Abstract

Electronics industry is one of the fastest growing industries in the world. In India also, there are high turnovers and growing demand of electronics product especially after post liberalization in early nineties. These products generate e-waste which has become big environmental issue. Industries can handle these e-waste and product returns efficiently by developing reverse logistics (RL) system. A thorough study of critical success factors (CSFs) and their ordered implementation is essential for successful RL implementation. The aim of the study is to review the CSFs, and to prioritize them for RL implementation in Indian electronics industry. Twelve CSFs were identified through literature review, and discussion with the experts from the Indian electronics industry. Fuzzy-Technique for Order Preference by Similarity to Ideal Solution (TOPSIS) approach is proposed for prioritizing these CSFs. Perusal of literature indicates that fuzzy-TOPSIS has not been applied earlier for prioritization of CSFs in Indian electronics industry. Five Indian electronics companies were selected for evaluation of this methodology. Results indicate that most of the identified factors are crucial for the RL implementation. Top management awareness, resource management, economic factors, and contracts terms and conditions are top four prioritized factor, and process capabilities and skilled workers is the least prioritized factor. The findings will be useful for successful RL implementation in Indian electronics industry.

Similar content being viewed by others

Introduction

The last decade has seen remarkable growth in the Indian economy due to economic liberalization started in early nineties. Also, during the post liberalization era, electronics industry is growing very fast in India. Due to the presence of global electronics companies and tremendous expansion of telecommunication, and information technology, Indian markets are flooded with electronics goods. This results in a new kind of waste known as electronics waste or e-waste. E-waste contains both toxic and valuable materials. The fraction including iron, copper, aluminium, gold and other metals in e-waste is over 60 %, while plastics account for about 30 % and the hazardous pollutants comprise only about 2.70 % (Widmer et al. 2005). This large percentage of valuable materials offers a business opportunity to recover value from the e-waste. It may be even profitable to collect and process e-waste. The hazardous pollutants though small in quantity but contain highly toxic materials like lead, mercury, arsenic, cadmium, chromium and many more. When these materials enter into the environment through land filling, causes damage to human health and the environment (Lee et al. 2000). E-waste can be well managed through development of RL system. Cheng and Lee (2010) found that effective RL focuses on the backward flow of materials to maximize value from returned items and guarantee their proper disposal. However, many companies are not yet ready to implement RL including Indian companies. Indian electronics industry has been selected for the study because it has a high consumption volume, and major source of e-waste generation. Also, this is one of the few sectors which come under e-waste regulations. A thorough study of CSFs and their ordered implementation is essential for successful RL implementation. Most of the researches on the CSFs of RL implementation are concentrated on developed countries, with relatively little attention being given to developing countries (Abdulrahman et al. 2014). The major intention of this study is to understand various CSFs for RL implementation in Indian electronics industry. The identification and prioritization of these factors will help the researchers and the managers in strategic decision making for RL implementation. After review of literature on RL and the opinion of experts from Indian electronics industry, 12 CSFs factors of RL implementation were identified. The experts were asked to rate each of these 12 factors in terms of their importance. A decision matrix was developed from these responses which are used in the application of fuzzy-TOPSIS methodology for prioritizing CSFs.

The main objectives of this paper are:

-

1.

to study the literature available on CSFs for RL implementation;

-

2.

to identify the CSFs which are important in Indian electronics industry;

-

3.

to find out the relative importance of these factors; and

-

4.

to discuss the managerial implications of this research.

The remaining of this paper is structured as follows: Section “Literature review” comprises a literature review on RL. CSFs for RL implementation are identified in Section “Identification of CSFs for RL implementation”. Step by step fuzzy-TOPSIS approach with case example of Indian electronics industry is discussed in Section “Fuzzy-TOPSIS methodology”. Section “Results and discussion”, summarizes all the findings and analyzed them in context of Indian electronics industry. Finally, Section “Conclusion” concludes the study along with future outlook and limitations of this research.

Literature review

Growing concern for the environment and government regulations in many countries has increased the interest in reverse flows, which has become the subject of attention over the last decade (Fleischmann et al. 1997). RL is the process of planning, implementing, and controlling the efficient, cost effective flow of raw materials, in-process inventory, finished goods, and related information from the point of consumption to the point of origin for the purpose of recapturing or creating value or proper disposal (Rogers and Tibben-Lembke 1999). Srivastava (2008) explained the flow of RL showing all the basic RL activities. The RL activities include collection, grading, reprocessing and re-distribution (Fleischmann 2003). A well-managed RL can provide important cost savings in procurement, disposal, inventory carrying and transportation (Kannan et al. 2009).

