Abstract

In this study, novel green and economical techniques were established to synthesize modified banana peel hydrochar (HBP) through hydrothermal carbonization. Chitosan nanoparticles, a green adsorbent with multiple features, were prepared, characterized, and used to enhance the performance of the hydrochar in THMs removals. The optimal method for hydrothermal carbonization was determined based on previously cited methods. The dried banana peels and HBP were characterized using Fourier transform infrared spectrometer (FTIR), pH, zero point of charge, and bulk density. The prepared chitosan nanoparticles were characterized using scanning electron microscope (SEM), transmission electron microscope (TEM), and zeta potential techniques. The average size of chitosan nanoparticles was 12.1 nm, and a 1:1 mixture of HBP and chitosan nanoparticles was used for the removal of THMs from an aqueous solution. The concentrations of THMs were measured using gas chromatography, and the effect of THMs’ initial concentrations, adsorbent doses, temperature, and pH value on the adsorption capacity was studied. The results showed that the 1:1 mixture of HBP and chitosan nanoparticles was an efficient adsorbent for removing THMs from aqueous solutions. This adsorbent was found to be effective in removing THMs from the aqueous solution, even at low temperature and pH values, with an estimated maximum sorption capacity (qm) of 588.23 g g−1, exceeding numerous other adsorbents previously studied, and the regression coefficient (R2 = 0.9959) for data fitting with the Freundlich isotherm. This research has the potential to offer a great avenue for future development and implementation in water treatment. It could lead to improved methods of treating water, which would be beneficial for both environmental protection and economic growth. The developed adsorbent had high adsorption affinity toward the THMs compounds, making the adsorption method efficient and viable technique for treating water containing such contaminants.

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Avoid common mistakes on your manuscript.

Introduction

Today, water pollution with different pollutants mostly DBPs has turned out to be a major issue due to extra chlorine dosages (Hrudey 2008), which are used in some wastewater plants to overcome the deficiencies in the treatment processes to ensure a supply of safe-treated wastewater regarding microbiological side (Yang 2005). This fact and the presence of organic matter (OM) in the wastewater increases are turn out to be major environmental problems due to the formation of chlorination by-products (Bond et al. 2009; Moustafa and Hesham 2018), as an example, trihalomethanes (THM), which are carcinogenic substances (Mohd Zainudin et al. 2018). Chlorinated DBPs can be generated during the reaction of chlorine with organic matter (OM) (Hesham and Moustafa 2019; Watson et al. 2012), as well as bromide. NOM is the main precursor of chlorinated DBPs in most water and signifies a considerable portion of all organic matter in most water supplies (Bond et al. 2012) as explained in chemical equation (A).

\(\mathbf{H}\mathbf{O}\mathbf{C}\mathbf{l}+{\mathbf{B}\mathbf{r}}^{-}+\mathbf{N}\mathbf{O}\mathbf{M}\to \mathbf{T}\mathbf{H}\mathbf{M}\mathbf{s}+\mathbf{H}\mathbf{A}\mathbf{A}\mathbf{s}+\mathbf{o}\mathbf{t}\mathbf{h}\mathbf{e}\mathbf{r}\mathbf{D}\mathbf{B}\mathbf{P}\mathbf{s}\) Chemical equation (A).

The various forms of THMs are produced through chlorination and are associated with various short-term and long-term health risks (Dong et al. 2023). It is important to understand the risks associated with THMs and to ensure that water is treated to reduce the levels of THMs. Furthermore, it is important to adhere to the regulations in place to limit the levels of THMs in drinking water (Dong et al. 2023; Villanueva et al. 2023). Effective processes for trihalomethane precursor control are: (1) oxidation with ozone or chlorine dioxide; (2) clarification through coagulation, settling, filtration, precipitative softening, or direct filtration; (3) adsorption with powdered activated carbon or granular activated carbon. Additionally, some moderate reduction or destruction of trihalomethane precursors can be accomplished through oxidation with potassium permanganate, lowering the pH, or relocating the chlorination point to clarified water (Ghernaout 2018).

Recent developments in the synthesis of different nanomaterials sizes, shapes, and functions have customarily used nanotechnology as an indispensable technology for water and wastewater treatment (Jahin et al. 2022; Nassar et al. 2023); this is due to many advantages of small nanomaterial sizes and interesting physical properties. The presence of hydroxyl and amino functional groups in chitosan nanoparticle present it as an excellent adsorbent. One study stated that chitosan-coated nanoparticle membranes were capable to get rid of bacteria much better than uncoated membranes (Li et al. 2010).

Absorbents must be formed that do not produce a secondary pollutant of the water throughout the treatment phases (Nakamura et al. 2001). Owing to the multifunctional features of fruit peels, the uptake of contaminants is achieved through a range of processes, involving electrostatic interactions and ion exchange (Hesham et al. 2021). Polar functional groups may be found in the peels of all fruits such as − COOH, − NH2, and − OH, on the surface (Hesham et al. 2021; Khairy et al. 2022).

As such, other nonconventional adsorbents from banana peels waste were prepared, proposed, and employed as low-cost and effective adsorbents due to their natural source and property to bind and adsorb metal ions from water (Ahmad et al. 2022). Hydrothermal carbonization (HTC) of carbon-rich biomass is a very important and useful process to produce hydrochar. The HTC technique may be best applied to wet feedstock, like fruit peels (Khan et al. 2022), biomass, and other wet materials, using relatively moderate temperatures (150–350 °C) (Hesham et al. 2021; John and Omorogie 2022). HTC is more efficient compared to dry pyrolysis regarding energy and char yield (Catenacci et al. 2022). Hydrochar had a stronger ability to deal with nonpolar and polar organic contaminants (Fang et al. 2018; Khairy et al. 2022). Because of its porous and reactive, functionalized/aromatic surfaces, it may be a viable low-cost adsorbent for removing contaminants from wastewater (Ngo et al. 2016; Sirajo and Zaini 2022). In recent years, there has been a growing concern about the presence of trihalomethanes (THMs) in our drinking water and the need to find ways to remove them (Qadafi et al. 2023). The goal of this research was to develop a novel combination of banana peel hydrochar and chitosan nanoparticles to eliminate trihalomethanes (THMs) from synthetic water. In order to achieve this, we explored a technique that utilizes the adsorption properties of the newly developed material. Furthermore, we discussed recent advancements in THM removal techniques and their effectiveness in eliminating these compounds from drinking water supplies. The results obtained through our study will provide valuable insight into how well this new method can reduce THM levels in water samples, thus making it an efficient solution for improving drinking water quality around the world.

Materials and methods

Chemicals

The chemicals used in this study were of analytical grade purity including chitosan powder, acetic acid, sodium tripolyphosphate (stp), Tween-80 (Sigma-Aldrich product), chloroform (CHCl3), bromoform (CHBr3), dibromochloromethane (CHBr2Cl), dichlorobromomethane (CHBrCl2), ethanol (C2H5OH, absolute alcohol, Sigma-Aldrich); banana peels were collected from local market. Deionized water ultra-pure was used to prepare solutions for the synthesis of chitosan nanoparticles and banana peels hydrochar adsorbent.

