Abstract

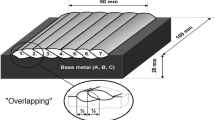

The new boron-alloyed 9Cr-1.5Mo-1Co cast steel designated as CB2 is used for intermediate pressure turbine inner casings with steam temperature up to 620 °C. To connect the casing with a pipe made of P92 steel, dissimilar welding is necessary. As flux cored arc welding (FCAW) is a highly productive welding process, the applicability of flux cored wires is evaluated. Therefore, three test welds in vertical-up position were produced with different welding procedures: the first with P92 tungsten inert gas (TIG) welding for root and second pass and P92 FCAW for intermediate and final passes; the second with P92 TIG welding for root and second pass and CB2 FCAW for intermediate and final passes; and the third with CB2 flux cored wire for all layers as no CB2 TIG rod is available yet. Cross-weld tensile tests and impact tests on weld metal and heat-affected zones were carried out after post weld heat treatment (PWHT) of 2 × 730 °C for 12 h. The differences in mechanical and technological properties are discussed, as well as the hardness profiles in the cross sections. Thermokinetic calculations with the software package MatCalc estimate the long-term microstructural evolution of precipitates depending on the chemical composition of the weld metal.

Similar content being viewed by others

References

Staubli M, Hanus R, Weber T, Mayer K.-H, Kern T.-U (2006) The European efforts in development of new high temperature casing materials—COST536, Materials for Advanced Power Engineering, Proceedings Part II, pp 855–870

Vanstone R, Chilton I, Jaworski P (2013) Manufacturing experience in an advanced 9 %CrMoCoVNbNB alloy for ultra-supercritical steam turbine rotor forgings and castings. J Eng Gas Turbines Power 135

Lochbichler C, Schmidtne-Kelity E, Baumgartner S (2013) Latest developments of cast materials and welding consumables for coal-fired steam turbines components/nickel-base alloy A625 and CB2 steel for the A-USC technology, Proceedings of Power Gen, Vienna

Bauné E, Cerjak H, Caminada St, Jochum C, Mayr P, Pasternak J (2006) Weldability and properties of new creep resistant materials for use in ultra supercritical coal fired power plants, Materials for Advanced Power Engineering, Proceedings Part II, pp 871–891

Posch G, Baumgartner S, Fiedler M (2009) GMA-welding of creep resistant steels with flux cored wires (FCAW): perspectives and limitations, Proceedings of the IIW International Conference on Advances in Welding and Allied Technologies, Singapore 16–17 July, pp 619–624

Baumgartner S, Posch G, Mayr P (2012) Welding advanced martensitic creep resistant steels with boron containing filler metal. Weld World 56(7/8), pp 2–9

Certificate No. 518950, Industeel, Belgium

Product data sheet of Böhler P92-IG, www.voestalpine.com/welding/austria/products

Baumgartner S, Schnitzer R, Schuler M, Schmidtne-Kelity E, Lochbichler C (2013) Flux cored wires for welding advanced 9–10 % Cr steels, advances in materials technology for fossil power plants, Proceedings from the Seventh International Conference October 22–25, Waikoloa, Hawaii, USA, pp 936–947

Kimura K, Sawada K, Kushima H, Toda Y (2011) Microstructural stability and long-term creep strength of grade 91 steel, energy materials: materials science and engineering for energy systems, Vol. 4, No. 4, 8th Charles Parsons Turbine Conference, pp 176–183

http://matcalc.tuwien.ac.at/, Vienna. 2013

Baumgartner S, Schuler M, Ramskogler C, Schmidtne-Kelity E, Sarić A, Schnitzer R, Lochbichler C, Enzinger N (2013) Mikrostrukturentwicklung von CB2 Fülldraht-Schweißungen, Tagungsband der 36. Vortragsveranstaltung der Arbeitsgemeinschaft für warmfeste Stähle und Hochtemperaturwerkstoffe in Düsseldorf, 22. November, pp 29–40

Schubert J, Schwass G (2012) Zeitstandverhalten von modernen martensitischen Stahlguss-Schweißverbindungen im Temperaturgebiet 550–650°C, Tagungsband der 35. Vortragsveranstaltung der Arbeitsgemeinschaft für warmfeste Stähle und Hochtemperaturwerkstoffe in Düsseldorf, 30. November, pp 22–38

Acknowledgments

The authors want to thank the Austrian “Forschungsförderungsgesellschaft” (FFG) for the financial support based on the contract no. 831995.

Author information

Authors and Affiliations

Corresponding author

Additional information

Doc. IIW-2553, recommended for publication by Commission IX “Behaviour of Metals Subjected to Welding”

Rights and permissions

About this article

Cite this article

Baumgartner, S., Schuler, M., Holy, A. et al. Dissimilar welding of the creep resistant steels CB2 and P92 with flux cored wires. Weld World 59, 655–665 (2015). https://doi.org/10.1007/s40194-015-0241-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-015-0241-4