Most of the organizations in the world are presently exploring the RL to make it profitable business. RL has been found to be beneficial to some of the industries in terms of the improvement of profits. Some of the organizations like HP, Dell have implemented RL for competitive advantage. Jayaraman and Luo (2007) mentioned that Kodak has successfully implemented recycling facilities and is able to reuse up to 86 % of a camera’s parts. Similarly other leading manufacturers such as Canon and Xerox have also attained remanufacturing rates of nearly 90 %. In fact, implementing RL programs to reduce, reuse, and recycle wastes produces tangible and intangible value and may lead to better corporate image (Carter and Ellram 1998). Lau and Wang (2009) studied the electronics industry in China, explored the problems encountered in the implementation of RL. Janes et al. (2010) worked on implementation of reserve logistics in consumer electronics industry of USA. Jayaraman et al. (2003) discussed RL systems for recycling and reusing of beverage containers. Biehl et al. (2007) worked on carpet industry, Bernon et al. (2011) worked on retail industry, Gonzalez-Torre et al. (2004) worked on bottling, and Gonzalez-Torre and Adenso-Diaz (2006) worked on packaging firms, Rahman and Subramanian (2012) worked on manufacturing, Clottey et al. (2013) worked on remanufacturing, Vishkaei et al. (2014) worked on returnable defective items, Khalili-Damghani and Najmodin (2014) worked on automobile industry; are some of the examples of previous research on RL implementation.

RL implementation involves many financial and operational issues which determine the productivity and performance of the RL. A critical analysis of the variables affecting RL and their mutual interactions can be a valuable source of information for the RL implementation (Ravi et al. 2005). Rogers and Tibben-Lembke (1999) suggested that there are a number of factors affecting RL practices. The presence or absence of these factors can become drivers or barriers to RL implementation in an industry. Several conceptual models have been developed for assisting in design and implementation of RL system. Brito and Dekker (2002) differentiate two types of factors, internal and external factors for existence of reverse flows. Carter and Ellram (1998) identified internal and external factors to examine whether a company is reactive, proactive, or value-seeking in RL implementation. They considered the internal factor of policy entrepreneur and two external factors of government regulations, and customer demands as the main factors of RL systems. Holt and Ghobadian (2009) suggested that the internal factors such as culture of organization, internal resources, and operation management control practices have positive correlation to environmental thoughts in the green supply chain. Stock (1998) mentioned that factors related to management and control, measurement, and finance are crucial for the successful RL implementation. Dowlatshahi (2000) focused on internal strategic and operational issues that may require consideration in RL implementation. Strategic factors include legislative concerns, environmental concerns, customer service, quality, and strategic costs while operational factors include cost benefit analysis, transportation, warehousing, supply management, remanufacturing or recycling and packaging. Later on Dowlatshahi (2005) suggested a five-factor strategic framework for successful RL implementation. He proposed these five factors as strategic costs, strategic quality, customer service, environmental concerns, and legal concerns. In a survey of consumer electronics, Janes et al. (2010) identified main facilitators of RL as top management awareness, strategic partnerships with supply chain partners, detailed insight into cost and performance, reclaiming value from returned products, and capability to put products rapidly back into the market. Rahman and Subramanian (2012) worked on end of life computers and found customer demand as one of the major factors. These factors have great impact on availability of resource, coordination and integration of recycling tasks, volume and quality of recyclable materials. Most of these factors are described from different perspectives, i.e. for particular sector or industry of a country or region. Khalili-Damghani et al. (2015) considered the factors such as green image, flexibility, quality, responsiveness, expenses, and value recovered for studying the relationship between supply chain performance and RL. The literature review of RL implementation across the industry is summarized in Table 1. It is evident from Table 1 that CSFs vary from industry to industry and country to country but many of them are common to all of these studies. A lot of work has been done in electronics industry in many countries and different methodologies have been used for prioritizing CSFs. Indian electronics industry is more dependent on the import of components and products for fulfilling growing demand of electronics goods. So CSFs may be different from other developing country like china which has own manufacturing facilities. Remanufacturing of products may not be economical (because of transportation cost) and technically feasible within the country. Therefore, it is important to identify the CSFs addressing these issues. No study was found on identification and prioritization of CSFs for RL implementation in Indian electronics industry. Also, Fuzzy-TOPSIS methodology is first time being utilized for prioritizing CSFs for Indian electronics industry.

Identification of CSFs for RL implementation

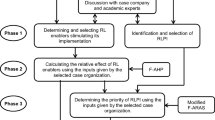

Several useful factors for RL implementation are pointed out in the literature review discussed in last section. Many CSFs are common to all of these studies and these factors can be utilized as base for discussion with expert from Indian electronics industry. Twelve CSFs were identified after pertinent literature review including studies discussed in “Introduction” and discussion with the number of experts from the Indian electronics industry. These factors are shown in Fig. 1 and are explained as follows.

Legislation

Legislation refers to regulations or acts passed by the government authorities to minimize the effect of end of life products on environment. Ravi et al. (2005) define legislation as one of the determinants of RL. In fact, focusing on environmental concerns is partly enforced by government legislation (Prendergast and Pitt 1996).

Recently, Government of India has instituted e-waste (Management and Handling) Rules, 2011 which have come into effect from May 2012. Experts mentioned that sooner or later Indian electronics manufacturer will have to comply with these e-waste management regulation.

Economic factors

Economics is seen as one of the driving forces to RL relating all the recovery options, where the company receives both direct as well as indirect economic benefits (Ravi et al. 2005). In a survey of mobile manufacturing company in Hong Kong, Chan and Chan (2008) found that majority of the returned products add extra value to the company. The recovery of the products for remanufacturing, repair, reconfiguration, and recycling can lead to profitable business opportunities (Andel 1997). Guide and Wassenhove (2003) discussed an example of the US firm ReCellular, which had gained economic advantage by refurbishing the cell phones.

