Abstract

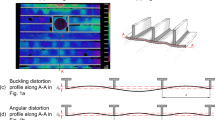

This paper focuses on a series of new developments on analytical treatment of secondary stress concentration effects caused by the presence of angular and buckling distortions in thin plate structures. The distortion profiles are idealized through a simple mechanics treatment upon which the analytical solution to the stress concentration factor (SCF) induced by secondary bending is further derived. With such approach, the distortion effects on fatigue behaviors can be captured without the need for performing detailed finite element calculations incorporating measured distortions. The applications of these analytical solutions incorporating secondary bending caused by distortions and remote loading are demonstrated by analyzing existing test data obtained on small-scale thin plate butt joints containing local and global angular distortions. By considering the fatigue test data as well as measured distortion data, the use of so calculated SCFs not only enable an effective correlation among simple butt-welded specimens with various forms of angular and axial misalignments, but also between the tested specimens and the 2007 ASME master S-N curve scatter band which contain large-scale fatigue test data with plate thicknesses ranging from 5 mm up to over 100 mm.

Similar content being viewed by others

References

Dong P (2005) Residual stresses and distortions in welded structures: a perspective for engineering applications. Sci Technol Weld Join 10(4):389–398

Jung G, Huang TD, Dong P, Dull RM, Conrardy CC, Porter NC (2007) Numerical prediction of buckling in ship panel structures. J Ship Prod 23(3):171–179

Yang YP, Dong P (2012) Buckling distortions and mitigation techniques for thin-section structures. J Mater Eng Perform 21(2):153–160

American Bureau of Shipping (2007) Guide for shipbuilding and repair quality standard for hull structures during construction

U.S. Navy (1967) Fairness tolerance criteria. MIL-STD-1689

Huang TD, Dong P, DeCan L, Harwig D, Kumar R (2004) Fabrication and engineering technology for lightweight ship structures, part 1: distortions and residual stresses in panel fabrication. J Ship Prod 20(1):43–59

Dong P, Brust FW (2000) Welding residual stresses and effects on fracture in pressure vessel and piping components: a millennium review and beyond. J Press Vessel Technol 122(3):329–338

Dong P, Song S, Zhang J, Kim MH (2014) On residual stress prescriptions for fitness for service assessment of pipe girth welds. Int J Press Vessel Pip 123:19–29

Song S, Dong P (2017) Residual stresses at weld repairs and effects of repair geometry. Sci Technol Weld Join 22(4):265–277

Dong P (2008) Length scale of secondary stresses in fracture and fatigue. Int J Press Vessel Pip 85(3):128–143

Antoniou AC (1980) On the maximum deflection of plating in newly built ships. J Ship Res 24(1)

Carlsen, C. A., & Czujko, J. (1978). The specification of post-welding distortion tolerances for stiffened plates in compression. Struct Eng 56

British Standards Institution (2013) Guide on methods for assessing the acceptability of flaws in metallic structures (BS7910:2013). British Standard Institution

Lillemäe I, Lammi H, Molter L, Remes H (2012) Fatigue strength of welded butt joints in thin and slender specimens. Int J Fatigue 44:98–106

Lillemäe I, Liinalampi S, Remes H, Itävuo A, Niemelä A (2017) Fatigue strength of thin laser-hybrid welded full-scale deck structure. Int J Fatigue 95:282–292

Xing S, Dong P, Threstha A (2016) Analysis of fatigue failure mode transition in load-carrying fillet-welded connections. Mar Struct 46:102–126

Xing S, Dong P, Wang P (2017) A quantitative weld sizing criterion for fatigue design of load-carrying fillet-welded connections. Int J Fatigue 101:448–458

Xing S, Dong P (2016) An analytical SCF solution method for joint misalignments and application in fatigue test data interpretation. Mar Struct 50:143–161

Eggert L, Fricke W, Paetzold H (2012) Fatigue strength of thin-plated block joints with typical shipbuilding imperfections. Weld World 56(11–12):119–128

Fricke W, Feltz O (2013) Consideration of influence factors between small-scale specimens and large components on the fatigue strength of thin-plated block joints in shipbuilding. Fatigue Fract Eng Mater Struct 36(12):1223–1231

Lillemäe I, Remes H, Romanoff J (2013) Influence of initial distortion on the structural stress in 3 mm thick stiffened panels. Thin-Walled Struct 72:121–127

Lillemäe I, Liinalampi S, Remes H, Avi E, Romanoff J (2016) Influence of welding distortion on the structural stress in thin deck panels. In: Proceedings of the 13th International Symposium on Practical design of ships and other floating structures, Copenhagen, Denmark

Hobbacher A (2009) Recommendations for fatigue design of welded joints and components. Welding Research Council, New York

Dong P, Xing S, Zhou W (2017) Analytical treatment of welding distortion effects on fatigue in thin panels: Part I – closed-form solutions and implications. Paper no. IMAM 2017 #184, Proceedings of IMAM 2017 Conference (Maritime Transportation and Harvesting of Sea Resources), pp 599–604

Dong P, Zhou W, Xing S (2017) Analytical treatment of welding distortion effects on fatigue in thin panels: Part II – applications in test data analysis. Paper no. IMAM 2017 #186, Proceedings of IMAM 2017 Conference (Maritime Transportation and Harvesting of Sea Resources). pp 605–610

Dong P (2001) A structural stress definition and numerical implementation for fatigue analysis of welded joints. Int J Fatigue 23(10):865–876

Dong P (2005) A robust structural stress method for fatigue analysis of offshore/marine structures. J Offshore Mech Arct Eng 127(1):68–74

Dong P, Hong JK, Osage DA, Dewees DJ, Prager M (2010) The master SN curve method an implementation for fatigue evaluation of welded components in the ASME B&PV Code, Section VIII, Division 2 and API 579-1/ASME FFS-1. Weld Res Counc Bull (523)

American Society of Mechanical Engineers (2007) ASME boiler and pressure vessel code, Section VIII, Division 2. Part 5.5.5

Funding

The authors acknowledge the support of this work through a grant from the National Research Foundation of Korea (NRF) Grant funded by the Korea government (MEST) through GCRC-SOP at the University of Michigan under Project 2-1 (No. 18-04523): Reliability and Strength Assessment of Core Parts and Material System. P. Dong also acknowledges the financial support made possible by the Traction Power National Key Laboratory Open Competition Grant (No. TPL 1605).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission X - Structural Performances of Welded Joints - Fracture Avoidance

Rights and permissions

About this article

Cite this article

Zhou, W., Dong, P., Lillemae, I. et al. A 2nd−order SCF solution for modeling distortion effects on fatigue of lightweight structures. Weld World 63, 1695–1705 (2019). https://doi.org/10.1007/s40194-019-00772-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-019-00772-7