Abstract

The main objective of this study is to investigate the inactivation efficacy of cold streamers in a sealed package on pathogenic fungi Aspergillus flavus (A. flavus) spores that artificially contaminated pistachio surface. To produce penetrating cold streamers, electric power supply was adapted to deposit adequate power into the package. The plasma streamers were generated by an alternating high voltage with carrier frequency of 12.5 kHz which was suppressed by a modulated pulsed signal at frequency of 110 Hz. The plasma exposition time was varied from 8 to 18 min to show the effect of the plasma treatment on fungal clearance while the electrode and sample remained at room temperature. This proved a positive effect of the cold streamers treatment on fungal clearance. Benefits of deactivation of fungal spores by streamers inside the package include no heating, short treatment time and adaptability to existing processes. Given its ability to ensure the safety and longevity of food products, this technology has great potential for utilization in food packaging and processing industry. In this study, moisture and pH changes of pistachio samples after plasma streamers treatment were also investigated.

Similar content being viewed by others

Introduction

Aspergillus flavus (A. flavus) is a saprotrophic and pathogenic fungus with a cosmopolitan distribution [22]. It is best known for its colonization of cereal grains and legumes. Post-harvest rot typically develops during harvest, storage, and/or transit. A. flavus infections can occur while hosts are still in the field (pre-harvest), but often show no symptoms (dormancy) until post-harvest storage and/or transport. In addition to causing pre-harvest and post-harvest infections, many strains produce significant quantities of toxic compounds known as mycotoxins, which are toxic to human and animals [22]. A. flavus is also an opportunistic human and animal pathogen causing aspergillosis in immune-compromised individuals [10].

Atmospheric pressure plasmas (APPs) system does not require vacuum systems and are a cost-effective and convenient alternative to low-pressure plasma systems [3]. APPs have the attractive feature of a non-equilibrium property by which hot electrons, cold neutral gas and ions can co-exist in the plasma state [14]. The energetic electrons lead to enhanced generation of reactive radicals and ions through collisions with the background neutral gas, while the gas temperature remains near the room temperature. As a result, APPs do not cause thermal damage to heat-sensitive biological systems such as cells and living tissue [9]. Plasma generators produce ultraviolet photons, charged particles and chemically active species. Dependent upon the working gases, the following species could be produced: negative and neutral atomic oxygen, ozone, singlet oxygen, superoxide, hydroxyl ions, and NOx compounds. This led to the plasma sterilization technique being used as a simple, fast and toxic-free residue in the study of disinfection. Limitations in conventional sterilization methods have motivated the search for novel sterilization methods. In recent years, plasmas have various promising applications such as treatment of mammalian and cancerous cells [16], sterilization [8], bacteria inactivation [25], surface modification of Raw and Frit glazes [11], silicon rubber surface modification [26], protein destruction [6] blood coagulations [17], treatment of living tissue [7], wound care [21], teeth bleaching [19], and treatment of dental diseases [15].

Gas discharge in a gap between two electrodes covered by dielectric materials can be run in several distinct discharge modes: corona, glow and streamers [12, 18, 23]. In dielectric barrier discharge (DBD) scheme, corona and glow are widely employed in many applications because of its stability at high power. However, streamers are rarely employed for disinfection due to their relatively high temperature and damaging effect on the sample. If one can reduce the streamer temperature, they could be used in sterilization as well. In this regard, we developed a device for cold plasma streamers and showed that the cold streamers seem to be relatively simple and inexpensive as well as their non-toxic nature gives them the potential to be used in deactivation of micro-organisms.

The microdischarge streamers can be characterized as non-equilibrium weakly ionized plasma channels with futures similar to those of transient high-pressure glow discharges. They initiate when the breakdown electric field is reached. The current flow at the streamer location is terminated within a few ns after breakdown thus the temperature of the ions and neutral species remains close to the room temperature. The individual streamer properties depend on the gas properties, the pressure and the gap spacing. For a given industrial application of DBD, the large spacing between the electrodes is favored because of treatment restrictions. The advantage of the current apparatus is treating the large samples close to the room temperature while the common dielectric barrier glow discharges suppress the streamers by reducing the electrode gap distances.

