Abstract

The define–measure–analyze–improve–control (DMAIC) approach is a five-strata approach, namely DMAIC. This approach is the scientific approach for reducing the deviations and improving the capability levels of the manufacturing processes. The present work elaborates on DMAIC approach applied in reducing the process variations of the stub-end-hole boring operation of the manufacture of crankshaft. This statistical process control study starts with selection of the critical-to-quality (CTQ) characteristic in the define stratum. The next stratum constitutes the collection of dimensional measurement data of the CTQ characteristic identified. This is followed by the analysis and improvement strata where the various quality control tools like Ishikawa diagram, physical mechanism analysis, failure modes effects analysis and analysis of variance are applied. Finally, the process monitoring charts are deployed at the workplace for regular monitoring and control of the concerned CTQ characteristic. By adopting DMAIC approach, standard deviation is reduced from 0.003 to 0.002. The process potential capability index (CP) values improved from 1.29 to 2.02 and the process performance capability index (CPK) values improved from 0.32 to 1.45, respectively.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

An engine crankshaft forms the most dynamic and crucial part of an engine. The manufacture of the crank shaft poses challenges as it involves as many as 23 critical to quality (CTQ) characteristics. Table 1 enlists all the 23 CTQ characteristics associated with the crankshaft manufacturing operations. One such CTQ characteristic is the stub-end-hole diameter formed by boring operation. This machining operation is important because, after this operation the finishing line operations of crankshaft journals’ and pins’ grinding and lapping succeed. So the stub-end-hole boring operation is the last roughing line operation of the crank shaft and is also a bottleneck operation. This is the inspiration behind to select the stub-end-hole boring operation for process capability improvement study.

Statistical process control (SPC) widely employs various process monitoring charts for determining whether the process under consideration is performing within the specified limits are not. Process monitoring charts gives a graphical description of the process performance and it instantly helps the process personnel to differentiate chance causes from assignable causes. Process capability indices are the measure of efficiency of the process to produce the product within the specified dimensional tolerance limits. To be specific, CP is the process potential capability index and CPK is the process performance capability index. CP gives a measure of the variation and deviation in the process. The higher the CP value, the less the variation and deviation in the process. CPK, on the other hand, is obtained from CPKU and CPKL. As a precaution of safety, the lower value among the CPKU and CPKL is considered to be the value of CPK. Elaborating on this, it can be said that centering of the process within the specification limits is done by CPK. It provides an indication whether the process is operating at the center of the specified tolerance zone or nearer to the upper or lower specification limits.

Literature review

Schilling (1994), has thrown light on the superiority of process control over the traditional sampling techniques. Locke (1994), stressed on the importance of process charts, cause and effect relationship and control charts. Lin (2004), had emphasized on process capability indices for normal distribution. Tong et al. (2004), focused on define–measure–analyze–improve–control (DMAIC) approach and its application for printed circuit board quality improvement. Li et al. (2008) adopted DMAIC approach to improve the capability of surface mount technology in solder printing process. Hwang (2006) employed the DMAIC procedure in context of application to manufacturing execution system. Gentili et al. (2006) applied the DMAIC process for a mechanical manufacturing process line, which manufactures both professional and simple kitchen knives. Sahay et al. (2011) used the DMAIC approach for analyzing the manufacturing lines of a brake lever at a Connecticut automotive component manufacturing company. Singh (2011) improved the process capability of polyjet printing for plastic components and charted the procedure for attaining the Cpk value attainment >1.33, i.e., >4 sigma level, which is considered as industrial benchmark. Lin et al. (2013) elaborated on the accurate yield assessment of the processes of multiple characteristics of the turbine blade manufacturing process. Kumaravadivel and Natarajan (2013) applied the cause and effect matrix and failure modes and effects analysis (FMEA) for solving problems associated with flywheel casting process. Mariajayaprakash et al. (2013) identified the CTQ characteristics of shock absorber manufacturing process and improved the process by minimizing the defects using Taguchi approach. Genetic algorithm was applied to optimize the parameters using Taguchi approach. Chen et al. (2013) applied Taguchi’s orthogonal array and analysis of variance (ANOVA) to find the optimal values for the nine process parameters namely, injection time, injection pressure, packing time, packing pressure, cooling time, cooling temperature, mold open time, melt temperature and mold temperature, in a plastic injection molding process. Lal et al. (2013) in their paper discussed about the performance of piston manufacturing plant through stochastic models. They concluded that the time-dependent availability of the piston manufacturing plant is affected by fixture seat machining and circlip grooving.

