Abstract

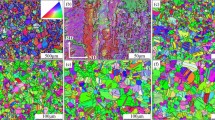

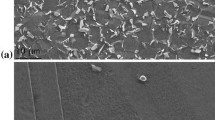

Recent advances in industries require materials with greater strength at higher temperatures without failure in service. Inconel 718 is a precipitation strengthened Nickel–iron-based superalloy for application at high temperatures. In view of this, the present study is aimed at monitoring the degradation during service due to microstructural changes. Inconel 718 alloy is solution annealed at 980 °C for 1 h, then subjected to aging treatment at different temperatures 650, 750, 800, 900 °C for times up to 100 h. On solution treatment, there was a decline in strength, but after aging process, there is an enhancement of strength. The heat treatments and respective microstructural phases, which in turn influence both ultrasonic velocities and elastic properties, have been studied. Further, by ultrasonic measurements the precipitation behavior in Inconel 718 can be monitored in nondestructive manner.

Similar content being viewed by others

References

C.T. Sims, W.C. Hagel, The Superalloys (Wiley, New York, 1972)

Matthew J. Donachie, Stephen J. Donachie, Superalloys: A Technical Guide (ASM International, Materials Park, 2002)

J.R. Davis, Heat Resistant Materials (ASM International, Materials Park, 1997)

Inconel Alloy 718, Special Metals Corporation (2007). http://www.specialmetals.com

G.E. Dieter, Mechanical Metallurgy (McGraw-Hill Book Co., London, 1988)

E.A. Loria, Superalloys 718, 625, 706 and Derivatives 2005 (TMS (The Minerals, Metals & Materials Society), Pittsburgh, 2005)

R. Cozar, A. Pineau, Morphology of γ′and γ″ precipitates and thermal stability of inconel 718 type alloys. Metals Trans. 4, 47 (1973)

A. Kumar, V. Shankar, T. Jayakumar, K. BhanuSankaraRao, B. Raj, Correlation of microstructure and mechanical properties with ultrasonic velocity in the Ni-based superalloy Inconel 625. Philos. Mag. A 82, 2529 (2002)

G.V.S. Murthy, S. Ghosh, M. Das, G. Das, R.N. Ghosh, Correlation between ultrasonic velocity and indentation-based mechanical properties with microstructure in Nimonic 263. Mat. Sci. Eng. A 488, 398 (2008)

C. Ramya, C.H.L Chester, A. M. Frishman, B. F. Larson, N. Nakagawa, Effects of cold work on near-surface conductivity profiles in laser-penned and shot penned Nickel-base alloy. in Review of QNDE, AIP Conference Proceedings, vol. 1430 (2012), p. 1473

Y. Xiaogang, T. Yi, S. Shuang, Y. Jenn-Ming, W. Yinong, L. Jiayan, Y. Qifan, Effect of solution heat treatment on the precipitation behaviour and strengthening mechanisms of electron beam smelted Inconel 718 super alloy. Mat. Sci. Eng. A 689 257–268 (2017)

G.V.S. Murthy, G. Sridhar, A. Kumar, T. Jayakumar, Characterization of intermetallic precipitates in a nimonic alloy by ultrasonic velocity measurements. Mat. Char. 60, 234 (2003)

N. Parveen, G.V.S. Murthy, Determination of elastic modulus in a nickel alloy from ultrasonic measurements. Bull. Mater. Sci. 34, 321 (2011)

P. McIntrie, Non-destructive Testing Handbook: Ultrasonic Testing, vol. 7 (ASTM, West Conshohocken, 1991)

B. Sebastian, Master thesis (Linkoping University) (2017)

S.-C. Lee, S.-H. Chang, T.-P. Tang, H.-H. Ho, J.-K. Chen, Improvement in the microstructure and tensile properties of Inconel 718 superalloy by HIP treatment. Mat. Trans. 47, 2877 (2006)

J. Wenming, F. Zitian, D. Yucheng, L. Chi, Effects of rare earth elements addition on microstructures, tensile properties and fractography of A357 alloy. Mat. Sci. Eng. A 597, 237 (2014)

Acknowledgments

This work was carried out at CSIR-National Metallurgical Laboratory (NML), Jamshedpur. The authors thank the Director, CSIR-National Metallurgical Laboratory (NML), for his kind permission to carry out and publish this work as well as Andhra University for their support to enable (DS and MVS) and carry out the project.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sindhura, D., Sravya, M.V. & Murthy, G.V.S. Comprehensive Microstructural Evaluation of Precipitation in Inconel 718. Metallogr. Microstruct. Anal. 8, 233–240 (2019). https://doi.org/10.1007/s13632-018-00513-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-018-00513-0