Abstract

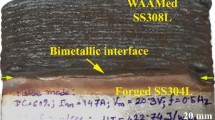

Hybrid manufacturing (HM) uses additive manufacturing (AM) techniques to prepare complex or fine structures on traditional processing parts, which can fully utilize the advantages of AM to form complex parts, and the high efficiency and low cost of conventional processing methods in manufacturing regular components. A bimetal material was produced by selective laser melting (SLM) of AlSi10Mg on the deformed Al6061 alloy substrate in this study. Firstly, the interface characteristics of the two alloys were studied. The results show that a metallurgical interface with a thickness of 100–200 μm was formed as the result of the Marangoni convection during SLM preparation. In detail, the circular flow in the melt pool at the interface led to the dilution of alloying elements and the change of microstructure. Moreover, a suitable first-layer thickness can effectively suppress the hot cracks at the interfacial region. Based on the optimized results, the hybrid manufactured samples with different SLM processed volume ratios (SLM-part) to the substrate were prepared to study the mechanical properties and the deformation behavior of hybrid parts. The results show that the volume ratio of the SLM-part to the substrate had an influence on the strength and the elasto-plastic behavior by affecting the distribution of plastic deformation.

Similar content being viewed by others

References

A. Poznak, D. Freiberg, P. Sanders, Fundamentals of Aluminium Metallurgy||automotive Wrought Aluminium Alloys (Elsevier Ltd, 2018)

J. Hirsch, T. Al-Samman, Acta Mater. 61, 818 (2013)

P. Sadeesh, K.M. Venkatesh, V. Rajkumar, P. Avinash, N. Arivazhagan, R.K. Devendranath, S. Narayanan, Procedia Eng. 75, 145 (2014)

R. Ma, K. Fang, J.G. Yang, X.S. Liu, H.Y. Fang, J. Mater. Process. Technol. 214, 1131 (2014)

N.T. Aboulkhair, M. Simonelli, L. Parry, I. Ashcroft, C. Tuck, R. Hague, Prog. Mater. Sci. 106, 100578 (2019)

W. Huang, X. Lin, Sci. Sin. Inform. 45, 1111 (2015)

X. Lin, W. Huang, Mater. China 34, 684 (2015)

L. Thijs, K. Kempen, J.P. Kruth, J. Van Humbeeck, Acta Mater. 61, 1809 (2013)

X. Liu, C. Zhao, X. Zhou, Z. Shen, W. Liu, Mater. Des. 168, 107677 (2019)

J. Chen, W. Hou, X. Wang, S. Chu, Z. Yang, Chin. J. Aeronaut. 33, 2043 (2020)

Z. Wang, X. Lin, N. Kang, Y. Hu, J. Chen, W. Huang, Addit. Manuf. 34, 101260 (2020)

H. Zhang, H. Zhu, X. Nie, J. Yin, Z. Hu, X. Zeng, Scr. Mater. 134, 6 (2017)

L.E. Loh, C.K. Chua, W.Y. Yeong, J. Song, M. Mapar, S.L. Sing, Z.H. Liu, D.Q. Zhang, Int. J. Heat Mass Transf. 80, 288 (2015)

M.L.M. Sistiaga, R. Mertens, B. Vrancken, X. Wang, B. Van Hooreweder, J.P. Kruth, J. Van Humbeeck, J. Mater. Process. Technol. 238, 437 (2016)

J.H. Martin, B.D. Yahata, J.M. Hundley, J.A. Mayer, T.A. Schaedler, T.M. Pollock, Nature 549, 365 (2017)

S.Z. Uddin, L.E. Murr, C.A. Terrazas, P. Morton, D.A. Roberson, R.B. Wicker, Addit. Manuf. 22, 405 (2018)

H. Azizi, R. Ghiaasiaan, R. Prager, M.H. Ghoncheh, K.A. Samk, A. Lausic, W. Byleveld, A.B. Phillion, Addit. Manuf. 27, 389 (2019)

