Abstract

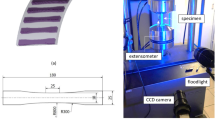

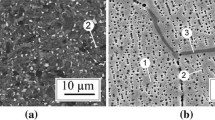

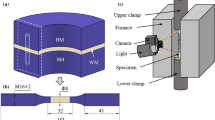

The paper investigates the fatigue damage processes of a welded joint made of 316L stainless steel plates by using the digital image correlation (DIC) technique. First, the strain partition around a surface defect evidenced very high value of strain up to 10% at the notch root during the tension stage, which explained the poor fatigue life of some welded joint specimen. In healthy specimen, a strain gradient from the base metal to the fusion zone in the range of 0.3–0.6% to 3% respectively was evidenced. Fatigue crack always initiated in the fusion zone where the deformation concentrated either early in the fatigue life at high stress or progressively by a mechanism of deformation transfer from the base metal to the fusion zone at low stress.

Graphical abstract

Similar content being viewed by others

References

Sharma K, Khandelwal HK, Bhasin V, Chhibber R (2012) Application of ball indentation technique for mechanical properties estimation of bi-metallic weld. Adv Mater Res 585:342–346. https://doi.org/10.4028/www.scientific.net/AMR.585.342

Abendroth M, Soltysiak S (2016) Assessment of material properties by means of the small punch tesT. Recent Trends in Fracture and Damage Mechanics 127–157.https://doi.org/10.1007/978-3-319-21467-2_6

Abendroth M, Kuna M (2004) Determination of ductile material properties by means of the small punch test and neural networks. Adv Eng Mater 6(7):536–540. https://doi.org/10.1002/adem.200400405

Auger T, Serre I, Lorang G, Hamouche Z, Gorse D, Vogt JB (2008) Role of oxidation on LME of T91 steel studied by small punch test. J Nucl Mater 376:336–340. https://doi.org/10.1016/j.jnucmat.2008.02.076

Lyu DY, You HS, Yoon JY et al (1992) Fracture strength evaluation of welded steel joint by means of small punch test. KSME Journal 6:73–80. https://doi.org/10.1007/BF02953073

Altstadt E, Ge HE, Kuksenko V, Serrano M, Houska M, Lasan M, Bruchhausen M, Lapetite JM, Dai Y (2016) Critical evaluation of the small punch test as a screening procedure for mechanical properties. J. Nucl Mater 472:186–195. https://doi.org/10.1016/j.jnucmat.2015.07.029

Li Y, Šturm R (2016) Punch test for weld heat affected zones. Mater High Temp 23:225–232. https://doi.org/10.1179/mht.2006.019

Fleury E, Ha JS (1998) Small punch tests to estimate the mechanical properties of steels for steam power plant: I. Mechanical strength. Int J Pres Ves Pip 75:699–706. https://doi.org/10.1016/S0308-0161(98)00074-X

Wen C, Xu T, Guan K (2016) Correlation factor study of small punch creep test and its life prediction. Mater 9(10):796. https://doi.org/10.3390/ma9100796

Roger Hurst C, Robert Lancaster J, Spencer Jeffs P, Martin Bache R (2016) The contribution of small punch testing towards the development of materials for aero-engine applications. Theor Appl Fract Mech 86:69–77. https://doi.org/10.1016/j.tafmec.2016.07.013

Mongabure P, Matheron P, Madi Y (2003) Mechanical cyclic behaviour of 316L welded joint. Mech Ind EDP Sciences 4:619–626. https://doi.org/10.1016/j.mecind.2003.09.003

Prakash RV, Madhavan K, Prakash AR, Sandhya R, Reddy GVP (2018) Fatigue response evaluation of stainless steel SS 304 L(N) and SS 316 L(N) through cyclic ball indentation studies. Ubiquity Proceedings 1(S1):38. https://doi.org/10.5334/uproc.38

Hutt T, Cawley P (2009) Feasibility of digital image correlation for detection of cracks at fastener holes. NDT and E Int 42:141–149. https://doi.org/10.1016/j.ndteint.2008.10.008

Corigliano P, Epasto G, Guglielmino E, Risitano G (2017) Fatigue analysis of marine welded joints by means of DIC and IR images during static and fatigue tests. Eng Fract Mech 183:26–38. https://doi.org/10.1016/j.engfracmech.2017.06.012

Górszczyk J, Malicki K, Zych T (2019) Application of digital image correlation (DIC) method for road material testing. Mater 12(15):2349. https://doi.org/10.3390/ma12152349