Preparation of Banana peels hydrochar (HBP)

The banana peels were washed with deionized water and dried at 100 °C in an oven until constant weight. Next, dried peels were crushed in a ball mill and sieved to particle sizes ≤ 1 mm and located in a desiccator till the hydrochar (HC) preparation step. The method of feedstock preparation was adapted from Chen et al. (Chen et al. 2018).

HBP was prepared as follows: 10 g of dried feedstock was prepared in the previous step mixed with 100 ml distilled water in a Teflon-sealed stainless steel reactor. Then, the reactor was heated at 180 °C for 3 h under autogenous pressures to produce banana peels hydrochar (HBP). The aqueous solution in the reactor was filtered after cooling down to ambient temperature, and the (HBP) was dried at 90 °C for 2 h.

Chitosan nanoparticles preparation (Ch. NPs)

The synthesis of chitosan nanoparticles was done in a clean pasteurized flask by the method described by (Wardani and Sudjarwo 2018) with some modifications. 2.0 g of chitosan powder was dissolved in 300 ml of 2% acetic acid and was kept under vigorous stirring for 45 min. A 0.85 g of sodium tripolyphosphate (STP) dissolved in 120 ml of deionized water, then added dropwise in presence of 1 ml of Tween-80 used as a dispersive agent, and stirred for 90 min. A milky-colored emulsion-like appearance of chitosan nanoparticles was formed. The nanoparticles were centrifuged using centrifuge Hermle Z 200A (Germany) with a maximum speed of 5000 rpm/min. The centrifuged chitosan nanoparticles were washed with deionized water (3 times) and then dried at 60 °C for 12 h using a drying oven.

pH and chemical characterization

The values of pH were measured by pH meter (Jenway model 3510) after it was calibrated by buffer solutions pH 4, pH 7, and pH 10.

Adsorbent characterization:

The Fourier transform infrared spectra (FTIR) were measured for banana peels feedstock (BP), banana peels hydrochar (HBP), and chitosan nanoparticles (Ch-NPs) using the FTIR spectrophotometer Bruker Tensor37 (Bruker Co., Billerica, MA, USA) with KBr discs with a resolution of 2 cm−1 and a range of 4000–400 cm−1.

The particle size of chitosan nanoparticles (Ch-NPs) was verified by using a transmission electron microscope (TEM JEOL model JEM-100SX), operated at 200 kV.

The morphology of chitosan nanoparticles (Ch-NPs) and banana peels hydrochar (HBP) were verified by using a scanning electron microscope (ZEISS, Japan) for surface observations; it was with a 7-kV voltage. Ten particles of each type were placed in different orientations on a double-faced adhesive and covered with a small layer of graphite C to facilitate electrons' conduction.

The zeta potential for Ch-NPs after diluting with deionized water was measured at room temperature with a Malvern Zetasizer (Malvern Instruments, UK). One milliliter of Ch-NPs suspension (each sample was diluted to 0.1 mg mL−1) was used and placed in a 10 mm × 10 mm quartz cuvette. The calculation was done by the Zetasizer Nano Software 7.13 (Malvern, UK).

The BET surface area full isotherm was determined using nitrogen adsorption–desorption measurements working at 77.35 K on a Nova Touch LX4 Quanta chrome, USA. Samples were degassed for 24 h at 200 °C in a high vacuum before being tested. Analyzing the volume of nitrogen gas adsorbed at certain pressures was carried out by measuring the volume of liquid nitrogen utilized to cool the samples. Using the Brunauer–Emmett–Teller (BET) technique, the BET pore volume and the Barrett–Joyner–Halenda (BJH) were measured.

Determination of Trihalomethanes concentrations

Chloroform (CHCl3), bromoform (CHBr3), dibromochloromethane (CHBr2Cl), and dichlorobromomethane (CHBrCl2) were measured following the US EPA 551.1 Method (US EPA, 1990), and their sums were reported as THMs using GC chromatography—Agilent 7890B GC interfaced with a mass spectrometer (MS). The instrument was calibrated by using chloroform (CHCl3), bromoform (CHBr3), dibromochloromethane (CHBr2Cl), and dichlorobromomethane (CHBrCl2) standard solutions at 8, 16, 32, 48, and 64 µg.l−1 to obtain the calibration curve.

Batch experiments

The sorption capacity

Adsorption experiments have been conducted by introducing a different dose of (1:1) (HBP: Ch-NPs) mixture (0.00, 0.01, 0.05, 0.1, and 0.15 g) to 40 mL containing equal concentrations of chloroform (CHCl3), bromoform (CHBr3), dibromochloromethane (CHBr2Cl), and dichlorobromomethane (CHBrCl2) 50 μg L−1 in falcon tubes. The falcon tubes were then sealed and shaken at 120 rpm in a water-bath shaker and for 120 min at ambient temperature. The falcon tubes were then removed from the shaker, and the final concentrations of (CHCl3), (CHBr2Cl), (CHBrCl2), and (CHBr3) in the solutions were determined using GC chromatography—Agilent 7890B GC interfaced with a mass spectrometer (MS). The amount of (CHCl3), (CHBr2Cl), (CHBrCl2), and (CHBr3) adsorption equilibrium \({q}_{e}\) (μg g−1) was calculated from equation no. (1) according to Eq. (1).

where Co and Ce (mg L−1) are the concentrations of (CHCl3), (CHBr2Cl), (CHBrCl2), and (CHBr3) at initial and equilibrium, respectively. V(L) is the volume of the solution, and W(g) is the mass of (1:1) (HBP: Ch-NPs). The kinetic tests followed the same technique as the equilibrium tests. The samples were taken at fixed intervals, and the concentrations of (CHCl3), (CHBr2Cl), (CHBrCl2), and (CHBr3) were measured the amount of adsorption on (1:1) (HBP: Ch-NPs) surface at time t, \({q}_{t}\) (µg g−1), estimated according to Eq. (2) (Xiao et al. 2014):

The initial concentration of THMs 50, 100, 150, and 200 μg L−1 has been used, and all falcon tubes were covered by aluminum foil.

Kinetics of adsorption

To study the kinetic progress of sorption procedures, 0.01 g of (1:1) (HBP: Ch-NPs) was added to 40 mL of 50 μg L−1 (CHCl3), (CHBr2Cl), (CHBrCl2), (CHBr3). Next, the mixture was shaken at ambient temperature for 120 min. The same handling of separation and analysis was followed to evaluate the sorption capacity using the pseudo-first order according to the equation given by (Lagergren 1898), by plotting ln (qe − qt) versus t, which gives a straight line with the slope − K1 and intercept ln qe using Eq. (3).

k1 is the pseudo-first-order constant rate for the adsorption process (min−1), while pseudo-second-order reaction kinetics equation, given by (Blanchard et al. 1984), used to plot (\({q}_{e}\), µg g.−1) as a function of contact time (t, min) to symbolize the data agreeing to (Eq. 4)

While Eq. (5) was used to estimate the sorption rate h (mg g−1 min−1) (Hassan et al. 2018).