The literature cited here reveals that the DMAIC approach is widely used for process capability improvements across the manufacturing sector. Hence, without any iota of doubt, this paper straightaway adopts the DMAIC approach for process capability improvement of the stub-end hole boring operation of an engine crankshaft manufacturing process.

Definition stratum

The definition stratum starts with defining the project charter and then the mapping of the machining sequence flow of the crankshaft. It is followed by identifying the CTQ characteristic of interest, for the scope of improvement study.

Project charter

The project charter for the process capability improvement of the stub-end hole boring operation of the crankshaft machining process is depicted in Table 1. The project charter outlines the objectives, deliverables and success metrics of this improvement project. The business impact in terms of monetary benefits is also reflected in the project charter.

Process mapping

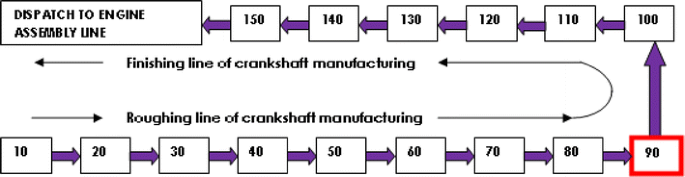

The process flow chart for machining line of the crankshaft manufacturing cell consists of the following machining operations sequence, as shown in the Fig. 1. The manufacturing sequence of the crankshaft consists a total of 15 operations. Of all the manufacturing operations, the operation number 90 is of concern. The operations from 10 to 90 constitute the roughing line operations involving mainly facing and centering, turning, whirling, drilling, tapping and chamfering. The operations from 100 to 150 constitute the finishing line operations involving mainly grinding, sursulfing and lapping.

Table 2 depicts the description of the machining operations of crankshaft manufacturing cell along with the associated CTQ characteristics.

Identifying CTQ characteristic

Timing belt pulley is located onto the stub-end-hole of the crank shaft. Hence if the stub-end-hole is undersize or oversize, it leads to incorrect fitment of the timing belt pulley and subsequently the timing belt. Ultimately, this leads to incorrect timing of fuel combustion within the cylinders and detonation and knocking. Therefore, from functional view-point, the Stub-end-hole diameter forms a CTQ characteristic. Second, from manufacturing view-point, the stub-end hole is the last operation performed on the roughing line and it forms the locating reference for the subsequently operations in the finishing line. Any small variations in the stub-end-hole boring operations are carried to the finishing operations of journal and pin grinding. Hence, unanimously, the stub-end-hole boring operation forms the prime choice for identifying it as a CTQ characteristic. Figure 2 shows the pictorial representation of the CTQ characteristic.

Measurement stratum

The measurement stratum involves data collection of the critical to quality characteristic and is performed for 32 consecutive machined components. Data collection is performed in 3 iterations spanning for a period of 4 weeks each, i.e., about 900 consecutive components. The data are tabulated in the tabular form in Table 3 and the graphical plot of the three sets of measurement iterations is captured in Fig. 3, in the form of process monitoring charts.

Analysis stratum

The analysis stratum comprises of performing the calculations for the C P and CPK values across each iteration. In this stratum, the root cause analysis is performed with the help of various quality control (QC) tools like cause and effect diagram and physical mechanism analysis. Prioritization of the corrective actions is extracted from the output of process FMEA. This is followed by one-way ANOVA method of investigation to test the differences between the three iterations of the data sets.

Calculations of CP and CPK

The calculations of CP and CPK are charted in Table 4. Based on the process monitoring charts and calculations of CP and CPK the following analysis is performed:

Iteration no. 1 primarily indicates the primitive status of the problem on hand before carrying out any improvement work. Continuous sets of measurements of the CTQ characteristic are taken and it is seen that the CP and CPK values here are below the target value of 1.33, with CP value equal to 1.29 and CPK equal to 0.32.