Reynolds AP, Duvall F (1999) Digital image correlation for determination of weld and base metal constitutive behaviour. Weld. Res. Suppl 355-360. https://doi.org/10.1007/s11340-006-9824-8

Saranath KM, Sharma A, Ramji M (2014) Zone wise local characterization of welds using digital image correlation technique. Opt and Lasers Eng 63:30–42. https://doi.org/10.1016/j.optlaseng.2014.06.006

Sierra G, Wattrisse B, Bordreuil C (2008) Structural analysis of steel to aluminum welded overlap joint by digital image correlation. Exp. Mech 48:213–223. https://doi.org/10.1007/s11340-007-9112-2

Genevois C, Deschamps A, Vacher P (2006) Comparative study on local and global mechanical properties of 2024 T351, 2024 T6 and 5251 O friction stir welds. MSE A 415:162–170. https://doi.org/10.1016/j.msea.2005.09.032

Boyce BL, Reu PL, Robino CV (2006) The constitutive behavior of laser welds in 304L stainless steel determined by digital image correlation. Metall Mater Trans A 37:2481–2492. https://doi.org/10.1007/BF02586221

Milosevic M, Milosevic N, Sedmak S, Tatic U, Mitrovic N, Hloch S, Jovicic R (2016) Digital image correlation in analysis of stiffness in local zones of welded joints. Teh vjesn 23(1):19–24. https://doi.org/10.17559/TV-20140123151546

Molak RM, Paradowski K, Brynk T, Ciupinski L, Pakiela Z, Kurzydlowski KJ (2009) Measurement of mechanical properties in a 316L stainless steel welded joint. Int J Pres Ves Pip 86:43–47. https://doi.org/10.1016/j.ijpvp.2008.11.002

Kartal M, Molak R, Turski M, Gungor S, Fitzpatrick ME, Edwards L (2007) Determination of weld metal mechanical properties utilising novel tensile testing methods. App. Mech Mater 7–8:127–132. https://doi.org/10.4028/www.scientific.net/AMM.7-8.127

Ren X, Xu X, Jiang C, Huang Z, He X (2020) Strain distribution and fatigue life estimation for steel plate weld joint low cycle fatigue based on DIC. Opt and Lasers Eng 124:105839. https://doi.org/10.1016/j.optlaseng.2019.105839

Langschwager K, Bosch A, Lang E, Rudolph J, Vormwald M, Scholz A, Oechsner M (2014) Fatigue behavior of butt weld seams-experimental investigation and numerical simulation. Proc. ASME Pressure Vessels & Piping Conference 20–24. https://doi.org/10.1115/PVP2014-28787

Sriba A, Vogt JB, Amara SE (2018) Microstructure, micro-hardness and impact toughness of welded austenitic stainless steel 316L. Trans Ind Inst Met 71:2303–2314. https://doi.org/10.1007/s12666-018-1362-4

Hong SG, Yoon S, Lee SB (2003) The effect of temperature on low-cycle fatigue behavior of prior cold worked 316L stainless steel. Int J Fatigue 25:1293–1300. https://doi.org/10.1016/S0142-1123(03)00154-3

Vogt JB, Magnin T, Foct J (1993) Effective stresses and microstructure in cyclically deformed 316L austenitic stainless steel: effect of temperature and nitrogen content. FFEMS 16:555–564. https://doi.org/10.1111/j.1460-2695.1993.tb00766.x

Wang B, Hong C, Winther G, Christiansen TL, Somers MAJ (2020) Deformation mechanisms in meta-stable and nitrogen-stabilized austenitic stainless steel during severe surface deformation. Materialia 12:100751. https://doi.org/10.1016/j.mtla.2020.100751

Agrawal R, Uddanwadiker R, Padole P (2014) Low cycle fatigue life prediction IJEERT 2:5–15

Roya SC, Goyalb S, Sandhyab R, Raya SK (2012) Low cycle fatigue life prediction of 316L(N) stainless steel based on cyclic elasto-plastic response. Nuc Eng Des 253:219–225. https://doi.org/10.1016/j.nucengdes.2012.08.024

Facheris G, Pham MS, Janssens KGF, Holdsworth SR (2013) Microscopic analysis of the influence of ratcheting on the evolution of dislocation structures observed in AISI 316L stainless steel during low cycle fatigue. MSE A 587:1–11. https://doi.org/10.1016/j.msea.2013.08.041

Phama MS, Solenthaler C, Janssens KGF, Holdsworth SR (2011) Dislocation structure evolution and its effects on cyclic deformation response of AISI 316L stainless steel. MSE A 528(7):3261–3269. https://doi.org/10.1016/j.msea.2011.01.015