Also, the continual intraparticle diffusion effect on adsorption (internal surface and pore diffusion) was considered according to (Weber Jr and Morris 1963) by Eq. (6).

where ki is the constant rate of intraparticle diffusion (mg. g−1. min.0.5) and X is the intercept which is strong-minded from the liner line of qt versus t0.5 and is typically used to compare the pollutant mass transfer rates. According to this equation, if intraparticle diffusion is included in the adsorption process, the plot of uptake, qt, versus the square root of time, t0.5, ought to be linear and if those lines start at the origin, the next intraparticle diffusion is the rate control stage (Rehman et al. 2019).

Also, the Elovich equation was normally applied to investigate the chemical adsorption; also, it is applicable when the adsorbent is heterogeneous according to (Chien and Clayton 1980) as described by Eq. (7).

where α is indicating the chemical adsorption rate (mg/mg min) and β is referring to the coefficient relationship between the increase of the covered surface and the chemical adsorption of activation energy (g/mg) (Khasri et al. 2018).

Effect of initial concentrations of pollutant

The impact of the initial concentrations of THMs on the adsorption kinetics was also assessed where 0.01 g of (1:1) (HBP: Ch-NPs) was added to 50, 100, 150, and 200 μg L−1 of THMs in an equal portion of the standard solutions of (CHCl3), (CHBr2Cl), (CHBrCl2), (CHBr3). Next, Freundlich, Langmuir, Temkin, and Dubinin-Radushkevich adsorption isotherm models were implemented to identify the adsorption mechanism. Langmuir isotherm supposes monolayer adsorption of THMs on equal active sites (same energy) of heterogeneous surfaces agreeing Eq. (8) where the maximum sorption capacity expressed as \({q}_{m}\) (μg g−1). Also, the Langmuir constant correlates to the adsorption energy expressed as b (L μg−1), while the RL factor points to the suitability of adsorbing THMs by (1:1) (HBP: Ch-NPs). The adsorption is suitable if RL is between 0 and 1. If RL is < 1, the adsorption is undesirable, and if it = 0, the adsorption is irreversible (Badeenezhad et al. 2019). The RL factor was 0.55 at the maximum initial concentration, implying the desirability of the adsorption process of THMs by (1:1) (HBP: Ch-NPs) as bioadsorbent. RL factor can be determined from Eqs. (8 and 9) according to (Langmuir 1918).

Additionally, the Freundlich isotherm model is applied for heterogeneous surface energy systems and a description of multilayer adsorption with the interaction between molecules of THMs that have been adsorbed by (1:1) (HBP: Ch-NPs) (Badeenezhad et al. 2019). The Freundlich isotherm model can be defined by Eq. (10) according to (Freundlich 1906).

When KF is the Freundlich constant which is affected by the adsorption capacity, Ce is the concentration of THMs by (1:1) (HBP: Ch-NPs). At equilibrium, qe is the equilibrium adsorption capacity and 1/n illustrates the intensity of adsorption. The plot for ln qe against ln Ce can explain the multilayer coverage of THMs by (1:1) (HBP: Ch-NPs) surface. When n = 1, Freundlich isotherm develops linear and reveals that all the sites on the (1:1) (HBP: Ch-NPs) have an equivalent affinity for the adsorbate THMs. When n > 1, the adsorption intensity implies that affinity decreases with the increase in adsorption density, while n < 1 reveals poor adsorption (Jain et al. 2018).

While Temkin isotherm model implies that the adsorption heat of all molecule phases reduces linearly as the substrate is covered and that the bond energy distribution of THMs is fixed and uniform on (1:1) (HBP: Ch-NPs) surface. Temkin isotherm constant, AT (L µg−1), also, bT (J mol−1) is Temkin constant about the heat of adsorption. The Temkin isotherm model is described by Eq. (11) and applied by plotting qe versus ln Ce according to (Temkin 1940).

Since the Dubinin-Radushkevich isotherm model is a practical model initially for the adsorption of subcritical vapors following a pore filling process on microporous solids, it is applied to distinguish between the chemical and physical adsorption processes to remove a molecule of THMs from its position on (1:1) (HBP: Ch-NPs) surface in the adsorption space to the infinity. The Dubinin-Radushkevich isotherm can be explained by Eq. (12) according to (Travis and Etnier 1981).

The KDR (J) is the constant of the sorption energy, the theoretical saturation capacity is QDR (mmol.g−1), and ɛ (J2.mol−2) is the Polanyi potential. R equal (8.314 Jmol−1.K−1) is the gas constant. T is the temperature value where the adsorption happens (Hassan et al. 2020a). As published in the journal of hazardous materials by (Zhou 2020), Polanyi potential from Dubinin-Radushkevich equation ɛ can easily be calculated according to Eq. (13).

Thermodynamics

In the fact, it is very significant to study the impact of the temperature on the adsorption. The adsorption experiments were executed at three different temperatures 277, 298, and 308 K. The adsorption equilibrium constant Kc was calculated from van’t Hoff equation according to (Hassan et al. 2020b), (Sawasdee and Watcharabundit 2015) as explained by Eq. (14).

And traditional thermodynamic Eq. (15) for calculating the thermodynamic constants of the adsorbents such as the enthalpy change ∆H°, the entropy change ∆S°, and the Gibbs free energy ∆G° is explained by Eqs. (15) and (16).

As can be seen from the positive value of ΔH0, there are endothermic adsorption mechanisms present. ∆G0 negative values prove the spontaneous adsorption reaction. The negative value of ∆G0 increased with raising temperature proving that the spontaneous favorability increases (Hassan et al. 2020b).

Effect of solution pH

The effect of pH value was investigated at pH = 3, 5, 7, and 9. Specifically, 0.01 g of (1:1) (HBP: Ch-NPs) was added to each 40 mL volume of each aqueous solution having an initial concentration of 50 μg L−1 equal portion of the standard solutions of (CHCl3), (CHBr2Cl), (CHBrCl2), (CHBr3) for a constant time of 120 min.

