Abstract

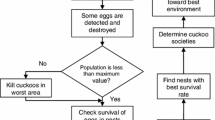

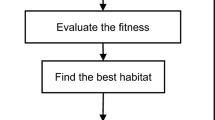

Laser machining is a promising non-contact process for effective machining of difficult-to-process advanced engineering materials. Increasing interest in the use of lasers for various machining operations can be attributed to its several unique advantages, like high productivity, non-contact processing, elimination of finishing operations, adaptability to automation, reduced processing cost, improved product quality, greater material utilization, minimum heat-affected zone and green manufacturing. To achieve the best desired machining performance and high quality characteristics of the machined components, it is extremely important to determine the optimal values of the laser machining process parameters. In this paper, fireworks algorithm and cuckoo search (CS) algorithm are applied for single as well as multi-response optimization of two laser machining processes. It is observed that although almost similar solutions are obtained for both these algorithms, CS algorithm outperforms fireworks algorithm with respect to average computation time, convergence rate and performance consistency.

Similar content being viewed by others

References

A.K. Dubey, V. Yadava, Laser beam machining—a review. Int. J. Mach. Tools Manuf. 48, 609–628 (2008)

A.K. Dubey, V. Yadava, Experimental study of Nd:YAG laser beam machining—an overview. J. Mater. Process. Technol. 195, 15–26 (2008)

A.S. Kuar, B. Doloi, B. Bhattacharyya, Modelling and analysis of pulsed Nd:YAG laser machining characteristics during micro-drilling of zirconia (ZrO2). Int. J. Mach. Tools Manuf. 46, 1301–1310 (2006)

R. Biswas, A.S. Kuar, S. Mitra, Influence of machining parameters on surface roughness in Nd:YAG laser micro-cutting of alumina–aluminium interpenetrating phase composite. Int. J. Surf. Sci. Eng. 2, 252–264 (2008)

U. Çaydaş, A. Hasçalık, Use of the grey relational analysis to determine optimum laser cutting parameters with multi-performance characteristics. Opt. Lasers Technol. 40, 987–994 (2008)

A.S. Kuar, P. Biswas, S. Mitra, R. Biswas, Experimental investigation of Nd:YAG laser micro-grooving operation of alumina workpiece using RSM. Int. J. Mater. Struct. Integr. 1, 355–370 (2008)

A.K. Dubey, V. Yadava, Multi-objective optimisation of laser beam cutting process. Opt. Lasers Technol. 40, 562–570 (2008)

D. Dhupal, B. Doloi, B. Bhattacharyya, Parametric analysis and optimization of Nd:YAG laser micro-grooving of aluminum titanate (Al2TiO5) ceramics. Int. J. Adv. Manuf. Technol. 36, 883–893 (2008)

D. Dhupal, B. Doloi, B. Bhattacharyya, Pulsed Nd:YAG laser turning of micro-groove on aluminum oxide ceramic (Al2O3). Int. J. Mach. Tools Manuf. 48, 236–248 (2008)

R. Biswas, A.S. Kuar, S. Mitra, Parametric study of hole circularity in Nd:YAG laser microdrilling of alumina–aluminium (Al2O3–Al) interpenetrating phase composite. Int. J. Manuf. Res. 4, 252–264 (2009)

J. Ciurana, G. Arias, T. Ozel, Neural network modeling and particle swarm optimization (PSO) of process parameters in pulsed laser micromachining of hardened AISI H13 steel. Mater. Manuf. Process. 24, 358–368 (2009)

D. Dhupal, B. Doloi, B. Bhattacharyya, Modeling and optimization on Nd:YAG laser turned micro-grooving of cylindrical ceramic material. Opt. Lasers Eng. 47, 917–925 (2009)

R. Rao, V. Yadava, Multi-objective optimization of Nd:YAG laser cutting of thin superalloy sheet using grey relational analysis with entropy measurement. Opt. Lasers Technol. 41, 922–930 (2009)

B. Doloi, D. Dhupal, B. Bhattacharyya, Modelling and analysis on machining characteristics during pulsed Nd:YAG laser microgrooving of aluminium titanate (Al2TiO5). Int. J. Manuf. Technol. Manage. 21, 30–41 (2010)

