Abstract

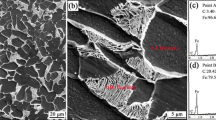

Corrosion performance of carbon steel in CO2 aqueous environment containing silty sand with different sizes was investigated by immersion tests and electrochemical measurements. Silty sand could form an adsorption layer on steel surface in initial period, and the sand adsorption layer was turned into a mixture film of silty sand with corrosion product in last period. The adsorption layer in 325 mesh condition (large size) had the fewest pores for H2CO3 transport, exhibiting the highest cathodic current inhibition. In spite of little corrosion product, the sand adsorption film formed in 325 mesh condition induced the lowest corrosion rate. For 1000 and 5000 mesh silty sand, the sand adsorption layer had some pores for H2CO3 transport, leading to low cathodic current inhibition and much matrix dissolution. But the adsorption layer for 5000 mesh silty sand (small size) had the largest special surface area to accelerate heterogeneous precipitation of corrosion product FeCO3. Therefore, the mixture film in 5000 mesh condition was more compact, exhibiting stronger anodic inhibition and lower corrosion rate than those in 1000 mesh condition.

Similar content being viewed by others

References

S. Nešić, Corros. Sci. 49, 4308 (2007)

S. Nešić, M. Nordsveen, R. Nyborg, A. Stangeland, A mechanistic model for CO2 corrosion with protective iron carbonate films. Paper presented at NACE CORROSION’2001, Houston, USA, March 2001, p. 40

J.K. Heuer, J.F. Stubbins, Corros. Sci. 41, 1231 (1999)

Z.G. Liu, X.H. Gao, C. Yu, L.X. Du, J.P. Li, P.J. Hao, Acta. Metall. Sin. (Engl. Lett.) 28, 739 (2015)

A. Neville, C. Wang, Wear 267, 195 (2009)

R. Barker, X. Hu, A. Neville, Tribol. Int. 68, 17 (2013)

P. Linhardt, G. Ball, AC Corrosion: results from laboratory investigations and from a failure analysis. Paper presented at NACE CORROSION’2006, Houston, USA, March 2006, p. 6160

S. Lux, M.R. Sustache, C. Marsh, J. Bushman, Dilute flowable backfill for corrosion mitigation of buried steel pipe: experimental procedure. Paper presented at NACE CORROSION’2012, Houston, USA, March 2012, p. 1750

M. Parsi, K. Najmi, F. Najafifard, S. Hassani, B.S. Mclaury, S.A. Shirazi, J. Nat. Gas. Sci. Eng. 21, 850 (2014)

C. Fan, B.S. Mclaury, S.A. Shirazi, E.F. Rybicki, Experimental research of sand erosion in gas dominant flows. Paper presented at NACE CORROSION’2012, Houston, USA, March 2012, p. 1422

T.C. Chevrot, E. Valentine, D. Cornally, J.M. Dubibe, Sand management of topside facilities and interfiled gas condensate lines of a HP/HT field. Paper presented at NACE CORROSION’2006, Houston, USA, March 2006, p. 6599

Z.B. Zheng, Y.G. Zheng, X. Zhou, S.Y. He, W.H. Sun, J.Q. Wang, Corros. Sci. 88, 187 (2014)

H.X. Guo, B.T. Lu, J.L. Luo, Electrochim. Acta. 51, 315 (2005)

C.Y. Wong, C. Solnordal, A. Swallow, J. Wu, Wear 303, 109 (2013)

A. Mansouri, H. Arabnejad, S. Karimi, S.A. Shirazi, B.S. Mclaury, Wear 338–339, 339 (2015)

W. Liu, J. Dou, S. Lu, P. Zhang, Q. Zhao, Appl. Surf. Sci. 367, 438 (2016)

J. Been, R. Given, K.I. Cameron, R.G. Worthingham, Factors affecting the rate and extent of disbondment of FBE coatings. Paper presented at NACE CORROSION’2005, Houston, USA, March 2005, p. 5138