Regeneration study

The generation method was modified from Dolgormaa’s method (Dolgormaa et al. 2018). The regeneration procedure of the (1:1) (HBP: Ch-NPs) was needed by the end of batch experiments to get rid of THMs from its surface so that the (1:1) (HBP: Ch-NPs) may long-last achieve the removal process. In this experiment, 0.01 g of (1:1) (HBP: Ch-NPs) was added to 40 mL of 50 μg L−1 equal portion of the standard solutions of (CHCl3), (CHBr2Cl), (CHBrCl2), (CHBr3) under continuous shaking for 90 min at 130 rpm and 25 °C. The residue of (1:1) (HBP: Ch-NPs) after the adsorption experiment was washed with deionized water and added to ethanol 70%, and the mixture was left for 2 h under magnetic stirring. After centrifugation, the precipitate was dried and added to 40 mL of 50 μg L−1 equal portion of the standard solutions of (CHCl3), (CHBr2Cl), (CHBrCl2), (CHBr3), and then, the mixture was shaken for 90 min before measuring the THMs equilibrium concentration.

Results and discussion

Bioadsorbent characterization

A transmission electron microscope (TEM) was implemented to determine the size of the Ch-NPs. The maximum size of synthesized Ch-NPs was around 15.41 nm, confirming that the synthesized chitosan particles are nano-size, while Scanning electron microscope (SEM) image indicates a spherical shape which provides a high surface area as shown in (Fig. 1). While the morphology of (HBP) was investigated using scanning electron microscopy (SEM), the images showed the opening of pores is noticeable. Also, destruction of the structure can be observed as shown in (Fig. 2), agreed with Putra and his research team (Putra et al. 2018).

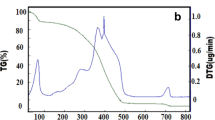

FTIR spectra for hydrochar (HBP) and (Ch-NPs) are demonstrated in (Fig. 3). The analysis confirmed that banana peels hydrochar (HBP) and (Ch-NPs) have many functional groups which supported the adsorption process. For BP aliphatic OH stretching vibration of OH and COOH functional groups was identified with strong and broad peaks between 3600 and 3000 cm1, while the peak of the C–H stretching vibration appeared between 3000 and 2800 cm−1. In addition, the peak between 1800 and 1600 cm1 relates to the stretching vibration of C = O bonds in esters, aldehydes, or carboxylic acids from cellulose. The peak between 1600 and 1500 cm1 is related to the C = C vibrations of the aromatic rings in the lignin. After the HTC process, for (HBP) the peak between 1600 and 1500 cm1 was reduced, inspecting that the lignin was only decomposed partially, while those peaks appeared between 1450 and 1200 cm−1 is related to the C–H bending vibration of aliphatic carbons, methylene, and methyl groups, which demonstrate that aliphatic structures are present. Moreover, peaks between 1200 and 1000 cm−1 represent the stretching vibrations of C–O groups from phenols, esters, and aliphatic alcohols. Peak located at < 1000 cm−1 identified only HC and resulted from the bend of the C–H bonds in aromatic compounds (Elaigwu and Greenway 2016), while for (Ch-NPs) the peaks of N–H bending vibration for amine I are at 1600 cm−1. The cross-linked chitosan shows a P = O peak at 1170 cm−1. These results have been assigned to the linkage between ammonium and phosphoric ions. So, we can conclude that the tripolyphosphoric group of TPP is linked with the ammonium group of chitosan. The terminal phosphate group of TPP binds with the amine (NH2) group of chitosan by an ionic bond (Bangun et al. 2018), while the strong and broad peak observed at the (3600–3000 cm−1) may be due to the aliphatic OH stretching vibration of hydroxyl and carboxyl functional groups as explained in (Fig. 3), agreed with (Badeenezhad et al. 2019).

Surface area

The surface area, pore size distribution, and pore volume properties of (Ch-NPs) and (HBP) have been examined through N2 adsorption–desorption study at 77 K. The isomers obtained could be classified as type IV (Figure S1) for (Ch-NPs) and (HBP), respectively. The presence of a noticeable hysteresis loop in these isotherms at the relative pressure of 0.05 < P/P0 < 0.95 for (Ch-NPs) and 0.05 < P/P0 < 0.97 for (HBP), where P and P0 are the equilibrium and saturation pressure, respectively, is an indication for irreversible desorption, which describes the existence of mesopores of the samples. The Brunauer–Emmett–Teller (BET) surface area for (HBP) was 28.6869 m2 g−1, and the total pore volume is 0.02335 cm3 g−1 with an average pore size of 1.6283 nm and average particle radius of 4.7535e + 001 nm, While for (Ch-NPs) the BET specific surface area is 30.4940 m2 g−1 and the total pore volume is 0.0209 cm3 g−1 with an average pore size of 1.3711 nm and average particle radius 4.4718e + 001 nm. The International Union of Pure and Applied Chemistry (IUPAC) defines the pores based on their pore diameter as micropores (< 20 Å), mesopores (20–500 Å), and macropores (> 500 Å) (Pure and Chemistry 1985). The pore size distribution reveals the mesopores character of (HBP) and (Ch-NPs). The obtained (Ch-NPs) and (HBP) has very poor porosity and surface area. Due to its high porosity, activated carbon typically has a specific surface area that is much than the hydrochar. The adsorption process does not only take into account the specific surface area, so the active sites on the adsorbent's surface also play a role in determining the adsorption capacity. Numerous carbon spheres make up the hydrochar, which has a core–shell structure with a hydrophilic shell and a hydrophobic core. The outer surface of HC has more oxygen-containing functional groups than activated carbon, including phenolic, carboxylic, hydroxyl, and carbonyl groups.

The determination of zero point charge (pH ZPC) and zeta potential

The surface charge at different pH values and pH of zero charge point (pH ZCP) of (Ch-NPs) and (HBP) have been investigated. The value of pHZCP for (Ch-NPs + HBP) and (HBP) was 2–4 as shown in (Fig. 4). The surface of (Ch-NPs + HBP) and (HBP) would be negatively charged at a pH value higher than 4. The negative charge of the surface of (Ch-NPs + HBP) and (HBP) would be attributed to the deprotonation of oxygen atoms of cellulose and lignin and nanoparticles of chitosan. The maximum values of ΔpH for (HBP) are 0.5 and − 2.7 at pH range 3–12, while those reported for (Ch-NPs + HBP) are 0.2 and − 3.5 at pH range 3–12. The obtained results show that the net charge of (Ch-NPs + HBP) is greater than that of HBP, indicating the high polarity of (Ch-NPs + HBP) for adsorbing organic pollutants like THMs. This may be attributed to the presence of chitosan nanoparticles besides the deprotonated phenolic and carboxylic groups in (HBP). Due to the buffering effect of water HBP and (Ch-NPs + HBP) surfaces, the pH measurements are only considered in the pH ranges of 5–10 for both (Fig. 4).

Zeta potential

Zeta potential (ZP) is describing the relation between the colloid stability and provides a sign of it. Zeta potential value of ± 0–10 mV states (highly unstable), ± 10–20 mV stating (relatively stable), ± 20–30 mV stating (moderately stable), and ± 30 mV stating (highly stable) (Demirezen et al. 2018).

