Abstract

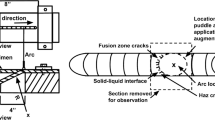

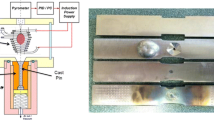

The use of Ni-30Cr components in nuclear power reactors requires a compatible filler metal to ensure reliable welded joints associated with reactor vessels, steam generators, and pressurizers. The high chromium content provides resistance to stress corrosion cracking (SCC), and niobium (Nb) additions provide ductility dip cracking (DDC) resistance. Previous work showed that solidification cracking susceptibility increases with 2–4 wt% Nb and decreases with 6–8 wt% Nb. This decrease is due to a eutectic backfilling phenomenon which “fills” freshly formed cracks when sufficient low-melting eutectic liquid is present upon solidification. A reduction in cracking susceptibility was also seen when molybdenum (Mo) was added in conjunction with high Nb levels, but the mechanism behind this effect is unknown. The objective is to address the potential effect Mo additions have on eutectic grain boundary wetting to better understand how crack healing may change with composition variance. Since Mo additions have no apparent effect on the fraction eutectic upon solidification, it is postulated that Mo may increase the “wettability” of the eutectic liquid along grain boundaries, allowing crack backfilling to occur more efficiently. Potentially, Mo additions may support more complete crack healing, thereby a further cracking susceptibility reduction, when the fraction eutectic is sufficiently high. A preliminary, qualitative approach was taken to induce local remelting and wetting of eutectic in weld metal samples with and without Mo additions. The results suggest that Mo changes the eutectic remelting and/or wetting characteristics to some degree. Fundamentally understanding molybdenum’s role in eutectic grain boundary wetting could facilitate the development of filler metals that rely on eutectic healing via backfilling to provide solidification cracking resistance.

Similar content being viewed by others

References

Kiser SD, Zhang R, Baker BA (2008) A new welding material for improved resistance to ductility dip cracking. Special Metals Welding Products Company and Huntington Alloys/Special Metals Corporation, NC, USA and WV, USA

Lippold JC, Kiser SD, DuPont JN (2009) Welding metallurgy and weldability of nickel base alloys. John Wiley and Sons, Inc, Noboken, N.J

McCracken S (2015) Dissimilar metal weld issues and repair strategies in the nuclear industry. Electric Power Research Institute

Ramirez AJ, Sowards JW, Lippold JC (2006) Improving the ductility-dip cracking resistance of Ni-base alloys. J Mater Process Technol 179:212–218

Bollinghaus T, Herald H, Cross C (2008) Hot cracking phenomena in Welds II. Springer, Berlin. Pgs. 166, 169, 208.

Kazuyoski S, Bunda K, Ogiwara H, Nishimoto K (2012) Hot cracking susceptibility of commercial Alloy 52 filler metals in multipass welding of Alloy 690. In: DebRoy T, David SA, DuPont J, et al. (eds) Trends Weld. Res. Proc. 9th Int. Conf. ASM International, pp 322–329

Borland JC (1960) Generalized theory of super-solidus cracking in welds and castings. Br Weld J 7:508–512

Wheeling RA, Lippold JC Solidification cracking susceptibility of Ni-30Cr weld metals with variable niobium and molybdenum. Weld. J.

Wheeling RA, Lippold JC Characterization of weld metal microstructure in a Ni-30Cr Alloy with additions of niobiumm and molybdenum. Mater. Charact.

Nelson DE, Baeslack W, Lippold JC (1987) An investigation of weld hot cracking in duplex stainless steels. Weld J 66:241s–250s

Lundin CD, Chou CPD, Sullivan CJ (1980) Hot cracking resistance of austenitic stainless steel weld metals increasing Mn and Mo content and avoiding multiple thermal cycles on. Weld Res Suppl:226s–232s. doi:10.1080/09507119809448487

Alexandrov BT, Lippold JC (2013) Use of the cast pin tear test to study solidification cracking. Weld World 57:635–648

Lippold JC, Kotecki DJ (2005) Welding metallurgy and weldability of stainless steels. John Wiley and Sons, Inc, Hoboken, N.J

Acknowledgements

The lead author (RW) would like to thank the Graduate School at the Ohio State University for providing a fellowship during the first year of graduate studies and to the Department of Energy (DOE) Nuclear Engineering University Program (NEUP) for providing continuing support through an NEUP Fellowship. Post-doctorate, Carolin Fink, and fellow graduate students Adam Hope and Daniel Tung are recognized for their instruction and guidance with experimental techniques. We also thank Ken Copley and Ed Pfeiffer, support staff in the Welding Engineering Program at OSU, for their dedication and commitment to the development of a safe and sustainable research environment.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended for publication by Commission IX - Behaviour of Metals Subjected to Welding

Rights and permissions

About this article

Cite this article

Wheeling, R.A., Lippold, J.C. Effect of composition on grain boundary wetting characteristics in Ni-30Cr weld metal. Weld World 61, 315–324 (2017). https://doi.org/10.1007/s40194-016-0411-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-016-0411-z