Abstract

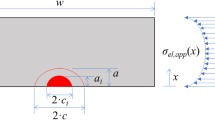

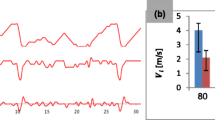

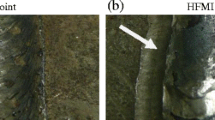

In this paper, recent fatigue tests conducted on welded specimens subjected to high frequency mechanical impact (HFMI) treatment are described, geometry measurements and metallurgical analyses of the tested specimens are presented, and efforts to estimate the test results using a nonlinear fracture mechanics model are discussed. The specimens were fabricated from 9.5-mm-thick (3/8 in.) aluminum (5083-H321) and high-strength steel (ASTM A514) plate. The specimen geometry and preparation followed procedures used in previous studies on mild steel (CSA 350W). Fatigue tests were performed on the as-welded and impact-treated specimens under two loading histories (constant amplitude with and without periodic under-loads) at several equivalent stress ranges. Residual stress distributions were determined by x-ray diffraction. In addition, weld toe geometry measurements were obtained using silicon impressions and micro-hardness distributions were obtained on polished weld samples for each material type. This information was used to establish parameter values for a nonlinear fracture mechanics analysis. The employed fracture mechanics model is reviewed in this paper, and its benefits as a tool for modelling the fatigue behavior of impact-treated welds are discussed. Following this, the effectiveness of the model in estimating the test results for the three materials is assessed.

Similar content being viewed by others

References

Roy S, Fisher JW, Yen BT (2003) Fatigue resistance of welded details enhanced by ultrasonic impact treatment (UIT). Int J Fatigue 25:1239–1247

Kuhlmann U, Bergmann J, Dürr A, Thumser R, Günther H-P, Gerth U (2005) Enhancement of the fatigue strength of welded high strength steels by application of post-weld treatment methods. Stahlbau 74:358–365

Weich I, Ummenhofer T, Nitschke-Pagel T, Dilger K, Eslami H (2009) Fatigue behaviour of welded high-strength steels after high frequency mechanical post-weld treatments. Weld World 53:R322–R332

Yildirim HC, Marquis GB (2012) Fatigue strength improvement factors for high strength steel welded joints treated by high frequency mechanical impact. Int J Fatigue 44:168–176

Yildirim HC, Marquis GB (2013) A round robin study of high-frequency mechanical impact (HFMI)-treated welded joints subjected to variable amplitude loading. Weld World 57:437–447

Tehrani Yekta R, Ghahremani K, Walbridge S (2013) Effect of quality control parameter variations on the fatigue performance of ultrasonic impact treated welds. Int J Fatigue 55:245–256

Ghahremani K, Safa M, Yeung J, Walbridge S, Haas C, Dubois S (2014) Quality assurance for high frequency mechanical impact (HFMI) treatment of welds using handheld 3D laser scanning technology. Weld. World

Marquis GB, Mikkola E, Yildirim HC, Barsoum Z (2013) Fatigue strength improvement of steel structures by high-frequency mechanical impact: proposed fatigue assessment guidelines. Weld World 57:803–822

Ghahremani K (2015) Fatigue assessment of repaired highway bridge welds using local approaches. Doctoral Thesis, University of Waterloo

Lihavainen V-M (2006) A novel approach for assessing the fatigue strength of ultrasonic impact treated welded structures. Thesis, Lappeenranta University of Technology

Josi G (2010) Reliability-based management of fatigue failures. Doctoral Thesis, University of Alberta

Ghahremani K, Ranjan R, Walbridge S, Ince A (2015) Fatigue strength improvement of aluminum and high strength steel welded structures using HFMI. 6th Fatigue Design Conference, Senlis, France

Ghahremani K, Walbridge S (2011) Fatigue testing and analysis of peened highway bridge welds under in-service variable amplitude loading conditions. Int J Fatigue 33:300–312

Canadian Institute of Steel Construction (CISC) (2006) Handbook of steel construction: 9th ed. Toronto

Aluminum Association (2010) ADM-10: aluminum design manual—specifications and guidelines for aluminum structures

Sonsino CM (2005) Principles of variable amplitude fatigue design and testing, fatigue testing and analysis under variable amplitude loading conditions. ASTM STP 1439:3–23

Yıldırım HC, Marquis G, Sonsino CM (2015) Lightweight design with welded high-frequency mechanical impact (HFMI) treated high-strength steel joints from S700 under constant and variable amplitude loadings. Int J Fatigue

Walbridge S (2008) Fatigue analysis of post-weld fatigue improvement treatments using a strain-based fracture mechanics model. Eng Fract Mech 75:5057–5071

Hobbacher A (2005) Recommendations for fatigue design of welded joints and components. International Institute of Welding: Doc. XIII-1965-03/XV-1127-03

American Society for Testing of Materials (2004) ASTM E8M-04 standard test methods for tension testing of metallic materials

American Society for Testing of Materials (2009) ASTM B 918M-09 standard practice for heat treatment of wrought aluminum alloys

Yuan KL, Sumi Y (2015) Modelling of ultrasonic impact treatment (UIT) of welded joints and its effect on fatigue strength. 5th Int Conf Crack Paths, Ferrara, Italy

American Society for Testing and Materials (2013) ASTM E647-13 standard test method for measurement of fatigue crack growth rates

Coughlin R, Walbridge S (2012) Fatigue testing and analysis of aluminum welds under in-service highway bridge loading conditions. ASCE J Bridge Eng 17(3):409–419

Khalil M, Topper TH (2003) Prediction of crack-opening stress levels for 1045 as-received steel under service loading spectra. Int J Fatigue 25(2):149–157

Dowling NE (2007) Mechanical behaviour of materials. Pearson Education Inc., Upper Saddle River

Newman JC (1994) A crack opening stress equation for fatigue crack growth. Int J Fract 24:R131–R135

Baumel A, Seeger T (1990) Materials data for cyclic loading—supplement 1. Elsevier Science Publishing Company, New York

Sonsino CM (2007) Course of SN-curves especially in the high-cycle fatigue regime with regard to component design and safety. Int J Fatigue 2246–2258

Newman JC (2015) Fatigue and crack-growth analyses under giga-cycle loading on aluminium alloys. Proc Eng 101:339–346

Acknowledgments

The financial support for this research provided by GDLS Canada is gratefully acknowledged. The impact treatment of the 5083 and A514 weld samples provided by Dave Pow and Brett Kilgour at Pow Engineering is also gratefully acknowledged. At the University of Waterloo, Richard Morrison, Rob Sluban, James St. Onge, Shui Guo, and Prof. Tim Topper are thanked for their technical input and assistance related to the laboratory testing aspects of the project.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended for publication by Commission XIII - Fatigue of Welded Components and Structures

Rights and permissions

About this article

Cite this article

Ranjan, R., Ghahremani, K., Walbridge, S. et al. Testing and fracture mechanics analysis of strength effects on the fatigue behavior of HFMI-treated welds. Weld World 60, 987–999 (2016). https://doi.org/10.1007/s40194-016-0354-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-016-0354-4