Experts comment that RL practices are assumed to be cost driven activity and the companies in India are waiting for the response from each other for adopting these practices. There is also need of analyzing indirect benefits like green image, tax benefits, preference for projects in government, and image of environmentally conscious organization in Indian electronics industry.

Environmental concerns

Environmental concerns are significant force shaping the economy, as well as one of the most important issues faced by businesses (Murphy and Poist 2003). Many companies have focused on RL operations because of environmental reasons (Rogers and Tibben-Lembke 1999).

Many power projects and real state projects have been delayed because of environmental clearances from Government of India. In last few years, Government of India has taken several initiatives because of environmental concerns. This is an indication for other industries to focus on environmental concerns.

Top management awareness

Top management awareness is very crucial for the success of RL implementation. A sincere and committed effort from the top management is essential for successful deployment of RL programs (Carter and Ellram 1998). Mintzberg (1973) stated that top management awareness is the dominant factor of corporate endeavors.

Top management awareness is needed to provide clear vision and value to RL programs. Top management awareness motivates employees and ensures full support from seniors.

Resource management

Miller and Shamsie (1996) categorized the resources into property-based resources and knowledge-based resources. Property-based resources including the physical facility, automated machines and equipment, financial and human resource are regarded as critical indicators of the competitiveness (Das and Teng 2000). Knowledge-based resources including managerial resources and technology are also critical for the success of RL. Availability and effective utilization of both types of resources is essential for exploring the true value potential of RL.

Human resource is crucial for RL implementation. Companies encounter challenges while implementing RL because of lack of knowledge of RL among their employees. In India, there are very few RL experts available in the market. Companies, willing to adopt RL will have to develop their own expertise through various education and training programs for promoting the environmental awareness in their organization.

Management information system

Information support is one of the important factors for developing linkages to achieve efficient RL operations (Daugherty et al. 2005). Efficient information systems are needed for individually tracking and tracing the information on reverse flows. Information and communication technologies assume tremendous importance in RL, which are needed to process and transmit information (Brito and Dekker 2002). IT enablement is necessary and one of the important factors for effective communication (Kumar et al. 2013).

Availability of prompt and accurate information may help managers in achieving operational efficiency in managing their RL. This is an important tool but cost is a concern. Integration with the current management information system is also crucial for successful implementation.

Contract terms and conditions

Contract terms and conditions with suppliers are one of the most important factors for RL implementation. Most of the parts and components are outsourced by the electronics companies in India. Legal terms and conditions with the contractors are important. Companies may enforce regulatory requirements in the contacts to meet the criteria for parts and components from environmental perspectives. Contractor’s ability to meet regulatory criteria and corresponding costs are still to be analyzed.

Direct and indirect taxes

According to Sharma et al. (2011), complex flows of goods as well as the diverse bought-in services engrained in the reverse chain create a high degree of tax complexity and lead to unexpected tax exposures and costs.

Direct and indirect taxes are very important factor for the financial consideration. Tax structure is very complex because of involvement of import–export, and no special consideration is given to the remanufactured products in India. In fact, direct and indirect taxes for remanufactured products need to be relooked for the promotion of environmental friendly practices.

Integration of forward and reverse supply chain

Integration of forward and reverse supply chain implies simultaneous management of material, information, and monetary flows as suggested by Fleischmann (2001) and by Tibben-Lembke and Rogers (2002). According to Mehrbod et al. (2014) the integration of forward and RL has attracted growing attention with the stringent pressures of customer expectations, environmental concerns, and economic factors. Greater resource utilization can be achieved through integration of forward and reverse supply chain.

In general, responsibility of RL is assigned to the supply chain department rather than having separate department. Therefore integration of forward and reverse supply chain plays an important role because same people work on both forward and reverse supply chains. One of the big concerns is the impact of reverse supply chain on forward supply chain. Experts fear that integration may disturb the whole of the forward supply chain. Employee’s awareness and motivation for the change is essential for successful integration.

Joint consortium

Experts’ opinion that joint consortium may be one of the options for handling returns just like telecommunication tower sharing in India. Earlier companies had their own telecommunication towers. Later on companies started tower sharing and now one tower in a particular region is being used by many companies reducing their investments and operational costs. There is need of exploring such kind of business model, for example common collection centre for all used cellular phones may reduce collection cost and also, economies of scale can be achieved. Joint consortium may be helpful, particularly in case of recycling where high product volume is important.

Process capabilities and skilled workers

Experts state that process capabilities and skilled workers are very important for successful implementation. Workers must be skilled enough to work simultaneously both on manufacturing and re-manufacturing efficiently. Machines, equipments and tools must also be developed to perform both the operations simultaneously as much as possible. This is important for effective utilization of resources because of uncertainty of product returns.

Consumer awareness and social acceptability

Sharma et al. (2011) suggested that the awareness of RL could bring economic benefits by recovery of the returned product for use. Research suggests that there is an increasing customer demand for green products and for organizations to engage in environmental supply chain practices (New et al. 2000).

Social acceptability of remanufactured products among the Indian consumers and society is crucial for the success of RL. Most of the remanufactured products in India are sold in secondary market at lower prices because these products are purchased by lower income group. Consumer awareness and social acceptability will not only increase the product returns but also will motivate them to buy refurbished or remanufactured products at reasonable price.

