Abstract

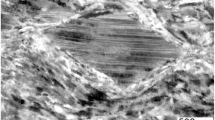

The evolutions of nano-twins and martensitic transformation in 316L austenitic stainless steel during large tensile deformation were studied by electron backscatter diffraction (EBSD) technology and transmission electron microscopy (TEM) in detail. The results show that due to the low stacking fault energy of the steel, phase transformation induced plasticity (TRIP) and twinning induced plasticity (TWIP) coexist during the tensile deformation. The deformation firstly induces the formation of deformation twins, and dislocation pile-up is caused by the reduction of the dislocation mean free path (MFP) or grain refinement due to the twin boundaries, which further induces the martensitic transformation. With the increase of tensile deformation, a large number of nano-twins and α’-martensite appear, and the width of nano-twins decreases gradually, meanwhile the frequency of the intersecting deformation twins increases. The martensitic transformation can be divided into two types: γ-austenite → α’-martensite and γ-austenite → ε-martensite. α’-martensite is mainly distributed near the twin boundaries, especially at the intersection of twins, while ε-martensite and stacking faults exist in the form of transition products between the twins and the matrix.

Similar content being viewed by others

References

B.D. Cooman, Y. Estrin, S.K. Kim, Acta Mater. 142, 283 (2017)

O. Bouaziz, S. Allain, P.C. Scott, P. Cugy, D. Barbier, Curr. Opin. Solid State Mat. Sci. 15, 141 (2011)

E.I. Galindo-Nava, P.E.J. Rivera-Díaz-del-Castillo, Acta Mater. 128, 120 (2017)

C. Gauss, I. Filho, M. Sandim, P.A. Suzuki, H. Sandim, Mater. Sci. Eng. A 651, 507 (2015)

Y.F. Shen, Y.D. Wang, X.P. Liu, X. Sun, R.L. Peng, S.Y. Zhang, L. Zuo, P.K. Liaw, Acta Mater. 61, 6093 (2013)

H. Zhi, C. Zhang, S. Antonov, H. Yu, Y. Su, Acta Mater. 195, 371 (2020)

M. Kang, W. Woo, Y.K. Lee, B.S. Seong, Mater. Lett. 76, 93 (2012)

Q. Xie, Y. Chen, P. Yang, Z. Zhao, Y.D. Wang, K. An, Scripta Mater. 150, 168 (2018)

S. Allain, J.P. Chateau, O. Bouaziz, Mater. Sci. Eng. A 387–389, 143 (2004)

L. Rémy, Metall. Trans. A 12, 387 (1981)

T.H. Lee, E. Shin, C.S. Oh, H.Y. Ha, S.J. Kim, Acta Mater. 58, 3173 (2010)

S.K. Mishra, S.M. Tiwari, A.M. Kumar, L.G. Hector, Metall. Mater. Trans. A 43, 1598 (2012)

L. Remy, A. Pineau, Mater. Sci. Eng. 28, 99 (1977)

S. Vercammen, B.C.D. Cooman, N. Akdut, B. Blanpain, P. Wollants, Steel Res. Int. 14, 370 (2003)

L. Chen, Z. Yang, X. Qin, Acta Metall. Sin. Engl. Lett. 26, 1 (2013)

H. Jacques, Scripta Mater. 63, 961 (2010)

S. Mishra, M. Yadava, K.N. Kulkarni, N.P. Gurao, Acta Mater. 178, 99 (2019)

L. Remy, Acta Metall. 26, 443 (1978)

S.L. Wong, M. Madivala, U. Prahl, F. Roters, D. Raabe, Acta Mater. 118, 140 (2016)

J.W. Christian, S. Mahajan, Prog. Mater. Sci. 39, 1 (1995)

J. Narayan, Y.T. Zhu, Appl. Phys. Lett. 92, 1275 (2008)

M. Niewczas, Dislocations in Solids, vol. 13 (Elsevier, 2007), pp.263–364

Y.T. Zhu, J. Narayan, J.P. Hirth, S. Mahajan, X.L. Wu, X.Z. Liao, Acta Mater. 57, 3763 (2009)

Q. Xie, Z. Pei, J. Liang, D. Yu, Z. Zhao, P. Yang, R. Li, M. Eisenbach, K. An, Acta Mater. 161, 273 (2018)

T.H. Ahn, S.B. Lee, K.T. Park, K.H. Oh, H.N. Han, Mater. Sci. Eng. A 598, 56 (2014)