Obrtlik K, Kruml T, Polak J (1994) Dislocation structures in 316L stainless steel cycled with plastic strain amplitudes over a wide interval. MSE A 187:1–9. https://doi.org/10.1016/0921-5093(94)90325-5

Chandra SK, Shankar VN, Mariappan K, Sandhya R, Chakraborty PC (2013) Effect of strain rate on the low cycle fatigue behavior of 316L(N) stainless steel weld joints. Proc Eng 55(3):176–180. https://doi.org/10.1016/j.proeng.2013.03.239

Jiang W, Xie X, Wang T, Zhang X, Tu ST, Wang J, Zhao X (2021) Fatigue life prediction of 316L stainless steel weld joint including the role of residual stress and its evolution: experimental and modelling. Int. J. Fatigue. 143:105997. https://doi.org/10.1016/j.ijfatigue.2020.105997

Otegui JL, Kerr HW, Burns JJ, Mohaupt HU (1989) Fatigue crack initiation from defects at weld toes in steel. Int J Pres Ves Pip 38:385–417. https://doi.org/10.1016/0308-0161(89)90048-3

Schork B, Kucharczyk P, Madia M, Zerbst U, Hensel J, Bernhard J, Tchuindjang D, Kaffenberger M, Oechsner M (2018) The effect of the local and global weld geometry as well as material defects on crack initiation and fatigue strength. Eng Fract Mec 198:103–122. https://doi.org/10.1016/j.engfracmech.2017.07.001

Schaumann P, Collmann M (2013) Influence of weld defects on the fatigue resistance of thick steel plates. Pro Eng 66:62–72. https://doi.org/10.1016/j.proeng.2013.12.062

Krewerth D, Lippmann T, Weidner A, Biermann H (2016) Influence of non-metallic inclusions on fatigue life in the very high cycle fatigue regime. Int J Fatigue 84:40–52. https://doi.org/10.1016/j.ijfatigue.2015.11.001

Prasad Reddy GV, Sandhya R, Valsan M, Bhanu Sankara Rao K (2010) Temperature dependence of low cycle fatigue of 316 (N) weld metals and 316L (N)/ 316 (N) weld joints. Mater Sc Tech 1384-1392. https://doi.org/10.1179/174328408X317110

Vogt JB, Salazar D, Proriol Serre I 2013 Partition of cyclic plasticity in the 25Cr‐7Ni‐0.25N duplex stainless steel investigated by atomic force microscopy. In: Alvarez‐Armas I Degallaix‐Moreuil S, editors. In Duplex stainless steels, London, pp 275–302. https://doi.org/10.1002/9781118557990.ch8

Bultel H, Vogt JB (2010) Influence of heat treatment on fatigue behaviour of 4130 AISI steel. Proc Eng 2:917–924. https://doi.org/10.1016/j.proeng.2010.03.099

Giuizani H, Tlili B, Chafra M (2021) Experimental characterization and fatigue behavior of thermally and mechanically treated 316L stainless steel MIG-welded joints. Weld World 65:67–78. https://doi.org/10.1007/s40194-020-00997-x

Xu K, Wang X, Cui H, Lu F (2019) Investigation on LCF behavior of welded joint at different temperatures for bainite steel. Chin. J. Mech. Eng. 32:29. https://doi.org/10.1186/s10033-019-0346-6

Acknowledgements

The authors would like to thank Jocelyn GOLEK technical engineer at UMET of Lille University for his help in conducting the fatigue-DIC tests.

The SEM and TEM national facility in Lille (France) is supported by the Conseil Régional des Hauts-de-France and the European Regional Development Fund (ERDF).

Funding

The research was supported by the institute of each author.

Author information

Authors and Affiliations

Contributions

All the authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by Dr. Amina SRIBA. Results analysis was performed by Dr. Amina SRIBA, Dr. Jérémie BOUQUEREL and Prof. Jean-Bernard VOGT. The first draft and revised version of the manuscript was written by Prof. Jean-Bernard VOGT, and all the authors commented on previous versions of the manuscript. All the authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval

The authors declare that the results have not yet been published elsewhere.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission XIII - Fatigue of Welded Components and Structures

Rights and permissions

About this article

Cite this article

Sriba, A., Bouquerel, J. & Vogt, JB. DIC-aided analysis of the fatigue behaviour of a welded 316L stainless steel. Weld World 66, 1915–1927 (2022). https://doi.org/10.1007/s40194-022-01355-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-022-01355-9