Iteration no. 2 corresponds to the intermediary phase readings after performing moderate improvements like setting up a standard procedure for tool-insert setting on boring bar, cleaning the filter–regulator–lubrication (FRL) unit of pneumatic gauges and replacing the worn out cutting tool insert edge. In Iteration 2, a slight cyclic pattern is observed. This is because of the reason that there is a constant progressive wear out of the boring bar insert on continued boring operation. After every ten components being machined, the boring bar insert must be compensated for the wear by elevating the insert by about five micrometers, over the diametric dimension. This exercise is performed with the help of a test mandrel and a boring bar tool insert setting Vee-block. Because of worn out Vee-surfaces of tool insert setting Vee-block, though the insert setting is done it is not accurate and this is reflected in the cyclic pattern observed in the second optimization step of Iteration 2. As a measure of corrective action, a new insert setting Vee-block is replaced with the old worn-out piece and the Vee surfaces of the Vee-Block are case hardened to achieve hardness up to 55 HRc with a case depth of 0.5–0.8 mm. In this iteration we see a marginal increase in CP to 1.32 and CPK to 0.90.

Finally, Iteration no. 3 corresponds to the final phase readings which are taken after introducing the corresponding corrective actions identified in the analysis stratum and bringing in a noticeable improvement in the process performance with CP = 2.02 and CPK = 1.45.

Cause and effect diagram

The cause and effect diagram, also known as Ishikawa diagram or fish-bone analysis, is a directional approach where the common as well as special causes are classified under the heading of 4 M’s, i.e., man, material, method and machine. All the causes are directed towards the common effect namely, CP and CPK of the CTQ being <1.33. Figure 4 below charts the detailed cause and effect diagram pertaining to this research.

Through the cause and effect diagram, and the PM analysis, the various causes for the poor performance of the machining operation can be identified and corrective actions are taken upon based on the prioritization by the risk priority number (RPN) generated in the FMEA.

Physical mechanism analysis

The PM analysis or in other words physical mechanism analysis is a QC tool originated during the quality improvements under the Hinshitsu Hozen pillar of total productive maintenance. The same concept is applied to this research.

Physical mechanism analysis starts with the identification of the “physics” related to the machining operation under study. The direction of components of the forces acting at the “junction point” of the cutting tool and the workpiece are identified. Conceptually, this Junction-point of the contact of tool and workpiece is the area which involves the cutting forces acting on tool as well as on workpiece, heat transfer, frictional forces opposing the cutting force. It is at this point where the cutting action starts for single as well as multi-point cutting tool. The “junction point” involves three aspects, namely:

Cutting tool aspect

Cutting tool insert indexing, insert changing for single point cutting tool like boring bar; cutting tool dressing for a multi point cutting tool like grinding wheel; cutting tool holder location and clamping aspects; calibration of cutting tool setting in the tool-pre-setting area.

Workpiece aspect

Work location, work holding, work clamping, work supporting, power required for driving the work and related machinery, coolant circulation continuity for flushing out the chips generated in the cutting process, heat dissipation by the coolant,

Measurement aspect

Measurement system comprising of the go and no-go gauges on the shop floor, calibration of gauges, the pneumatic pressure fluctuation in the pressure lines corresponding to the pneumatic gauges, the FRL unit maintenance, in-process sensing instrument sensitivity and repeatability.

Process failure modes and effects analysis (FMEA)

Process FMEA is an approach for prioritizing the sequence of corrective actions. Based on the severity, occurrence and detection ratings the RPN is calculated. The RPN >100 are of concern and liable for corrective action. The detailed FMEA sheet for stub-end-hole boring operation is tabulated in Table 5.

Among the various enlisted causes, the cause which most affects and responsible for the poor performance of the CTQ characteristic, is found by using the ANOVA technique.

Analysis of variance (ANOVA)

ANOVA starts with the formulation of the hypothesis to be tested, followed by, tests for the assumption about the normality of the data and the homogeneity of variance among the sets of the data.

A post hoc analysis is required if FSTATISTIC is found to be >FCRITICAL.

Formulating the hypothesis and testing the assumptions for normality of data and homogeneity of variance

The null hypothesis (H0) and the alternate hypothesis (H1) can be formulated in the present context as

where µ i is the population mean for level i, and µ is the overall grand mean of all levels.