The large gap spacing results in brighter, stronger, thicker and hotter streamers. Therefore, for large gaps, the temperature of the microdischarge streamer tends to grow. However, optimizing large gap spacing for a given application will prevent possible thermal damage of the target.

Elimination of fungus before toxin production must be the actual goal rather than the removal of toxins once produced. It is of great interest to develop novel, practical, and cost-effective methods or processes to reduce or if possible completely eliminate fungus before aflatoxins are proceed during storage. The contaminations of nuts by toxic fungal species, and consequently the presence of aflatoxins are unavoidable [1]. Low-pressure cold plasma (LPCP) using air and sulfur hexafluoride (SF6) was developed and tested for anti-fungal efficacy against Aspergillus parasiticus on various nut samples [2]. There are several works on spores deactivation by atmospheric pressure plasma. For example, Iseki et al. [13] used plasma of argon gas, Lim et al. [20] used Ar/O2 plasma discharge and Uhm et al. [27] utilized argon gas plasma for spore deactivation. Recently, Connolly et al. [5] used Helium/air plasma at atmospheric pressure for antimicrobial efficacy against E.coli in a plastic package. However, deactivation of fungal spores inside a sealed package is very important and to our knowledge, it has not been investigated by cold plasma streamers, yet. It is one of the goals of this research to develop a room temperature instrument for A. flavus spores deactivation on pistachio surface inside a closed glass package without any feed gas. To lead the goal, we developed cold plasma streamer generator to change neutral air molecules that trapped in the package into reactive neutral species, positive- and negative-charged particles. In this regard, we adapted the electric power supply to produce cold streamers to penetrate into the package and cover the pistachio sample. We examined temperature, color, moisture and pH of raw pistachios before and after plasma exposure, too.

Materials and methods

Experimental setup

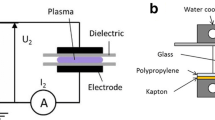

The setup of the DBD is mainly based on the principle of a dielectric barrier discharge and contains a high-voltage electrode, a ground electrode and a resistance. The discharge burned between two plane metal electrodes, both covered by plane Pyrex glass with 1 mm thickness. Diameters of circle metal electrodes were 44 mm and dimensions of plane Pyrex glass covering the electrodes were 100 × 75 mm. The distance between electrodes was 8 mm when plasma was used. The sample with its closed package was fixed in the middle of the discharge gap and was directly exposed to the plasma. The scheme of the experimental setup is shown in Fig. 1. The plasma was generated in open air by an alternating high voltage with carrier frequency of 12.5 kHz which was suppressed by a modulated pulsed signal at frequency of 110 Hz. Duty cycle of the applied voltage was 8.6 %. The electric power consumption was 2.49 W/cm3 during the treatments. The full width at half maximum of each modulated signal pulse was 0.25 ms. The optical emission spectroscopy of the dielectric barrier discharge atmospheric cold plasma was carried out using a compact spectrometer (Solar Laser Systems, S-100) that records extremely wide optical range—from 190 to 1100 nm—with average resolution of about 1 nm. Figure 1 shows the schematic of the experimental setup to measure the optical emission spectra, the current and discharge voltage. An optical fiber was inserted in the gap between two electrodes. The distance of the fiber end to the electrodes was 2 cm.

Schematic setup of plasma streamer sterilization unit and the optical emission spectra measurements in the configuration. 1 Modulated high-voltage AC power supply, 2 resistance, 3 pistachio sample, 4 closed package, 5 dielectric, 6 electrode, 7 plexiglass sheet, 8 screw, 9 O-ring, δ 1 = δ 2 = 2 mm, δ 3 = 1 mm

Voltage and current measurements were performed using a high-voltage probe (Tektronix P6015A) and a current monitor (Pearson 4100) with a digital oscilloscope (Tektronix DPO2012) (Fig. 1). Ozone concentration was measured outside the package by an ozone sensor (A-21ZX). It was about 8.5 ± 0.01 ppm.