B. Ingham, M. Ko, G. Kear, P. Kappen, N. Laycock, J.A. Kimpton, D.E. Williams, Corros. Sci. 52, 3052 (2010)

D.G. Li, Y.R. Feng, Z.Q. Bai, M.S. Zheng, Appl. Surf. Sci. 253, 8371 (2007)

W. Sun, S. Nešić, R.C. Woollam, Corros. Sci. 51, 1273 (2009)

F.F. Eliyan, A. Alfantazi, Corros. Sci. 85, 380 (2014)

L. Niu, Y.F. Cheng, Appl. Surf. Sci. 253, 8626 (2007)

R. Barker, B. Pickles, A. Neville, General corrosion of X65 steel under silica sand deposits in CO2-saturated environments in the presence of corrosion inhibitor components. Paper presented at NACE CORROSION’2014, Houston, USA, March 2014, p. 4215

V. Pandarinathan, K. Leplová, W.V. Bronswijk, Corros. Sci. 85, 26 (2014)

J. Huang, B. Brown, S. Nesic, Localized corrosion of mild steel under silica deposits in inhibited aqueous CO2 solutions. Paper presented at NACE CORROSION’2013, Houston, USA, March 2013, p. 2144

L.G.S. Gray, B.G. Anderson, M.J. Danysh, P.R. Tremaine, Mechanisms of carbon steel corrosion in brines containing dissolved carbon dioxide at pH 4. Paper presented at NACE CORROSION’1989, Houston, USA, March 1989, p. 464

L.G.S. Gray, B.G. Anderson, M.J. Danysh, P.R. Tremaine, Effect of pH and temperature on the mechanism of carbon steel corrosion by aqueous carbon dioxide. Paper presented at NACE CORROSION’1990, Houston, USA, March 1990, p. 40

Y. Ishiguro, K. Fujimura, K. Eguchi, T. Nakahashi, Electrochemical analyses of 15%Cr and 17%Cr martensite-based stainless steel OCTG materials with a possible range of austenite ratio. Paper presented at NACE CORROSION’2016, Houston, USA, March 2016, p. 7474

C.D. Waard, D.E. Milliams, Corrosion 31, 177 (1975)

J. Huang, B. Brown, X. Jiang, B. Kinsella, S. Nesic, Internal CO2 corrosion of mild steel pipelines under inert solid deposits. Paper presented at NACE CORROSION’2010, Houston, USA, March 2010, p. 10379

G.A. Zhang, N. Yu, L.Y. Yang, X.P. Guo, Corros. Sci. 86, 202 (2014)

V. Pandarinathan, K. Lepková, W.V. Bronswijk, Corros. Sci. 85, 26 (2014)

D. Han, R.J. Jiang, Y.F. Cheng, Electrochim. Acta 114, 403 (2013)

M.L. Johnson, M.B. Tomson, Ferrous carbonate precipitation kinetics and its impact on CO2 corrosion. Paper presented at NACE CORROSION’1991, Houston, USA, March 1991, p. 268

E.W.J. Hunnik, B.F.M. Pots, E.L.J.A. Hendriksen, The formation of protective FeCO3 corrosion product layers in CO2 corrosion. Paper presented at NACE CORROSION’1996, Houston, USA, March 1996, p. 6

Acknowledgement

The authors are grateful to the funding support from the National Natural Science Foundation of China (Project No. 51571027) and the National Environmental Corrosion Platform (NECP).

Author information

Authors and Affiliations

Corresponding author

Additional information

Available online at http://link.springer.com/journal/40195

Rights and permissions

About this article

Cite this article

Lu, S., Liu, W., Zhang, S. et al. Corrosion Performance of Carbon Steel in CO2 Aqueous Environment Containing Silty Sand with Different Sizes. Acta Metall. Sin. (Engl. Lett.) 30, 1055–1066 (2017). https://doi.org/10.1007/s40195-017-0645-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-017-0645-9