Abstract

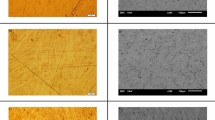

The simultaneous enhancement of magnetic and mechanical properties is desirable but challenging for soft-magnetic materials. A fabrication strategy to meet this requirement is therefore in high demand. Herein, bulk equiatomic dual-phase AlCoFeMnNi high-entropy alloys were fabricated via a magnetic levitation induction melting and casting process followed by annealing at 700–1000 °C, and their microstructures as well as mechanical and magnetic properties were investigated. The as-cast alloy possessed a single metastable B2-ordered solid solution that decomposed upon annealing into a dual-phase structure comprising an Al- and Ni-rich body-centered cubic (BCC) matrix and Fe- and Mn-rich face-centered cubic (FCC) precipitates both in the grain interior and along the grain boundaries. The magnetic and mechanical properties were closely related to the relative volume fraction of FCC in the alloy. The FCC volume fraction could be increased by increasing the annealing temperature, thereby offering tunable properties. The optimal annealing temperature for balanced magnetic and mechanical properties was found to be 800 °C. The alloy annealed at this temperature had an average BCC grain size of 12 ± 3 μm and FCC volume fraction of 41 ± 4%. Correspondingly, the saturation magnetization and coercivity reached 82.57 Am2/kg and 433 A/m, respectively. The compressive yield strength and fracture strength were 1022 and 2539 MPa, respectively, and the plasticity was 33%. Owing to its adjustable microstructure and properties, the AlCoFeMnNi alloy has potential for use as a multi-functional soft-magnetic material.

Similar content being viewed by others

References

O. Gutfleisch, M.A. Willard, E. Brück, C.H. Chen, S.G. Sankar, J.P. Liu, Adv. Mater. 23, 821 (2011)

T. Zuo, M. Zhang, P.K. Liaw, Y. Zhang, Intermetallics 100, 1 (2018)

G. Ouyang, X. Chen, Y. Liang, C. Macziewski, J. Cui, Mater. 481, 234 (2019)

G.V. Kurlyandskaya, S.V. Shcherbinin, S.O. Volchkov, S.M. Bhagat, E. Calle, R. Pérez, M. Vazquez, Mater. 459, 154 (2018)

H. Li, A. He, A. Wang, L. Xie, Q. Li, C. Zhao, G. Zhang, P. Chen, Mater. 471, 110 (2019)

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, S.Y. Chang, Adv. Eng. Mater. 6, 299 (2004)

D.B. Miracle, O.N. Senkov, Acta Mater. 122, 448 (2017)

E.J. Pickering, N.G. Jones, Int. Mater. Rev. 61, 183 (2016)

Z. Li, H. Xu, Y. Gu, M. Pan, L. Yu, X. Tan, X. Hou, J. Alloys Compd. 746, 285 (2018)

Z. Li, C. Wang, L. Yu, Y. Gu, M. Pan, X. Tan, H. Xu, Entropy 20, 872 (2018)

X.L. Shang, Z.J. Wang, Q.F. Wu, J.C. Wang, J.J. Li, J.K. Yu, Acta Metall. Sin. (Engl. Lett.) 32, 41 (2019)

Y. Ikeda, B. Grabowski, F. Körmann, Mater. Charact. 147, 464 (2019)

C.H. Chang, P.W. Li, Q.Q. Wu, M.H. Wang, C.C. Sung, C.-Y. Hsu, Mater. Technol. 34, 343 (2019)

C. Chen, N. Liu, P. Zhou, H. Xiang, Mater. Sci. Forum 944, 169 (2019)

A. Emamifar, B. Sadeghi, P. Cavaliere, H. Ziaei, Powder Metall. 62, 61 (2019)

A. Esfandiarpour, M.N. Nasrabadi, Intermetallics 104, 59 (2019)

Z. Fu, B.E. MacDonald, T.C. Monson, B. Zheng, W. Chen, E.J. Lavernia, J. Mater. Res. 37, 1 (2018)

T. Borkar, V. Chaudhary, B. Gwalani, D. Choudhuri, C.V. Mikler, V. Soni, T. Alam, R.V. Ramanujan, R. Banerjee, Adv. Eng. Mater. 19, 1700048 (2017)

Q. Zhang, H. Xu, X.H. Tan, X.L. Hou, S.W. Wu, G.S. Tan, L.Y. Yu, J. Alloys Compd. 693, 1061 (2017)

T. Borkar, B. Gwalani, D. Choudhuri, C.V. Mikler, C.J. Yannetta, X. Chen, R.V. Ramanujan, M.J. Styles, M.A. Gibson, R. Banerjee, Acta Mater. 116, 63 (2016)