Fungal strain

A. flavus (AF-1329) strain was chosen in this study. It was obtained from Fungal Collection of Faculty of Veterinary Medicine, Amol University of Special Modern Technologies, Amol, Iran.

Mycological examination before plasma exposure

Fungal strain was cultured on Sabouraud glucose agar (Merck Co.,Darmstadt, Germany) and incubated at 28 °C for 7 days. Conidia were harvested from 7-day-old cultures by pouring a sterile 0.1 % aqueous solution of Tween 80 onto the culture plates and scraping the plate surface with a bent glass rod to facilitate the release of conidia. The number of conidia in the suspension was adjusted to approximately 6 × 107 conidia/ml using a haemocytometer slide. Two microliters of the conidia suspension was inoculated on pistachio samples. The samples were dried under a laminar hood within an hour.

Plasma streamer treatment on contaminated pistachio samples

In this study, contaminated pistachio samples were prepared in closed package. The samples were analyzed before treatment. The samples were placed between the electrodes and then exposed to the plasma at 8, 10, 12, 14, 16 and 18 min. After plasma exposure, the treated samples were transferred for fungal analysis, each treatment was repeated thrice.

Mycological examination after plasma streamer exposure

Two hours after exposure, the dilution rates including 1:50, 1:500, 1:5000 and 1:50,000 were prepared in tubes containing 0.1 % peptone water solution. From each dilution, 100 µl of samples was spread on Sabouraud glucose agar, incubated at 28 °C and read visually after 7 days of incubation. The experiments were repeated three times. The number of A. flavus colonies was reported in each sample as colony forming units (CFUs).

Measurement of pistachio moisture and pH

To investigate the effects of air plasma on moisture and pH of pistachio samples, we compared moisture and pH of uncontaminated pistachio samples with or without air plasma treatment. Moisture and pH analysis tests were carried out at two points: 0 and 18 min of plasma treatment.

Moisture of the samples was determined using the internationally approved method AACC 44-14A. This method determines moisture content in grain using a simple and acceptable formula: \({\text{moisture content}} = \frac{\text{mass change}}{\text{initial mass}} \times 100\). In this method, an oven is used. At first, powder of the sample is prepared, then 5.00 g of the pistachio powder is heated at 130 °C for 90 min on the oven. The net change in the mass is the moisture content of the sample. The experiment is repeated 5 times for each sample. To measure the sample pH, Iranian national standards number 37 was used. In this method, 10 grams of the pistachio powder is mixed with 100 CC deionized water, after settling the powder, the pH of the solution was measured by a pH meter.

Discussion

Non-thermal streamers initiated from the upper electrode, diffused into the sealed package and whelmed the pistachio sample, then finished at the bottom electrode. Modulated high voltage adapted adequate electric power transfer to the package. Therefore, negligible heat produced inside the package keeps the sample at room temperature during treatment. Since, the streamers are moderately high-density plasma and are rich in cold-reactive species, high-energy electrons and cold ions, the spore deactivation efficiency by our device seems to be satisfactory. On the other hand, modulated high voltage with low enough repetition rate let the streamers to be cold. Although the streamers are seen continuously, they actually are discrete in time. In this work, the duration time of each streamer is in the order of 10 μs as measured by current spikes using oscilloscope. As illustrated in Fig. 1, the electric field required for the electric discharge inside the package was about 1 kV/mm. So, according to the dielectric envelope of the package, electric discharge takes place due to charge accumulation on the dielectric surfaces. As shown in Fig. 2b, this process led to ignition of the trapped air molecules inside the package, in which cold streamers smudged the pistachio.

a. Cold streamers before inserting the package into the plasma gap, 1 upper electrode, 2 upper dielectric barrier, 3 lower dielectric barrier, 4 lower electrode. b Cold streamers diffused in the closed package and whelmed the pistachio sample 5 upper sheet of package, 6 pistachio sample, 7 lower sheet of package

