Abstract

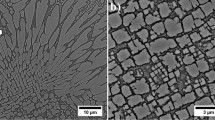

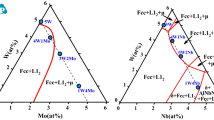

Two experimental alloys containing different contents of Ru were investigated to study the effect of Ru on the microstructural evolution during long-term thermal exposure. The increase in Ru promoted the formation of cubical, tiny, and even γ′ phase after full heat treatment. Moreover, the samples after full heat treatment were exposed at 1100 °C for different time. Based on the classical model by Lifshitz, Slyozov, and Wagner, the coarsening of γ′ phase of the alloy containing 2.5 and 3.5 wt.% Ru during the long-term aging was controlled by the interface reaction and diffusion, respectively. The γ/γ′ lattice misfit was more negative with the increment of Ru addition, which induced the formation of stable rafted γ′ phase in the alloy containing 3.5 wt.% Ru at the initiation of long-term aging. Besides, the increase in Ru reduced the diffusion coefficient, which could restrain the γ′ phase coarsening. The lower γ/γ′ lattice misfit of the alloy containing 2.5 wt.% Ru promoted the interface reaction, which induced the rapid coarsening of γ′ phase. Therefore, the increase in Ru improved the microstructural stability of the alloys. On the other hand, the raise of Ru induced “reverse partitioning” behavior, which was effective in suppressing the emergence of the topologically close-packed phase (TCP phase). The TCP phase occasionally occurred in the alloy containing 2.5 wt.% Ru, which was attributed to the high temperature and the supersaturation of the γ matrix. Moreover, the TCP phase was determined as μ phase, which had a high concentration of Co, Re, Mo, and W. A sketch map describing the evolution of the TCP phase was also constructed.

Similar content being viewed by others

References

L. Liu, J. Meng, J.L. Liu, H.F. Zhang, X.D. Sun, Y.Z. Zhou, Acta Metall. Sin.-Engl. Lett. 32, 381 (2019)

R.C. Reed, The superalloys: fundaments and applications (Cambridge University Press, Cambridge, 2006)

Y.B. Hu, T.S. Cao, C.Q. Cheng, L. Zhang, J. Zhao, Appl. Surf. Sci. 209, 484 (2019)

P.J. Warren, A. Cerezo, G.D.W. Smith, Mater. Sci. Eng. A 250, 88 (1998)

A. Epishin, U. Brückner, P.D. Portella, T. Link, Scr. Mater. 48, 455 (2003)

J. Zhang, L.H. Lou, Acta Metall. Sin. 54, 1637 (2018). (in Chinese)

A.C. Yeh, A. Sato, T. Kobayashi, H. Harada, Mater. Sci. Eng. A 490, 445 (2008)

F. Sun, J.X. Zhang, P. Liu, Q. Feng, X.D. Han, S.C. Mao, J. Alloys Compd. 536, 80 (2012)

B. Seiser, R. Drautz, D.G. Pettifor, Acta Mater. 59, 749 (2011)

R. Rettig, A. Heckl, R.F. Singer, Adv. Mater. Res. 278, 180 (2011)

X.P. Tan, J.L. Liu, X.P. Song, T. Jin, X.F. Sun, Z.Q. Hu, J. Mater. Sci. Technol. 27, 889 (2011)

W. Sun, X.Z. Qin, J.T. Guo, L.H. Lou, Acta Metall. Sin. 51, 67 (2015). (in Chinese)

Y. Chao, W. Huan, T.G. Jian, Y.Q. He, Mater. Sci. Forum. 816, 546 (2015)

J.V. Goerler, I. Lopez-Galilea, L. Mujic-Roncery, O. Shchyglo, W. Theisen, I. Steinbacha, Acta Mater. 124, 151 (2017)

M.V. Acharya, G.E. Fuchs, Mater. Sci. Eng. A 381, 143 (2004)

J.Y. Chen, Q. Feng, Z.Q. Sun, Scr. Mater. 63, 795 (2010)

X.P. Tan, J.L. Liu, T. Jin, Z.Q. Hu, H.U. Hong, B.G. Choi, I.S. Kim, C.Y. Jo, Mater. Sci. Eng. A 528, 8381 (2011)

