Abstract

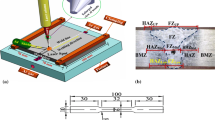

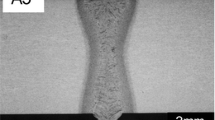

A series of laser welding experiments were carried out on low-alloy high-strength steel specimens under subatmospheric pressure. The welding penetration and weld bead formation characteristics were evaluated by performing metallographic examination on weld bead cross sections. The effects of technological parameters such as ambient pressure, laser power, and welding speed on weld bead formation were investigated. A multi-factor regression prediction model of welding penetration was established on the basis of the above experimental investigation to evaluate the welding penetration in accordance with the adopted welding parameters under certain ambient pressures. To have more insights into the effect of dynamic behavior of molten pool on the bead formation, the laser welding on “glass-metal” composite samples was performed under varied ambient pressures, and a high-speed digital camera was employed to observe the keyhole profile and the molten pool surface during welding process. A correlation between the welding penetration and the ambient pressure for laser welding of high-strength steel was found that in the range of 101–3 kPa, the decrease of ambient pressure leads to the raise of welding penetration and a smoother weld bead appearance.

Similar content being viewed by others

References

Hong KM, Shin YC (2017) Prospects of laser welding technology in the automotive industry: a review. J Mater Process Technol 245:46–69

Oliveira JP, Miranda RM, Fernandes FMB (2017) Welding and joining of NiTi shape memory alloys: a review. Prog Mater Sci 88:412–466

Katayama S, Mizutani M, Kawahito Y, Ito S and Sumimori D (2015) Fundamental research of 100 kW fiber laser welding technology. Lasers in Manufacturing Conference 2015

Katayama S, Youhei A, Mizutani M, Kawahito Y (2011) Development of deep penetration welding technology with high brightness laser under vacuum. Phys Procedia 12(Part A):75–80

Sokolov M, Salminen A, Katayama S, Kawahito Y (2015) Reduced pressure laser welding of thick section structural steel. J Mater Process Technol 219:278–285

Reisgen U, Olschok S, Jakobs S, Turner C (2016) Laser beam welding under vacuum of high grade materials. Weld World 60:403–413

Reisgen U, Olschok S, Jakobs S, Mücke M (2015) Welding with the laser beam in vacuum. Laser Tech J 12(2):42–46. https://doi.org/10.1002/latj.201500014

Katayama S, Kobayashi Y, Mizutani M, Matsunawa A (2001) Effect of vacuum on penetration and defects in laser welding. J Laser Appl 13(5):187–192

Youhei A, Yousuke K, Hiroshi N, Koji N, Masami M, Katayama S (2014) Effect of reduced pressure atmosphere on weld geometry in partial penetration laser welding of stainless steel and aluminium alloy with high power and high brightness laser. Sci Technol Weld Join 19(4):324–332

Reisgen U, Olschok S, Turner C (2017) Welding of thick plate copper with laser beam welding under vacuum. J Laser Appl 29(2):022402

Luo Y, Tang XH, Lu FG (2014) Experimental study on deep penetrated laser welding under local subatmospheric pressure. Int J Adv Manuf Technol 73(5–8):699–706

Luo Y, Tang XH, Lu FG, Chen QT, Cui HC (2015) Effect of subatmospheric pressure on plasma plume in fiber laser welding. J Mater Process Technol 215:219–224

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended for publication by Commission IV - Power Beam Processes

Rights and permissions

About this article

Cite this article

Tang, X., Deng, S., Lu, F. et al. Bead formation characteristics in laser welding of high-strength steel under subatmospheric pressures. Weld World 63, 401–407 (2019). https://doi.org/10.1007/s40194-018-0647-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-018-0647-x