Abstract

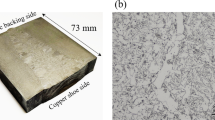

An electrogas weld metal deposited with an approximately 20 kJ/mm heat input was examined to investigate the chemical and microstructural characteristics of nonmetallic inclusions related to the weld microstructure. The inclusions in this weld were found to be very active for ferrite nucleation, and the larger inclusions tended to be more effective for multiple-nucleation. Experimental evidence demonstrated that the high nucleation potency of inclusions was attributable to the TiO layer formed on the inclusion surface and that the multiple-nucleation was due to the polycrystalline nature of the TiO layer. In addition, small patches of the TiN phase were present on the outer surface of inclusions. From the morphological and chemical composition, this phase was believed to be formed from the steel matrix by the precipitation reaction upon cooling.

Similar content being viewed by others

References

Norcross JE (1965) Electroslag/Electrogas welding in the free world. Weld J 44(3):177–186

Takeuchi N, Nagashima M, Tsuruga S (1985) Automated welding in tank construction and its cost-reducing effect. Weld J 84(2):18–29

Sasaki K, Suda K, Motomatsu R, Hashiba Y, Ohkita S, Imai S (2004) Development of two-electrode electrogas arc welding process. Nippon Steel Tech Report 90:67–74

Ryu K-M, Kim D-W, Lee J-W, Bang H-C, Park C-K, Jeong H (2017) High heat input electrogas welding of TMCP plate for steel storage tanks. J Weld Join 35(6):27–31 (in Korean)

Jeong HC, An YH, Choo WY (2002) The effect of TiN particles on the HAZ microstructure and toughness in high nitrogen TiN steel. Int J KWS 2(1):25–28

Suzuki S, Ichimiya K, Akita T (2005) High strength steel plates with excellent HAZ toughness for shipbuilding - JFE EWEL technology for excellent quality in HAZ of high heat input welded joints. JFE Technical Rep 5:45–52

Minagawa M, Ishida K, Funatsu Y, Imai S (2004) 390 MPa yield strength steel plate for large heat-input welding for large container ships. Nippon Steel Tech Rep 90:7–10

Seo K, Ryoo H, Kim HJ, Yoon JG, Lee C (2020) Characterization of the local brittle layer formed in electro-gas weld metals. Weld World 65(3):513–524

Hashiba Y, Kojima K, Kasuya T, Kumagai T (2015) Development of welding consumables and welding process for newly developed steel plates. Nippon Steel Sumitomo Metal Tech Rep 110:90–96

Banaschik R, Herholz H, Henkel K-M (2015) Flux-cored wire electrodes for electrogas welding in the European economic region-Current development status. Schweissen Schneiden 67(5):243–249

Sarma DS, Karasev AV, Jönsson PG (2009) On the role of nonmetallic inclusions in the nucleation of acicular ferrite in steels. ISIJ Int 49(7):1063–1074

Loder D, Michelic SK, Bernhard C (2017) Acicular ferrite formation and its influencing factors-A review. J Mater Sci Res 6(1):24–43

Lee J-S, Yun J-O, Jeong S-H, Park CG, An YH (2010) The study about characteristics of welding consumables and weld metal for EGW. J KWJS 28(2):199–203 (in Korean)

Jeong HC, Park YH, An YH, Lee JB (2007) Mechanical properties and microstructures of high heat input welded tandem EGW joint in EH36-TM steel. J KWJS 25(1):57–62 (in Korean)

Ito Y, Nakanishi M (1976) Study on Charpy impact properties of weld metal with submerged arc welding. Sumitomo Search 15:42–61

Horii Y, Ichkawa K, Ohkita S, Funaki S, Yurioka N (1995) Chemical composition and crystal structure of oxide inclusions promoting acicular ferrite transformation in low alloy submerged arc weld metal. Quarterly J JWS 13(4):500–507

St-Laurent S, L’Esperance G (1992) Effects of chemistry, density and size distribution of inclusions on the nucleation of acicular ferrite of C-Mn steel shielded-metal-arc-welding weldments. Mater Sci Eng A149:203–216

Jiang QL, Li YJ, Wang J, Zhang L (2011) Effects of Mn and Ti on microstructure and inclusions in weld metal of high strength low alloy steel. Mater Sci Technol 27(9):1385–1390

Nako H, Hatano H, Okazaki Y, Yamashita K, Otsu M (2014) Crystal orientation relationship between acicular ferrite, oxide, and the austenite matrix. ISIJ Int 54(7):1690–1696

Evans GM (1991) The effect of titanium in SMA C-Mn steel multipass deposits. Weld J 71(12):447s–454s

Evans GM (1993) The effect of titanium in manganese-containing SMA weld deposits. Weld J 72(3):123s–133s

Mills AR, Thewlis G, Whiteman JA (1987) Nature of inclusions in steel weld metals and their influence on the formation of acicular ferrite. Mater Sci Tech 3:1051–1061

