., Lee, K.T., Bhatia, S., Mohamed, A.R.: Heterogeneous catalysts for production of chemicals using carbon dioxide as raw material: a review. Renew. Sustain. Energy Rev. 16, 4951–4964 (2012). https://doi.org/10.1016/j.rser.2012.04.012

Ma, J., Sun, N., Zhang, X., Zhao, N., Xiao, F., Wei, W., Sun, Y.: A short review of catalysis for CO2 conversion. Catal. Today. 148, 221–231 (2009). https://doi.org/10.1016/j.cattod.2009.08.015

Wang, W., Wang, S., Ma, X., Gong, J.: Recent advances in catalytic hydrogenation of carbon dioxide. Chem. Soc. Rev. 40, 3703–3727 (2011). https://doi.org/10.1039/c1cs15008a

Schulz, H.: Short history and present trends of Fischer–Tropsch synthesis. 186, 3–12 (1999)

Chen, C.S., Cheng, W.H., Lin, S.S.: Enhanced activity and stability of a Cu/SiO2 catalyst for the reverse water gas shift reaction by an iron promoter. Chem. Commun. (2001). https://doi.org/10.1039/b104279n

Lortie, M., Isaifan, R., Liu, Y., Mommers, S.: Synthesis of CuNi/C and CuNi/-Al2O3 catalysts for the reverse water gas shift reaction`. Int. J. Chem. Eng. 2, 2 (2015). https://doi.org/10.1155/2015/750689

Liu, S., Li, Y.W., Wang, J., Jiao, H.: Reactions of CO, H2O, CO2, and H2 on the clean and precovered Fe(110) surfaces—a DFT investigation. J. Phys. Chem. C. 119, 28377–28388 (2015). https://doi.org/10.1021/acs.jpcc.5b07497

Zhu, M., Wachs, I.E.: Iron-based catalysts for the high-temperature water-gas shift (HT-WGS) reaction: a review. ACS Catal. 6, 722–732 (2016). https://doi.org/10.1021/acscatal.5b02594

Khan, A., Smirniotis, P.G.: Relationship between temperature-programmed reduction profile and activity of modified ferrite-based catalysts for WGS reaction. J. Mol. Catal. A Chem. 280, 43–51 (2008). https://doi.org/10.1016/j.molcata.2007.10.022

Zhu, M., Wachs, I.E.: Resolving the reaction mechanism for H 2 formation from high-temperature water-gas shift by chromium-iron oxide catalysts. ACS Catal. 6, 2827–2830 (2016). https://doi.org/10.1021/acscatal.6b00659

Huang, L., Han, B., Zhang, Q., Fan, M., Cheng, H.: Mechanistic study on water gas shift reaction on the Fe 3 O 4 (111) reconstructed surface. J. Phys. Chem. C. 119, 28934–28945 (2015). https://doi.org/10.1021/acs.jpcc.5b09192

Pekridis, G., Kalimeri, K., Kaklidis, N., Vakouftsi, E., Iliopoulou, E.F., Athanasiou, C., Marnellos, G.E.: Study of the reverse water gas shift (RWGS) reaction over Pt in a solid oxide fuel cell (SOFC) operating under open and closed-circuit conditions. Catal. Today. (2007). https://doi.org/10.1016/j.cattod.2007.05.026

Avanesian, T., Gusmão, G.S., Christopher, P.: Mechanism of CO2 reduction by H2 on Ru(0 0 0 1) and general selectivity descriptors for late-transition metal catalysts. J. Catal. (2016). https://doi.org/10.1016/j.jcat.2016.03.016

Chen, C.-S., Cheng, W.-H., Lin, S.-S.: Mechanism of CO formation in reverse water–gas shift reaction over Cu/Al2O3 catalyst. Catal. Lett. 68, 45–48 (2000). https://doi.org/10.1002/adma.201402322

Chen, C., Cheng, W., Lin, S.: Study of reverse water gas shift reaction by TPD , TPR and CO 2 hydrogenation over potassium-promoted Cu/SiO2 catalyst. 238, 55–67 (2003)

Ernst, K.H., Campbell, C.T., Moretti, G.: Kinetics of the reverse water-gas shift reaction over Cu(110). J. Catal. (1992). https://doi.org/10.1016/0021-9517(92)90210-9

Fujita, S., Terunuma, H., Nakamura, M., Takezawa, N.: Mechanisms of methanation of carbon monoxide and carbon dioxide over nickel. Ind. Eng. Chem. Res. 30, 1146–1151 (1991). https://doi.org/10.1021/ie00054a012

