Abstract

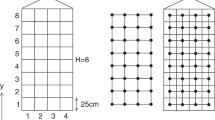

A critical component in a coal export supply chain is the stockyard at a terminal, as this is where coal from different mines is “mixed” in a stockpile before being loaded onto vessels. We develop a tree search algorithm for managing the stockyard aimed at maximizing the throughput. The algorithm relies on the analysis and use of geometric properties of a coal assembly plan when represented in a space–time diagram. A computational study establishes the efficacy of the algorithm and analyzes the merit of commonly used stockyard management rules.

Similar content being viewed by others

References

Abdekhodaee A, Dunstall S, Ernst AT, Lam L (2004) Integration of stockyard and rail network: a scheduling case study. In: Proceedings of the fifth Asia Pacific industrial engineering and management systems conference 2004

Bay M, Crama Y, Langer Y, Rigo P (2010) Space and time allocation in a shipyard assembly hall. Ann Oper Res 179:57–76

Bierwirth C, Meisel F (2009) A fast heuristic for quay crane scheduling with interference constraints. J Sched 12:345–360

Bierwirth C, Meisel F (2010) A survey of berth allocation and quay crane scheduling problems in container terminals. Eur J Oper Res 202:615–627

Boland NL, Savelsbergh MWP, Waterer H (2013) Shipping data generation for the hunter valley coal chain. Optimization Online e-Print ID 2013–02-3755

Boland NL, Gulczynski D, Savelsbergh MWP (2012) A stockyard planning problem. EURO J Transp Logist 1:197–236

Boland NL, Savelsbergh MWP (2012) Optimizing the hunter valley coal chain. In: Gurnani H, Mehrotra A, Ray S (eds) Supply chain management: theory and practice of managing risk. Springer, Berlin

Hunter Valley Coal Chain Coordinator (2012) Hunter valley coal chain—overview presentation—2012. http://www.hvccc.com.au/

Crainic TG, Perboli G, Tadei R (2008) Extreme-point-based heuristics for the three-dimensional bin packing problem. INFORMS J Comput 20:368–384

Hu D, Yao Z (2012) Stacker-reclaimer scheduling in a dry bulk terminal. Int J Comput Integr Manuf 25:1047–1058

Lee D-H, Wang HQ, Miao L (2008) Quay crane scheduling with non-interference constraints in port container terminals. Transp Res Part E Logist Transp Rev 44:124–135

Legato P, Trunfio R, Meisel F (2012) Modeling and solving rich quay crane scheduling problems. Comput Oper Res 39:2063–2078

Li W, Wu Y, Petering MEH, de Souza R (2009) Discrete time model and algorithms for container yard crane scheduling. Eur J Oper Res 198:165–172

Lodi A, Martello S, Vigo D (2002) Recent advances on two-dimensional bin packing problems. Discrete Appl Math 123:379–396

Ng WC (2005) Crane scheduling in container yards with inter-crane interference. Eur J Oper Res 164:64–78

Ng WC, Mak KL (2005) Yard crane scheduling in port container terminals. Appl Math Model 29:263–276

Ng WC, Mak KL (2006) Quay crane scheduling in container terminals. Eng Optim 38:723–737

Singh G, Garca-Flores R, Ernst A, Welgama P, Zhang M, Munday K (2013) Medium-term rail scheduling for an iron ore mining company. Interfaces, 2013. Published online in Articles in Advance 21 Feb 2013.

Singh G, Sier D, Ernst AT, Gavriliouk O, Oyston R, Giles T, Welgama P (2012) A mixed integer programming model for long term capacity expansion planning: a case study from The Hunter Valley Coal Chain. Eur J Oper Res 220:210–224

Thomas A, Singh G, Krishnamoorthy M, Venkateswaran J (2012) Distributed optimisation method for multi-resource constrained scheduling in coal supply chains. Int J Prod Res 51:2740–2759

Zhu W, Zhang Z, Oon W-C, Lim A (2012) Space defragmentation for packing problems. Eur J Oper Res 22:452–463

Acknowledgments

We want to express our thanks to the cargo assembly planners and the members of the strategic planning team at HVCCC who shared their knowledge of the practices and challenges of stockyard management and who provided feedback and suggestions during the course of our research and development efforts.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Savelsbergh, M., Smith, O. Cargo assembly planning. EURO J Transp Logist 4, 321–354 (2015). https://doi.org/10.1007/s13676-014-0048-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13676-014-0048-2