Kluken AO, Grong Ø (1989) Mechanisms of inclusion formation in Al-Ti-Si-Mn deoxidized steel weld metals. Met Trans A 20A(8):1335–1349

Es-Souni M, Beaven PA (1990) Microanalysis of inclusion/matrix interfaces in weld metals. Surf Interface Anal 16:504–509

Blais C, L’Esperance G, Evans GM (1999) Characterization of inclusions found in C-Mn steel welds containing titanium. Sci Tech Weld Join 4(3):143–150

Yamata T, Terasaki H, Komizo Y (2009) Relation between inclusion surface and acicular ferrite in low carbon low alloy steel welds. ISIJ Int 49(7):1059–1062

Takada A, Terasaki H, Komizo Y (2013) Effect of aluminum content on acicular ferrite formation in low carbon steel weld metals. Sci Tech Weld Join 18(2):91–97

Fujiyama N, Shigasato G (2011) Effects of Mn and Al on acicular ferrite formation in SAW weld metal. ISIJ Int 61(5):1614–1622

Seo K, Kim Y-M, Evans GM, Kim HJ, Lee C (2015) Formation of Mn-depleted zone in Ti-containing weld metals. Weld World 59:373–380

Seo JS, Kim HJ, Lee C (2013) Effect of Ti addition on weld microstructure and inclusion characteristics of bainitic GMA welds. ISIJ Int 53(5):880–886

Seo K, Kim Y-M, Kim HJ, Lee C (2015) Characterization of inclusions formed in Ti-containing steel weld metals. ISIJ Int 55(8):1738–1746

Seo K, Kim K, Kim HJ, Ryoo H, Evans GM, Lee C (2020) Microstructural and inclusion characteristics of C-Mn steel welds at a minimal level of titanium. Met Mater Int 26(8):1226–1234

Kang Y, Jeong S, Kang J-H, Lee C (2016) Factors affecting the inclusion potency for acicular ferrite nucleation in high-strength steel welds. Metal Mater Tran A 47A(6):2842–2854

Kang Y, Lee C (2016) Nucleation behavior of acicular ferrite in 1 GPa class high strength steel weld metal. J Weld Join 37(1):21–26 (in Korean)

North TH, Bell HB, Koukabi A, Craig I (1979) Notch toughness of low oxygen content submerged arc deposits. Weld J 58(12):343s–354s

Eijk C, Walmsley J, Grong Ø (2002) Effects of titanium containing oxide inclusions on steel weldability. 6th Int Trends in Weld Res Conf Proc, 15–19 April, Pine Mountain GA, ASM Int: 730–735

Lau TW, Sadowski MM, North TH, Weatherly GC (1988) Effect of nitrogen on properties of submerged arc weld metal. Mater Sci Tech 4(1):52–61

Grong Ø, Kluken AO, Nylund HK, Dons AL, Hjelen J (1995) Catalyst effects in heterogeneous nucleation of acicular ferrtie. Met Trans A 26A(3):525–534

Kojima A, Kasuya T, Tsuruta T, Minami K (2007) Study on application of electrogas arc welding to SM570 steel in bridge fabrication. Trans Jpn Soc Civil Eng A 63(1):1–13 (in Japanese)

Lee T-K, Kim HJ, Kang BY, Hwang SK (2000) Effect of inclusion size on the nucleation of acicular ferrite in welds. ISIJ Int 40(12):1260–1268

Ricks RA, Howell PR, Barritte GS (1982) The nature of acicular ferrite in HSLA steel weld metals. J Mater Sci 17:732–740

Seo K, Ryoo H, Kim HJ, Lee C (2019) Quantitative evaluation of nucleation potency of Ti-containing inclusions for acicular ferrite. ISIJ Int 59(6):1105–1112

Kayali ES, Corbett JM, Kerr HW (1983) Observations on inclusions and acicular ferrite nucleation in submerged arc HSLA welds. J Mater Sci Lett 2:123–128

Grong Ø, Kluken AO, Nylung HK, Dons AL, Hjelen J (1995) Catalyst effects in heterogeneous nucleation of acicular ferrite. Met Trans A 26A(8):525–534

Wakoh M, Sawai T, Mizoguchi S (1996) Effect of S content on the MnS precipitation in steel with oxide nuclei. ISIJ Int 36(8):1014–1021

Yamamoto K, Hasegawa T, Takamura J (1966) Effect of boron on intra-granular ferrite formation in Ti-oxide bearing steels. ISIJ Int 36(1):80–86

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission IX—Behaviour of Metals Subjected to Welding

Rights and permissions

About this article

Cite this article

Seo, K., Ryoo, H., Kim, H.J. et al. Nature of nonmetallic inclusions in electrogas weld metal. Weld World 66, 379–390 (2022). https://doi.org/10.1007/s40194-021-01246-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-021-01246-5