Abstract

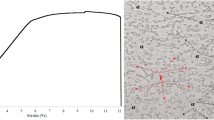

In the microjoining process, heat input is the most distinctive parameter that is well correlated with the performance of the weld joint. On the ground of energy transferred at a particular travel speed, micro plasma arc welding is performed on 500-μm-thick plates of two different materials. The characteristic performance of the micro joint on different graded steels is analyzed in a comparative mode. A process window in terms of welding current and speed is evaluated to predict the defect-free microwelded joint. The plasma current range of 8–13 A produces high-quality welded joints for all the selected materials. For the same heat input to weld these materials, there is significant difference in weld geometry, residual distortion, and micro hardness. The finite element-based thermo-mechanical model is also developed to carry out the differential influence of process parameters for these two materials. The computationally estimated macrographs as well as residual distortion show relatively better agreement with the experimental results.

Similar content being viewed by others

References

Batool S, Khan M, Jaffery SHI et al (2016) Analysis of weld characteristics of micro-plasma arc welding and tungsten inert gas welding of thin stainless steel (304L) sheet. Proc. IMechE Part L: J Mater Design Appl 230:1005–1017

Wu CS, Wang I, Ren WL et al (2014) Plasma arc welding: process, sensing, control and modelling. J Manuf Process 16:74–85

Gao X, Zhang L, Liu J et al (2013) A comparative study of pulsed Nd:YAG laser welding and TIG welding of thin Ti6Al4V titanium alloy plate. Mater Science Eng A 559:14–21

Gao X, Zhang L, Liu J et al (2014) Effects of weld cross-section profiles and microstructure on properties of pulsed Nd:YAG laser welding of Ti6Al4V sheet. Int J Adv Manuf Technol 72:895–903

Fatima S, Khan M, Husain S et al (2015) Optimization of process parameters for plasma arc welding of austenitic stainless steel (304 L) with low carbon steel (A-36). Proc IMechE Part L: J Mater Design Appl 230:640–653

McDill JMJ, Oddy AS, Goldak JA et al (1990) Finite element analysis of weld distortion in carbon and stainless steels. J Strain Analysis Design 50:51–53

Rui W, Sherif R, Hisashi S et al (2008) Numerical and experimental investigation of welding deformation. Trans JWRI 37:79–90

Torkamany MJ, Sabbaghzadeh J, Hamedi MJ et al (2012) Effect of laser welding mode on the microstructure and mechanical performance of dissimilar laser spot welds between low carbon and austenitic stainless steels. Mater Design 34:666–672

Charde N (2013) Experimental investigation on spot weld growth on dissimilar joints of 304L austenitic stainless steel and medium carbon steel (part 1). Int J Adv Appl Sci 2:25–32

Yoshioka S, Miyazaki T, Kimura T et al (1993) Thin-plate welding by a high-power density small diameter plasma arc. CIRP Annals Manuf Technol 42:215–218

Tseng KH, Hsieh ST, Tseng CC et al (2003) Effect of process parameters of micro-plasma arc welding on morphology and quality in stainless steel edge joint welds. Sci Technol Weld Join 8:423–429

Prasad KS, Rao CS, Rao DN et al (2014) Study on weld quality characteristics of micro plasma arc welded austenitic stainless steels. Procedia Eng 97:752–757

Sánchez-Tovar R, Montañés MT, García-Antón J et al (2011) Corrosion behaviour of micro-plasma arc welded stainless steels in H3PO4 under flowing conditions at different temperatures. Corrosion Sci 53:1237–1246

Rahul RS, Bag S (2014) Influence of displacement constraints in thermo mechanical analysis of laser micro-spot welding process. J Manuf Process 16:264–275

Baruah M, Bag S (2013) Numerical modelling of heat transfer and fluid flow in laser microwelding. Int J Mechatronics Manuf Systems 6:310–334

Gharibshahiyan E, Honarbakhsh-Raouf A, Parvin N, Rahimian M (2011) The effect of microstructure on hardness and toughness of low carbon welded steel using inert gas welding. Mater Design 32:2042–2048

Baruah M, Bag S (2016) Influence of heat input in microwelding of titanium alloy by micro plasma arc. J Mater Process Technol 231:100–112

Deng D, Zhou Y, Bi T et al (2013) Experimental and numerical investigations of welding distortion induced by CO2 gas arc welding in thin-plate bead-on joints. Mater Design 52:720–729

Mills KC (2002) Recommended values of thermophysical properties for selected commercial alloys. Wiltshire, England

Zhu XK, Chao YJ (2014) Numerical simulation of transient temperature and residual stresses in friction stir welding of 304L stainless steel. J Mater Process Technol 146:263–272

Yilbas BS, Arif AFM, Abdul Aleem BJ et al (2010) Laser welding of low carbon steel and thermal stress analysis. Opt Laser Technol 42:760–768

Deng D, Murakawa H (2008) Prediction of welding distortion and residual stress in a thin plate butt-welded joint. Comput Mater Sci 43:353–365

Frewin MR, Scott DA (1999) Finite element model of pulsed laser welding. Weld J 78:15–22

Kohandehghan AR, Serajzadeh S (2011) Arc welding induced residual stress in butt-joints of thin plates under constraints. J Manuf Process 13:96–103

Yadaiah N, Bag S (2012) Effect of heat source parameters in thermal and mechanical analysis of linear GTA welding process. ISIJ Int 52:2069–2075

Murugan S, Rai SK, Kumar PV et al (2011) Temperature distribution and residual stresses due to multipass welding in type 304 stainless steel and low carbon steel weld pads. Int J Pressure Vessels Piping 78:307–331

Wang J, Rashed S, Murakawa H et al (2014) Mechanism investigation of welding induced buckling using inherent deformation method. Thin-walled Structure 8:103–119

Acknowledgements

The authors gratefully acknowledge the financial support provided by the Science and Engineering Research Board (SERB), India (Grant no. SERB/F/0797/2013-2014 dated 20.05.2013) to carry out this research work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended for publication by Select Committee MICRO - Research Developments and Applications in Micro- and Nano-Joining Technologies

Rights and permissions

About this article

Cite this article

Baruah, M., Bag, S. Characteristic difference of thermo-mechanical behavior in plasma microwelding of steels. Weld World 61, 857–871 (2017). https://doi.org/10.1007/s40194-017-0472-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-017-0472-7