S. Huang, W. Li, X. Li, S. Schönecker, L. Bergqvist, E. Holmström, L.K. Varga, L. Vitos, Mater. Des. 103, 71 (2016)

C.Y. Cheng, Y.C. Yang, Y.Z. Zhong, Y.Y. Chen, T. Hsu, J.W. Yeh, Curr. Opin. Solid State Mater. Sci. 21, 299 (2017)

Z. Li, K.G. Pradeep, Y. Deng, D. Raabe, C.C. Tasan, Nature 534, 227 (2016)

A. Karati, K. Guruvidyathri, V.S. Hariharan, B.S. Murty, Scr. Mater. 162, 465 (2019)

C.H. Liebscher, V.R. Radmilović, U. Dahmen, N.Q. Vo, D.C. Dunand, M. Asta, G. Ghosh, Acta Mater. 92, 220 (2015)

V. Alijani, S. Ouardi, G.H. Fecher, J. Winterlik, S.S. Naghavi, X. Kozina, G. Stryganyuk, C. Felser, E. Ikenaga, Y. Yamashita, S. Ueda, K. Kobayashi, Phys. Rev. B 84, 224416 (2011)

T. Zuo, M.C. Gao, L. Ouyang, X. Yang, Y. Cheng, R. Feng, S. Chen, P.K. Liaw, J.A. Hawk, Y. Zhang, Acta Mater. 130, 10 (2017)

P. Li, A. Wang, C.T. Liu, J. Alloys Compd. 694, 55 (2017)

R. Wei, H. Sun, C. Chen, Z. Han, F. Li, J. Magn. Magn. Mater. 435, 184 (2017)

R. Kulkarni, B.S. Murty, V. Srinivas, J. Alloys Compd. 746, 194 (2018)

V. Alijani, J. Winterlik, G.H. Fecher, S.S. Naghavi, C. Felser, Phys. Rev. B 83, 184428 (2011)

R.H. Yu, S. Basu, Y.F. Li, Y. Zhang, G.C. Hadjipanayis, B.E. Lorenz, J.Q. Xiao, J. Magn. Soc. Jpn. 23, 397 (1999)

G. Herzer, IEEE Trans. Magn. 26, 1397 (1990)

S.G. Ma, Y. Zhang, Mater. Sci. Eng., A 532, 480 (2012)

Y.F. Kao, S.K. Chen, T.J. Chen, P.C. Chu, J.W. Yeh, S.J. Lin, J. Alloys Compd. 509, 1607 (2011)

C. Li, Y. Ma, J. Hao, Y. Yan, Q. Wang, C. Dong, P.K. Liaw, Mater. Sci. Eng., A 737, 286 (2018)

C. Shang, E. Axinte, W. Ge, Z. Zhang, Y. Wang, Surf. Interfaces 9, 36 (2017)

S. Singh, N. Wanderka, K. Kiefer, K. Siemensmeyer, J. Banhart, Ultramicroscopy 111, 619 (2011)

O. Schneeweiss, M. Friák, M. Dudová, D. Holec, M. Šob, D. Kriegner, V. Holý, P. Beran, E.P. George, J. Neugebauer, A. Dlouhý, Phys. Rev. B 96, 014437 (2017)

J. Wang, J. Li, J. Wang, F. Bu, H. Kou, C. Li, P. Zhang, E. Beaugnon, Entropy 20, 275 (2018)

Acknowledgements

This work was supported by the Fundamental Research Funds for the Central Universities (NO. 2018CDPTCG0001/42), the National Special Support Program for High-Level Personnel Recruitment, and GDAS’ Project of Science and Technology Development (No. 2020GDASYL-20200102030).

Author information

Authors and Affiliations

Contributions

Chengbo Yang and Jing Zhang conceived and designed the experiments; Chengbo Yang performed the experiments; Chengbo Yang, Jing Zhang and Meng Li performed the data analysis and drafted the manuscript; Chengbo Yang and Xuejian Liu participated in the data analysis, discussion, and interpretation; Chengbo Yang completed the paper; Jing Zhang revised the paper. All authors have read and approved the final manuscript.

Corresponding author

Additional information

Available online at http://link.springer.com/journal/40195.

Rights and permissions

About this article

Cite this article

Yang, C., Zhang, J., Li, M. et al. Soft-Magnetic High-Entropy AlCoFeMnNi Alloys with Dual-Phase Microstructures Induced by Annealing. Acta Metall. Sin. (Engl. Lett.) 33, 1124–1134 (2020). https://doi.org/10.1007/s40195-020-01086-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-020-01086-0