Surface removal of A. flavus from pistachio

Air plasma effect on A. flavus elimination was investigated at 8–18-min treatment periods. Figure 3 shows the inactivation kinetics of plasma gases of air in the case of fungal spores. The initial mold viable count on PDA plates was 1.2 × 105 CFU/sample in the contaminated control nut samples. Air plasma treatment at 8–16 min resulted about 1-log reduction with a lag phase of A. flavus spores population. Figure 3 summarizes the results observed for the microbial-contaminated pistachio exposed to air plasma streamers by varying the plasma exposition time. It can be seen that the number of survival spores decreases with increase in the treatment time. As illustrated in Fig. 3, fungal contamination was completely removed after 18 min of plasma exposure.

Analysis of pH and moisture

No considerable changes in pH and moisture were observed after plasma treatment. Results showed that the plasma treatment of 18 min increased pH from 6.13 to 6.23 and decreased moisture from 3.73 to 2.62 % (Table 1). Figures 4 and 5 show the images of untreated and treated pistachio samples, respectively. It is seen that the treated sample is drier than the untreated one.

Optical emission spectroscopy and V-I characteristics

Optical emission spectroscopy was used to measure the optical emission of the plasma streamers in air at atmospheric pressure. Emission spectrum of the DBD at 10.7 kV over the range of 200–1000 nm is presented in Fig. 6. The major peaks of active oxygen and nitrogen could be identified on light emission spectra. The reactive species can contribute to higher sterilization efficiency. On the other hand, the measurements revealed that the device produces less than 10 ppm ozone during the plasma treatments.

Among the other species of plasma streamers, energetic electrons, atomic oxygen, singlet oxygen, ozone, negative oxygen molecule, and hydroxyl played the major role in deactivation process. The generation of atomic oxygen, singlet oxygen, ozone and hydroxyl takes place by the following reactions as indicated in Table 2 [3, 24].

Ozone is unstable, will degrade into molecular oxygen and monatomic oxygen, and the latter is another oxidant and some of the monatomic oxygen will combine with molecular oxygen, so they leave no harmful by-products at the end. Ozone, as a kind of gas, can pervade the whole space and leaves no dead angle. Furthermore, \({\text{OH}}(A^2 \sum\nolimits^+ \to X^2 \prod )\) at 308 nm is the other discharge product present as the result of water vapor dissociation.

Potential targets in fungal cells include the cell wall, the plasma membrane, ribosomes, RNA, DNA, and structural and functional proteins. Cell destruction by plasma occurs if the levels of exposure exceed the capacity of the cell defense systems by affecting the many macromolecules within the cell including DNA, proteins and lipids. One of the most important mechanisms is DNA lesions by induction of breaks in DNA. Another mechanism is lipid peroxidation. Other mechanism is formation of the superoxide anion (O2 −) in the oxidation/reduction (redox) reactions of mitochondria. Furthermore, the presence of humidity leads to the generation of OH, OH+, and OH−, which also have a noticeable disinfection effect.

Formation of such intense reactive species in plasma streamers is beneficial for spore deactivation applications. On the other hand, the energetic electrons inside a streamer play a key role in deactivation. They collide with the sample surface and damage the fungal cell walls. It is worth to note that the ratio of electrons to the neutral particles is about 10−6. Such a low ionization degree together with modulated electric power supply guarantied deactivation of A.flavus spores on pistachio surface at room temperature by plasma streamers.

Figure 5 shows the typical voltage and current waveforms. It is seen that the duty cycle of the applied voltage is low enough for preventing heat production. In other words, it was 8.6 %. Therefore, the temperature of the electrodes and gas gap remained almost unchanged during 18-min plasma exposition. For clearance, a snapshot of carrier voltage wave and total current are illustrated in Fig. 7b. The DBD current includes displacement and discharge current. Figure 7c shows the displacement current after signal processing. Chaotic behavior of the streamers involved short current spikes in micro-seconds duration, randomly, which is shown in Fig. 7d; instantaneous power is shown in Fig. 8, too. The current spikes and instantaneous electric power are only shown during each modulated signal in Figs. 7 and 8. To identify averaged deposited electrical power to the plasma, we calculated mean power, P, using the following relation between instant voltage and current [4]:

The electric power consumption obtained was 2.49 W/cm3 during the treatments.