With respect to the data in Table 3, it is seen that there are 3 levels (i.e., 3 iterations) with each level consisting of 32 measurement readings of stub-end-hole diameter of connecting rod. The data plot for normality is captured in Fig. 5, and the histogram bar chart is captured in Fig. 6. The pre-requisite for performing one-way ANOVA test is to find departure from normality and to check the homogeneity of variance among the sets of the data. The normal probability plot is seen linear with equispaced values and this is supported by the histogram with near bell-shaped curvature. The P value is <0.005, which is less than the α value of 0.05, thereby indicating that a linear relationship exists with normality retained. The results are further strengthened by the fact that there are no unusual data points. The sample size of 32 is sufficient to detect differences among means and because all the sample sizes are >15, normality is not an issue. Also based on the data observations and alpha level of 0.05, there is at least a 90 % chance of detecting a difference of standard deviation of 0.0023297 and at most a 60 % chance of detecting a difference of standard deviation of 0.0013632.

Finding the FSTATISTIC

The ANOVA Table obtained from Minitab software is captured in Table 6. Here it is seen that

An α value of 0.05 is typically used, corresponding to 95 % confidence levels. If α is defined to be equal to 0.05, then the critical value for rejection region is FCRITICAL(α, K−1, N−K). and is obtained to be 3.094. Thus,

Hence, it is seen that

Therefore, the decision will be to reject the null hypothesis. If the decision from the ANOVA is to reject the null hypothesis, then it indicates that at least one of the means (µ i ) is different from the remaining other means. In order to figure out where this difference lies, a post hoc ANOVA test is required.

Post-hoc ANOVA test

Since here the sample sizes are same, we go for the Tukey’s test for conducting the Post-hoc ANOVA test. In Tukey’s test, the honestly significant difference (HSD) is calculated as

where q is the studentized range statistic which is equal to a value of 3.38, for a df of 93 and k = 3, i.e., number of levels as 3.

If “C1” denotes “Iteration 1”, “C2” denotes “Iteration 2” and “C3” denotes for “Iteration 3”, then from Minitab software, the following grouping information using Tukey method is shown in Table 7:

From Table 7, it is seen that means that do not share a letter are significantly different, i.e., Iteration 1 is significantly different from Iterations 2 and 3.

The pairwise comparison using Minitab is depicted in Table 8.

In Table 8, it is seen that the pairwise comparison between C2 and C3 is 0.000375 which is less than HSD is Eq. (3), whereas the pairwise comparison between C1 and C2 is 0.004312 and that between C1 and C3 is 0.004687, which are greater than that of the HSD in Eq. (4), with the difference 0.004687 being the largest. So, it is deduced that the differences are statistically significant. Hence, it is concluded that among all the different causes enumerated in the cause and effect diagram, the most influencing causes are the worn out cutting tool insert, insert setting v-block wear out and non-calibration of the vernier calipers and tool setting mandrel.

Control stratum

In the control stratum, the X-bar and R control charts are implemented at the workplace for monitoring the process and preventing it from deviating. These charts ensure that the process remains capable and is prevented from deviations. The X-Bar and R chart are shown in Fig. 7. It can be deduced that the all the mean and the range values are within the upper and lower control limits and that there are no outliers and no out-of-control subgroups. The data points are also equally distributed across the mean line. Thus, the process mean as well as the process variation are stable and the process is controlled. The causal factor matrix is summarized in Table 9.

Results

It is seen that replacement of the worn-out insert tip was the major contributor followed by wear out of tool setting mandrel, insert setting v-block and calibration of air gage, air pressure regulation and air filter maintenance. As a part of standardizing the process, the following activities are carried out:

-

1.

After every 400 components being bored, the indexing of the cutting edge of tool insert is done.

-

2.

Regular machine maintenance schedule has been established and regular checks are included in the checklist.

-

3.

After every 10 components bored, the pneumatic gauge is calibrated with the standard ring gauge corresponding to the pneumatic gauging system.

-

4.

The gauge calibration is done periodically as a part of measurement system analysis and properly calibrated pneumatic gauge is used at the workplace.

-

5.

After every 2 months i.e., after about (1,600)–(1,800) components, the FRL unit maintenance is incorporated in the preventive maintenance checklist.

-

6.

Coolant recirculation pressure is set at a value of around 3.0 kgf/sq.cm.

