Abstract

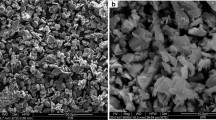

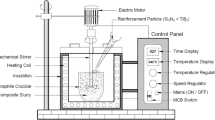

The effect of TiB2 (titanium diboride) and Gr (graphite) additions on the mechanical properties of AA7075 alloy is investigated. The composites were formed using stir casting and hot rolling. The in situ reaction method was used to develop 5wt% TiB2 particles, while graphite particles were added externally in 2–8% insteps of 2. With an 80% reduction ratio, the cast composites were hot rolled at 400 °C. The microstructure examination reveals exceptional dispersion of titanium diboride and graphite reinforcement particles, as well as excellent bonding with the matrix alloy. Particles have been positioned more uniformly after hot rolling. Hot rolled hybrid composites, as opposed to cast alloys and composites, have demonstrated exceptional strength and microhardness. The hardness and ultimate tensile strength of the hot rolled composite are increased by 61% and 89%, respectively, when compared to the hot rolled alloy in the cast process. SEM analysis of tensile fractured surfaces revealed ductile and brittle fracture combination modes for hybrid composites in hot rolled and cast conditions.

Similar content being viewed by others

References

I.A. Ibrahim, F.A. Mohamed, E.J. Lavernia, Particulate reinforced metal matrix composites—a review. J. Mater. Sci. 26, 1137–1156 (1991)

W.D. Callister, Material Science and Engineering—an Introduction (John Wiley & Sons, New York, 2007), p. 577

Y. Sahin, M. Acilar, Production and properties of SiCp-reinforced Aluminium alloy composites. Compos Part A. 34, 709–718 (2003)

J.W. Luster, M. Thumman, R. Banmann, Mechanical properties of Aluminium alloy 6061-Al2O3 composite. Mater. Sci. Technol. 9, 853–862 (1993)

V.R. Surya, K.M.V. Kumar, R. Keshavamurthy, G. Ugrasen, H.V. Ravindra, Prediction of machining characteristics using artificial neural network in wire EDM of Al7075 based in-situ composite. Mater. Today Proc. 4(2), 203–212 (2017)

J.T. Kavya, R. Keshavamurthy, G.S.P. Kumar, Studies on parametric optimization for abrasive water jet machining of Al7075-TiB2 in-situ composite, in IOP Conference Series: Materials Science and Engineering, vol 149(1), p. 012024.

R. Keshavamurthy, M. Pavan, M. Abdul Tazamul Haq, D. Zinge, Y. Mohammed, Hardness and Tensile behavior of forged Al7075-SiC composite. Int. J. Appl. Eng. Res. 10(55), 3769–3772 (2015)

V.R. Dalve, R. Keshavamurthy, G. Ugrasen, C.P.S. Prakash, Experimental investigations on Wire EDM of Al7075-TiB2 in situ metal matrix composite. Appl. Mech. Mater. 592, 321–325 (2014)

R. Keshavamurthy, J.M. Sudhan, N. Gowda, R.A. Krishna, Effect of thermo-mechanical processing and heat treatment on the tribological characteristics of Al based MMC’s, in IOP Conference Series: Materials Science and Engineering, vol. 149, p. 012118 (2016)

K.V.S. Murthy, R. Keshavamurthy, D.P. Girish, Mechanical characteristics of hot forged Al6061-Al2O3 composite, in Applied Mechanics and Materials, vol 787, pp. 598–601 (2015)

K.V.S. Murthy, D.P. Girish, R. Keshavamurthy, T. Varol, P.G. Koppad, Mechanical and thermal properties of AA7075/TiO2/Fly ash hybrid composites obtained by hot forging. Progress Nat. Sci. Mater. Int. 27(4), 474–481 (2017)

R.V. Kumar, R. Keshavamurthy, C.S. Perugu, P.G. Koppad, M. Alipour, Influence of hot rolling on microstructure and mechanical behaviour of Al6061-ZrB2 in-situ metal matrix composites. Mater. Sci. Eng. A 738, 344–352 (2018)

S. Manjoth, R. Keshavamurthy, G.S.P. Kumar, Optimization and analysis of laser beam machining parameters for Al7075-TiB2 In-situ composite, in IOP Conference Series: Materials Science and Engineering vol. 149 (1), p. 012013.

G.S.P. Kumar, R. Keshavamurthy, C.S. Ramesh, B.H. Channabasappa, Tribological characteristics of Al6061-TiC composite synthesized by in situ technique. Appl. Mech. Mater. 787, 653–657 (2015)

Y.B. Mukesh, T.P. Bharathesh, R. Saravanan, R. Keshavamurthy, Effect of hot extrusion on mechanical behaviour of boron nitride reinforced aluminium 6061-based metal matrix composites. Int. J. Mater. Eng. Innov. 10(2), 135–151 (2019)

G.S.P. Kumar, R. Keshavamurthy, V. Tambrallimath, R. Biswas, Y.S. Andhale, Mechanical properties of AA7075-SiC-TiO2 hybrid metal matrix composite, in Advanced Manufacturing and Materials Science. ed. by K. Antony, J.P. Davim (Springer, Cham, 2013), pp. 301–307

A. El-Sabbagh, M. Soliman, M. Taha, H. Palkowski, Hot rolling behaviour of stir-cast Al 6061 and Al6082 alloys—SiC fine particulates reinforced compoistes. J. Mater. Process. Technol. 212, 497–508 (2012)

A.k. Gajakosh, R. Keshavamurthy, T. Jagadeesha, R.S. Kumar, Investigations on mechanical behaviour of hot rolled AA7075/TiO2/Gr hybrid composites Ceramics International, November 2020.