J. Liu, Y. Jin, X. Fang, C. Chen, Q. Feng, X. Liu, Y. Chen, T. Suo, F. Zhao, T. Huang, Sci. Rep. 6, 35345 (2016)

Y. Tomita, T. Iwamoto, Int. J. Mech. Sci. 37, 1295 (1995)

X.L. Wu, M.X. Yang, F.P. Yuan, L. Chen, Y.T. Zhu, Acta Mater. 112, 337 (2016)

X.S. Yang, S. Sun, H.H. Ruan, S.Q. Shi, T.Y. Zhang, Acta Mater. 136, 347 (2017)

S.I. Baik, Y.W. Kim, Materials 10, 100677 (2020)

D. Goodchild, W.T. Roberts, D.V. Wilson, Acta Metall. 18, 1137 (1970)

I.R. Souza Filho, A. Dutta, D.R. Almeida Junior, W. Lu, M.J.R. Sandim, D. Ponge, H.R.Z. Sandim, D. Raabe, Acta Mater. 197, 123 (2020)

K.H. Kwon, B.C. Suh, S.I. Baik, Y.W. Kim, N.J. Kim, Sci. Technol. Adv. Mater. 14, 014204 (2013)

Z.Y. Tang, R.D.K. Misra, M. Ma, N. Zan, Z.Q. Wu, H. Ding, Mater. Sci. Eng. A 624, 186 (2015)

J.K. Hwang, I.C. Yi, I.H. Son, J.Y. Yoo, B. Kim, A. Zargaran, N.J. Kim, Mater. Sci. Eng. A 644, 41 (2015)

S. Martin, C. Ullrich, D. Rafaja, Mater. Today Proc. 2, S643 (2015)

M. Soleimani, A. Kalhor, H. Mirzadeh, Mater. Sci. Eng. A 795, 140023 (2020)

D. Molnar, X. Sun, S. Lu, W. Li, G. Engberg, L. Vitos, Mater. Sci. Eng. A 759, 490 (2019)

R.E. Schramm, R.P. Reed, Metall. Trans. A 6, 1345 (1975)

K.S. Cheong, E.P. Busso, J. Mech. Phys. Solids 54, 671 (2006)

B. Gwalani, W. Fu, M. Olszta, J. Silverstein, D.R. Yadav, P. Manimunda, A. Guzman, K. Xie, A. Rohatgi, S. Mathaudhu, Materials 18, 101146 (2021)

M. Kamaya, Mater. Charact. 60, 125 (2009)

M. Kamaya, A.J. Wilkinson, J.M. Titchmarsh, Nucl. Eng. Des. 235, 713 (2005)

X. Ma, C. Huang, J. Moering, M. Ruppert, H.W. Höppel, M. Göken, J. Narayan, Y. Zhu, Acta Mater. 116, 43 (2016)

A. Harte, M. Atkinson, M. Preuss, J. Fonseca, Acta Mater. 195, 555 (2020)

R.R. Shen, P. Efsing, Ultramicroscopy 184, 156 (2017)

L. Meng, P. Yang, Q. Xie, H. Ding, Z. Tang, Scripta Mater. 56, 931 (2007)

E. Bouyne, H.M. Flower, T.C. Lindley, A. Pineau, Scripta Mater. 39, 295 (1998)

J. Xie, H. Fu, Z. Zhang, Y. Jiang, Intermetallics 23, 20 (2012)

K.R. Limmer, J.E. Medvedeva, D. Aken, N.I. Medvedeva, Comp. Mater. Sci. 99, 253 (2015)

Acknowledgements

This work was supported by the Natural Science Foundation of Shaanxi Province, China (No. 2021JM-061).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors state that there are no conflicts of interest to disclose.

Additional information

Available online at http://link.springer.com/journal/40195.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, JW., Luo, X., Huang, B. et al. Nano-Twinning and Martensitic Transformation Behaviors in 316L Austenitic Stainless Steel During Large Tensile Deformation. Acta Metall. Sin. (Engl. Lett.) 36, 758–770 (2023). https://doi.org/10.1007/s40195-022-01487-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-022-01487-3