Conclusions

The results suggested that the cold plasma streamers of air gas could be efficient in the disinfection of A. flavus spores in solid foods. The plasma streamers had no significant effect on the temperature, pH, moisture and color of the sample. The plasma streamer application with specifically chosen electric power supply and gases may offer a novel and efficient method for disinfections of dry food surfaces at atmospheric pressure. The research instruments developed in this work, guarantied deactivation of A. flavus spores on pistachio surface inside a closed package at room temperature. The disinfections of heat-sensitive food surfaces with plasma streamers open up an alternative novel route for the development of advanced technologies for the elimination of fungal contamination, provided that an ideal gaseous compound together with a proper electric power supply is employed. The modulation that we used in high-voltage wave form made the power supply to deposit less electric power into the glass package while deactivation of the A. flavus spores took place by reactive species, ions and energetic electrons.

References

Arrus, K., Blank, G., Abramson, D., Clear, R., Holley, R.A.: Aflatoxin production by Aspergillus flavus in Brazil nuts. J. Stored Prod. Res. 41(5), 513–527 (2005)

Basaran, P., Basaran-Akgul, N., Oksuz, L.: Elimination of Aspergillus parasiticus from nut surface with low pressure cold plasma (LPCP) treatment. Food Microbiol. 25(4), 626–632 (2008)

Becker, K.H., Kogelschatz, U., Schoenbach, K.H., Barker, R.J. (eds.): Non-Equilibrium Air Plasmas at Atmospheric Pressure. CRC Press (2004)

Cheng, C., et al.: Development of a new atmospheric pressure cold plasma jet generator and application in sterilization. Chin. Phys. 15(7), 1544 (2006)

Connolly, J., Valdramidis, V.P., Byrne, E., Karatzas, K.A., Cullen, P.J., Keener, K.M., Mosnier, J.P.: Characterization and antimicrobial efficacy against E. coli of a helium/air plasma at atmospheric pressure created in a plastic package. J. Phys. D Appl. Phys. 46, 035401 (2013)

Deng, X.T., Shi, J.J., Kong, M.G.: Protein destruction by a helium atmospheric pressure glow discharge: capability and mechanisms. J. Appl. Phys. 101(7), 074701 (2007)

Dobrynin, D., Fridman, G., Friedman, G., Fridman, A.: Physical and biological mechanisms of direct plasma interaction with living tissue. New J. Phys. 11(11), 115020 (2009)

Ehlbeck, J., Schnabel, U., Polak, M., Winter, J., Von Woedtke, T., Brandenburg, R., Weltmann, K.D.: Low temperature atmospheric pressure plasma sources for microbial decontamination. J. Phys. D Appl. Phys. 44(1), 013002 (2011)

Fridman, G., Brooks, A.D., Balasubramanian, M., Fridman, A., Gutsol, A., Vasilets, V.N., Friedman, G.: Comparison of direct and indirect effects of non-thermal atmospheric-pressure plasma on bacteria. Plasma Process. Polym. 4(4), 370–375 (2007)

Hedayati, M.T., Pasqualotto, A.C., Warn, P.A., Bowyer, P., Denning, D.W.: Aspergillus flavus: human pathogen, allergen and mycotoxin producer. Microbiology 153(6), 1677–1692 (2007)

Ghasemi, M., Sohbatzadeh, F., Mirzanejhad, S.: Surface modification of Raw and Frit glazes by non-thermal helium plasma jet. J. Theor. Appl. Phys. 9(3), 177–183 (2015)

Gherardi, N., Gouda, G., Gat, E., Ricard, A., Massines, F.: Transition from glow silent discharge to micro-discharges in nitrogen gas. Plasma Sources Sci. Technol. 9(3), 340 (2000)