R. Biswas, A.S. Kuar, S.K. Biswas, S. Mitra, Effects of process parameters on hole circularity and taper in pulsed Nd:YAG laser microdrilling of TiN–Al2O3 composites. Mater. Manuf. Process. 25, 503–514 (2010)

A.S. Kuar, S.K. Dhara, S. Mitra, Multi-response optimisation of Nd:YAG laser micro-machining of die steel using response surface methodology. Int. J. Manuf. Technol. Manage. 21, 17–29 (2010)

R. Biswas, A.S. Kuar, S.K. Biswas, S. Mitra, Characterization of hole circularity in pulsed Nd:YAG laser micro-drilling of TiN–Al2O3 composites. Int. J. Adv. Manuf. Technol. 51, 983–994 (2010)

R. Biswas, A.S. Kuar, S. Sarkar, S. Mitra, A parametric study of pulsed Nd:YAG laser micro-drilling of gamma-titanium aluminide. Opt. Lasers Technol. 42, 23–31 (2010)

T.V. Sibalija, S.Z. Petronic, V.D. Majstorovic, R. Prokic-Cvetkovic, A. Milosavljevic, Multi-response design of Nd:YAG laser drilling of Ni-based superalloy sheets using Taguchi’s quality loss function, multivariate statistical methods and artificial intelligence. Int. J. Adv. Manuf. Technol. 54, 537–552 (2011)

S. Panda, D. Mishra, B.B. Biswal, Determination of optimum parameters with multi-performance characteristics in laser drilling—a grey relational analysis approach. Int. J. Adv. Manuf. Technol. 54, 957–967 (2011)

A. Sharma, V. Yadava, Modelling and optimization of cut quality during pulsed Nd:YAG laser cutting of thin Al-alloy sheet for curved profile. Opt. Lasers Eng. 51, 77–88 (2013)

G. Kibria, B. Doloi, B. Bhattacharyya, Experimental investigation and multi-objective optimization of Nd:YAG laser micro-turning process of alumina ceramic using orthogonal array and grey relational analysis. Opt. Lasers Technol. 48, 16–27 (2013)

A. Ghosal, A. Manna, Response surface method based optimization of ytterbium fiber laser parameter during machining of Al/Al2O3-MMC. Opt. Lasers Technol. 46, 67–76 (2013)

G. Kibria, B. Doloi, B. Bhattacharyya, Predictive model and process parameters optimization of Nd:YAG laser micro-turning of ceramics. Int. J. Adv. Manuf. Technol. 65, 213–229 (2013)

Y. Tan, Y. Zhu, Fireworks algorithm for optimization, in Advances in Swarm Intelligence, ed. by Y. Tan, Y. Shi, K.C. Tan (Springer-Verlag, Berlin, 2010), pp. 355–364

Pei Y, Zheng S, Tan Y, Takagi H (2012) An empirical study on influence of approximation approaches on enhancing fireworks algorithm, Proceedings of IEEE International Conference on Systems, Man, and Cybernetics, Korea, 1322–1327

X.-S. Yang, S. Deb, Engineering optimisation by cuckoo search. Int. J. Math. Model. Numer. Optim. 1, 330–343 (2010)

R. Rajabioun, Cuckoo optimization algorithm. Appl. Soft Comput. 11, 5508–5518 (2011)

R.B. Payne, M.D. Sorenson, K. Klitz, The Cuckoos (Oxford University Press, Oxford, 2005)

I. Pavlyukevich, Cooling down Lévy flights. J. Phys. A 40, 12299–12313 (2007)

Yang X-S, Deb S (2009) Cuckoo search via Levy flights. Proceedings of World Congress on Nature and Biologically Inspired Computing (NaBIC) 210–214

A.H. Gandomi, X.-S. Yang, A.H. Alavi, Cuckoo search algorithm: a metaheuristic approach to solve structural optimization problems. Eng. Comput. 29, 17–35 (2013)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Goswami, D., Chakraborty, S. A Study on the Optimization Performance of Fireworks and Cuckoo Search Algorithms in Laser Machining Processes. J. Inst. Eng. India Ser. C 96, 215–229 (2015). https://doi.org/10.1007/s40032-014-0160-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40032-014-0160-y