Fuzzy-TOPSIS methodology

There are various methods used to prioritize CSFs. Multiple criteria decision making (MCDM) is one of the powerful tools widely used for dealing with unstructured problems containing multiple and potentially conflicting objectives (Lee and Eom 1990). A number of approaches have been developed for solving MCDM problems such as analytical hierarchy process (AHP), data envelopment analysis (DEA), and TOPSIS. These traditional MCDM approaches measure the alternative ratings and weights of the criteria in crisp or precise numbers which depends upon decision makers preferences (Wang and Lee 2009). The TOPSIS method was developed by Hwang and Yoon (1981) to provide solutions of the MCDM the problems. Kim et al. (1997) stated the advantages of TOPSIS as follows:

-

A sound logic that represents the rationale of human choice;

-

a scalar value that accounts for both the best and worst alternatives simultaneously; and

-

a simple computation process that can be easily programmed into a spreadsheet.

TOPSIS is useful particularly when there are a large number of alternatives and criteria. In such cases, methods like AHP which require pair wise comparison are avoided. Also, TOPSIS has the fewest rank changes reversals when an alternative is added or removed in comparison to other MCDM methods (Zanakis et al. 1998). These advantages make TOPSIS a major MCDM technique as compared with other related techniques such as analytical hierarchical process (AHP) and ELECTRE. The traditional TOPSIS method considers ratings and weights of criteria’s in crisp numbers. However, crisp data are inadequate to represent the real life situation since human judgements are vague and cannot be estimated with exact numeric values. In such situations, the fuzzy set theory is useful to capture the uncertainty of human judgments. Zadeh (1965) first introduced fuzzy set theory into MCDM including TOPSIS as an approach for effectively working with the vagueness and ambiguity of the human judgements. In fuzzy TOPSIS, all the ratings and weights are defined by means of linguistic variables. There are following two main characteristics of fuzzy systems given by Kahraman et al. (2007):

-

Fuzzy systems are suitable for uncertain or approximate reasoning, especially for the system with a mathematical model that is difficult to derive; and

-

Fuzzy logic allows decision-making with estimated values under incomplete or uncertain information.

Because of all these advantages, fuzzy logic has been combined and used along with TOPSIS known as fuzzy-TOPSIS methodology. The fuzzy-TOPSIS methodology has been used to solve many problems ranging from facility location selection (Chu 2002), robot selection (Chu and Lin 2003), selection and ranking of the most suitable third party logistics service provider (Bottani and Rizzi 2006) to service quality in airline service (Nejati et al. 2009), competitive advantage of shopping web-sites (Sun and Lin 2009), e-sourcing problem (Singh and Benyoucef 2011), maintenance problem (Ding and Kamaruddin 2014), traffic police center performance (Sadi-Nezhad and Khalili-Damghani 2014), and sustainable project selection (Khalili-Damghani and Sadi-Nezhad 2014). Fuzzy-TOPSIS methodology based on the technique introduced by Chen (1997) is selected for this study. The technique given by Chen (1997) is selected for prioritizing CSFs because this technique gives better result in comparison to other techniques. The following steps of fuzzy TOPSIS are used for the proposed research.

Step 1

Collect the required data containing linguistics terms. A proper scale must be chosen to represent the data accurately and more precisely. Respondents must be asked to choose the best alternative among the linguistics terms for a given question. Linguistics terms must be converted into the fuzzy number. For example, triangular fuzzy numbers are used for the study and a 5-point scale having the linguistic terms low (L), fairly low (FL), medium (M), fairly high (FH), and high (H); are selected as shown in Fig. 2. Triangular fuzzy numbers are used because it is intuitively easy for the respondents to use and calculate.

The fuzzy number of each linguistic term is determined with the help of Fig. 2. Fuzzy numbers for the selected linguistics terms are presented in Table 2.

Step 2

The TOPSIS method evaluates the following fuzzy decision matrix

where x ij \(( = (a_{ij} , b_{ij} , c_{ij} ))\) is a fuzzy number corresponding to the linguistic term assigned by the ith Decision Maker (DM) to the jth factor. i = 1, 2, …, m are the number of DMs and j = 1, 2, …, n are the number of factors (CSFs).

Step 3

This step includes neutralizing the weight of decision matrix and generating fuzzy un-weighted matrix (R).

To generate \(R\), following relationship can be applied.

where \(c_{j}^{*} = \mathop {\hbox{max} }\limits_{i} c\)

Step 4

Calculate the weighted normalized decision matrix

The weighted normalized value \(v_{ij}\) is calculated as

where w j is the weight given to each decision maker. \(w_{j} = \left( {1,1,1,1,1} \right)\forall j \in n\), because all the DMs are considered to have same weight for this study.

Step 5

Determine the ideal and negative-ideal solution for the CSFs

Since the positive and negative ideas introduced by Chen (1997) are used for the research. The following terms are used for ideal and negative ideal solution.

Step 6

Calculate the sum of distances from positive and negative ideal solution for each factor.

\(d\left( {v_{ij } - v_{i}^{*} } \right)\) is the distance between two fuzzy numbers which can be calculated using the vector algebra. For example distance between two numbers \(A1\left( {a_{1} , b_{1} , c_{1} } \right)\,{\rm and}\,A2(a_{2} , b_{2} , c_{2} )\) can be calculated as

Similarly, the separation from the negative ideal solution is given as

Step 7

Calculate the relative closeness to the ideal solution. The relative closeness with respect to A* is defined as

Step 8

Prioritize the preference order based on the order of the values of C j .