J.J. Huo, Q.Y. Shi, Y.R. Zheng, Q. Feng, J. Alloys Compd. 15, 460 (2017)

J.X. Zhang, T. Murakumo, Y. Koizumi, H. Harada, J. Mater. Sci. 38, 4883 (2003)

W. Song, X.G. Wang, J.G. Li, L.H. Ye, G.C. Hou, Y.H. Yang, J.L. Liu, J.D. Liu, W.L. Pei, Y.Z. Zhou, X.F. Sun, Mater. Sci. Eng. A 772, 138646 (2020)

A. Epishin, T. Link, U. Brückner, P.D. Portella, Acta Mater. 49, 4017 (2001)

A.F. Giamei, D.L. Anton, Metall. Trans. 16, 1997 (1985)

E.H.V.D. Molen, J.M. Oblak, O.H. Kriege, Metall. Trans. 2, 1627 (1971)

W.A. Sun, Acta Mater. 55, 313 (2007)

J. Komenda, P.J. Henderson, Scr. Mater. 37, 1821 (1997)

T. Link, S. Zabler, A. Epishin, A. Haibel, M. Bansal, X. Thibault, Mater. Sci. Eng. A 425, 47 (2006)

V.A. Vorontsov, J.S. Barnard, K.M. Rahman, H.Y. Yan, P.A. Midgley, D. Dye, Acta Mater. 120, 14 (2016)

J.W. Christian, Mater. Today 6, 53 (2003)

Z.H. Tan, X.G. Wang, L.H. Ye, G.C. Hou, R. Li, Y.H. Yang, J.L. Liu, J.D. Liu, L. Yang, B. Wang, P. Dong, J.G. Li, Y.Z. Zhou, X.F. Sun, Mater. Sci. Eng. A 761, 138042 (2019)

S. Lay, J.M. Missiaen, R. Bonnet, Scr. Mater. 35, 885 (1996)

W. Sun, X.Z. Qin, J.T. Guo, L.H. Lou, L.Z. Zhou, Acta Metall. Sin. 51, 67 (2015). (in Chinese)

Q.Z. Gao, Y.J. Jiang, Z.Y. Liu, Mater. Sci. Eng. A 779, 139139 (2020)

J.Y. Chen, B. Zhao, Q. Feng, L.M. Cao, Z.Q. Sun, Acta Metall. Sin. 46, 897 (2010). (in Chinese)

Z.Y. Liu, Q.Z. Gao, H.L. Zhang, Mater. Sci. Eng. A 755, 106 (2019)

A. Heckl, S. Neumeier, M. Göken, R.F. Singer, Mater. Sci. Eng. A 528, 3435 (2011)

B. Wang, J. Zhang, X.J. Pan, T.W. Huang, L. Liu, H.Z. Fu, Acta Metall. Sin. 53, 298 (2017). (in Chinese)

W.Z. Wang, T. Jin, J.L. Liu, X.F. Sun, H.R. Guan, Z.Q. Hu, Mater. Sci. Eng. A 148, 479 (2008)

W.Y. Ma, Y.F. Han, S.S. Li, Y.R. Zheng, S.C. Gong, Acta Metall. Sin. 42, 1191 (2006). (in Chinese)

H.B. Long, Y.N. Liu, S.C. Mao, H. Wei, J.X. Zhang, Q.S. Deng, Y.H. Chen, Z. Zhang, X.D. Han, Scr. Mater. 157, 100 (2018)

Acknowledgements

This work was financially supported by the National Science and Technology Major Project (No. 2017-VI-0002–0072), the National Key R&D Program of China (No. 2017YFA0700704), the National Natural Science Foundation of China (Nos. 51671188, 51601192 and 51701210), the Youth Innovation Promotion Association, Chinese Academy of Sciences and State Key Lab of Advanced Metals and Materials Open Fund (No. 2018-Z07).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Available online at http://link.springer.com/journal/40195.

Rights and permissions

About this article

Cite this article

Song, W., Wang, XG., Li, JG. et al. Role of Ru on the Microstructural Evolution During Long-Term Aging of Ni-Based Single Crystal Superalloys. Acta Metall. Sin. (Engl. Lett.) 33, 1689–1698 (2020). https://doi.org/10.1007/s40195-020-01110-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-020-01110-3