-

7.

Insert presetting on the boring-bar is carried out with the help of a portable Vee-block insert setting gauge on the horizontal boring-bar.

The improvement in the process performance is fostered by the fact that the sigma levels (standard deviation) are reduced from 0.003 to 0.002 as captured in Table 3.

Conclusion

This paper traces the DMAIC approach for improving the process capability levels of the stub-end-hole boring operation of the crankshaft manufacturing process. The QC tools predominantly used for tracing out the causes for poor process performance are the Ishikawa diagram, physical mechanism analysis and the failure modes and effects analysis. The process monitoring charts are employed at the workplace for monitoring the process performance and preventing it from deviations. In order to trace out the extent of influence of the causes identified, the ANOVA procedure is adopted. The predominant causes identified are worn out cutting tool inserts, worn out insert setting v-block and non-calibration of the vernier calipers and tool setting mandrel. Finally, on eliminating the causes one-by-one, the process potential capability index (CP) showed an improvement from 1.29 to 2.02 and the process performance capability index (CPK) improved from 0.32 to 1.45.

References

Chen WL, Huang CY, Huang CY (2013) Finding efficient frontier of process parameters for plastic injection molding. J Ind Eng Int 9:25

Gentili E, Aggogeri F, Mazzola M (2006) The improvement of a manufacturing stream using the DMAIC method. University of Brescia, Paper No. IMECE2006-14469, pp 127–133. doi:10.1115/IMECE2006-14469, ASME 2006

Hwang YD (2006) The practices of integrating manufacturing execution system and six sigma methodology. Int J Adv Manuf Technol 30:761–768. doi:10.1007/s00170-005-0090-1. Springer, London

Kumaravadivel A, Natarajan U (2013) Application of six-sigma DMAIC methodology to sand-casting process with response surface methodology. Int J Adv Manuf Technol. doi:10.1007/s00170-013-5119-2. Springer, London

Lal AK, Kaur M, Lata S (2013) Behavioral study of piston manufacturing plant through stochastic models. J Ind Eng Int 9:24

Li MHC, Al-Refaie A, Yang CY (2008) DMAIC approach to improve the capability of SMT solder printing process. IEEE Trans Electron Packag Manuf 31(2):126

Lin HC (2004) The measurement of a process capability for folded normal process data. Int J Adv Manuf Technol 24:223–228. doi:10.1007/s00170-003-1615-0. Springer, London

Lin SJ, Yang DL, Cheng FT, Wu MF (2013) Aircraft turbine engine manufacturing with multiple specifications. J Test Eval 41(1):1–7. doi:10.1520/JTE20120022 (ISSN 0090-3973)

Locke JW (1994) Statistical measurement control. In: Kowalewski MJ Jr (ed) Quality and statistics: total quality management. ASTM STP 1209, American Society for Testing and Materials, Philadelphia

Mariajayaprakash A, Senthilvelan T, Vivekananthan KP (2013) Optimisation of shock absorber process parameters using failure mode and effect analysis and genetic algorithm. J Ind Eng Int 9:18

Sahay C, Ghosh S, Bheemarthi PK (2011) Process improvement of brake lever production using DMAIC (+). University of Hartford, West Hartford, CT Paper No. IMECE2011-63813, pp 801–826. doi:10.1115/IMECE2001-63813, ASME 2011

Schilling EG (1994) The transition from sampling to SPC. In: Kowalewski MJ Jr (ed) Quality and statistics; total quality management. ASTM STP 1209, American Society for Testing and Materials, Philadelphia

Singh R (2011) Process capability study of polyjet printing for plastic components. J Mech Sci Technol 25(4):1011–1015. http://www.springerlink.com/content/1738-494x; doi:10.1007/s12206-011-0203-8

Tong JPC, Tsung F, Yen BPC (2004) A DMAIC approach to printed circuit board quality improvement. Int J Adv Manuf Technol 23:523–531. doi:10.1007/s00170-003-1721-z. Springer, London

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Sharma, G.V.S.S., Rao, P.S. A DMAIC approach for process capability improvement an engine crankshaft manufacturing process. J Ind Eng Int 10, 65 (2014). https://doi.org/10.1007/s40092-014-0065-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40092-014-0065-7