The ZP of the Ch-NPs in aqueous solutions expresses the surface charge, which can significantly affect particle stability in aqueous solutions via the electrostatic attraction between particles which can be easily explained according to Coulombic interaction law which states that like charges repel, while opposite charges attract each other; this results in an attractive force known as van der Waals forces which holds the particles together even when there is no physical contact between them. In case of composite adsorbents and THMs, both possess negative charge on their surfaces due to dissociation or ionization processes, so they tend to attract one another leading toward formation strong bonds by means electrostatic attractions at molecular level resulting into removal/adsorption process for effective purification purposes. Furthermore, the strength of these interactions also depends upon surface properties, charges distribution among ions, etc. Also, it can control nanoparticle contact with the anionic pollutants which are usually negatively charged. Figure 5a shows that the surface of Ch-NPs has a positive charge of 23.9 mV; this proved that the prepared Ch-NPs are very stable. While the graph of ZP for the (HBP) shows that the surfaces of (HBP) have a negative charge of about − 17.8 mV in Fig. 5b, this proved that the prepared (HBP) and Ch-NPs are stable. Understanding the nature of binding THMs to (1:1) (HBP: Ch-NPs) will reflect these charging domains, the adsorption capacity is expected to vary consequently. Recall the charge of (CHCl3), (CHBr2Cl), (CHBrCl2), and (CHBr3) expects a removal superiority at the (1:1) (HBP: Ch-NPs) composite at high pH values.

Effect of pH

The effect of pH value on the efficiency of (1:1) (HBP: Ch-NPs) is illustrated in (Figure S2). With the increase of pH value, the adsorption capacity for (CHCl3), (CHBr2Cl), (CHBrCl2), and (CHBr3) on (1:1) (HBP: Ch-NPs) is increased. The effect of pH was investigated from pH (3–9) with a stirring time of 120 min and the (1:1) (HBP: Ch-NPs) dosage (0.01 g for 40 ml of 50 μg L−1 (CHCl3), (CHBr2Cl), (CHBrCl2), (CHBr3) solution to get a fitting optimization for the sorption process). The best pH for THMs removal has occurred at pH 9 with the maximum adsorption capacity.

Accordingly, the maximum THMs adsorption by (1:1) (HBP: Ch-NPs) has occurred at both strong basic conditions. The removal rate of THMs reached from 9.16% at pH = 3 and 30.58% at pH = 9, respectively.

Effect of adsorbent dosage

Sample of 0.01, 0.05, 0.10, or 0.15 g (1:1) (HBP: Ch-NPs) was used for each 40 mL volume of 50 µg L−1 THMs solution, containing equal portion of (CHCl3), (CHBr2Cl), (CHBrCl2), (CHBr3) to study the application rate of (1:1) (HBP: Ch-NPs) for (CHCl3), (CHBr2Cl), (CHBrCl2), (CHBr3) sorption, and the pH was 5.3 without any adjustment. Increasing the dose of (1:1) (HBP: Ch-NPs) led to an increase in ((CHCl3), (CHBr2Cl), (CHBrCl2), (CHBr3) removal ratio. However, the removal efficacy of each contaminant was not like the increase in (1:1) (HBP: Ch-NPs) mass. This might be due to the increase in adsorbent mass encouraging the (CHCl3), (CHBr2Cl), (CHBrCl2), and (CHBr3) to occupy the available adsorption sites on the surface of (1:1) (HBP: Ch-NPs). For instance, results demonstrate that amount of 0.01, 0.05, 0.10, or 0.15 (1:1) (HBP: Ch-NPs) removed THMs from aqueous solution by 28.6%, 61.8%, 79.6%, and 97.2%. The obtained optimal mass for the studied adsorbent equaled 0.15 g as shown in (Figure S3).

Effect of temperature

A sample of 0.01 g (1:1) (HBP: Ch-NPs) was used for each 40 mL volume of 50 µg L−1 THMs solution, which contains an equal portion of (CHCl3), (CHBr2Cl), (CHBrCl2), (CHBr3) to study the effect of different temperatures. The experiments were measured at 4, 25, and 35 °C for 120 min for (CHCl3), (CHBr2Cl), (CHBrCl2), and (CHBr3) removal, showing that the removal ratio increased gradually by increasing temperature as explained in (Fig. S4).

Effect of contact time

The adsorption isotherm of THMs on (1:1) (HBP: Ch-NPs) was studied in a batch experiment. It is presented in (Figure S5); this batch experiment was done using 0.01 g (1:1) (HBP: Ch-NPs), and the initial THMs concentration was 50 μg L−1 equal portion of the standard solutions of (CHCl3), (CHBr2Cl), (CHBrCl2), (CHBr3) at room temperature. It showed a fast early (within ~ 30 min) removal of THMs followed by a much slower step earlier reaching equilibrium. The contact time of 60 min was enough to saturate the surface of (1:1) (HBP: Ch-NPs) with (CHCl3), (CHBr2Cl), (CHBrCl2), (CHBr3).

The adsorption process for THMs on the surface of (1:1) (HBP: Ch-NPs) was assessed using the linear form of a pseudo-first-order kinetic, pseudo-second-order kinetic, intraparticle diffusion, and Elovich kinetic model. Estimated values of kinetic model constants (k, \(q\) e, and h) are presented in Table 1. Experimental data matched with pseudo-second-order kinetic.

Effect of initial concentrations

The initial concentrations effect of (CHCl3), (CHBr2Cl), (CHBrCl2), and (CHBr3) on the equilibrium sorption capacity and removal ratio using (1:1) (HBP: Ch-NPs) are defined in (Fig. S6).

The initial concentrations of (CHCl3), (CHBr2Cl), (CHBrCl2), (CHBr3) solution tested were 50, 100, 150, and 200 µg L−1 (as THMs concentration), and the experiments were measured at 25 °C for 120 min. The results indicated a substantial increase in \({\mathrm{q}}_{\mathrm{e}}\) of (CHCl3), (CHBr2Cl), (CHBrCl2), (CHBr3) at the surface of (1:1) (HBP: Ch-NPs) with increasing the initial THMs concentration. It was raised from 74.08 to 130.76 µg g−1 with 50 and 200 µg L−1 initial concentrations of THMs, respectively. The adsorption of (CHCl3), (CHBr2Cl), (CHBrCl2), (CHBr3) on (1:1) (HBP: Ch-NPs) nanocomposite is described preferably by the pseudo-second-order kinetic model with a regression coefficient (R2 = 1). This could guess that the overall removal process of (CHCl3), (CHBr2Cl), (CHBrCl2), and (CHBr3) by (1:1) (HBP: Ch-NPs) composite was usually controlled by the pH.