Cao, D.-B., Li, Y.-W., Wang, J., Jiao, H.: CO2 dissociation on Ni(211). Surf. Sci. 603, 2991–2998 (2009). https://doi.org/10.1016/j.susc.2009.08.008

Liu, C., Cundari, T., Wilson, A.: CO2 reduction on transition metal (Fe Co, Ni, and Cu) surfaces: in comparison with homogeneous catalysis. J. Phys. Chem. C. 116(9), 5681–5688 (2012)

Li, H.-J., Ho, J.-J.: Density functional calculations on the hydrogenation of carbon dioxide on Fe(111) and W(111) surfaces. J. Phys. Chem. C. 114, 1194–1200 (2010). https://doi.org/10.1021/jp909428r

Kwawu, C.R., Tia, R., Adei, E., Dzade, N.Y., Catlow, C.R.A., De Leeuw, N.H.: CO2 activation and dissociation on the low miller index surfaces of pure and Ni-coated iron metal: a DFT study. Phys. Chem. Chem. Phys. 19, 19478–19486 (2017). https://doi.org/10.1039/c7cp03466k

Giannozzi, P., Baroni, S., Bonini, N., Calandra, M., Car, R., Cavazzoni, C., Ceresoli, D., Chiarotti, G.L., Cococcioni, M., Dabo, I., Dal Corso, A., de Gironcoli, S., Fabris, S., Fratesi, G., Gebauer, R., Gerstmann, U., Gougoussis, C., Kokalj, A., Lazzeri, M., Martin-Samos, L., Marzari, N., Mauri, F., Mazzarello, R., Paolini, S., Pasquarello, A., Paulatto, L., Sbraccia, C., Scandolo, S., Sclauzero, G., Seitsonen, A.P., Smogunov, A., Umari, P., Wentzcovitch, R.M.: QUANTUM ESPRESSO: a modular and open-source software project for quantum simulations of materials. J. Phys. Condens. Matter. 21, 395502 (2009). https://doi.org/10.1088/0953-8984/21/39/395502

Perdew, J.P., Burke, K., Ernzerhof, M.: Generalized Gradient Approximation Made Simple. Phys. Rev. Lett. 77, 3865–3868 (1996). https://doi.org/10.1103/PhysRevLett.77.3865

Kokalj, A.: XCrySDen-a new program for displaying crystalline structures and electron densities. J. Mol. Graph. Model. 17, 176–179 (1999). https://doi.org/10.1016/S1093-3263(99)00028-5

Watson, G.W., Kelsey, E.T., de Leeuw, N.H., Harris, D.J., Parker, S.C.: Atomistic simulation of dislocations, surfaces and interfaces in MgO (1996)

Kwawu, C.R., Aniagyei, A., Tia, R., Adei, E.: A DFT investigation of the mechanisms of CO2 and CO methanation on Fe (111). Mater. Renew. Sustain. Energy. (2020). https://doi.org/10.1007/s40243-020-0164-x

Nassir, M.H.: Sequential carbon oxygen bond cleavage in chemisorption of CO2 on Fe(100). J. Vac. Sci. Technol. 11, 2104 (1993). https://doi.org/10.1116/1.578376

Vesselli, E., Rizzi, M., De Rogatis, L., Ding, X., Baraldi, A., Comelli, G., Savio, L., Vattuone, L., Rocca, M., Fornasiero, P., Baldereschi, A., Peressi, M.: Hydrogen-assisted transformation of CO 2 on nickel: the role of formate and carbon monoxide. J. Phys. Chem. Lett. 1, 402–406 (2010). https://doi.org/10.1021/jz900221c

Vesselli, E., De Rogatis, L., Ding, X., Baraldi, A., Savio, L., Vattuone, L., Rocca, M., Fornasiero, P., Peressi, M., Baldereschi, A., Rosei, R., Comelli, G.: Carbon dioxide hydrogenation on Ni(110). J. Am. Chem. Soc. 130, 11417–11422 (2008). https://doi.org/10.1021/ja802554g

Acknowledgements

CRK is grateful for funding from The World Academy of Sciences (grant 18-032RG/CHE/AF/AC_I). CRK acknowledges the UK Royal Society and LeverhulmeTrust for a research grant under the Royal Society-Leverhulme Africa Postdoctoral FellowshipAward Scheme (grant LAF\R1\180013). The authors acknowledge the Centre for High-Performance Computing (CHPC), South Africa, for additional computing resources.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kwawu, C.R., Aniagyei, A., Konadu, D. et al. Mechanisms of CO2 reduction into CO and formic acid on Fe (100): a DFT study. Mater Renew Sustain Energy 10, 9 (2021). https://doi.org/10.1007/s40243-021-00194-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40243-021-00194-w