Abstract

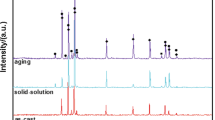

A large amount of directional and willow-like β′ phase was precipitated in Mg–10Gd–3Y–0.4Zr (GW103K) alloy after solution treatment and subsequently aged treatment (T6). In order to explore the effect of the precipitates on the corrosion behavior of the GW103K alloy, the alloy was subjected to solution treatment (T4) at 773 K for 4 h at first, subsequently aged at 498 K for 193 h (T6). The microstructure evolution of the GW103K alloy after this treatment was investigated by scanning electron microscopy and transmission electron microscopy. The high-angle annular detector dark-field scanning transmission electron microscopy was used to observe the typical corrosion morphologies of the nanoscale precipitation phases (β′) in the T6-treated alloy. The corrosion rate was measured by potentiodynamic polarization test. Combining with the potential measurement results by scanning Kelvin probe force microscopy, the effects of the skeleton-like Mg24(Gd, Y)5 and β′ precipitates on the corrosion behavior of GW103K alloy were explored. The results showed that the corrosion rate of the GW103K alloy in different conditions was ranked as: as-cast alloy> T4-treated alloy> T6-treated alloy, attributing to the fact that the relative potential differences of skeleton-like Mg24(Gd, Y)5 were lower than those of the matrix, therefore Mg24(Gd, Y)5 phase formed micro-galvanic coupling with the matrix and corrosion dissolution occurred. The nanoscale β′ precipitates in T6-treated alloy can retard the cathodic process.

Similar content being viewed by others

References

M.K. Kulekci, Int. J. Adv. Manuf. Technol. 39, 851 (2008)

S.B. Shen, S. Cai, X.G. Bao, P. Xu, Y. Li, S. Jiang, G.H. Xu, Chem. Eng. J. 339, 7 (2018)

X.R. Chen, F.K. Ning, J. Hou, Q.C. Le, Y. Tang, Ultrason. Sonochem. 40, 433 (2018)

X.W. Liu, Y. Liu, B. Jin, Y. Lu, J. Lu, J. Mater. Sci. Technol. 33, 224 (2017)

L.P. Zhong, Y.J. Wang, M. Gong, X.W. Zheng, J. Peng, Mater. Charact. 138, 284 (2018)

D.F. Zhang, X. Chen, F.S. Pan, L.Y. Jiang, G.S. Hu, D.L. Yu, Funct. Mater. 45, 05001 (2014)

R.L. Satet, M.J. Hoffmann, J. Am. Ceram. Soc. 88, 2485 (2005)

Y.R. Wu, W.Y. Hu, L.X. Sun, J. Phys. D: Appl. Phys. 40, 7584 (2007)

L.L. Tang, Y.H. Zhao, R.K. Islamgaliev, R.Z. Valiev, Y.T. Zhu, J. Alloys Compd. 721, 577 (2017)

Y. Gao, Q.D. Wang, J.H. Gu, Y. Zhao, Y. Tong, J.Y. Kaneda, J. Rare Earths 26, 298 (2008)

X.B. Liu, R.S. Chen, E.H. Han, J. Alloys Compd. 465, 232 (2008)

S.Q. Liang, D.K. Guan, X.P. Tan, L. Chen, Y. Tang, Mater. Sci. Eng., A 528, 1589 (2011)

Q. Wang, L. Xiao, W.C. Liu, H.H. Zhang, W.D. Cui, Z.Q. Li, G.H. Wu, Mater. Sci. Eng., A 705, 402 (2017)

S.Q. Liang, D.K. Guan, L. Chen, Z.H. Gao, H.X. Tang, X.T. Tong, R. Xiao, Mater. Des. 32, 361 (2011)

H. Liu, Y. Gao, J.Z. Liu, Y.M. Zhu, Y. Wang, J.F. Nie, Acta Mater. 61, 453 (2013)

D.K. Xu, E.H. Han, Y.B. Xu, Prog. Nat. Sci.-Mater. 26, 117 (2016)

Y.X. Li, D. Qiu, Y.H. Rong, M.X. Zhang, Intermetallics 40, 45 (2013)

J.X. Zheng, Z. Li, L.D. Tan, X.S. Xu, R.C. Luo, B. Chen, Mater. Charact. 117, 76 (2016)

Y.C. Wan, H.C. Xiao, S.N. Jiang, B. Tang, C.M. Liu, Z.Y. Chen, L.W. Lu, Mater. Sci. Eng., A 617, 243 (2014)

Y.W. Song, D.Y. Shan, E.H. Han, J. Mater. Sci. Technol. 33, 945 (2017)

J.H. Liu, Y.W. Song, J.C. Chen, P. Chen, D.Y. Shan, E.H. Han, Electrochim. Acta 189, 190 (2016)

L.M. Peng, J.W. Chang, X.W. Guo, A. Atrens, W.J. Ding, Y.H. Peng, J. Appl. Electrochem. 39, 913 (2009)

S.Q. Liang, D.K. Guan, X.P. Tan, Mater. Des. 32, 1194 (2011)

J.Z. Zhang, Z.X. Ma, D.F. Li, Mater. Heat Treat. 38, 73 (2007)

K. Zhang, X.G. Li, Y.J. Li, M.L. Ma, Trans. Nonferrous. Met. Soc. China 18, 12 (2008)

X.M. Zhang, Z.Y. Mu, Y.L. Deng, C.P. Tang, L.Q. Guan, J. Sci. Technol. 44, 2223 (2013)

J. Zhao, J.P. Li, Y.C. Guo, Z. Yang, Y.M. Yang, M.X. Liang, Rare Met. Mater. Eng. 37, 281 (2008)

L.Y. Wang, J. Huang, J. Dong, K. Feng, Y.X. Wu, P.K. Chu, Mater. Charact. 118, 486 (2016)

T. Honma, T. Ohkubo, K. Hono, S. Kamado, Mater. Sci. Eng., A 395, 301 (2005)

C. Antion, P. Donnadieu, F. Perrard, A. Deschamps, C. Tassin, A. Pisch, Acta Mater. 51, 5335 (2003)

J.X. Zheng, X.S. Xu, K.Y. Zhang, B. Chen, Mater. Lett. 152, 287 (2015)

S.M. He, X.Q. Zeng, L.M. Peng, X. Gao, J.F. Nie, W.J. Ding, J. Alloys Compd. 421, 309 (2006)

Acknowledgements

This work was supported financially by the National Natural Science Foundation of China (No. 51531007), the Natural Science Foundation of Inner Mongolia (No. 2016MS0538) and the Research Fund of State Key Laboratory for Marine Corrosion and Protection of Luoyang Ship Material Research Institute (LSMRI) (No. KF160408). The authors are grateful to Dr. Ping Qiu for modification in English.

Author information

Authors and Affiliations

Corresponding author

Additional information

Available online at http://link.springer.com/journal/40195

Rights and permissions

About this article

Cite this article

Yu, S., Jia, RL., Zhang, T. et al. Effect of Different Scale Precipitates on Corrosion Behavior of Mg–10Gd–3Y–0.4Zr Alloy. Acta Metall. Sin. (Engl. Lett.) 32, 433–442 (2019). https://doi.org/10.1007/s40195-018-0792-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-018-0792-7