Abstract

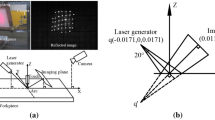

This paper presents an approach towards a better understanding of spatter formation in laser beam welding. Hereunto, experimental investigations and numerical simulation are carried out. For the study, various steels and aluminium alloys were selected to investigate the influences of alloying elements upon spatter formation. The welding was performed by applying a laser beam oscillation technique in which weld seam is generated by a spiral movement of the laser beam, in order to check the influence of weld pool movement according to spatter formation. This strategy was also transferred to the numerical simulation to get a detailed insight into the processes taking place in the keyhole when spatters form. Furthermore, a new detection method is presented which allows a three-dimensional tracking of spatters by using a pair of synchronised stereo cameras.

Similar content being viewed by others

References

Schmitt F (2012) Laserstrahl-Mikroschweißen mit Strahlquellen hoher Brillanz und örtlicher Leistungsmodulation. Dissertation RWTH Aachen, Shaker Verlag GmbH – Laser beam micro welding using high brilliant laser sources and local power modulation

Schweier M, Hatwig J, Zaeh MF, Reppich J (2011) Single mode fiber beam welding with superposed beam oszillations. In Proceedings of the ICALEO, pp 536–546

Mahrle A, Beyer E (2007) Control of the energy deposition during laser beam welding by oscillation techniques. In: Proceedings of Lasers in Manufacturing, pp. 97–104

Kraetsch M, Standfuss J, Klotzbach A, Kaspar J, Brenner B, Beyer E (2011) Laser beam welding with high-frequency beam oscillation: welding of dissimilar materials with brilliant fiber lasers. In: Lasers in Manufacturing, pp. 142–149

Meier O (2006) Hochfrequentes Strahlpendeln zur Erhöhung der Prozessstabilität mit hoher Schmelzbaddynamik. AiF-final report of project 13600 N, High frequency beam oscillation for increased process robustness with high weld pool dynamics

Schweier M, Heins JF, Haubold MW, Zaeh MF (2013) Spatter formation in laser welding with beam oscillation, Proceedings of Laser in Manufacturing, pp. 20–30

Funk M (1994) Absorption von CO2-Laserstrahlung beim Laserstrahlschweißen von Grobblech. Dissertation RWTH Aachen, Shaker Verlag GmbH, Absorption of CO2 laser radiation at laser beam welding of thick plates

Fabbro R, Silami S (2007) Melt pool dynamics during deep penetration cw Nd-Yag laser welding. In: Proceedings of Lasers in Manufacturing, pp. 259–264

Weberpals J.-P (2010) Nutzen und Grenzen guter Fokussierbarkeit beim Laserschweißen. Dissertation of IFSW, Stuttgart, Benefits and limits of strong focusability at laser welding

Kaplan A, Powell J (2010) Laser welding: the spatter map. In: Proceedings of ICALEO, pp. 683–690

Kägeler C, Schmidt M (2010) Frequency Analysis of Frequency-based analysis of weld pool dynamics and keyhole oscillations at laser beam welding of galvanized steel sheets, Proceedings of the LANE, Part 2, pp. 447–453

Cai H, Xiao R (2011) Comparison of spatter characteristics in fiber and CO2 laser beam welding of aluminium alloy. In: Proceeding of ICALEO, 150–158

Erhardt KM, Heine A, Pommersberger H (1993) Laser in der Materialbearbeitung. Vogel Buchverlag, Laser in material processing

Geiger M, Leitz K-H, Koch H, Otto A (2009) A 3D transient model of keyhole and melt pool dynamics in laser beam welding applied to the joining of zinc coated sheets. In: Production Engineering - Research and Development 3, 127–136

Otto A, Schmidt M (2010) Towards a universal numerical simulation model for laser material processing, Proceedings of the LANE, 35–46

Brandes EA (1992) Smithells metals reference book, 6th edn. Butter-worth Publishers, Stoneham

Schmidt P (1894) Zerstäuben von Flüssigkeiten, Übersichtsvortrag Universität Essen, 1984. Disintegration of liquids, survey lecture, University of Essen

Kolmogorov et al (2001) Computing visual correspondence with occlusions using graph cuts, Proceedings of the International Conference On Computer Vision, Vancouver

Author information

Authors and Affiliations

Corresponding author

Additional information

Doc. IIW-1148, recommended for publication by Commission IV “Power Beam Processes”.

Rights and permissions

About this article

Cite this article

Hugger, F., Hofmann, K., Kohl, S. et al. Spatter formation in laser beam welding using laser beam oscillation. Weld World 59, 165–172 (2015). https://doi.org/10.1007/s40194-014-0189-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-014-0189-9