Adsorption kinetics and mechanism studies

Through the comparison of the fourth kinetic models pseudo-first-order, pseudo-second-order, intraparticle diffusion, and Elovich kinetic model, the pseudo-second-order R2 for (CHCl3), (CHBr2Cl), (CHBrCl2), (CHBr3), THMs are much higher than those of pseudo-first-order, intraparticle diffusion, and Elovich kinetic model R2 which was (0.7178), (0.7836), (0.7153), (0.6682), and (0.7205), respectively, for pseudo-first order, while it was (1) for all of them according to pseudo-second order; while it was (0.7746), (0.7750), (0.7750), (0.7750), and (0.7749), respectively, for intraparticle diffusion; it was (0.9298), (0.9298), (0.9300), (0.9299), and (0.9299), respectively, for Elovich. The plot for pseudo-first-order, pseudo-second-order, intraparticle diffusion, and Elovich kinetic models is explained in Fig. 6A, B, C, and D, respectively. The rate-limiting step in this adsorption process may be chemisorption involving strong forces through the sharing or exchanging of electrons between sorbent and sorbate. As a result, the pseudo-second-order kinetic model can be used to estimate the adsorption kinetics, based on the hypothesis that the rate-limiting step may be chemisorption involving electrostatic forces via the sharing or exchange of electrons between the adsorbent and the adsorbate.

Adsorption isotherms

In this study Langmuir, Freundlich, Dubinin-Radushkevich, and Temkin isotherm models were applied to investigate the adsorption isotherm process, where a plot of the Ce/qe as a function of Ce agreeing to the Langmuir model as shown in the findings demonstrated by Langmuir isotherm for (CHCl3), (CHBr2Cl), (CHBrCl2), (CHBr3), and THMs was with regression coefficient (R2 = 0.9572, 0.9400, 0.9576, 0.9473, and 0.9446).

While the Freundlich isotherm model is used to describe heterogeneous surface energy systems and multilayer description adsorption with the interaction between adsorbed molecules for heterogeneous surface energy systems,

the plot for ln qe against ln Ce showed the multilayer coverage of (CHCl3), (CHBr2Cl), (CHBrCl2), and (CHBr3) on the surface of (1:1) (HBP: Ch-NPs). The obtained results showed Freundlich isotherm (R2 = 0.9933, 0.9987, 0.9926, 0.9915, and 0.9959), respectively, for (CHCl3), (CHBr2Cl), (CHBrCl2), (CHBr3), and THMs.

While Dubinin-Radushkevich model is applied to differentiate between the physical and chemical adsorption process to disconnect a molecule from its position in the sorption space to the infinity, the Dubinin-Radushkevich plotted between ln qe against ɛ2. The obtained results showed Dubinin-Radushkevich isotherm (R2 = 0.9572, 0.9400, 0.9576, 0.9473, and 0.9446), respectively, for (CHCl3), (CHBr2Cl), (CHBrCl2), (CHBr3), and THMs.

While the Temkin model is considered that the adsorption heat of all phase molecules decreases linearly as the substrate is filled and the bond energy distribution is uniform, the Temkin isotherm constant, AT (L mg−1), also, bT (J mol−1) is Temkin constant concerning heat of adsorption. The Temkin isotherm model was used to depict qe versus ln Ce. The obtained results showed Temkin isotherm (R2 = 0.9841, 0.9773, 0.9917, 0.9936, and 0.9895), respectively, for (CHCl3), (CHBr2Cl), (CHBrCl2), (CHBr3), and THMs. The parameters of the THMs adsorption by (1:1) (HBP: Ch-NPs) using the Langmuir, Freundlich, Dubinin-Radushkevich, and Temkin isotherm model are presented in Table 2.

The adsorption experimental data fitted with both the Langmuir and Freundlich isotherm with higher regression coefficient for Freundlich. These outcomes agreed with Chungsying Lu et. al, (Lu et al. 2005). Plots for Langmuir, Freundlich, Dubinin–Radushkevich, and Temkin isotherm models are provided in Fig. 7A, B, C, and D, respectively.

Thermodynamic parameters

The standard enthalpy change ∆H° and the standard entropy change ∆S° value for the adsorption process was estimated from the plot of ln Kc versus 1/T by calculating the slope and intercept as shown in (Figure S7). The thermodynamic parameter values are stated in Table 3. The positive value of ∆H° confirms the endothermic nature of the adsorption process.

Regeneration of (1:1) (HBP: Ch-NPs)

In this experiment, 0.01 g of (1:1) (HBP: Ch-NPs) was added to 40 mL of 50 μg.L−1 equal portion of the standard solutions of (CHCl3), (CHBr2Cl), (CHBrCl2), and (CHBr3) under a continuous shaking for 90 min at 130 rpm and 25 °C. The regeneration procedure of the (1:1) (HBP: Ch-NPs) was needed by the end of batch experiments to get rid of THMs from its surface so that the (1:1) (HBP: Ch-NPs) may long-last achieve the removal process. The residue of (1:1) (HBP: Ch-NPs) after the adsorption experiment was washed with deionized water, added to ethanol 70%, and the mixture was left for 2h under magnetic stirring.

After centrifugation, the precipitate was dried and added to 40 mL of 50 μg.L−1 equal portion of the standard solutions of (CHCl3), (CHBr2Cl), (CHBrCl2), and (CHBr3), and then, the mixture was shaken for 90 min before measuring the THMs equilibrium concentration. The experiment condition was at (pH = 5.3). The same handling procedure was recurrent for four successive cycles. The results presented that after consecutive four cycles (1:1) (HBP: Ch-NPs) still can remove THMs from polluted water with 80% as shown in (Fig. 8). The generation method was adapted from Alireza Khataee’s method (Khataee et al. 2016).

Comparison evaluation for (1:1) (HBP: Ch-NPs)

Comparison of adsorption capacities for THMs removal from aqueous solution using (1:1) (HBP: Ch-NPs) against various adsorbents is provided in Table 4 which showed the excellent performance of (1:1) (HBP: Ch-NPs) as promising adsorbent.

Applications

Wastewater samples were freshly collected from Shershaba wastewater plant effluent, from Gharbia governorate, middle delta, Egypt. Samples were collected in glass bottles with a screw cap total volume of 40 ml containing sodium thiosulfate to remove residual chlorine. 0.45-μm membrane filter was used to filtrate all the water samples through analysis was done immediately after filtration using GC chromatography—Agilent 7890B GC interfaced with a mass spectrometer (MS). (CHCl3), (CHBr2Cl), (CHBrCl2), and (CHBr3) were analyzed following the US EPA Method 551.1 (US EPA, 1990), and their sum was reported as THMs. The analyses were repeated three times for each sample, and the removal average was calculated. 0.15 g from (1:1) (HBP: Ch-NPs) powder was mixed with 40 ml from the wastewater samples in a falcon tube and then agitated for two hours at room temperature. No adjustment for pH has been done, and the pH was 5.3. The average removal ratio for (CHCl3), (CHBr3), (CHBr2Cl), (CHBrCl2), and (THMs) was 76.36, 83.72, 79.83, 78.74, and 78.18%, respectively, as shown in Table 5.