Application of the fuzzy-TOPSIS methodology

The fuzzy-TOPSIS methodology, presented in this research paper has been evaluated in context of Indian electronics industry. Five experts from electronic companies participated in this study. Name of the companies are not mentioned because of confidentiality of data. Profile of the decision makers and their respective organization is given as follows:

First decision maker (DM1) is a supply chain manager in a mobile manufacturing company, ABC-1 limited which is interested in RL implementation. DM1 has responsibility of developing a RL system for the company. The company is a pioneer in the manufacturing of mobile phones. The company has received many awards for best quality and management practices. The company has annual turnover of approximately USD 200 million from its business in India. In India, the company has a mobile handset manufacturing facility in Chennai. At present the company has approximately 110,000 outlets including 50,000 stores selling company’s product exclusively. The company has outsourced its forward logistics to other computer manufacturing companies for distribution to city warehouses and city warehouse company’s own employee for distributing products to the retailers. Recently, company has decided to develop its own forward logistics system along with development of RL system.

Second decision maker (DM2) is a logistics manager in an electronics manufacturing company, ABC-2 limited. The company manufactures, assembles, and distributes a comprehensive range of electronic hardware including computer peripherals in India. The company has annual turnover of approximately USD 50 million. The company has manufacturing facilities in Chennai, Pondicherry, and Uttaranchal. It has strong chain of distributors and dealers with 92,500 outlets in 8700 towns in India. The company has not given much attention to the EOL computers. Green awareness and implementation of e-waste management rules prompted them to think about implementing RL system for handling product returns and EOL computers. This company is also interested in working towards sustainability.

Third decision maker (DM3) is a logistics manager in an electronics manufacturing company, ABC-3 limited. The company assembles and distributes consumer electronics products in India including refrigerators, LCD, CTV, mobiles, washing machines, and microwave ovens. The company has annual turnover of approximately USD 120 million. The company has manufacturing facility in NCR Delhi having more than 1200 employees. The company has mother warehouse in the NCR Delhi and four child warehouses in the cities Chennai, Ahmadabad, Kolkata, and Bangalore in India. The company has its own well-established distribution system and logistics facilities. The major challenge for the company is to implement RL without effecting the current operations. This company has already taken several green initiatives including take back program for used products.

Fourth decision maker (DM4) is a marketing executive looking after north India region of an electronics manufacturing company, ABC-4 limited. The company manufactures, assembles, and distributes colour television sets in India. The company has annual turnover of approximately USD 30 million. The company has manufacturing facility in NCR Delhi having more than 350 employees. The company has strong chain of distributors and dealers. The company manufactures CTV mainly in rural markets in India. Growing demand for the LCDs and LEDs may hamper the demand of CTVs in future for the company. The company is willing to introduce new electronics product in the market for sustaining their business.

Fifth decision maker (DM5) is vice president of operations management of an electronics company, ABC-5 limited engaged in manufacturing of consumer electronics products. The company has annual turnover of approximately USD 130 million. The company has manufacturing facilities in NCR Delhi and in Bangalore. The company has more than 1500 employees. The company has strong supply chain for forward operations and willing to integrate it with its reverse supply chain.

Results and discussion

To prioritize the CSFs for RL implementation in Indian electronics industry, 12 factor legislation, economic factors, environmental concerns, top management awareness, resource management, management information system, contracts terms and conditions, direct and indirect taxes, integration of forward and reverse supply chain, joint consortium, process capabilities and skilled workers, and consumer awareness and social acceptability, identified in section “Identification of CSFs for RL implementation” are considered for the prioritization. Five decision makers DM1, DM2, DM3, DM4, and DM5 were asked to rate the importance of the above mentioned each CSF on a 5-point scale having the linguistic terms low (L), fairly low (FL), medium (M), fairly high (FH), and high (H). The decision-makers used the linguistic variables shown in Table 2 to assess the importance of the CSFs. A decision matrix was prepared based on the responses received from the DMs shown in Table 3.

As mentioned in the fuzzy-TOPSIS methodology step 1, triangular fuzzy numbers were used to convert linguistics variable into the fuzzy numbers. By converting the fuzzy linguistic variables into triangular fuzzy numbers using Table 2, the fuzzy decision matrix D was obtained. In the next step un-weighted fuzzy decision matrix R was enumerated. Further steps were followed to obtain the weighted fuzzy normalized decision matrix, to find the ideal and negative-ideal solutions for the CSFs. The distance D − and D * of each CSF is derived, respectively, by using Eqs. (7), (8), (9), and (10). The closeness coefficient C for each CSF is obtained by using Eq. (11). Values of \(D^{-}\), D * and closeness coefficient C for each CSF are shown in Table 4. The prioritization of CSFs was obtained and is shown in Table 4. The most important CSF among the 12 CSFs is top management awareness and the least important CSF is process capabilities and skilled workers.