T. DebRoy, H.L. Wei, J.S. Zuback, T. Mukherjee, J.W. Elmer, J.O. Milewski, A.M. Beese, A. Wilson-Heid, A. De, W. Zhang, Prog. Mater. Sci. 92, 112 (2018)

P. Wang, C.S. Lao, Z.W. Chen, Y.K. Liu, H. Wang, H. Wendrock, J. Eckert, S. Scudino, J. Mater. Sci. Technol. 36, 18 (2020)

Y. Zhu, J. Li, X. Tian, H. Wang, D. Liu, Mater. Sci. Eng. A 607, 427 (2014)

C. Tan, K. Zhou, W. Ma, L. Min, Mater. Des. 155, 77 (2018)

S. Shakerin, A. Hadadzadeh, B.S. Amirkhiz, S. Shamsdini, J. Li, M. Mohammadi, Addit. Manuf. 29, 100797 (2019)

M.H. Ghoncheh, M. Sanjari, E. Cyr, J. Kelly, H. Pirgazi, S. Shakerin, A. Hadadzadeh, B.S. Amirkhiz, L.A.I. Kestens, M. Mohammadi, Int. J. Plast. 133, 102840 (2020)

K. Sindo, Welding Metallurgy, 2nd edn. (Wiley, New York, 2003)

R. Li, M. Wang, Z. Li, P. Cao, T. Yuan, H. Zhu, Acta Mater. 193, 83 (2020)

C. Leitão, I. Galvão, R.M. Leal, D.M. Rodrigues, Mater. Des. 33, 69 (2012)

M. Rappaz, J.M. Drezet, M. Gremaud, Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 30, 449 (1999)

Y. Qi, H. Zhang, X. Nie, Z. Hu, H. Zhu, X. Zeng, Addit. Manuf. 35, 101346 (2020)

S.G. Shabestari, M.H. Ghoncheh, H. Momeni, Thermochim. Acta 589, 174 (2014)

M.H. Ghoncheh, S.G. Shabestari, M.H. Abbasi, J. Therm. Anal. Calorim. 117, 1253 (2014)

A. Hadadzadeh, B.S. Amirkhiz, S. Shakerin, J. Kelly, J. Li, M. Mohammadi, Addit. Manuf. 31, 100937 (2020)

Z. Li, Z. Li, Z. Tan, D.B. Xiong, Q. Guo, Int. J. Plast. 127, 102640 (2020)

H. Chen, Y. Lu, D. Luo, J. Lai, D. Liu, J. Mater. Process. Technol. 285, 116782 (2020)

D. Walton, B. Chalmers, Trans. AIME. 215, 447 (1959)

N. Hansen, Scr. Mater. 51, 801 (2004)

Q. Yan, B. Song, Y. Shi, J. Mater. Sci. Technol. 41, 199 (2020)

B. Chen, S.K. Moon, X. Yao, G. Bi, J. Shen, J. Umeda, K. Kondoh, Scr. Mater. 141, 45 (2017)

J. Wu, X.Q. Wang, W. Wang, M.M. Attallah, M.H. Loretto, Acta Mater. 117, 311 (2016)

H. Suthar, A. Bhattacharya, S.K. Paul, CIRP J. Manuf. Sci. Technol. 30, 12 (2020)

I. Rosenthal, A. Stern, N. Frage, Mater. Sci. Eng. A 682, 509 (2017)

Y. Peng, C. Wu, J. Gan, J. Dong, Constr. Build. Mater. 171, 485 (2018)

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors state that there are no conflicts of interest to disclose.

Additional information

Available online at http://link.springer.com/journal/40195.

Rights and permissions

About this article

Cite this article

Wang, H., Lin, X., Kang, N. et al. Interfacial Characteristics and Mechanical Behavior of Hybrid Manufactured AlSi10Mg–Al6061 Bimetal via Selective Laser Melting and Forging. Acta Metall. Sin. (Engl. Lett.) 35, 375–388 (2022). https://doi.org/10.1007/s40195-021-01349-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-021-01349-4