Chitosan nanoparticles drawbacks

Chitosan nanoparticles have been used in environmental applications for a number of years due to their ability to absorb and bind certain pollutants. However, their use can also come with drawbacks. The main drawback of using chitosan nanoparticles in environmental applications is the cost of preparation. Additionally, chitosan nanoparticles still need more studies on toxicity for the aquatic species of the ecosystem (Singh et al. 2023). This is because the nanoparticles may interfere with the natural balance of the environment. Also, the chitosan nanoparticles have a limited shelf life and need to be replaced or recycled regularly (Yaqoob et al. 2023).

Conclusion

A promising mixture of (1:1) (HBP: Ch-NPs) powder composite was effectively developed. Both composite components were characterized with FTIR, TEM, and zeta potential which affirmed the effective and successful preparation with good stability of the developed nanoparticles. Results of dynamic kinetic assessments revealed that the (1:1) (HBP: Ch-NPs) powder would display outstanding execution in the environmental application. The adsorption maximum capacity for THMs was 588.23 µg g−1. Equilibrium adsorption data fitted well to both Langmuir and Freundlich isotherm models with higher regression coefficient matching with Freundlich. This research presents a different viewpoint for the synthesis of a well-designed and low-cost hydrochar and chitosan nanoparticles composite for trihalomethanes removal from wastewater. It could be concluded that (1:1) (HBP: Ch-NPs) composite can be recommended for wastewater treatment to remove disinfection by-products. Further studies are necessary to set guidelines for the commercial application of the developed adsorbent.

References

Ahmad AY, Al-Ghouti MA, Khraisheh M, Zouari N (2022) Development and application of bio-waste-derived adsorbents for the removal of boron from groundwater. Groundw Sustain Dev 48:100793

Badeenezhad A, Azhdarpoor A, Bahrami S, Yousefinejad S (2019) Removal of methylene blue dye from aqueous solutions by natural clinoptilolite and clinoptilolite modified by iron oxide nanoparticles. Mol Simul 45:564–571

Bangun H, Tandiono S, Arianto A (2018) Preparation and evaluation of chitosan-tripolyphosphate nanoparticles suspension as an antibacterial agent. J Appl Pharm Sci 8:147–156

Blanchard G, Maunaye M, Martin G (1984) Removal of heavy metals from waters by means of natural zeolites. Water Res 18:1501–1507

Bond T, Henriet O, Goslan EH, Parsons SA, Jefferson B (2009) Disinfection byproduct formation and fractionation behavior of natural organic matter surrogates. Evviron Sci Technol 43(15):5982–5989

Bond T, Goslan EH, Parsons SA, Jefferson B (2012) A critical review of trihalomethane and haloacetic acid formation from natural organic matter surrogates. Environ Technol Rev 1(1):93–113

Catenacci A, Boniardi G, Mainardis M, Gievers F, Farru G, Asunis F, Malpei F, Goi D, Cappai G, Canziani R (2022) Processes, applications and legislative framework for carbonized anaerobic digestate: Opportunities and bottlenecks. A critical review. Energy Convers Manag 263:115691

Chen Y, Wang H, Zhao W, Huang S (2018) Four different kinds of peels as adsorbents for the removal of Cd (II) from aqueous solution: kinetics, isotherm and mechanism. J Taiwan Inst Chem Eng 88:146–151

Chien S, Clayton W (1980) Application of Elovich equation to the kinetics of phosphate release and sorption in soils. Soil Sci Soc Am J 44:265–268

Demirezen DA, Yilmaz D, Yilmaz Ş (2018) Green synthesis and characterization of iron nanoparticles using Aesculus hippocastanum seed extract. Int J Adv Sci Eng Technol 6:2321–8991

Dolgormaa A, Lv C-J, Li Y, Yang J, Yang J-X, Chen P, Wang H-P, Huang J (2018) Adsorption of Cu (II) and Zn (II) ions from aqueous solution by gel/PVA-modified super-paramagnetic iron oxide nanoparticles. Molecules 23:2982

Dong F, Zhu J, Li J, Fu C, He G, Lin Q, Li C, Song S (2023) The occurrence, formation and transformation of disinfection byproducts in the water distribution system: a review. Sci Total Environ 65:161497

Elaigwu SE, Greenway GM (2016) Microwave-assisted hydrothermal carbonization of rapeseed husk: a strategy for improving its solid fuel properties. Fuel Process Technol 149:305–312

Fang J, Zhan L, Ok YS, Gao B (2018) Minireview of potential applications of hydrochar derived from hydrothermal carbonization of biomass. J Ind Eng Chem 57:15–21

Freundlich H (1906) Uber die adsorption in losungen. Z Phys Chem 57:385–470

Ghernaout D (2018) Disinfection and DBPs removal in drinking water treatment: a perspective for a green technology. Int J Adv Appl Sci 5:108–117

Hassan MA, Mohammad AM, Salaheldin TA, El-Anadouli BE (2018) A promising hydroxyapatite/graphene hybrid nanocomposite for methylene blue dye’s removal in wastewater treatment. Int J Electrochem Sci 13:8222–8240

Hassan N, Shahat A, El-Didamony A, El-Desouky M, El-Bindary A (2020a) Mesoporous iron oxide nano spheres for capturing organic dyes from water sources. J Mol Struct 1217:128361

Hassan N, Shahat A, El-Didamony A, El-Desouky M, El-Bindary A (2020b) Synthesis and characterization of ZnO nanoparticles via zeolitic imidazolate framework-8 and its application for removal of dyes. J Mol Struct 1210:128029

Hesham A, Moustafa R (2019) Enhancing the adsorption of disinfection by-products onto activated carbon using TiO2 nanoparticles. Int J Chem Technol 3:67–71

Hesham A, Awad Y, Jahin H, El-Korashy S, Maher S, Kalil H, Khairy G (2021) Hydrochar for industrial wastewater treatment: an overview on its advantages and applications. J Environ Anal Toxicol 11:69

Hrudey SE (2008) Chlorination disinfection by-products (DBPs) in drinking water and public health in Canada.