The overall prioritization of CSFs is

Top management awareness has the highest value and is prioritized as top most factors. Top management initiates, guides, and motivates the organization for adoption and implementation of RL implementation. Resource management is prioritized as 2nd most important CSF. Previous studies also support this result like Richey et al. (2005) showed that resource commitment makes RL more efficient and more effective. Economic factors are prioritized 3rd and are very crucial for RL implementation. Recaptured value is the major source of direct revenue generation from RL implementation. Higher recapturing value motivates the management for RL implementation. Ravi et al. (2005) also found economic factor as important factor for RL implementation. Contracts term and conditions is prioritized fourth and are very important to meet environmental objectives. Most of the outsourced parts/components can be reprocessed through legal terms and conditions for reprocessing returned products. Contract terms and conditions are particularly important in cases where component/products are outsourced from other countries. Legislation is prioritized 5th and has become very important for Indian electronics industry after enforcement of e-waste management rules and regulations in 2012. This finding is also supported by earlier research (Walker et al. 2008). Joint consortium is ranked 6th and has great influence on the success of RL implementation in Indian electronics industry. Joint consortium is important to have co-operation with other companies to minimize the e-waste and to recapture maximum value while satisfying regulatory requirements. Joint consortium may help in achieving economies of scale and also, may help in reduced investment for joint reprocessing/recycling facilities. Consumer awareness and social acceptability is prioritized 7th. This factor is very important to achieve a good volume and quality of returned products, and to gain profit through resale of remanufactured products. Ravi and Shankar (2004) also found lack of awareness as a chief barrier of RL benefits in Indian automobile supply chain. Environmental concerns are ranked 8th and are mentioned by most of previous research on RL implementation. Management information system is ranked 9th. This factor is important for operational efficiency but ranked lower because managers of the opinion that it is not easy to integrate reverse logistics in current management information system. Daugherty et al. (2005) also suggested that development of information technology capabilities may give better performance in reverse supply chain organizations. Integration of forward and reverse supply chain is ranked lower because it is more dependent on the characteristics of the organization. Direct and indirect tax is ranked 11th and does not make much difference to implementation because of being part of government policy, and industry does not have any control on this factor. Process capabilities and skilled workers are ranked 12th. This factor is important for the operational performance of RL. Managers stated that it may require considerable investment in education and training of employees.

Conclusion

RL is in focus worldwide because of its inherent advantages of reducing the impact of hazard materials on human life and environment. Reuse/recycle of materials is important because of rising costs of materials, limited resources and growing environmental concerns. RL is relatively new for Indian industry and limited studies are available for RL practices. This research paper provides the valuable information on RL implementation for Indian electronics industry. The research identified 12 CSFs for RL implementation in Indian electronics industry. The identified factors are somewhat similar to those identified by various researchers all over the world. Still, factors like contracts terms and conditions, direct and indirect taxes, joint consortium, process capabilities, and skilled workers are rarely included in other studies. Analysis of the findings shows that top four prioritized factors top management awareness, resource management, economic factors, and contracts terms and conditions are the most important among all 12 factors. Briefly, the contributions of this study are summarized as follows:

-

(a)

The study provides the insight into previous research on RL implementation.

-

(b)

Identifies the CSFs based on past literature review and experts opinion for successful reverse logistics implementation.

-

(c)

The research work proposes a framework for evaluating and prioritizing the CSFs by using Fuzzy-TOPSIS methodology for RL implementation.

-

(d)

The study will help the managers and practitioners implementation of RL. It will enable the managers in identifying the factors which they need to work out for successful implementation.

The findings of the research will help the managers and academicians in the development of RL strategies and practices in Indian electronics industry. These CSFs can also be used for RL implementation in other sectors of Indian industry. Like other studies; this study also has some limitations. This study is conducted using five experts from the Indian electronics industry. Future studies may consider larger sample size to assess the methodology and the effectiveness of the proposed solution to enable generalization. Furthermore, the wider rating of the 7 or 11-point linguistic scale could be used instead of using a 5-point linguistics scale. Researchers may utilise other methodologies including other MCDM methodologies and may compare the results. Future studies may be carried out to identify company-specific or product-specific identification of CSFs for RL implementation.

References

Abdulrahman MD, Gunasekaran A, Subramanian N (2014) Critical barriers in implementing reverse logistics in the Chinese manufacturing sectors. Int J Prod Econ 147(B):460–471

Andel T (1997) Reverse logistics: a second chance to profit. Transp Distrib 38(7):61–64

Bernon M, Rossi S, Cullen J (2011) Retail reverse logistics: a call and grounding framework for research. Int J Phys Distrib Logist Manag 41(5):484–510

Biehl M, Prater E, Realff MJ (2007) Assessing performance and uncertainty in developing carpet reverse logistics systems. Comput Oper Res 34:443–463

Bottani E, Rizzi A (2006) A fuzzy TOPSIS methodology to support outsourcing of logistics services. Supply Chain Manag Int J 11(4):294–308

Carter C, Ellram L (1998) Reverse logistics: a review of literature and framework for future investigation. J Bus Logist 19(1):85–102

Chan FTS, Chan HK (2008) A survey on reverse logistics system of mobile phone industry in Hong Kong. Manag Decis 46(5):702–708

Chen CT (1997) Extensions of the TOPSIS for group decision-making under fuzzy environment. Fuzzy Sets Syst 114:1–9

Cheng YH, Lee F (2010) Outsourcing reverse logistics of high-tech manufacturing firms by using a systematic decision-making approach: TFT-LCD sector in Taiwan. Ind Mark Manag 39(7):1111–1119

