Abstract

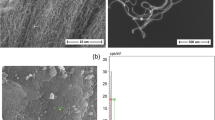

Nowadays, environmental pollution due to industrial waste is one of the biggest challenges around the world. However, various technologies are used to reduce the environmental problem from this waste. But, these technologies are costly and degrade lots of agricultural lands. In the present investigation, an attempt is made to utilize waste bagasse ash (BGA) in the fabrication of a composite material with eggshell (ES). To improve the wettability of reinforcement particles, nano-CuO particles with an amount of 1.5% were added to all the fabricated composite samples. Microstructure results indicate the uniform distribution of reinforcements. Proper wettability can be observed between the matrix and reinforcement particles. The presence of nano-CuO particles promoted the wettability between the matrix and reinforcement particles (ES and BGA). The optimal amount of reinforcement parameters was found to be BGA wt.% of 9.11, BGA preheat temperature of 282.14 °C, ES preheat temperature of 328.42 °C, and ES wt.% of 5.37, respectively, for achieving tensile strength of 239.77 MPa. Hardness, toughness, ductility, and corrosion behavior were also measured for examining the influence of BGA, ES, and nano-CuO particles in aluminum alloy.

Similar content being viewed by others

References

B. Yan, Y. Wang, X. Wu, Adv. Compos. Mater 27, 387 (2018)

M. Mousa, Y. Dong, I. Davies, Adv. Compos. Mater 27, 499 (2018)

Y. Ma, D. Xing, Y. Ruan, X. Du, P. La, Environ. Eng. Sci. 35, 219 (2018)

A. Pramanik, Trans. Nonferrous Met. Soc. China. 26, 348 (2016)

H.Y. Yue, B. Wang, X. Gao, S.L. Zhang, X.Y. Lin, L.H. Yao, E.J. Guo, J. Alloy. Compd. 692, 395 (2017)

H.K. Durmus, C. Meric, Mater. Des. 28, 982 (2007)

Z. Liu, M. Adams, T.R. Walker, Resources. Conserv. Recycl. 136, 22 (2018)

V.K. Sharma, R.C. Singh, R. Chaudhary, Eng. Sci. Technol. Int. J. 20, 1318 (2017)

S.P. Dwivedi, N.K. Maurya, M. Maurya, A. Saxena, A.K. Srivastava, Mater. Test. 63, 1041 (2021)

S.P. Dwivedi, M. Maurya, S. Sharma, Green Mater. (2021). https://doi.org/10.1680/jgrma.21.00035

S.P. Dwivedi, A. Saxena, N. Srivastava Mater. Test. 63, 462 (2021)

S.P. Dwivedi, A. Saxena, S. Sharma, A.K. Srivastava, N.K. Maurya, Int. J. Cast Met. Res. 34, 43 (2021)

R. Yadav, V.K. Dwivedi, A. Islam, S.P. Dwivedi, World J. Eng. 18, 930 (2021)

S.P. Dwivedi, G. Dwivedi, World J. Eng. 17, 399 (2020)

C.U. Atuanya, A.O.A. Ibhadode, I.M. Dagwa, Results Phys. 2, 142 (2012)

M. Satheesh, M. Pugazhvadivu, Phys. B 572, 70 (2019)

N. Panwar, A. Chauhan, H.S. Pali, M.D. Sharma, Mater. Today Proc. 21, 2014 (2020)

K.C. Nayak, P.R. Deshmukh, A.K. Pandey, P. Vemula, P.P. Date, Mater. Sci. Eng., A 773, 138895 (2020)

S.B. Hassan, V.S. Aigbodion, J. King Saud Univ. Eng. Sci. 27, 49 (2015)

M.B.N. Shaikh, S. Arif, T. Aziz, A. Waseem, M.A.N. Shaikh, M. Ali, Surf. Interfaces. 15, 166 (2019)

M.S. Kumar, M. Vasumathi, S.R. Begum, S.M. Luminita, S. Vlase, C.I. Pruncu, J. Mater. Res. Technol. 15, 1201 (2021)

K.K. Alaneme, M.O. Bodunrin, A.A. Awe, J. King Saud Univ. Eng. Sci. 30, 96 (2018)

C.U. Atuanya, V.S. Aigbodion, J. Alloy. Compd. 601, 251 (2014)

V.S. Aigbodion, J King Saud Univ. Eng. Sci. 26, 144 (2014)

J. Gayathri, R. Elansezhian, J. Alloy. Compd. 829, 154538 (2020)

R. Senthilkumar, N. Arunkumar, M.M. Hussian, Results Phys. 10, 215 (2015)

S. Ugender, A. Kumar, A.S. Reddy, Procedia Mater. Sci. 5, 824 (2014)

R. Kadaganchi, M.R. Gankidi, H. Gokhale, Def. Technol. 11, 209 (2015)

A. Verma, A. Pal, S.P. Dwivedi, S. Sharma, Mater. Test. 61, 894 (2019)

S.P. Dwivedi, A.K. Mishra, V.R. Mishra, J. Ceram. Process. Res. 20, 632 (2019)

S.P. Dwivedi, Int. J. Cast Met. Res. 33, 35 (2020)

S.K. DS, K. Chethan, H. GS, M.K. Yashwanth, Int. J. Civ. Eng. Technol. 10, 1003 (2019)

R. Bhaumik, N.K. Mondal, B. Das, P. Roy, K.C. Pal, C. Das, A. Banerjee, J.K. Datta, J. Chem. 9, 1457 (2012)

K.A. Masri, E. Ganesan, P.J. Ramadhansyah, S.I. Doh, S.M.Z.N. Syafiqah, Z.F.M. Jaafar, N. Mashros, IOP conf. Ser. Earth Environ. Sci. 682, 012056 (2021)

Funding

This research received no specific grant from any funding agency.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Dwivedi, S.P., Sahu, R. Development of Aluminum-Based Composite Material by using Bagasse Ash and Eggshell as Reinforcement Along with Nano-CuO Particles. J. Inst. Eng. India Ser. D 104, 489–502 (2023). https://doi.org/10.1007/s40033-022-00417-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40033-022-00417-y