Jahin HS, Kandil MI, Nassar MY (2022) Facile auto-combustion synthesis of calcium aluminate nanoparticles for efficient removal of Ni (II) and As (III) ions from wastewater. Environ Technol 69:1–16

Jain M, Yadav M, Kohout T, Lahtinen M, Garg VK, Sillanpää M (2018) Development of iron oxide/activated carbon nanoparticle composite for the removal of Cr (VI), Cu (II) and Cd (II) ions from aqueous solution. Water Resour Indust 20:54–74

John KI, Omorogie MO (2022) Biomass-based hydrothermal carbons for catalysis and environmental cleanup: a review. Green Chem Lett Rev 15:160–184

Khairy GM, Hesham AM, Jahin HES, El-Korashy SA, Awad YM (2022) Green synthesis of a novel eco-friendly hydrochar from Pomegranate peels loaded with iron nanoparticles for the removal of copper ions and methylene blue from aqueous solutions. J Mol Liq 368:120722

Khan MA, Hameed B, Siddiqui MR, Alothman ZA, Alsohaimi IH (2022) Physicochemical, structural and combustion analyses to estimate the solid fuel efficacy of hydrochar developed by co-hydrothermal carbonization of food and municipal wastes. Biomass Convers Biorefinery 96:1–12

Khasri A, Bello OS, Ahmad MA (2018) Mesoporous activated carbon from Pentace species sawdust via microwave-induced KOH activation: optimization and methylene blue adsorption. Res Chem Intermed 44:5737–5757

Khataee A, Kayan B, Kalderis D, Karimi A, Akay S (2016) Ultrasonics sonochemistry ultrasound-assisted removal of acid red 17 using nanosized Fe3O4-loaded coffee waste hydrochar. Ultrason Sonochem 35:72–80

Lagergren SK (1898) About the theory of so-called adsorption of soluble substances. Sven Vetenskapsakad Handingarl 24:1–39

Langmuir I (1918) The adsorption of gases on plane surfaces of glass, mica and platinum. J Am Chem Soc 40:1361–1403

Li LH, Deng JC, Deng HR, Liu ZL, Xin L (2010) Synthesis and characterization of chitosan/ZnO nanoparticle composite membranes. Carbohydr Res 345(8):994–998

Lu C, Chung YL, Chang KF (2005) Adsorption of trihalomethanes from water with carbon nanotubes. Water Res 39(6):1183–1189

Mohd Zainudin F, Abu Hasan H, Sheikh Abdullah SR (2018) An overview of the technology used to remove trihalomethane (THM), trihalomethane precursors, and trihalomethane formation potential (THMFP) from water and wastewater. J Indust Eng Chem 57:1–14

Moustafa R, Hesham A (2018) Evaluation of the levels of haloacetic acids in gharbiya governorate. Egypt Int J Environ Pollut Environ Modell 1:110–115

Nakamura T, Kawasaki N, Araki M, Yoshimura K, Tanada S (2001) Trihalomethane removal by activated carbon fiber. J Environ Sci Health 36(7):1303–1310

Nassar AE, El-Aswar EI, Rizk SA, Gaber SE-S, Jahin HS (2023) Microwave-assisted hydrothermal preparation of magnetic hydrochar for the removal of organophosphorus insecticides from aqueous solutions. Sep Purif Technol 306:122569

Ngo HH, Guo W, Hang Nguyen TA, Surampalli RY, Zhang TC (2016) Agricultural by-products for phosphorous removal and recovery from water and wastewater: a green technology. Green Technol Sustain Water Manag 58:491–533

Pure IUO, Chemistry A (1985) Reporting physisorption data for gas/solid systems. Pure Appl Chem 57:987

Putra HE, Damanhuri E, Dewi K and Pasek AD (2018) Hydrothermal carbonization of biomass waste under low temperature condition. MATEC web of conferences, 2018. EDP Sciences, 01025.

Qadafi M, Rosmalina RT, Pitoi MM, Wulan DR (2023) Chlorination disinfection by-products in Southeast Asia: a review on potential precursor, formation, toxicity assessment, and removal technologies. Chemosphere 58:137817

Rehman R, Farooq S, Mahmud T (2019) Use of agro-waste Musa acuminata and Solanum tuberosum peels for economical sorptive removal of emerald green dye in ecofriendly way. J Clean Prod 206:819–826

Sawasdee S, Watcharabundit P (2015) Equilibrium, kinetics and thermodynamic of dye adsorption by low-cost adsorbents. Int J Chem Eng Appl 6:444

Singh P, Chugh V, Banerjee A, Pathak S, Bose S, Nayak R (2023) Nanomaterials: compatibility towards biological interactions. In: Mukherjee TK, Malik P, Mukherjee S (eds) Practical approach to mammalian cell and organ culture. Springer, Singapore

Sirajo L, Zaini MAA (2022) Existing and emerging technologies for the removal of orthophosphate from wastewater by agricultural waste adsorbents: a review. Biomass Conv Biorefinery 65:1–17

Temkin M (1940) Kinetics of ammonia synthesis on promoted iron catalysts. Acta Physiochim URSS 12:327–356

Travis C, Etnier EL (1981) A survey of sorption relationships for reactive solutes in soil. J Environ Qual 10:8–17

Villanueva CM, Evlampidou I, Ibrahim F, Donat-Vargas C, Valentin A, Tugulea A-M, Echigo S, Jovanovic D, Lebedev AT, Lemus-Pérez M (2023) Global assessment of chemical quality of drinking water: the case of trihalomethanes. Water Res 48:119568

Wardani G, Sudjarwo SA (2018) In vitro antibacterial activity of chitosan nanoparticles against Mycobacterium tuberculosis. Pharmacogn J 10:589

Watson K, Shaw G, Leusch FDL, Knight NL (2012) Chlorine disinfection by-products in wastewater effluent: bioassay-based assessment of toxicological impact. Water Res 46(18):6069–6083

Weber WJ Jr, Morris JC (1963) Kinetics of adsorption on carbon from solution. J Sanit Eng Div 89(2):31–59

Xiao J, Yue Q, Gao B, Sun Y, Kong J, Gao Y, Li Q, Wang Y (2014) Performance of activated carbon/nanoscale zero-valent iron for removal of trihalomethanes (THMs) at infinitesimal concentration in drinking water. Chem Eng J 253:63–72

Yang X, Shang C, Huang JC (2005) DBP formation in breakpoint chlorination of wastewater. Water Res 39(19):4755–4767

Yaqoob AA, Guerrero-Barajas C, Ahmad A, Ibrahim MNM, Alshammari MB (2023) Advanced technologies for wastewater treatment. Green Chem Sustain Water Purif 179:459

Zhou X (2020) Correction to the calculation of polanyi potential from Dubinnin-Rudushkevich equation. J Hazard Mater 384:121101

Acknowledgements

The authors would like to acknowledge Central Laboratories for Environmental Quality Monitoring, National Water Research Center, Egypt, for their support during this work using its laboratory equipment. Also, the authors would like to thank The Science and Technology Development Fund (STDF) for their support of the work done during this study (Capacity Building Grants (CBG) Project ID:38308).

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Corresponding author

Additional information

Editorial responsibility: Maryam Shabani.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Jahin, H.S., Hesham, A., Awad, Y.M. et al. THMs removal from aqueous solution using hydrochar enhanced by chitosan nanoparticles: preparation, characterization, kinetics, equilibrium studies. Int. J. Environ. Sci. Technol. 21, 2811–2826 (2024). https://doi.org/10.1007/s13762-023-05150-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-023-05150-x