Chiou YC et al (2012) Consideration factors of reverse logistics implementation—a case study of Taiwan’s electronics industry. Procedia Soc Behav Sci 40:375–381

Chu TC (2002) Selecting plant location via a fuzzy TOPSIS approach. Int J Adv Manuf Technol 20:859–864

Chu TC, Lin YC (2003) A fuzzy TOPSIS method for robot selection. Int J Adv Manuf Technol 21:284–290

Clottey T, Benton JWC, Srivastava R (2013) Forecasting product returns for remanufacturing operations. Decis Sci 43(4):589–614

Das TK, Teng BS (2000) A resource-based theory of strategic alliances. J Manag 26(1):31–61

Daugherty PJ, Richey RG, Genchev SE, Chen H (2005) Reverse logistics: superior performance through focused resource commitments to information technology. Trans Res: Part E 41(2):77–92

Brito MP De, Dekker R (2002) Reverse logistics: a framework. Econometric Institute report EI 38

Ding SH, Kamaruddin S (2014) Assessment of distance-based multi-attribute group decision making methods from a maintenance strategy perspective. J Ind Eng Int 10:78. doi:10.1007/s40092-014-0078-2

Dowlatshahi S (2000) Developing a theory of reverse logistics. Interfaces 30(3):43–55

Dowlatshahi S (2005) A strategic framework for the design and implementation of remanufacturing operations in reverse logistics. Int J Prod Res 43(16):3455–3480

Fleischmann M (2001) Reverse logistics network structures and design. In: Guide VDR Jr, Van Wassenhove LN (eds) Business aspects of closed-loop supply chains. Carnegie Bosch Institute, Pittsburgh, pp 117–148

Fleischmann M (2003) Reverse logistics network structures and design. In: Guide VDR, Van Wassenhove LN (eds) Business aspects of closed-loop supply chains. Carnegie Mellon University Press, Pittsburgh, pp 117–148

Fleischmann M, Bloemhof-Ruwaard JM, Dekker R, van der Laan E, Van Nunen JAEE, van Wassenhove LN (1997) Quantitative models for reverse logistics: a review. Eur J Oper Res 103(1):1–17

Gonzalez-Torre PL, Adenso-Diaz B (2006) Reverse logistics practices in the glass sector in Spain and Belgium. Int Bus Rev 15(5):527–546

Gonzalez-Torre PL, Adenso-Diaz B, Artiba H (2004) Environmental and reverse logistics policies in European bottling and packaging firms. Int J Prod Econ 88(1):95–104

Gonzalez-Torre PL, Alvarez M, Sarkis J, Adenso-Diaz B (2012) Barriers to the implementation of environmentally oriented reverse logistics: evidence from the automotive industry sector. Br J Manag 21:889–904

Guide VDR, Wassenhove LN (2003) Full cycle supply chains. Carnegie Mellon Press, Pittsburgh

Holt D, Ghobadian A (2009) An empirical study of green supply chain management practices among UK manufacturers. J Manuf Technol Manag 20(7):933–956

Hwang CL, Yoon KP (1981) Multiple attribute decision making: methods and applications. Business and Economics. Springer, New York

Janes B, Schuur P, Brito DMP (2010) A reverse logistics diagnostic tool: the case of the consumer electronics industry. Int J Adv Manuf Technol 47(5–8):495–513

Jayaraman V, Luo Y (2007) Creating competitive advantages through new value creation: a reverse logistics perspective. Acad Manag Perspect 21(2):56–73

Jayaraman V, Patterson RA, Rolland E (2003) The design of reverse distribution networks: models and solution procedures. Eur J Oper Res 150:128–149

Jindal A, Sangwan KS (2013) Development of an interpretive structural model of drivers for reverse logistics implementation in Indian industry. Int J Bus Perform Supply Chain Modell 5(4):325–342

Kahraman C, Ates NY, Cevik S (2007) Hierarchical fuzzy TOPSIS model for selection among logistics information technologies. J Enterp Inf Manag 20(2):143–168

Kannan G, Haq AN, Devika M (2009) Analysis of closed loop supply chain using genetic algorithm and particle swarm optimization. Int J Prod Res 47(5):1175–1200

Kannan D, Diabat A, Shankar KM (2014) Analyzing the drivers of end-of-life tire management using interpretive structural modeling (ISM). Int J Adv Manuf Technol 72:1603–1614

Khalili-Damghani K, Najmodin M (2014) A conceptual model for measuring reverse logistics performance in automobile industry. Int J Strat Decis Sci 5(2):21–29. doi:10.4018/ijsds.2014040102

Khalili-Damghani K, Sadi-Nezhad S (2014) A decision support system for fuzzy multi-objective multi-period sustainable project selection. Comput Ind Eng 64:1045–1060

Khalili-Damghani K, Tavana M, Najmodin M (2015) Reverse logistics and supply chains: a structural equation modeling investigation. J Ind Eng Int 22(3):354–368

Kim G, Park CS, Yoon KP (1997) Identifying investment opportunities for advanced manufacturing systems with comparative-integrated performance measurement. Int J Prod Econ 50(1):23–33

Knemeyer AM, Ponzurick TG, Logar CM (2002) A qualitative examination of factors affecting reverse logistics systems for end of life computers. Int J Phys Distrib Logist Manag 32(6):455–479