G.S.P. Kumar, R. Keshavamurthy, C.S. Ramesh, T.P. Bharathesh, Mechanical properties of hot forged Al6061-TiB2 In-situ metal matrix composites. Mater. Today Proc. 2(4–5), 3107–3115 (2015)

A.K. Gajakosh, R. Keshavamurthy, G. Ugrasen, H. Adarsh, Investigation on mechanical behavior of hot rolled AA7075-TiB2 in-situ metal matrix composite. Mater. Today Proc. 5(11), 25605–25614 (2018)

R.G. Papagiannakis, Fabrication of hybrid (Al+TiO2+Gr) metal matrix composites An Experimental Study. Rev. Téc. Ing. Univ. Zulia 37(2), 33–36 (2014)

C.S. Ramesh, A. Ahamed, B.H. Chanabasappa, R. Keshavamurthy, Development of Al 6063-TiB2 insitu composites. Mater. Design 31, 2230–2236 (2010)

R.K. Sabat, P.K. Samal, S.M. Ahamed, Effect of strain path on the evolution of microstructure, texture and tensile properties of WE43 alloy. Mater. Sci. Eng. A 715(7), 348–358 (2018)

R.K. Sabat, M.V.S.S.D.S. Surya Pavan, D.S. Aakash, M. Kumar, S.K. Sahoo, Mechanism of texture and microstructure evolution during warm rolling of Ti–6Al–4V alloy. Philos. Mag. 98(28), 2562–2581 (2018)

S. Sankaranarayanan, R.K. Sabat, S. Jayalakshmi, S. Walker, S. Suwas, M. Gupta, Using heat treatment effects and EBSD analysis to tailor microstructure of hybrid Mg nanocomposite for enhanced overall mechanical response. Mater. Sci. Technol. 30(11), 1309–1320 (2014)

K.T. Kashyap, T. Chandrashekar, Effects and mechanisms of grain refinement in aluminium alloys. Bull. Mater. Sci. 24, 345–353 (2001)

P. Sahoo, M.J. Koczak, Microstructure-property relationships of in-situ reacted TiC/Al-Cu metal matrix composites. Mater. Sci. Eng. A 131, 69–76 (1991)

C.S. Ramesh, R. Keshavamurthy, S. Pramod, P.G. Koppad, Abrasive wear behavior of Ni-P coated Si3N4 reinforced Al6061 composites. J. Mater. Process. Technol. 211, 1423–1431 (2011)

T.P.D. Rajan, R.M. Pillai, B.C. Pai, Characterization of centrifugal cast functionally graded aluminum-silicon carbide metal matrix composites. Mater. Charact. 61(10), 923–928 (2010)

J.C. Byun, J.Y. Oh, C.S. Seok, H.I. Lee, Efect of arious processing methods on the interfacial reactions in Sic 2024 AIçomposites. Acta Materilia 45, 5303 (1997)

H.Q. Gao, L.D. Wang, W.D. Fei, E.A. Feest, Interfacial phenomena in metal matrix Composites. Composites 25, 75 (1994)

C.S. Ramesh, R. Keshavamurthy, J. Madhusudhan, Fatigue behavior of Ni-P coated Si3N4 reinforced Al6061 composites. Procedia Mater. Sci. 6, 1444–1454 (2014)

W.C. Shi, L. Yuam, Z.Z. Xheng, D.B. Shan, Effect of forging on the microstructure and tensile properties of 2024Al/Al18B4O33w composite. Mater. Sci. Eng. A 615, 313–319 (2014)

U. Cocen, K. Onel, Ductility and strength of extruded aluminum alloy Composites. Compos. Sci. Technol. 62, 275–282 (2002)

K.F. Ho, M. Gupta, T.S. Srivatsan, The mechanical behavior of Magnesium alloy AZ91 reinforced with fine copper particulates. Mater. Sci. Eng. A 369(1–2), 302–308 (2004)

W. Muhammad, R.K. Sabat, A.P. Brahme, J. Kang et al., Deformation banding in a precipitation hardened aluminum alloy during simple shear deformation. Scripta Mater. 162(15), 300–305 (2019)

R.K. Sabat, W. Muhammad, R.K. Mishra, K. Inal, Effect of microstructure on fracture in age hardenable Al alloys. Philos. Mag. 100(11), 1476–1498 (2020)

W. Muhammad, A.P. Brahme, R.K. Sabat, R.K. Mishra, K. Inal, A criterion for ductile failure in age-hardenable aluminum alloys. Mater. Sci. Eng. A 759(24), 613–623 (2019)

Funding

No funding was received for this research work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There is no conflict of Interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ahmed, S.S., Girisha, H.N. & Keshavamurthy, R. Impact of Hot Rolling on Mechanical Characteristics of AA7075/TiB2/Graphite Hybrid Composites. J. Inst. Eng. India Ser. D 103, 191–201 (2022). https://doi.org/10.1007/s40033-021-00311-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40033-021-00311-z