Iseki, S., Ohta, T., Aomatsu, A., Ito, M., Kano, H., Higashijima, Y., Hori, M.: Rapid inactivation of Penicillium digitatum spores using high-density nonequilibrium atmospheric pressure plasma. Appl. Phys. Lett. 96(15), 153704 (2010)

Iza, F., Kim, G.J., Lee, S.M., Lee, J.K., Walsh, J.L., Zhang, Y.T., Kong, M.G.: Microplasmas: sources, particle kinetics, and biomedical applications. Plasma Process. Polym. 5(4), 322–344 (2008)

Jiang, C., Chen, M.T., Gorur, A., Schaudinn, C., Jaramillo, D.E., Costerton, J.W., Gundersen, M.A.: Nanosecond pulsed plasma dental probe. Plasma Process. Polym. 6(8), 479–483 (2009)

Kim, W., Woo, K.C., Kim, G.C., Kim, K.T.: Nonthermal-plasma-mediated animal cell death. J. Phys. D Appl. Phys. 44(1), 013001 (2011)

Kuo, S.P., Tarasenko, O., Chang, J., Popovic, S., Chen, C.Y., Fan, H.W., Nikolic, M.: Contribution of a portable air plasma torch to rapid blood coagulation as a method of preventing bleeding. New J. Phys. 11(11), 115016 (2009)

Laroussi, M., Kong, M.G., Morfill, G. (eds.): Plasma Medicine: Applications of Low-Temperature Gas Plasmas in Medicine and Biology. Cambridge University Press, Cambridge (2012)

Lee, H.W., Nam, S.H., Mohamed, A.A.H., Kim, G.C., Lee, J.K.: Atmospheric pressure plasma jet composed of three electrodes: application to tooth bleaching. Plasma Process. Polym. 7(3–4), 274–280 (2010)

Lim, J.P., Uhm, H.S., Li, S.Z.: Influence of oxygen in atmospheric-pressure argon plasma jet on sterilization of Bacillus atrophaeous spores. Phys. Plasmas 14, 093504 (2007)

Lloyd, G., Friedman, G., Jafri, S., Schultz, G., Fridman, A., Harding, K.: Gas plasma: medical uses and developments in wound care. Plasma Process. Polym. 7(3–4), 194–211 (2010)

Machida, M., Gomi, K. (eds.): Aspergillus: Molecular Biology and Genomics. Caister Academic Press, NorfolK, UK (2010)

Rajasekaran, P., Mertmann, P., Bibinov, N., Wandke, D., Viöl, W., Awakowicz, P.: Filamentary and homogeneous modes of dielectric barrier discharge (DBD) in air: investigation through plasma characterization and simulation of surface irradiation. Plasma Process. Polym. 7(8), 665–675 (2010)

Raizer, Y.P.: Gas Discharge Physics, 2nd edn. Springer, Berlin (1997)

Sohbatzadeh, F., Colagar, A.H., Mirzanejhad, S., Mahmodi, S.: E. coli, P. aeruginosa, and B. cereus bacteria sterilization using afterglow of non-thermal plasma at atmospheric pressure. Appl. Biochem. Biotechnol. 160(7), 1978–1984 (2010)

Sohbatzadeh, F., Mirzanejhad, S., Ghasemi, M., Talebzadeh, M.: Characterization of a non-thermal plasma torch in streamer mode and its effect on polyvinyl chloride and silicone rubber surfaces. J. Electrostat. 71(5), 875–881 (2013)

Uhm, H.S., Lim, J.P., Li, S.Z.: Sterilization of bacterial endospores by an atmospheric-pressure argon plasma jet. Appl. Phys. Lett. 90(26), 261501 (2007)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Sohbatzadeh, F., Mirzanejhad, S., Shokri, H. et al. Inactivation of Aspergillus flavus spores in a sealed package by cold plasma streamers. J Theor Appl Phys 10, 99–106 (2016). https://doi.org/10.1007/s40094-016-0206-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40094-016-0206-z