Kumar S, Luthra S, Haleem A (2013) Customer involvement in greening the supply chain: an interpretive structural modeling methodology. J Ind Eng Int 9:6

Lau KH, Wang Y (2009) Reverse logistics in the electronic industry of China: a case study. Supply Chain Manag Int J 14(6):447–465

Lee SM, Eom HB (1990) Multiple-criteria decision support systems: the powerful tool for attacking complex, unstructured decisions. Syst Pract 3(1):51–65

Lee CH, Chang SL, Wang KM, Wen LC (2000) Management of scrap computer recycling in Taiwan. J Hazard Mater 73:209–220

Mehrbod M, Tu N, Miao L (2014) A hybrid solution approach for a multi-objective closed-loop logistics network under uncertainty. J Ind Eng Int. doi:10.1007/s40092-014-0089-z

Miller D, Shamsie J (1996) The resource-based view of the firm in two environments: the Hollywood film studios from 1936 to 1965. Acad Manag J 39(3):519–543

Mintzberg H (1973) Strategy making in three modes. Calif Manag Rev 16(3):44–58

Mittal VK, Sangwan KS (2013) Assessment of hierarchy and inter-relationships of barriers to environmentally conscious manufacturing adoption. World J Sci Technol Sustain Dev 10(4):297–307

Murphy P, Poist R (2003) Green perspectives and practices: a comparative logistics study. Supply Chain Manag Int J 8(2):122–131

Nejati M, Nejati M, Shafaei A (2009) Ranking airlines’ service quality factors using a fuzzy approach: study of the Iranian society. Int J Qual Reliab Manag 26(3):247–260

New S, Green K, Morton B (2000) Buying the environment: the multiple meanings of green supply. In: Fineman S (ed) The business of greening. Routledge, London, pp 35–54

Prendergast G, Pitt L (1996) Packaging, marketing, logistics and the environment: are there trade-offs? Int J Phys Distrib Logist Manag 26(6):60–72

Rahman S, Subramanian N (2012) Factors for implementing end-of-life computer recycling operations in reverse supply chains. Int J Prod Econ 140(1):239–248

Ravi V, Shankar R (2004) Analysis of interactions among the barriers of reverse logistics. Technol Forecast Soc Change 72(8):1011–1029

Ravi V, Shankar R, Tiwari MK (2005) Productivity improvement of a computer hardware supply chain. Int J Prod Perform Manag 54(4):239–255

Richey RG, Genchev SE, Daugherty PJ (2005) The role of resource commitment and innovation in reverse logistics performance. Int J Phys Distrib Logist Manag 35(4):233–257

Rogers DS, Tibben-Lembke R (1999) Going backwards: reverse logistics trends and practices. RLEC Press, Pittsburgh

Sadi-Nezhad S, Khalili-Damghani K (2014) Application of a fuzzy TOPSIS method base on modified preference ratio and fuzzy distance measurement in assessment of traffic police centers performance. Appl Soft Comput 10:1028–1039

Sharma SK, Panda BN, Mahapatra SS, Sahu S (2011) Analysis of barriers for reverse logistics: an Indian perspective. Int J Model Optim 1(2):101–106

Singh RK, Benyoucef L (2011) A fuzzy TOPSIS based approach for e-sourcing. Eng Appl Artif Intell 24:437–448

Srivastava S (2008) Network design for reverse logistics. Omega 36(4):535–548

Stock JR (1998) Development and implementation of reverse logistics program. Council of Logistics Management, Oak Brook

Sun C, Lin GTR (2009) Using fuzzy TOPSIS method for evaluating the competitive advantages of shopping websites. Exp Syst Appl 36(9):11764–11771

Tibben-Lembke RS, Rogers DS (2002) Differences between forward and reverse logistics in a retail environment. Supply Chain Manag Int J 7(5):271–282

Tyagi RK, Dhanda KK, Young S (2012) An operational framework for reverse supply chains. Int J Manag Inf Syst 16(2):137–150

Vishkaei BM, Niaki STA, Farhangi M, Rashti MEM (2014) Optimal lot sizing in screening processes with returnable defective items. J Ind Eng Int 10:70. doi:10.1007/s40092-014-0070-x

Walker H, Sisto LD, McBain D (2008) Drivers and barriers to environmental supply chain management practices: lessons from public and private sectors. J Purch Supply Manag 14:69–85

Wang TC, Lee HD (2009) Developing a fuzzy TOPSIS approach based on subjective weights and objective weights. Expert Syst Appl 36(5):8980–8985

Widmer R, Oswald-Krapf H, Sinha-Khetriwal D, Schnellmann M, Boeni H (2005) Global perspectives on e-waste. Environ Impact Assess Rev 25:436–458

Zadeh LA (1965) Fuzzy sets. Inf Control 8:338–353

Zanakis SH, Solomon A, Wishart N, Dublish S (1998) Multi-attribute decision making: a simulation comparison of selection methods. Eur J Oper Res 107:507–529

Acknowledgments

We would like to express our special gratitude and thanks to electronics industry experts for giving us such attention and time.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Agrawal, S., Singh, R.K. & Murtaza, Q. Prioritizing critical success factors for reverse logistics implementation using fuzzy-TOPSIS methodology. J Ind Eng Int 12, 15–27 (2016). https://doi.org/10.1007/s40092-015-0124-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40092-015-0124-8